Plastics-recycling – Circular-economy 10-06-2022 - Arhive

Plastics-recycling – Circular-economy

Crude Oil Prices Trend

-Remondis and Werner & Mertz cooperate on plastics recycling

Werner & Mertz and Remondis have joined forces under the umbrella of the “Recyclat-Initiative” to demonstrate how plastic cycles can be fully closed using practical application examples. The common goal is to establish sustainable material cycles and to use the recyclable material from the source “yellow bag” in Germany for this purpose.

During a joint press conference at Ifat, Reinhard Schneider, Managing Partner of Werner & Mertz, Herwart Wilms, Managing Director of Remondis, and Dr Nabila Rabanizada, Technical Manager for plastics recycling at Remondis, explained the path taken by the raw material from the yellow bag via the further developed mechanical processing back into the production cycle and into new sustainable packaging.

The panel participants also reiterated their demand for improved political framework conditions in the EU. Plastics-recycling – Circular-economy

Reinhard Schneider, Managing Partner of Werner & Mertz: “The ‘Recyclat-Initiative’ of Werner & Mertz has proven that high-quality recyclate can be obtained from household collection. In order to compensate for the continuing lower prices for virgin material and to trigger high-quality applications for recycled raw materials in the sense of closed loops, I am campaigning for the introduction of a plastic tax on virgin material.”

Herwart Wilms, Managing Director of Remondis, added in this context that the introduction of a polluter-pays tax on non-recycled old plastic packaging, the so-called “plastic tax”, could only have the desired steering effect if it was used in a targeted manner: “In order to promote the recycling of plastics more strongly and make it a successful model with a worldwide exemplary character, the tax would have to be converted into a purpose-bound levy. Only in this way could sustainable production be promoted in a targeted way instead of using the tax money for other tasks.”

-OECD says plastic pollution will grow faster than recycling rate

Globally, discarded plastic levels could nearly triple by 2060, with about half of the plastic ending up in landfill and less than a fifth recycled, an OECD report projected.

The Organization for Economic Cooperation and Development (OECD), a global policy forum that counts developed countries among its members, released a preliminary version of a global plastics outlook report on June 3. The document said that without “radical action to curb demand, increase product lifespans and improve waste management and recyclability, plastic pollution will rise in tandem with an almost threefold increase in plastics use.” Plastics-recycling – Circular-economy

OECD plans to release the full “Global Plastics Outlook: Policy Scenarios to 2060” report on June 21.

The preliminary version forecast that almost two-thirds of discarded plastic in 2060 will be from packaging, low-cost products and textiles.

“If we want a world that is free of plastic pollution, in line with the ambitions of the United Nations Environment Assembly, we will need to take much more stringent and globally coordinated action,” OECD Secretary-General Mathias Cormann said in a statement. “This report proposes concrete policies that can be implemented along the lifecycle of plastics that could significantly curb – and even eliminate – plastic leakage into the environment.”

The report builds on OECD’s “Global Plastics Outlook: Economic Drivers, Environmental Impacts and Policy Options,” which was released in February. That report found that discarded plastic volumes have doubled in two decades, with most ending up in landfills, incinerated or in the environment.

Since that report release, U.N. member states have pledged to negotiate a legally binding international agreement by 2024 to end plastic pollution, the statement noted.

-PET Recycling Coalition Formed to Improve Plastic Packaging Circulatory

Leading companies such as Eastman, Indorama Ventures, P&G, Danone, Coca-Cola Co. take action to unlock the environmental and economic benefits of PET recycling.

The Recycling Partnership has launched the PET Recycling Coalition, an initiative informed by industry knowledge and expertise to improve polyethylene terephthalate (PET, plastic #1) circularity. Its work will focus on four key opportunities to increase PET recycling:

- Increasing the capture of PET bottles;

- Broadening the acceptance of PET trays, cups, and clamshells in community recycling collection programs;

- Unlocking new supplies of recycled PET (rPET) for packaging manufacturers; Plastics-recycling – Circular-economy

- Strengthening recycling systems for pigmented and opaque PET.

