Plastics recycling – EV batteries 03-05-2023 - Arhive

Plastics recycling – EV batteries

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

-Erema Group ends financial year with significant increase in turnover

The Erema Group, a plastics recycling company, reported a significant increase in turnover, reaching around EUR 355 million in the 2022/2023 financial year, despite challenges such as supply chain delays and unexpected supplier outages.

The group produced 270 extruders in Austria and 350 in total across the group, including those from its Italian subsidiary, Plasmac.

The recycled pellet production capacity of all extrusion systems delivered in the financial year was approximately 1.6 million tonnes per year, and the group launched seven new recycling systems and components. Plastics recycling – EV batteries

Erema celebrated its 40th anniversary in April 2023 and is hosting various events, including the Erema Discovery Day, to showcase its latest recycling technologies and officially open its newly built research and development centre.

EREMA Extruder

-The upcoming Waste Framework Directive revision is not bold enough

New White Paper says more radical rethink on EU materials and waste policy essential

Rewiring our relationship with resources through the Waste Framework Directive (WFD) is vital for the EU to continue to innovate and lead the world in reaching a circular economy by 2040. The revision offers an unparalleled opportunity to design a coherent and consistent policy framework for a circular economy. recycling Packaging battery

These are the findings of a White Paper published 20 April by Handelens Miljøfond, Minderoo Foundation, Tomra, and Zero Waste Europe.

Developed by Eunomia Research & Consulting, the White Paper, sets out a vision for 2040 where society will use materials and products more efficiently in an economy that is well on its way to circularity. Plastics recycling – EV batteries

However, this will not be achieved within the scope of the drafted revision of the Waste Framework Directive, which has guided EU policy in this area since 1975.

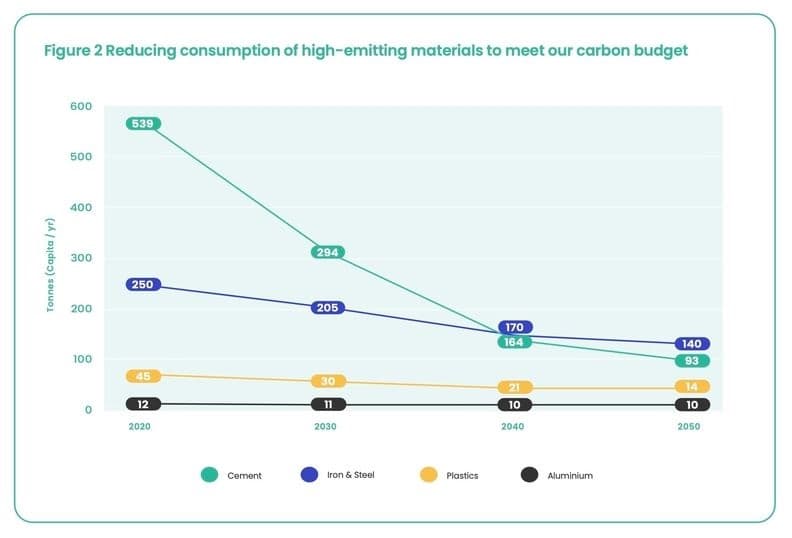

According to this report, steady but slow reductions in emissions will spend our carbon budget too soon. ‘Achieving greenhouse gas (GHG) emission reductions at the speed and scale we need will mean significantly reducing our material consumption by moving from an inefficient, material-hungry, linear economy to a circular one that keeps materials in use for as long as possible,’ the authors state.

A genuinely circular economy would mean far less extraction and use of virgin resources, with a focus on a service economy that keeps products and materials in circulation for as long as possible, making full use of digital technology, systems, and data to manage th use of materials and products. recycling Packaging battery

According to Cecilie Lind, CEO of Handelens Miljøfond the White Paper demonstrates the urgency of rethinking our approach to materials and waste policy in order to build a sustainable and circular economy by 2040. “The revision of the Waste Framework Directive is a critical step in achieving that goal,” she said. Plastics recycling – EV batteries

The White Paper also presents an accompanying blueprint for a policy framework that will drive these changes effectively and at scale, harnessing the power of the single market to give businesses confidence to invest in the new business models necessary to deliver prosperity and profitability while reducing material consumption.

