Plastic Pyrolysis Oil

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

Pyrolysis Oil Pricing Indexes: Shaping the Future of Plastic Waste Recycling

In the ongoing battle against plastic waste, the need for reliable pricing indicators has become more critical than ever. In a significant development, ICIS, a renowned consulting firm known for its expertise in tracking prices of virgin and recycled plastics and other chemical commodities, has unveiled a groundbreaking service known as the Pyrolysis Oil Pricing Indexes. This innovative index aims to shed light on the pricing dynamics of pyrolysis oil, a product obtained through the chemical recycling of waste plastics. The Pyrolysis Oil Pricing Indexes will be seamlessly integrated into the existing Mixed Plastic Waste – Europe report, introduced in 2021, leading to a name change for the report itself: it will now be known as Mixed Plastic Waste and Pyrolysis Oil.

The existing Mixed Plastic Waste pricing service has already been instrumental in capturing the prices of mixed polyolefin bales and high-plastic-content waste bales, two key sources from which pyrolysis oil is derived. Plastic Pyrolysis Oil

With the addition of pyrolysis oil pricing data, this comprehensive index will cover the pricing trends and market dynamics of the two primary methods of plastic waste recycling: mechanical and chemical recycling.

One significant aspect highlighted by ICIS is that pyrolysis oil prices do not necessarily follow the trends observed in equivalent virgin feedstocks. This divergence underscores the unique nature of this emerging market, where reliable and independent price indicators have been notably absent.

As per ICIS Recycling Supply Tracker – Chemical, waste plastic pyrolysis plants, particularly those focused on mixed polyolefins, currently constitute approximately 60% of all chemical recycling capacity in Europe. This sector is poised for remarkable growth, with European capacity projected to increase nearly sevenfold by 2028, reaching approximately 600,000 tons annually based on projects that have reached the final investment decision (FID) stage. Plastic Pyrolysis Oil

Moreover, when considering projects that are still in the announcement phase but have not yet reached FID, the total capacity for pyrolysis of mixed plastic waste could potentially reach a staggering 1.7 million tons annually within the next five years. This forecast demonstrates the immense potential of chemical recycling in addressing the plastic waste crisis and transforming waste materials into valuable resources.

The introduction of the Pyrolysis Oil Pricing Indexes is a pivotal moment in the field of plastic waste recycling. By providing accurate and up-to-date pricing information for pyrolysis oil, ICIS is empowering stakeholders across the industry with the data they need to make informed decisions. This includes recyclers, manufacturers, investors, policymakers, and environmental advocates who are all dedicated to creating a sustainable future by reducing plastic waste. Plastic Pyrolysis Oil

One of the key advantages of the index is its ability to bridge a significant gap in the market. Unlike traditional recycling practices, which often rely on mechanical processes, pyrolysis represents a chemical recycling method. This means that it can handle a wider range of plastics, including those that are challenging to recycle mechanically. Pyrolysis offers a pathway to recycle mixed and contaminated plastics effectively, helping to divert more waste from landfills and incineration.

Additionally, the Pyrolysis Oil Pricing Indexes will promote transparency and stability in the pyrolysis oil market. This is crucial for the industry’s long-term growth and the development of a circular economy for plastics. Transparent pricing mechanisms encourage investment, innovation, and the adoption of sustainable practices, further driving the transition away from linear, disposable plastic consumption. Plastic Pyrolysis Oil

As the demand for sustainable solutions to plastic waste continues to grow, the Pyrolysis Oil Pricing Indexes will serve as an invaluable tool for tracking market trends, evaluating investment opportunities, and shaping the future of plastic waste recycling. Its integration into the Mixed Plastic Waste – Europe report underscores the importance of pyrolysis oil as a key component in the evolving landscape of plastic recycling.

In conclusion, ICIS’s launch of the Pyrolysis Oil Pricing Indexes is a significant step forward in addressing the global plastic waste crisis. With the capacity of pyrolysis recycling set to soar in the coming years, the need for accurate and independent pricing information is paramount. This index not only fills that gap but also heralds a new era in the recycling industry, where the transformation of plastic waste into valuable resources is guided by data-driven insights and sustainability principles. Plastic Pyrolysis Oil

Wood and OMV sign collaboration agreement for plastic recycling technology

Wood has signed a collaboration agreement with OMV for the commercial licensing of its innovative plastic recycling technology, ReOil®. This agreement will support significant advancements in chemical-based plastic recycling, helping to build a circular economy solution for end-of-life plastics that would otherwise be sent to landfill or waste incineration.

