Plastics sustainable – The global Alpla Group is steering towards significant growth in injection moulding by launching the ALPLAinject division 21-05-2024

Plastics sustainable

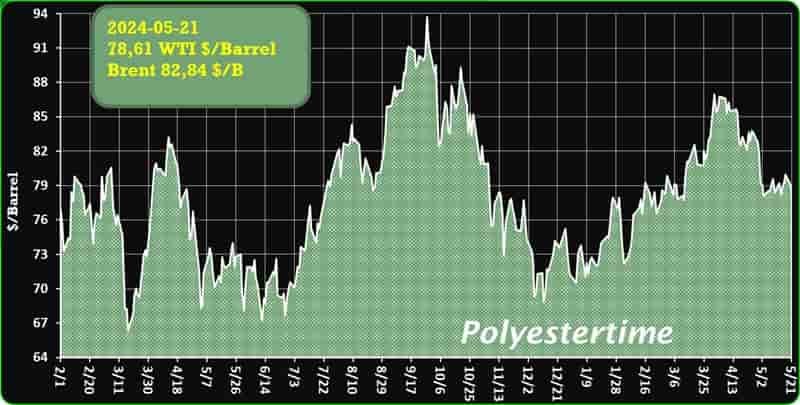

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

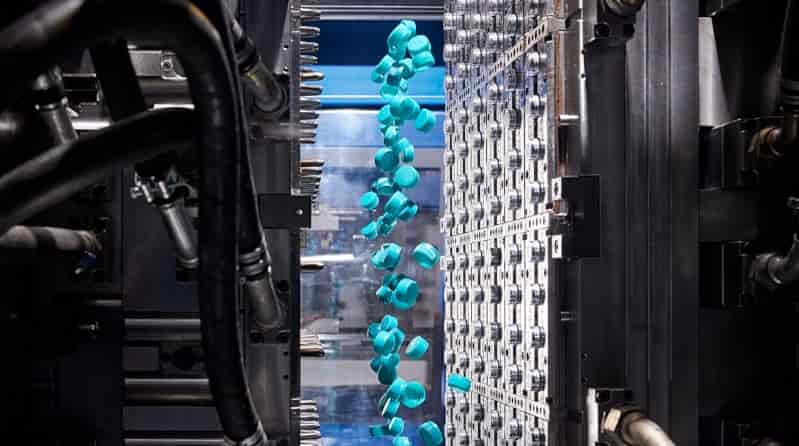

The global Alpla Group is steering towards significant growth in injection moulding by launching the ALPLAinject division

ALPLAinject specializes in high-quality injection-moulded parts like closures, caps, jars, and multi-part packaging components such as pumps and deodorant sticks. It centralizes human and technical resources in a unified organizational structure, encompassing three core technologies: injection blow moulding, compression moulding, and injection moulding. Plastics sustainable

“With ALPLAinject, we address the dynamic injection moulding market’s specific needs. By combining technological expertise with regional market knowledge, we promote innovative processes globally and help our customers bring products to market faster,” emphasizes Michael Feltes, the new ALPLAinject Managing Director, formerly the Business Development Director in the injection moulding sector since October 2022.

The global headquarters of the new division are located at Alpla’s headquarters in Hard, with global teams across all nine Alpla Group regions.

ALPLAinject produces approximately 60 billion injection-moulded parts annually at 43 plants worldwide, utilizing over 600 state-of-the-art machines and systems. “The injection moulding sector is a strategic growth driver with enormous potential. ALPLAinject, as a dedicated division, will continue to secure our competitiveness,” asserts Alpla CEO Philipp Lehner. The new division reports directly to the CEO. Plastics sustainable

LDPE Prices Experience a Downshift in first half of May, Globally

The global Low-density Polyethylene (LDPE) market experienced a decline in the first half of May 2024. This downturn in LDPE prices was noted across major markets including the US, Europe, and Asia.

The primary causes for this decline were weakened demand and an oversupply of LDPE worldwide. Additionally, production costs were reduced due to lower prices of feedstock ethylene, naphtha, and crude oil. Plastics sustainable

Geopolitical tensions causing disruptions in supply chains further compounded the pressure on the market.

Consequently, European prices for film-grade FD Hamburg (Germany) decreased by 2%, US LDPE film-grade FOB Texas dropped by 1%, and Chinese LDPE adhesive film-grade CFR Shanghai prices saw a slight decrease of 0.7% during this timeframe.

In May 2024, the European market saw a second consecutive month of declining LDPE prices, with initial offers showing significant reductions rather than minor adjustments in some cases. Plastics sustainable

This bearish trend is mainly due to abundant supply, weak demand, and competitive offers from overseas traders, rather than a decrease in monomer contract prices. Market participants are now considering whether these recent price reductions will boost sales, especially given the shorter month due to holidays.

