Post-consumer Polymers – At CHINAPLAS 2024, BASF showcases its dedication to sustainability with a range of circular solutions and recycled materials 25-04-2024

Post-consumer Polymers

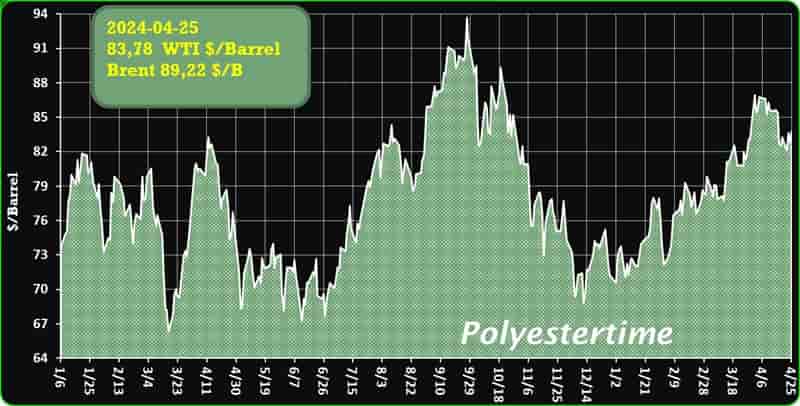

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

Paag, a subsidiary of Bell Holding A.Ş., has launched a new PET bottle-to-bottle recycling line at its Gebze facility in Kocaeli, near Istanbul

This advanced recycling line, developed by Starlinger, features a recoSTAR PET 165 HC iV+ system and began operations in March 2024. With a capacity to process up to 1,800 kg/h, Paag’s installation aims to bolster sustainability by reducing the reliance on virgin plastics, minimizing carbon emissions, and supporting circular economy principles.

The facility plans to recycle about 1,200 tons of PET bottles monthly, primarily supplying recycled PET to Senapa Stampa, a fellow Bell Holding company, and selling to external customers. Post-consumer Polymers

This initiative is part of a broader strategy to integrate recycled materials into their products, thereby lessening their overall environmental impact.

Vice Chairman Bekir Öktenoğlu emphasized that this move reflects Paag’s commitment to environmental stewardship and high-quality, food-safe production, compliant with EFSA and FDA standards for food-grade recycled PET (rPET).

Additionally, Paag has introduced ‘To-Ka’, a door-to-door collection system to enhance PET bottle recycling. This initiative, which stands for ‘collect – win’, encourages participation through a rewards system accessible via an app, facilitating easy collection and recycling of PET bottles. Post-consumer Polymers

At CHINAPLAS 2024, BASF showcases its dedication to sustainability with a range of circular solutions and recycled materials

Featured products include the Ultramid® Ccycled® polyamide, which incorporates pyrolysis oil derived from post-consumer plastic waste collected in Asia. This initiative is part of BASF’s mass balance approach, aimed at transforming feedstock within its integrated value chains.

BASF also introduces its innovative ‘Design-for-Recycling’ polyurethane foam technology, which simplifies the recycling process, enhancing the scalability of recycled polyurethane foam. The company continues to advance in sustainable plastics by offering a comprehensive portfolio of recycled grades, aligning with its commitment to environmental stewardship. Post-consumer Polymers

The event also highlights BASF’s latest plastic additives, which improve the sustainability of various applications. These innovations are crucial for the mechanical and chemical recycling processes that support the circular economy by enabling the reuse of plastic waste.

Additionally, BASF’s IrgaCycle® additive technology enhances recycled content in products, while maintaining quality and performance. New technologies like Irgastab® PUR 71 and Tinuvin® 2730 will also be displayed, demonstrating advancements in durability and stability for automotive and marine applications. Post-consumer Polymers

Heubach GmbH required to file for insolvency

Heubach GmbH applied to the Braunschweig insolvency court for the initiation of regular insolvency proceedings concerning its assets. This application included a request to designate the Braunschweig court as the overseeing court for the German subsidiaries within the Heubach Group.

The court is expected to soon appoint an insolvency administrator who will explore potential business continuity, restructuring, or sale options. Post-consumer Polymers

This move comes as a response to the imminent risk of excessive debt exacerbated by volatile financial markets over the past two years, coupled with unsuccessful efforts to achieve financial restructuring involving all shareholders and creditors.