OMV, the integrated energy, fuels & feedstock and chemicals & materials company, developed the proprietary ReOil technology to convert plastic waste into pyrolysis oil, a valuable resource primarily used to produce high-performing and sustainable plastics. ReOil offers an innovative solution to support the growth of plastic recycling – it is estimated that around 60% of plastics production will come from recycled feedstock by 2050. Plastic Pyrolysis Oil

Under the agreement, Wood and OMV will bring ReOil jointly to the market, combining Wood’s proprietary heater technology with OMV’s chemical recycling process. The companies have established a combined technology and engineering delivery team to support clients with the implementation of ReOil at their sites. In addition, Wood will work with ReOil licensees to provide full asset lifecycle support globally.

Craig Shanaghey, Wood’s Executive President of Projects, said: “Building on our excellent long-term relationship with OMV, we are excited to formally partner on the ReOil technology. ReOil is a proven solution to the complex problem of plastic waste and aligns with Wood’s strategic priorities to design a more sustainable future. We look forward to working with OMV to deploy this technology at scale.” Plastic Pyrolysis Oil

Daniela Vlad, Executive Vice President Chemicals & Materials at OMV, said: “We are delighted to enter this long-term relationship with Wood to provide a licensing offer which will further enable global licensees to make use of future circular economy solutions. This is in line with our strategic priorities to establish OMV as a leader in renewable and circular economy solutions and diversify our portfolio by entering adjacent products and business areas.”

A ReOil pilot plant has been operating in the OMV refinery in Schwechat, Austria since 2018 and has processed end-of-life plastics for more than 22,000 hours to date. A 16,000 tons per year ReOil plant is currently in construction at the same site and Wood is working with OMV on the development of an industrial-scale plant with a capacity of 200,000 tons per year. Plastic Pyrolysis Oil

More…

Arçelik – Bio-attributed polystyrene in the refrigerator

In its commitment to sustainability in the use of plastics, the Turkish appliance manufacturer Arçelik (part of the Koç group) has chosen to use polystyrene grades obtained from biobased raw materials, attributed by mass balance, for some components of its innovative latest generation Bio Fridge refrigerators, such as the internal linings and drawers.

This bio-attributed styrenic resin maintains the same properties and characteristics of its conventional counterpart, being indistinguishable from it, but offers a significant advantage in terms of reducing the carbon footprint. The attribution of renewable raw materials, starting from styrene, and their traceability along the production chain are guaranteed by an ISCC Plus certified mass balance. Plastic Pyrolysis Oil

Trinseo launched two years ago the Styron BIO85 HIPS and Styron BIO95 GPPS grades, produced with bio-attributed styrene, which boast a reduction in product carbon footprint (PCF) of 71% and 84% compared to variants obtained from fossil sources.

Arçelik has made a commitment to achieve a percentage of 40% recycled plastic and 5% bio-attributed materials in all its products by 2030, thus demonstrating its commitment to environmental sustainability.

Eni’s record discovery: a field of 140 billion cubic meters of gas in Indonesia

Eni has identified a significant gas field in Indonesia, located approximately 85 kilometers off the coast of Kalimantan. This discovery confirms the crucial importance of methane in the context of the energy transition.

Initial estimates indicate that the field, identified by the Geng North-1 well, drilled to a depth of 5,025 meters in 1,947 meters of water depth, in the North Ganal license, has total volumes of approximately 140 billion cubic meters of gas and contains approximately 400 million barrels of condensates.

Eni’s CEO, Claudio Descalzi, speaking to CNBC, underlined that gas remains fundamental to meeting ever-growing energy demand, highlighting its importance in several regions such as China, India and Europe. Plastic Pyrolysis Oil

He defined the discovery of Geng North as “strategic”, given its proximity to growing markets and its position close to structures already discovered in the past, allowing to consider the start of a new production hub.

Geng North, given its location and size, has the potential to significantly contribute to a new production hub in the northern part of the Kutei Basin, connecting to the Bontang liquefaction (LNG) sites on the East Kalimantan coast.

The Geng North well is adjacent to the Indonesia Deepwater Development (IDD) area, which includes several undeveloped discoveries.

Eni’s goal is to achieve a production mix of 60% gas and liquefied natural gas (LNG) by 2030, with an increase in proprietary LNG production.

By that date, installed renewable energy capacity is expected to exceed 15 gigawatts through the Plenitude project.