“Unless we make EU policies fit for purpose we can’t shift away from current inefficient linear take-make-waste economic models,” Joan Marc Simon, Director-Founder of Zero Waste Europe pointed out.

He added: “It’s imperative that the EU makes it easier and cheaper for citizens, businesses, and organisations to make the right choices.

-Hyundai and SK on have announced their plans to collaborate on building an electric vehicle battery factory in the United States, in response to the U.S. Inflation Reduction Act that was implemented in March 2023.

The act requires carmakers to produce electric vehicles in the U.S. and use components, especially large-capacity batteries, made in American factories to be eligible for tax credits of up to $75,000 for buyers of clean energy vehicles. Plastics recycling – EV batteries

Hyundai currently manufactures the electrified version of the GV70 SUV model of their premium sub-brand Genesis at a factory in Alabama, using batteries assembled by SK on, which sources battery cells made in China.

The two companies will jointly invest 6.5 trillion won ($4.8 billion) in a new EV battery factory located in Bartow County, Georgia, with an annual production capacity of 35 gigawatt-hours, equivalent to approximately 300,000 EV battery units. The factory is scheduled to be operational by the second half of 2025 and will be owned equally by Hyundai and SK on.

The location of the factory was chosen to provide easy access to supply Kia’s Georgia factory, Hyundai’s Alabama factory, and the carmaker group’s first dedicated EV plant, which is also expected to be built in Georgia State by 2025.

Hyundai hopes the partnership with SK on will improve local battery supply and increase EV sales. Plastics recycling – EV batteries

[Courtesy of Hyundai Motor]

-LyondellBasell takes full ownership of QCP recycling facilities

LyondellBasell Industries has acquired full ownership of recycling plants in the Netherlands and Belgium for an undisclosed price.

Houston-based LBI had owned half of Quality Circular Polymers BV in a 50-50 joint venture with Veolia Environment SA of France. In a news release, LBI officials said that with full ownership of QCP, the firm “is progressing its strategy to build a profitable circular and low carbon solutions business [and] to meet customer demand for more sustainable products and solutions.”

The QCP mechanical recycling plants make blends using household plastic waste. Those recycled materials are used to make items such as bottles, buckets, caps and closures as well as strollers and suitcases. LyondellBasell will continue to offer QCP polymers under its Circulen Recover brand, with QCP as its growth platform to enable circular solutions.

Veolia is a major plastics recycler with almost 200 sorting centers and 40 recycling and compounding plants worldwide. The firm annually delivers more than 1 billion pounds of circular polymers to thousands of customers. Plastics recycling – EV batteries

LBI also recently reported first-quarter financial results. The firm’s sales for the quarter were down 22 percent to a little less than $10.3 billion vs. the year-ago period, with profit down 64 percent to $474 million. LBI’s quarterly profit was impacted by an impairment charge for its Advanced Polymer Solutions unit.

First-quarter sales in LBI’s Olefins & Polyolefins-Americas unit — including polyethylene and polypropylene resins — were down 25 percent to $2.8 billion, with operating income down 51 percent to $371 million. LBI’s APS unit, including North America’s largest compounding business, saw quarterly sales fall 12 percent to just under $1 billion. That unit showed an operating loss of $247 million for the quarter, after having operating profit of $38 million in the first quarter of 2022. Plastics recycling – EV batteries

For sales volume in pounds, O&P-Americas had PE volumes drop 5 percent to nearly 1.7 billion pounds in the quarter, with PP sales volumes down 8 percent to 550 million pounds. Quarterly sales volumes at APS were down 5 percent to 843 million pounds.

-Better recycling of plastic packaging

New process extracts fragrances

What doesn’t smell good is hard to recycle. This simple rule also applies to the growing volume of plastic waste worldwide.

One way to recycle it in an environmentally compatible and climate-friendly manner as high-quality post-consumer recyclates is through improved sorting and reprocessing. Until now, the reduced material quality has considerably limited the reuse of plastic recyclates, and this is mainly due to their odor.