PET plastic is in high demand for use in textiles such as polyester clothing and carpet and it’s the most common type of plastic utilized in liquid bottles and food packaging today. While eliminating unnecessary usage is an important component of circularity, increased PET recycling is another critical step in advancing circularity. Along with company commitments and recycled content mandates in proposed US legislation, this is causing to skyrocketing demand for recycled PET, yet supply is limited.

Most Americans with recycling access can recycle PET bottles; however, only 54% can recycle other types of PET packaging like plastic egg cartons and fruit containers. Furthermore, the recycling rate for PET bottles was only 26.6% in 2021. While most PET never makes it into the recycling bin due to insufficient access and participation, as much as 17% of bottles that are recovered are lost at Materials Recovery Facilities (MRFs) due to sortation challenges. By supporting solutions identified by the PET Recycling Coalition, there is a great opportunity to increase recovery and reduce plastic waste and help make progress toward packaging circularity goals.

Grants, technical assistance, and knowledge sharing.

The PET Recycling Coalition will make grants to recycling facilities for sorting equipment and related capital needs.

These upgrades will improve PET bottle capture, deliver more rPET for use back into bottles and thermoforms, increase the acceptance of non-bottle rigid items in community recycling programs, and strengthen recycling opportunities for pigmented and opaque PET. Plastics-recycling – Circular-economy

Through grants, technical assistance, and knowledge sharing, the Coalition envisions a thriving PET recycling system that captures significantly more material, enabling more circular PET packaging with increased amounts of recycled content.

-Govt rejects anti-dumping duty recommendations on import of low-density polyethylene

In a major setback for domestic manufacturers, the government of India has rejected the recommendations to levy anti-dumping duty on the import of low-density polyethylene (LDPE) from Qatar, Saudi Arabia, Singapore, Thailand, United Arab Emirates (UAE), and the United States of America (USA).

In an office memorandum issued on Monday, the Department of Revenue under the Ministry of Finance, said, “The central government, after considering the final findings of the designated authority, has decided not to accept the recommendations to impose anti-dumping duty on the import of LDPE.”

The designated authority i.e. the Directorate General of Trade Remedies (DGTR), under the Union Ministry of Commerce & Industry, had received an application from the country’s premier industry body viz Chemicals and Petrochemicals Manufacturers Association (CPMA) wherein the association had requested initiation of an ADD investigation on the imports of LDPE originating in or exported from Qatar, Saudi Arabia, USA, Thailand, and Singapore. The authority commenced the investigation for the three years period between 2016-17 and 2018-19. Plastics-recycling – Circular-economy

CPMA was not immediately reached for comments. The association, however, had alleged in its application to the DGTR that the dumping of LDPE into India is causing big injury to the domestic producers.

Based on the evidence provided by CPMA, the designated authority started investigations by seeking information from all companies involved in the business to export LDPE to India. The objective of this investigation was to determine the existence, degree, and effect of the alleged dumping of LDPE originating in or exported from the aforementioned exporting countries. Also, the objective of this investigation was to recommend the amount of ADD, which if levied, would be adequate to remove the alleged injury to the domestic industry.

After consulting with all stakeholders including exporters, importers, and Indian producers the DGTR had recommended ADD levy between the US $17 and US$216 on various overseas exporters who were allegedly dumping their goods in India.

-European Parliament vote on climate measures critical for chemicals

Industry wants clarity from Members of the European Parliament (MEPs) who are voting on changes to Europe’s ambitious carbon emissions trading scheme and the bloc’s Fit-for-55 climate proposals on Wednesday, European Commission Executive Vice President, Frans Timmermans has stressed. Plastics-recycling – Circular-economy

Ahead of votes on key amendments, Europe’s big energy users, alongside other industrial sectors likely to be impacted the most from the extensive Emissions Trading System (ETS) and Fit-for-55 revisions, have been lobbying hard.

