Plastic pyrolysis – Australian lithium stocks surge amid speculation of mine closure in China 22-02-2024

Plastic pyrolysis

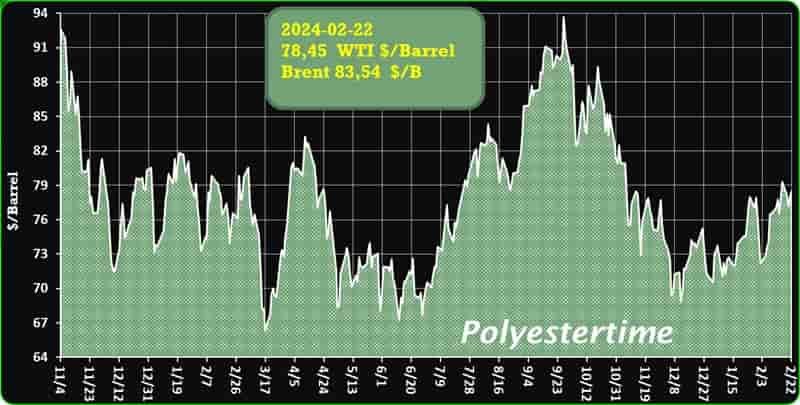

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

Australian lithium stocks surge amid speculation of mine closure in China

Australian lithium stocks surged on Monday amid speculation surrounding the closure of the Jianxiawo mine in China, a significant producer of the material essential for electric vehicle batteries, prompting a surge in Australian resources companies. Pilbara Minerals, Australia’s largest pure play lithium miner, saw its shares jump by as much as 4.9%, while Liontown Resources surged by 7.7%.

The Jianxiawo mine specializes in lepidolite, a relatively expensive form of lithium. Reports indicate that CATL, the Chinese battery giant, may have shuttered the mine due to production costs. Plastic pyrolysis

This potential closure could impact the global lithium market, leading to a shift from a projected surplus to a deficit of around 20,000 tons for the year 2024.

In Australia, developers experienced significant gains, with Patriot Battery Metals rising by 6%, Wildcat Resources by 5.8%, and Sayona Mining by 7.7%. Pilbara Minerals, despite being heavily shorted by investors concerned about a slowdown in electric vehicle demand, witnessed a notable increase in its stock value.

Analysts, including Lachlan Shaw from UBS, noted that while it’s not uncommon for Chinese facilities to close or reduce operations during the Chinese New Year holiday, the potential permanent closure of Jianxiawo could signal an important shift in the lithium market dynamics. Plastic pyrolysis

Questions arise about CATL’s decision to close a fully integrated lithium mine amidst growing demand and stable prices, indicating potential broader implications for the industry’s supply chain.

What fuel can be made from waste plastic pyrolysis plants?

Source: Henan Doing Machinery Equipment Co., Ltd.

Plastic Pyrolysis Plant Final Products and Pyrolysis Fuel Applications

In today’s world, the escalating issue of plastic waste disposal demands more sustainable solutions. The waste plastic pyrolysis plant, a groundbreaking innovation, holds tremendous potential to address this challenge. This article will delve into the various fuels that can be derived from such plants. Plastic pyrolysis

Fuel Production:

Waste plastic pyrolysis plants utilize pyrolysis, a thermochemical process that breaks down plastic waste in the absence of oxygen. This plastic pyrolysis process results in the production of three primary fuels:

- Pyrolysis Oil:

The pyrolysis of plastics generates a valuable dark brown liquid known as pyrolysis oil. Rich in hydrocarbon compounds, this oil exhibits great versatility. It can serve as an industrial fuel, replacing traditional fossil fuels in industries like cement, ceramics, and power plants. Additionally, with further refinement, it can be processed into high-quality non-standard diesel by pyrolysis oil distillation plant, making it an attractive renewable substitute. Plastic pyrolysis

- Pyrolysis Gas:

Syngas, or pyrolysis gas, is a gas mixture obtained during the waste plastic pyrolysis process. Composed of hydrogen, hydrocarbons, and carbon monoxide, this gas holds significant potential. It can be utilized as a clean-burning fuel for heating or electricity generation, meeting the energy requirements of various industries and reducing their carbon footprint.

