PP-PE-polymerisation – PET-Recycling 18-06-2022 - Arhive

PP-PE-polymerisation – PET-Recycling

-EREMA Group and Borealis at K 2022: a first glimpse of K show topics, activities and highlights

13 June, EREMA Group and Borealis invited representatives of the international plastics and recycling trade press to Upper Austria for a sneak preview of the technological developments and lighthouse projects that the companies will present at K 2022, the plastics industry’s international meeting place. The venue for the pre-K event was EREMA Group headquarters in Ansfelden.

Publishers and editors of more than 50 international trade magazines accepted EREMA and Borealis invitation to Ansfelden to get information first-hand about the companies’ trade fair topics and activities.

“Our mission ‘Another life for plastic, because we care’, is also our tagline at this year’s trade fair. This underlines what EREMA company group will be showing plastics industry insiders and all other visitors to the trade fair: That it is possible to implement a circular economy if everyone in the value chain works together,” said Manfred Hackl, CEO EREMA Group GmbH, in his opening presentation.

EREMA Group K 2022 preview

In Düsseldorf, the subsidiaries of the EREMA Group – which are EREMA, PURE LOOP, UMAC, 3S, KEYCYCLE and PLASMAC – will present their technological innovations, services and support together at a Group trade fair stand for the first time. Seven new recycling systems and components will be presented that enable large-scale plants with a production capacity of up to 6 t/h while setting a milestone in recyclate quality and process stability. This is made possible by technological innovations in the plasticizing unit that have been specially developed for high throughputs with low specific energy consumption, the new EREMA 406 laser filter with a 50 percent larger screening area, and new digital assistance systems that will be launched at K 2022 and made available on the BluPort® customer platform. These include, for example, the PredictOn app, which helps to anticipate and eliminate imminent malfunctions based on continuous measurement and evaluation of machine data.

New series of machines for new target groups

“CHEMAREMA is a new series we have developed for mechanical material processing as part of the chemical recycling process,” says Hackl by way of introducing another EREMA innovation. Mechanical processes are often at the beginning of the process chain for chemical recycling to prepare input streams and ensure a reliable, continuous and energy-efficient flow of feed material. CHEMAREMA features extrusion technology that can be adapted to the application requirements and is designed precisely for downstream chemical processes.

For customers looking for rapidly available recycling systems for simple applications, EREMA Group subsidiary UMAC has an innovation in store for K 2022. The company, which has so far specialised in refurbishing and trading in previously owned equipment, is expanding its business area and in Düsseldorf will launch READYMAC, a standardised, prefabricated recycling solution that can be produced from stock, based on proven EREMA TVE technology.

Speaking at a pre-K event in Rotterdam today, additive specialist Palsgaard announced it will launch a new anti-fouling additive for use during the PP and PE polymerisation process – dubbed Einar 981 – which it claims replaces existing chemistry.

Bjarne Nielsen, business development manager, confirmed that the new additive is also plant-based and food-grade.

Nielsen explained that static build-up during polymerisation can cause fouling of the reactor wall. The new additive works to remove this effect, helping PP and PE producers maintain the cooling efficiency of the reactor. It needs only to be used at low concentrations (100-300 ppm), Nielsen added. PP-PE-polymerisation – PET-Recycling

The group is positioning the new product as an alternative to the ethoxylated amine chemistry currently used. Einar 981 is supplied as a clear, pumpable liquid for use in existing dosing systems. The active compound is a polyglycerol ester (PGE) blend of fatty acids derived from RSPO certified sustainable palm oil.

A statement from the group also read: “As a non-toxic and food-contact approved anti-fouling additive, the product offers a drop-in regulatory-compliant solution to replace incumbent ethoxylated amines and can also be used as a more efficient alternative to sorbitan monooleates. This makes it an ideal process additive in the polymerisation of PP and PE materials for sensitive applications, including e.g. medical devices and baby food containers.” PP-PE-polymerisation – PET-Recycling

Ulrik Aunskjaer, global business director, bio specialty additives at Palsgaard, added:

“Polyolefin producers are under growing pressure from converters and brand owners to abandon the use of ethoxylated amines in their polymerisation processes and switch to safer products without any regulatory concerns,”