Essentially, however, European industry wants, in Timmermans words, “clarity, predictability and reliability”, from the measures being considered at this stage in the legislative process.

Time is of the essence if companies are to be able to invest to facilitate real climate action, a fact that has been stressed many times before.

And the details of proposals that are being considered now will create the ‘playing field’ on which companies will operate for years to come – and have an impact far beyond the EU’s borders.

Energy intensive industries such as chemicals, however, do feel that the playing field is being tilted against them in Europe despite their broad support for more intense climate action.

Energy intensive industries CEOs, in an open letter this week, said that legislation needs to accompany the energy transition with predictable measures and realistic timelines.

They are clearly concerned about step changes that run the risk of overburdening companies before they can invest to further tackle climate change and develop markets for low carbon products. Plastics-recycling – Circular-economy

“In this regard, latest proposals on ETS and CBAM [carbon border adjustment mechanism] weaken carbon leakage provisions, further increase unilateral regulatory costs and harm the competitiveness of European industries in EU or international markets,” the letter, signed by almost 300 of them, said.

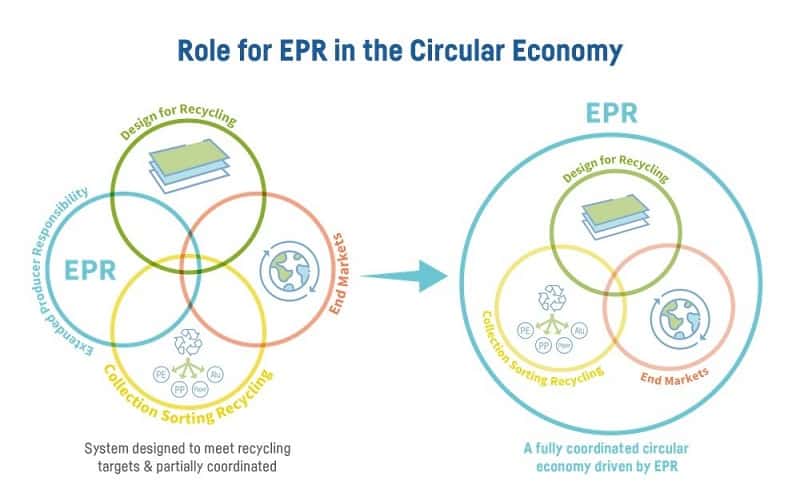

Extended User Responsibility (EPR) schemes play a substantial role in the collection, sorting and recycling of post-consumer products. The Circular Economy for Flexible Packaging (CEFLEX) project, a collaboration of over 180 European companies, associations and organisations, believes these schemes are well positioned to be a key enabler and co-ordinator of the circular economy.

What role does EPR play in the circular economy? CEFLEX launches EPR ‘Criteria for Circularity’ in flexible packaging Plastics-recycling – Circular-economy

The CEFLEX ‘Criteria for Circularity’ have been developed as a constructive and practical check list for EPR schemes and stakeholders to work through on their journey to making packaging waste materials circular. They come at a critical moment, as EPR schemes look to meet higher recycling targets and align with other legislation driving changes to how packaging waste is collected, sorted and recycled to be used again.

The criteria are a basis for further discussion and development in four pillars: operational, financial, communication and governance. These pillars are designed to connect and build on work from the Consumer Goods Forum and others, adding further perspectives for flexible packaging. ‘The criteria are part of a long-standing CEFLEX dialogue on EPR, which is vital to making flexible packaging circular, sustainable and economically viable,’ a recent press release states.

CEFLEX Project Co-ordinator Graham Houlder elaborated: “In a circular economy, all materials need to be captured, recycled and used in a wide range of sustainable end markets – independent of cost and recycling targets.