Scientists at the Fraunhofer Institute for Structural Durability and System Reliability LBF have developed a new environmentally friendly process on a laboratory scale to remove odors from plastic packaging. Fraunhofer LBF will present the results of the research project at the Plastics Recycling Show Europe PRSE, Amsterdam (May 10 to 11, 2023, Hall 11, Booth P3) and at Plastics World Expo Europe, Essen (June 14 to 15, 2023, Booth C834). Plastics recycling – EV batteries

The new process is based on pressurized water extraction. It removes the tracer fragrance limonene from commercial HDPE packaging and does not require organic solvents.

This reduces costs and protects the environment. In this way, the material quality of processed plastic waste can be significantly increased within one hour.

The in-process analysis is based on infrared spectroscopy and mass spectrometry that provide the research team with data on the chemical composition of the samples as a function of different extraction conditions.

The analytical data show that significantly less limonene is present in the samples after extraction.

Furthermore, in addition to the fragrance, other impurities and short-chain HDPE are removed from the samples that were originally contained in the packaging.

Based on these analyses, the Darmstadt experts determined the optimal process parameters for pressurized water extraction of fragrances from HDPE packaging.

“The project results demonstrate the benefits of a systemic approach to solving current plastics technology issues with great social relevance,” emphasizes Dr. Guru Geertz, who oversees the project at Fraunhofer LBF. Plastics recycling – EV batteries

Material analysis with machine learning methods optimizes extraction process

To develop the process, detailed insights into the chemical kinetics of the extraction process were necessary, which were made possible by a novel approach for in-process analytics: Evaluating the data with the aid of machine learning methods was the key to optimize the extraction parameters in terms of the desired economical process control.

-Glass vs. Plastic: BBC Article Makes Surprising Call

Despite conventional wisdom, glass is no better than plastic from an environmental perspective.

Not to disdain the BBC — a venerable news organization that has my respect — but it’s not typically my source for balanced reporting on the plastics industry. So, when I saw the headline, “Glass or plastic: Which is better for the environment?,” I figured I knew where the writer would land. Well, knock me over with a polyester feather: I was wrong.

Readers of PlasticsToday are well aware that, when you take the full lifecycle into account, plastic has a better environmental record than alternative materials, such as glass and paper. In the article published on April 27 in BBC Future, journalist Claudia Lee concedes that plastic does, indeed, have an edge when you consider where glass comes from and how it is made. Plastics recycling – EV batteries

Glass is mainly made from silica, which is a natural compound that makes up 59% of the Earth’s crust, writes Lee. “The mining of silica sand can cause significant environmental damage, ranging from land deterioration to the loss of biodiversity. Some studies have also shown that extended exposure to silica dust can pose a public health risk, as it can lead to acute silicosis, an irreversible, long-term lung disease caused by the inhalation of silica dust over an extended period of time,” writes Lee.

She also notes that the extraction of sand for glass production may contribute to the global sand shortage. “Sand is the second most-used resource in the world after water — people use some 50 billion tonnes of ‘aggregate,’ the industry term for sand and gravel, each year,” writes Lee.

And then there’s the energy-intensive manufacturing process, which releases greenhouse gases. She cites the International Energy Agency, which reports that the container and flat-glass industries emit over 60 megatonnes of CO2 per year. It may seem surprising, she adds, but a study from the University of Southampton found that “plastic bottles are less environmentally damaging than glass bottles.” Plastics recycling – EV batteries

While glass is recycled at a much higher rate than plastic — in Europe, glass recycling averages 76% compared with 41% for plastic, according to statistics cited by Lee — that doesn’t actually work in its favor. Glass requires higher temperatures than plastic to melt and form, she writes, and the remelting process accounts for 75% of energy consumption during production. Moreover, glass “is often treated as single-use” and when it is sent to landfill, it can take “up to one million years to decompose.”

-Consumer brands push for tougher plastics treaty language

Major consumer brands including Coca-Cola, PepsiCo, Unilever and Walmart are pushing for a more aggressive global plastics treaty, which will include reductions in virgin plastic production language, stronger extended producer responsibility laws, reusable packaging and recyclability.

The Business Coalition for a Global Plastics Treaty wants the treaty to have legally binding global rules and measures that will drive change on a global scale.

They also want to see the treaty address reuse and refill standards, recyclability and extended producer responsibility. Plastics recycling – EV batteries

The Paris meeting in May will be the second of five sessions planned, with expectations to finish an agreement by late 2024.