- Carbon Black:

One of the vital byproducts derived from waste plastic pyrolysis is carbon black. After briquetted by carbon black briquette machine, this solid material finds extensive applications as a fuel source in industrial settings. Moreover, due to its unique properties, it is widely employed as a raw material in manufacturing tires, rubber products, ink, and paint, contributing to increased sustainability in these sectors. Plastic pyrolysis

These fuels produced from waste plastic pyrolysis are considered alternative energy sources that can help reduce reliance on traditional fossil fuels and contribute to waste management and environmental sustainability.

In the realm of waste plastic pyrolysis plants, Henan Doing Company stands out as a world-leading pyrolysis plant and tire plastic pyrolysis oil to diesel distillation plant manufacturer, supplier and exporter.

By producing environmentally high quality pyrolysis plants capable of efficiently converting plastic waste into valuable fuels, Henan Doing Company won the recognition and good feedback from customers from different countries, such as India, Thailand, Russia, Mexico, Kenya, Philippines, Vietnam, Indonesia, Japan, etc. Welcome all the customers to send us inquiries for free quotations! Plastic pyrolysis

New Battery Technology Enables Long-Range Electric Vehicle Travel

Electric vehicle (EV) owners often face the challenge of limited driving range, but a polymer physicist named Chelsea Chen is working to change that. Chen, a researcher at Oak Ridge National Laboratory, is studying ion transport in solid electrolytes to develop batteries with higher energy density and longer battery life.

Chen’s research focuses on solid-state electrolytes, which are key to achieving higher energy density in EV batteries. Plastic pyrolysis

By understanding and optimizing the structure and properties of these electrolytes, Chen aims to improve the performance of solid-state batteries. Her work is part of the Fast and Cooperative Ion Transport in Polymer-Based Materials (FaCT) center, a US Department of Energy-funded research facility.

One of the main advantages of solid-state electrolytes is their compatibility with lithium metal anodes, which have a higher energy density compared to traditional graphite or silicon anodes. However, the challenge with lithium metal anodes is their reactivity with liquid electrolytes, which can lead to safety issues. Solid-state electrolytes offer a potential solution by providing a stable interface between the anode and electrolyte.

Chen’s expertise in polymer science and engineering has positioned her well for this research. With a background in controlling nanoparticle distribution within polymers, Chen has a deep understanding of polymer structures and properties. Her work at Oak Ridge National Laboratory focuses on developing solid-state batteries and studying ion transport in polymer-ceramic composite electrolytes. Plastic pyrolysis

Beyond her research in battery technology, Chen is also interested in the sustainable use of polymers. She believes that recycling and upcycling polymers can contribute to a more sustainable future. Just as EV manufacturers are exploring ways to recycle spent batteries, Chen advocates for considering the end-of-life issues in polymer design.

mLLDPE Prices Escalate in the US while Stability Prevails in China in February 2024

In the initial half of February 2024, the Metallocene Linear Low-Density Polyethylene (mLLDPE) market experienced a notable surge in spot prices in the US while China showed stability by the end of the second week. The US market saw a significant uptick in purchasing activities in February 2024, spurred by heightened consumer demand from downstream construction and packaging sectors. Plastic pyrolysis

Market observers noted a marked increase in mLLDPE transactions, with buyers demonstrating heightened interest and preparedness to make purchases. Meanwhile, the Chinese mLLDPE market was initially affected by the Lunar New Year festivities, witnessing price increments following stabilization by the second week of the month. This market dynamic was further exacerbated by tight supply from the Middle East, impacting material availability and influencing price trajectories. Additionally, the escalation in the price of feedstock Ethylene exerted cost pressures on mLLDPE.

Throughout this period, demand for mLLDPE in the USA remained robust, fueled by both domestic and international buyers gradually leading to the upward price trend. Nevertheless, there was a steady influx of off-grade railcars into the market. Producers continued to restrict mLLDPE availability, redirecting surplus supplies to the flourishing export market. Plastic pyrolysis

Tetra Pak invests to boost recycling across EU

In particular, the company says its strategic investments are aimed at increasing the recycling capacity for carton packaging. Plastic pyrolysis

Lausanne, Switzerland-based packaging developer Tetra Pak has announced several strategic investments designed to level up the recycling capacity for carton packages in the European Union.

The company says the move supports the goals of the proposed EU Packaging and Packaging Waste Regulation (PPWR) by ensuring all packaging components are recycled and valuable raw materials are kept in circulation for longer, therefore showcasing the pivotal role of recycling in the green transition of the food packaging sector.