Despite these challenges, Heubach is striving to fulfill its commitments to employees, customers, and suppliers, operating within the limits of its financial capabilities and under the constraints of legal regulations. Post-consumer Polymers

NEXTCHEM (MAIRE) is reinforcing its dedication to plastic upcycling through its subsidiary, NextChem Tech, by increasing its shares from 51% to 85% in MyReplast Industries S.r.l. and MyReplast S.r.l

These companies are known for their innovative NX Replast technology and a production facility in Bedizzole, Northern Italy, that specializes in high-purity recycled polymers. The transaction involves an overall payment of approximately €8.9 million, with €5.1 million payable at closing and the remainder to be paid in increments by the end of 2027.

MyReplast Industries, a key player in the NextChem portfolio since 2019, has a production capacity of 40,000 tons annually. It focuses on mechanical upcycling processes to produce polymers that can substitute for virgin materials in various industries, including automotive and construction. The NX Replast technology was recently chosen by Aliplast for a new project in Modena. Post-consumer Polymers

This strategic expansion enhances NEXTCHEM’s position in the circular polymers market, driven by increased regulatory demands and the voluntary commitments of purchasers. The company’s efforts are part of a broader movement towards sustainable practices in response to the global rise in plastic use and the pressing need for circular economic solutions.

Research Project on PHA for Packaging

Coordinated by the Spanish company Cetec, the ViSS project aims to demonstrate the effectiveness of PHBV as an alternative to fossil-based plastics in food packaging. Initiated in September of the previous year and funded by the EU through the Horizon program, ViSS is set to conclude in 2027. Post-consumer Polymers

The project, led by the Spanish technology center Cetec, focuses on developing a biopolymer made from the copolymer poly(3-hydroxybutyrate-co-3-hydroxyvalerate), commonly known as PHBV. This material is intended for use in food packaging applications. PHBV belongs to the polyhydroxyalkanoates (PHA) family, which are biobased and biodegradable materials. They can degrade in soil and water and are recyclable and compostable in both domestic and industrial settings. Its flexibility, workability, recyclability, and biodegradability make PHBV particularly suitable for packaging applications.

In the course of the research, PHBV will be produced through the fermentation of industrial food waste. Post-consumer Polymers

At the Chinaplas 2024 trade fair in Shanghai, Covestro debuted its new range of polycarbonates, Makrolon® RP, derived from chemically recycled material sourced from post-consumer waste via mass balance

This initiative is part of Covestro’s commitment to the circular economy, involving collaborations with Neste and Borealis for raw material supplies. The introduction of Makrolon® RP, particularly targeted for high-purity applications in the automotive sector, is a significant step towards using sustainable materials that meet stringent purity standards.

Lily Wang, the Global Head of Engineering Plastics at Covestro, expressed enthusiasm about the expansion of their sustainable product line, emphasizing the role of partnerships in conserving fossil resources and enhancing waste management. Post-consumer Polymers

The company aims to support its customers’ sustainability objectives by offering high-quality materials that align with emerging regulatory demands and voluntary environmental standards, such as the European End-of-Life Vehicle Directive and the U.S. EPEAT for electronics.

Makrolon® RP, which matches the quality of traditional fossil-based polycarbonates, is part of Covestro’s CQ family, signifying a minimum of 25% alternative raw materials content. Production at certain facilities, like Krefeld-Uerdingen in Germany, is powered exclusively by renewable energy. Neste and Borealis contribute by providing high-quality recycled feedstock, which Borealis converts into phenol and acetone for Covestro’s use.

Jeroen Verhoeven from Neste and Thomas Van De Velde from Borealis highlighted the importance of chemical recycling and collaboration across the value chain in achieving recycling targets and advancing sustainable practices. Post-consumer Polymers

Far Eastern New Century Corp. (FENC) has initiated the expansion of its FE Green PET facility in Malacca, Malaysia, which focuses on producing green polyethylene terephthalate (PET)

The expansion will include a new production line that uses waste PET bottles from local sources to manufacture 50,000 tons per year of food-grade recycled PET. The operation of this new line is slated to start by mid-2025.

This expansion aligns with FENC’s commitment to addressing global climate change. The company plans to implement energy-efficient technology, utilize carbon capture solutions, and introduce other innovative practices to cut carbon emissions.

The targeted reductions are 20% by 2025, 40% by 2030, with a goal of achieving net zero emissions by 2050. Post-consumer Polymers

Additionally, it was reported earlier that FENC, along with Alpek and Indorama Ventures, had put on hold the construction of another PET plant in Corpus Christi, Texas. This plant was intended to have a production capacity of 1.1 million tons of PET annually. The site was also expected to house a facility capable of producing 1.3 million tons of purified terephthalic acid (PTA) each year, further expanding FENC’s manufacturing capabilities.

Post-consumer Polymers