-Origin Materials and Kuraray Announce Carbon Negative Materials Partnership

Kuraray signed a multi-year capacity reservation agreement to purchase sustainable carbon negative materials from Origin Materials

Origin Materials, Inc. (“Origin” or “Origin Materials”) (NASDAQ: ORGN, ORGNW), the world’s leading carbon negative materials company with a mission to enable the world’s transition to sustainable materials, and Kuraray Co., Ltd (“Kuraray”), a leading manufacturer of specialty chemicals, fibers, and other materials, today announced a strategic partnership to commercialize advanced carbon negative materials for diverse polymer applications. PP-PE-polymerisation – PET-Recycling

As part of the strategic partnership, Kuraray signed a capacity reservation agreement with Origin Materials to purchase sustainable, carbon negative intermediate chemicals used in the large-scale synthesis of many polymers, including PTA, PET, and polyamide. The materials from Origin will enhance Kuraray’s mission to develop innovative solutions with unique products and cleaner technologies to improve the natural environment and enhance quality of life for people everywhere.

Origin’s patented technology platform, which turns the carbon found in sustainable wood residues into useful materials, can help revolutionize the production of a wide range of end products and supports industry’s transition to sustainable materials and lower GHG emissions.

“We are thrilled to partner with Kuraray, a leading global manufacturer with a deep commitment to the highest standards for performance and sustainability,” said Rich Riley, Co-CEO of Origin Materials. PP-PE-polymerisation – PET-Recycling

-New US PET Recycling Coalition

The Recycling Partnership, a US force for improving recycling, announced the launch of its PET Recycling Coalition, an initiative informed by industry knowledge and expertise to improve PET circularity. Its work will focus on addressing four key opportunities to increase recycling of this valuable material:

- Increasing the capture of PET bottles

- Broadening the acceptance of PET trays, cups, and clamshells in community recycling collection programs

- Unlocking new supplies of recycled PET (rPET) for packaging manufacturers

- Strengthening recycling systems for pigmented and opaque PET

While eliminating unnecessary usage is an important component of circularity, increased PET recycling is another critical step in advancing circularity, states the Coalition.

This along with company commitments and recycled content mandates in proposed U.S. legislation is leading to skyrocketing demand for recycled PET but supply is currently limited. PP-PE-polymerisation – PET-Recycling

Most Americans with recycling access are able to recycle PET bottles; however, just 54% can recycle other types of PET packaging like plastic egg cartons and fruit containers. Furthermore, the recycling rate for PET bottles was only 26.6% in 2021. While most PET never makes it into the recycling bin due to insufficient access and participation, as much as 17% of bottles that are recovered are lost at Materials Recovery Facilities (MRFs) due to sortation challenges. By supporting solutions identified by the PET Recycling Coalition, there is a great opportunity to increase recovery and reduce plastic waste and help make progress toward packaging circularity goals.

The PET Recycling Coalition will make grants to recycling facilities for sorting equipment and related capital needs. These upgrades will improve PET bottle capture, deliver more rPET for use back into bottles and thermoforms, increase the acceptance of non-bottle rigid items in community recycling programs, and strengthen recycling opportunities for pigmented and opaque PET. Through grants, technical assistance, and knowledge sharing, the Coalition envisions a thriving PET recycling system that captures significantly more material, enabling more circular PET packaging with increased amounts of recycled content. PP-PE-polymerisation – PET-Recycling

“The Recycling Partnership is dedicated to building a stronger U.S. recycling system, including material-focused efforts such as the PET Recycling Coalition. The success of these material-specific coalitions shows us that when we take a systems approach, we’re able to not only lift up that targeted material but all the other recyclables in the bin as well,” said Keefe Harrison, CEO of The Recycling Partnership.