In 2023, Tetra Pak invested nearly 40 million euros ($42.9 million) to accelerate beverage carton recycling worldwide, and says it plans to increase this even further in the coming years to achieve a greater material circularity. The recent initiatives and investments are set to boost the EU’s ability to recycle beverage cartons, including the non-fiber protective layers of polyethylene (PE) and aluminum, known as “polyAl.” The company says this will be achieved either by unlocking new collaborations or by strengthening the capabilities of established recyclers to turn all materials from postconsumer cartons into new, high-quality resources and goods. Plastic pyrolysis

These add to the existing and well-established recycling infrastructure in the EU, where beverage cartons are recycled in 20 specialized paper mills, with polyAl currently processed by seven facilities.

Tetra Pak’s major 2023 investments include:

- A feasibility study in Sweden along with Axjo Group to build a new recycling line for polyAl that will accommodate volumes from Sweden, Denmark and Norway, fostered by a joint investment of up to 24 million euros ($25.7 million) and featuring an annual recycling capacity of 10,000 tons. The facility will recycle and incorporate polyAl into injection molded plastic products made by Axjo, including cable drums, reels, spools and plastic storage boxes. Plastic pyrolysis

Plastic recycling infrastructures: urgent environmental need, business opportunity

The Philippines is the world’s biggest contributor to marine plastic waste with 350,000 tons of it leaking into the ocean annually, according to the independent UK organization Utility Bidder.

A World Bank study on the Plastics Circularity Opportunities and Barriers said the Philippines is losing 78 percent of the material value of its plastics supply chain worth US$ 890 million each year. The recycling capacity gap stands at 85 percent.

For investors, these figures suggest a potential business opportunity: setting up large-scale plastic recycling infrastructures in the country, even while doing much-needed environmental good by reusing plastic waste that impact negatively on people and the planet. Recycling plastic into useful material for manufacturing contributes to building a circular economy, in which waste is eliminated by putting it to productive use and preserving value. Plastic pyrolysis

Given the urgent environmental need along with the potential business opportunity, the Department of Environment and Natural Resources (DENR) and Nestlé Philippines are continuing their partnership for environmental sustainability, by holding the Philippine National Recycling Conference: The Loop Towards Recyclability and Circularity this Thursday, Feb. 22, 2024 at the Marriott Hotel Manila.

The multisectoral event will serve as a forum for potential investors, key waste management businesses, related organizations, and government agencies to discuss possible opportunities and challenges of building plastic recycling facilities, and increasing the supply of recycled packaging materials. Plastic pyrolysis

Mandated extended producer responsibility (EPR) for plastic waste lapsed into law in 2022. Companies called obliged enterprises with total assets of P100 million and above are now required to be environmentally responsible for plastic waste from products they manufacture, import, distribute or sell to consumers, up to the post-consumer stage. EPR compliance rules include collecting plastic waste and regular reporting requirements with the aim of generating a circular economy.

PlantSwitch raises $8 million to commercialise bioplastics technology

The company promises to make bioplastics cost competitive

PlantSwitch announced it has raised $8 million to commercialise its bioplastics technology.

The North Carolina-based materials company will use the funding to build its first commercial manufacturing facility and expand its 12-person team. The Sanford plant is expected to produce over 22,000 tonnes (50 million pounds) of resin per year and span 52,000 square feet. Commissioning is expected by 2025. Plastic pyrolysis

PlantSwitch has developed what it claims is the most sustainable, lowest-cost, completely compostable ‘drop-in’ plastic replacement, sourced from the abundant supply of agricultural residues — mainly rice hulls. Its material is used in containers and eating utensils applications. Its customers include some of the leading brands and manufacturers in food service, consumer packed goods, cosmetics, and agricultural products.

High production costs have so far limited bioplastics to a niche market, but PlantSwitch promises to make biopolymers cost competitive.

The company says using agricultural side streams as feedstock allows it to be ‘the lowest cost plastic alternative on the market’. Its resin can be used as ‘drop-in’ replacement to fossil-based plastics in existing machinery, with ‘negligible’ costs, according to the company. The material reportedly fully breaks down in backyard compost in less than 12 months, leaving no microplastics behind. Plastic pyrolysis

Hydrogen scenarios – New findings on shedding behaviour of polyester 21-02-2024

Plastic pyrolysis