Coca-Cola has achieved a significant milestone in Canada by shifting all its 500ml sparkling beverage bottles to 100% recycled plastic

This eco-friendly move, first announced in the previous year, is now in full swing, with the exclusion of caps and labels from the initiative. The bottles, which are now entirely made from recycled materials, are produced by Coke Canada Bottling at their facilities located in Brampton, Calgary, Lachine, and Richmond. Plastics sustainable

This transition is not only a win for sustainability but also a substantial step towards reducing plastic waste. It is projected to save about 7.6 million pounds of virgin plastic for the year 2024. Moreover, it’s expected to significantly reduce the carbon footprint by cutting down nearly 7,000 tonnes of carbon dioxide emissions each year. This effort aligns with global environmental goals and sets a precedent for the beverage industry in terms of responsible packaging and waste management. Coca-Cola’s commitment to using recycled plastic bottles in Canada reflects its dedication to environmental stewardship and sustainable business practices. Plastics sustainable

Sweden-based Nexam Chemical has achieved scientific validation for its Reactive Recycling additives, marking a breakthrough in polypropylene (PP) recycling

This patented technology repairs polymers degraded during recycling, enabling sustainable and efficient processes. The Reactive Recycling additives address the limitations of mechanical recycling, which often results in downcycling. Extensive research confirms these additives restore molecular weight and enhance the processability of recycled PP (rPP), benefiting high-demand engineering sectors. Plastics sustainable

A recent study by the Department of Applied Science and Technology at Politecnico di Torino, published in Polymer Degradation and Stability, demonstrated the additive’s effectiveness. The study focused on the thermomechanical degradation of PP microstructure over multiple extrusion cycles, finding that Nexam Chemical’s additive not only maintained molecular weight but also improved melt structuring.This advancement supports the circular economy, promoting sustainable practices and resource efficiency.”

Marketed under the brand name Reactive Recycling, these additives are suitable for both post-industrial and post-consumer mechanical recycling. Plastics sustainable

Alternative materials to plastics for packaging are not always more sustainable

The increasing sense of environmental responsibility of both consumers and companies has triggered a transition towards alternative materials which are perceived as more sustainable than plastics.

A new study conducted by the AWARE (Assessment on WAste and REsources) research group of Politecnico di Milano, recently published in Waste Management & Research: The Journal for a Sustainable Circular Economy, examines the real sustainability of these materials. The research analyzed 53 peer-reviewed life cycle assessment (LCA) studies published in 2019-2023. The aim was to gain in-depth understanding of the environmental impacts of packaging, focusing on the comparison between plastics and alternative materials. Plastics sustainable

In the contemporary business landscape, plastic packaging continues to play a crucial role in several sectors, especially in the food industry, where it accounts for more than half of total sales.

Contrary to common perceptions, the study revealed that conventional plastics are not always the least environmentally friendly choice. Bioplastics, in particular, have emerged as a viable alternative in terms of climate change and depletion of fossil resources. However, other environmental impact categories show some disadvantages, indicating that there is no one-size-fits-all solution. Plastics sustainable

Aduro Clean Technologies Provides Results on Testing of Hard to Recycle Crosslinked Polymers

Aduro Clean Technologies Inc. , a Canadian technology company using the power of chemistry to transform lower value feedstocks, like waste plastics, heavy bitumen, and renewable oils, into resources for the 21st century, is pleased to share exciting results from preliminary tests achieved with deconstructing crosslinked polymers, using the Company’s Hydrochemolytic™ Technology. Plastics sustainable

Crosslinked polymers are pivotal to numerous industries, thanks to their exceptional durability, chemical resistance, and mechanical strength. They are integral to many products ranging from automotive tires to household adhesives, protective coatings, and medical devices. Their critical applications span sectors such as aerospace, automotive, construction, and electronics, where their unique properties are indispensable. Roughly 2.5 million metric tons of XLPE is produced annually representing a $6.4 billion industry growing at 6.5% CAGR to $8.7 billion by 2028.

However, the same characteristics that make crosslinked polymers so valuable also create significant recycling challenges. Unlike thermoplastics, these materials do not melt under heat, making them difficult to recycle by traditional technologies. High-temperature technology processes typically result in char and fuel gas, which are unsuitable for repurposing into new materials. This challenge underscores the pressing need for innovation in chemical recycling technologies. Plastics sustainable

NEXTCHEM completes acquisition of GasConTec

MAIRE has announced that NEXTCHEM has finalised the acquisition of 100% of GasConTec GmbH (GCT), a company specialised in technology development and process engineering.

GCT has over 80 patents and extensive expertise in the synthesis of low-carbon products such as hydrogen, methanol, olefins, gasoline and integrated methanol-ammonia processes. The company’s portfolio includes the autothermal reforming, a well-established technology, that can generate low-carbon hydrogen with very high carbon capture rates. This process achieves high hydrogen yields while reducing external energy needs, ensuring efficiency and cost-effectiveness, especially for large-scale plants. Also known for its expertise in process engineering, the company has access to a German-based industrial-scale demonstration plant for high-pressure partial oxidation, which is a global standard for the industry. Plastics sustainable

GCT’s distinctive technologies will complement and significantly strengthen NEXTCHEM’s commercial offering in the low-carbon, green and circular solutions.

Plastics sustainable