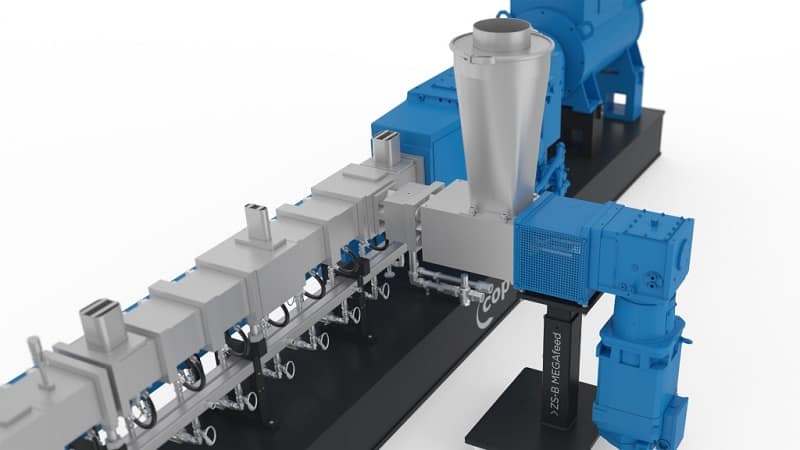

-Use Coperion’s new side feeder to recycle intake-limited plastic recyclate

With the goal of making recycling of lightweight, high-volume fibre and flake recyclate more economical and, in some cases even possible, Coperion has developed a new version of its ZS-B side feeder. Using the ZS-B MEGAfeed, plastic recyclate with a bulk density under 200 kg/m cubed, long considered intake-limited and not worth recycling, can be reliably fed in large quantities into Coperion’s ZSK twin screw extruder and be concurrently recycled and compounded. PP-PE-polymerisation – PET-Recycling

The ZS-B side feeder’s design makes it possible to feed high rates of fibre and flakes, such as PA, PE, PET, and PP. As a result, the ZSK twin screw extruder’s high capacity can be fully exploited when the ZS-B MEGAfeed is used. Ideal throughputs in both mechanical and chemical recycling of post-industrial and post-consumer waste are achieved.

Increased throughput numbers

With a ZSK 58 Mc18 twin screw extruder, the throughput increase and thus the potential of the new ZS-B MEGAfeed becomes very clear. When recycling PA fibres with a bulk density of ~40-50 kg/m cubed, throughputs of 70 kg/h were previously achieved using conventional equipment. When the PA fibres were fed into the ZSK extruder using the ZS-B MEGAfeed, throughputs increased about fourteenfold to 1,000 kg/h.

Similar results were achieved recycling carbon fibres with a bulk density of ~50 to 70 kg/m cubed; in this case, throughputs increased from 50 kg/h to 2,500 kg/h using the ZS-B MEGAfeed. PP-PE-polymerisation – PET-Recycling

When recycling PCR (post-consumer recycled) flakes, throughputs increased from 50 kg/h to 700 kg/h, and from 80 kg/h to 1,300 kg/h with multilayer film flakes.

-BASF plans to increase prices for nylon 6 in N America

BASF is seeking a 22 cent/lb (USD485/tonne) increase on its caprolactam and nylon 6 in North America, effective 1 July, said the company.

The company did not provide a reason in the media release for the July increase initiative. US June contracts for upstream benzene settled at a 35% increase from May. Spot benzene last traded at USD6.50/gal. PP-PE-polymerisation – PET-Recycling

We remind, in May, BASF increased prices for its Refinery Catalysts portfolio globally. With immediate effect, BASF’s Refinery Catalysts business will increase prices for its portfolio globally. The price adjustment is in response to continuously surging raw material, transportation, and energy costs.

BASF’s Catalysts division is the world’s leading supplier of environmental and process catalysts. The group offers exceptional expertise in the development of technologies that protect the air we breathe, produce the fuels that power our world and ensure efficient production of a wide variety of chemicals, plastics and other products, including advanced battery materials. PP-PE-polymerisation – PET-Recycling

-AdvanSix Announces Price Increase on Nylon 6 & 6/66

AdvanSix Announces Price Increase on Nylon 6 & 6/66

Chattanooga, TN, June 16, 2022-Due to increases in raw materials prices and continued demand for nylon 6, 6/66 and nylon 6 intermediates, AdvanSix will increase the prices in the Americas of caprolactam, Aegis nylon 6 and nylon 6/66 copolymer resins by $0.20/pound, effective July 1 or as contracts allow. PP-PE-polymerisation – PET-Recycling

AdvanSix is also analyzing the impact of unprecedented energy costs in its operations and anticipates the need to communicate an energy surcharge in the future.

PP-PE-polymerisation – PET-Recycling