EPR systems designed to deliver circular materials and funded accordingly, will help create the conditions to allow all parts of the value chain to make the changes necessary to go circular.” Plastics-recycling – Circular-economy

-Unifi to launch new product made from ocean waste

Unifi, Inc., makers of REPREVE®, the leading recycled fiber, has launched a new sustainable solution that allows customers and consumers to help solve the ever-growing problem of ocean plastic pollution. REPREVE® Our Ocean™ fiber is created from bottles collected within 50 kilometers of coasts in countries or areas without established garbage or recycling programs, addressing the fundamental source of ocean plastic. Plastics-recycling – Circular-economy

Jay Hertwig, Senior Vice President of Global Brand Sales for Unifi, said that REPREVE Our Ocean is a premium collection of fiber and resin obtained from bottles that are at high danger of entering the ocean. For years, they’ve been converting billions of plastic bottles into REPREVE recycled fiber to protect air, land, and natural resources. REPREVE Our Ocean is a project that aims to restore our ocean. They provide a one-of-a-kind chance for companies to convey an ocean-focused story with REPREVE Our Ocean.

At least 8.8 million tons of plastics are dumped into the ocean each year, the equivalent of one garbage truck discharging its contents into the ocean every minute. Furthermore, at least 80% of plastic enters the waters from land, and at present rates, there will be more plastic than fish in the oceans by 2050.

Hertwig added that forward-thinking firms who want to make an even more explicit statement about saving the environment—and want to take a greater position in addressing ocean pollution—now have a brand new choice. REPREVE Our Ocean is designed for the betterment of tomorrow, and this high-end product will appeal to people who want to do all possible to help conserve the environment for future generations. Plastics-recycling – Circular-economy

-BASF light stabilizer increases the durability of pontoons used for aquaculture in China

Tinuvin® in plastic pontoons provides long-lasting protection against harsh weather conditions

Improved service life helps to save resources and reduce costs for fish farmers

BASF’s light stabilizer Tinuvin® has been applied by Fujian Atlantis Plastic Products Co. Ltd., a company specialized in the production and processing of plastic products for marine floats, to protect polypropylene (PP) pontoons used by fish farmers in Ningde, Fujian Province of China.

Like all plastics, PP is susceptible to UV light and heat, which can result in color change, surface cracking, and ultimately, product failure. To make the pontoons resistant to intense sunlight, a light stabilizer such as Tinuvin is added to the polymer during manufacturing. Tinuvin protects the PP pontoons from the negative effects of prolonged exposure to UV light thereby improving its weatherability and extending its lifetime from 3 years to more than 5 years. Plastics-recycling – Circular-economy

“Strong, durable, and safe – these are qualities that should always come to mind when employing a plastic floatation system,” said Hermann Althoff, Senior Vice President, Performance Chemicals Asia Pacific, BASF. “Our UV stabilization products create a stress-crack-resistant platform that maintains the structural integrity of the plastic article for many years.”

Ningde in southeast China’s Fujian Province produces most of the country’s cultured seafood. Thousands of fish farmers, who have resided along this coastal area for decades have transformed this little fishing village into the epicenter of the yellow croaker industry – producing 75 percent of the nation’s total output in 2019.

In aquaculture, floating pontoons interconnected by plastic walkways act as enclosures to raise seafood like shrimp, oysters, and fish. While raising fish, crustaceans, and mollusks in landlocked ponds and fenced-in ocean pens has gone on for decades, what has changed is the traditional solution of low-end, low-cost applications for fish farmers.

“Fish farmers are sensitive to cost, and previously used pontoons made of foamed plastics. These become brittle and prematurely break,” said Min Lin, General Manager of Fujian Atlantis. “By using Tinuvin, we could achieve a high-quality, more durable pontoon that is not susceptible to breakage, chalking and fading even under extreme sunlight. Plastics-recycling – Circular-economy

Plastics-recycling – Circular-economy