This year, capacity will reach 3 gigawatts. Plastic Pyrolysis Oil

Recycling CO2 to produce methanol

A question of balance

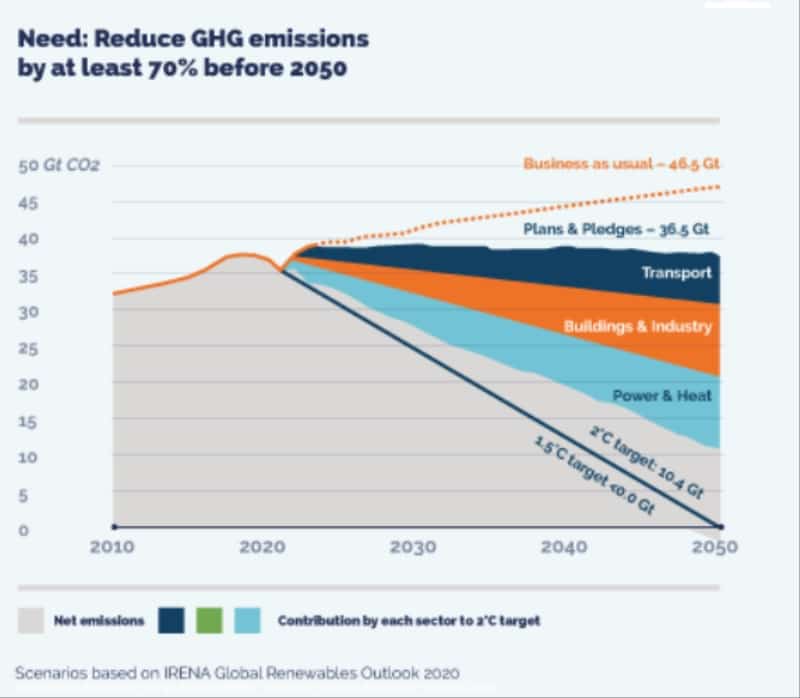

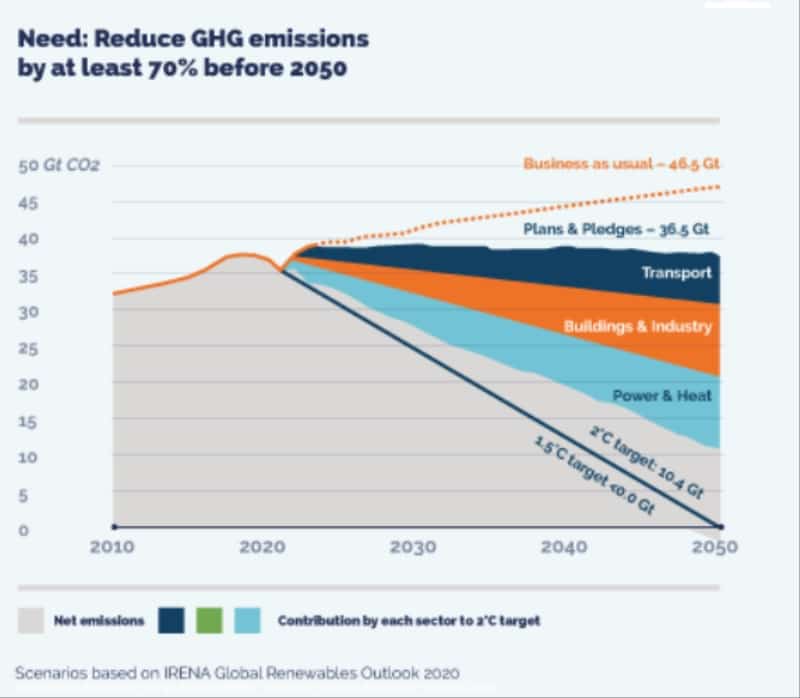

Reducing global Greenhouse Gases emissions to net zero by 2050 increasingly hangs on our ability to make a significant change in our relationship with CO2. Perhaps the most critical component of the global economy, until now, we have treated it as a waste stream and discarded it in the atmosphere. For the world to end its reliance on fossil fuels, CO2 must instead be treated as a precious resource that we re-cycle and reuse. Carbon will continue to be needed to support human progress, but we must manage it within a closed loop system to make it sustainable. Plastic Pyrolysis Oil

Since 2006 CRI has pioneered the development of the technology required to produce sustainable methanol from carbon emissions and is rolling it out to help partners achieve industrial scale Carbon Capture Utilisation and Storage (CCUS) projects.

Capturing CO2 emissions, combining them with green or recovered H2 to produce methanol and feeding them back into our industrial processes as a renewable energy source and feed stock, provides an accelerated path toward a Circular Economy.

Renewable methanol enables a rapidly growing proportion of the global economy to become carbon neutral using existing processes and infrastructures, by enabling collaboration between different sectors to reduce overall CO2 emissions.

In China, a CO2-producing industry is supplying carbon neutral methanol as raw material for chemical production, instead of emitting. Plastic Pyrolysis Oil

In Scandinavia a CO2-producing smelter will soon supply clean burning fuel for maritime transport.

The carbon dioxide challenge

Compared with the pre-industrial era, levels of CO2 in our atmosphere are now 50% higher and still rising. The first 25% of that increase took 200 years, but it has taken only 30 years to double. The primary cause of that increase is our dependence on fossil fuels as an energy source.

The consequence of this sharp rise is going to be global warming and the current levels of CO2 already represent an unavoidable temperature rise, accompanied by environmental effects such as rising sea levels. Plastic Pyrolysis Oil

More…

Repsol selects Honeywell technology for biofuel production in Spain

Honeywell International Inc. (Charlotte, N.C.) announced that Repsol S.A. (Madrid, Spain) has licensed Honeywell Ecofining technology to produce renewable fuels from feedstocks such as used cooking oil and waste animal fat at Repsol’s facility in Puertollano, Spain. Repsol is designing this plant to convert approximately 240,000 metric tons per year (m.t./yr) of waste feeds/feedstocks to renewable diesel and other products.

The Honeywell UOP Ecofining process will provide Repsol with an efficient and high yield solution to produce renewable fuels and petrochemical precursors from residual feedstocks. Plastic Pyrolysis Oil

“Renewable fuels are a key pillar in our commitment to achieve net zero emissions by 2050 and Honeywell is providing us with the cutting-edge Ecofining technology to accomplish this,” said Berta Cabello, Repsol’s Director of Renewable Fuels. “This will be Repsol’s second plant exclusively dedicated to producing 100% renewable fuels, allowing us to lead the market for these products in the Iberian Peninsula where we already have more than 20 service stations supplying 100% renewable diesel.”

“Honeywell’s Ecofining technology will allow Repsol to economically convert waste feeds into renewable fuels and reduce its carbon footprint,” said Barry Glickman, vice president and general manager, Honeywell Sustainable Technology Solutions. “Renewable Diesel and SAF can significantly reduce greenhouse gas emissions compared to conventional diesel or aviation fuel.” Plastic Pyrolysis Oil

More…

Microban Launches Ascera™: A Patent-Pending, Cutting-Edge Antimicrobial Technology Inspired By Nature

Microban International is pleased to introduce its latest ground-breaking technology – AsceraTM. This patent-pending, next generation antimicrobial technology uses an active ingredient inspired by nature*, and is designed for use in olefinic polymers and solvent-based coatings. Ascera is sustainable, metal free and less toxic than alternative technologies, and provides the lifelong antimicrobial product protection that Microban is known for around the world. Plastic Pyrolysis Oil

As the global leader in antimicrobial and odor-control technologies, Microban is committed to the development of solutions that support product sustainability by extending their useful lifetimes. Ascera exemplifies the company’s commitment to sustainability by offering lasting product protection while maintaining critical attributes, such as ease of incorporation, safe handling, and good chemical, thermal and UV stability. Ascera will perform for the product’s expected lifetime when applied according to Microban’s standards, effectively inhibiting the growth of odor-causing bacteria to prevent stains and premature aging of the finished product.

“Microban has always led the antimicrobial industry with technological innovations that contribute to product sustainability,” said Dr. Souvik Nandi, Vice President of R&D at Microban International.“In the past decade, regulatory and environmental groups have put increasing pressure on many of the antimicrobial chemistries that are currently used. As a result, Microban has invested significant resources in identifying naturally occurring solutions that are more sustainable and effective. We are very proud to roll out Ascera, which represents the culmination of many years of intensive research. This is the first of an exciting series of nature-inspired solutions that we will be launching in the next few years for different market segments and material types.” Plastic Pyrolysis Oil

More…

Hydrogen plastic waste – Carbios’ textile preparation line ‘closes loop’ on fibre-to-fibre recycling 05-10-2023

Plastic Pyrolysis Oil