R-PET-price – 3D-woven fabrics 27-04-2023 - Arhive

R-PET-price – 3D-woven fabrics

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

-Lummus and Citroniq Sign Letter of Intent for Green Polypropylene Projects

Partnership will leverage expertise and innovation to produce green polypropylene

Lummus Technology, a global provider of process technologies and value-driven energy solutions, and Citroniq Chemicals, a world-scale producer of carbon-negative materials, announced that the two companies have signed a letter of intent (LOI) for the development of Citroniq’s green polypropylene (PP) projects in North America. These projects will use Lummus’ VerdeneTM PP technology suite.

“Lummus is honored to collaborate with Citroniq to bring this innovative and sustainable technology to market, which will facilitate further decarbonization of our industry,” said Leon de Bruyn, President and Chief Executive Officer of Lummus Technology. “Lummus is the global leader in licensing PP technology, and we can serve as a launch pad for Citroniq’s green, carbon-negative PP to meet the growing demand for products using sustainable materials.” R-PET-price – 3D-woven fabrics

“Together, Citroniq and Lummus are creating the first world-scale sustainable bio-polypropylene production process in North America,” said Kelly Knopp, Principal and Co-Founder of Citroniq Chemicals. “The first plant will sequester about 1.2 MM tons of CO2 annually as solid polypropylene pellets, providing customers an impactful solution for reducing their carbon footprint and meeting their ESG goals.”

“With a projected investment of over US $5 billion and a combined PP annual capacity of over 3.5 billion pounds, Citroniq is prepared to execute a rapid expansion plan of its E2O process, to meet the market’s growing need for sustainable, carbon negative polypropylene at a competitive price,” said Mel Badheka, Principal and Co-Founder of Citroniq Chemicals. “Located in the Midwest, Citroniq’s first plant is scheduled to start production in 2026 and provide identical, drop-in products that can be directly certified as biogenic through physical testing.”

-Alpek swings to Q1 net loss

Alpek swung to a first-quarter net loss of USD6m amid poorer demand due to high polyethylene terephthalate (PET) inventory levels in the market, said the Mexican polyester producer.

Overall sales volumes fell by 5% year on year to 1.16m tonnes in the first quarter, with total production down by 9% year on year to 1.38m tonnes in the first quarter.

“The polyester segment experienced softer demand throughout the quarter due to high PET inventory levels in the market, particularly at the beginning of the year, a decrease in exports, as well as continued seasonality,” said Alpek CEO Jorge Young in the statement.

“However, despite lower demand in the polyester & chemicals segment in certain industries and rising polypropylene (PP) supply in the Americas, volume remained slightly above that of last quarter,” he said. R-PET-price – 3D-woven fabrics

We remind, Alpek, Indorama and FENC announced earlier that Corpus Christi Polymers (CCP) will resume construction on the facility in August. The plant is expected to begin production of polyethylene terephthalate (PET) and purified terephthalic acid (PTA) in early 2025. Construction of the state-of-the-art plan is resuming following a period of pandemic-related disruptions. The new facility is expected to be the largest vertically integrated PTA-PET production plant in the Americas, with annual capacities of 1.1m tonnes of PET and 1.3m tonnes of PTA. It will employ three state-of-the-art technologies.

-Lacklustre demand lingers across most classes

R-PET continues to face strongest downward price pressure

The price of most recycled plastics classes have continued to fall over the last two months. R-PET has seen the steepest price decline with clear flake prices down by a combined total of €160/tonne over March and April with food-grade pellets down by €100/tonne over the same period.

R-LDPE natural film grade prices have fallen by €50-60/tonne with black extrusion pellets down by €40/tonne and translucent film pellets down by €30/tonne. R-HDPE prices have softened slightly over the last two months with blow moulding grade prices falling €40/tonne and injection moulding prices €30/tonne lower over the last two months.

R-PP prices, on the other hand, have actually increased slightly; mainly because of better demand. R-HIPS prices have stabilised in a well-balanced market.

Low demand continues to characterise the market for recycled plastics with order activity well below what would normally be expected for the time of year.

Only R-PP and R-HIPS has reported an upswing in sales over the last two months.

Demand weakness can be easily explained by the slowdown in European economies and weakness in key end use markets for recyclate such as construction and packaging. Recyclate is also facing growing competition from the falling cost of off-spec virgin material and competition from cheaper imported material from the Far East.

Recyclers have continued to curb production to avoid a build-up of excess stocks; yet there has been no major shortage of material reported. R-PET-price – 3D-woven fabrics

In May, prices are likely to remain under pressure as a significant upturn in demand is not expected.

Recycled polyethylene terephthalate (R-PET)

R-PET prices have now fallen in every month since August 2022. In March and April, R-PET clear flake prices fell by a combined €160/tonne, R-PET clear food-grade pellet prices were down by €100/tone and coloured flake prices fell by €90/tonne over the same period.

R-PET prices have fallen because of the availability of competitively-priced imports from Vietnam and substitution by the less expensive virgin material. In addition, the cost of clear and coloured bottle scrap has fallen across Europe.

While producers continue to curb production rates supply is more than sufficient to meet demand because of the additional imports from Asia. R-PET-price – 3D-woven fabrics

While seasonal demand from the beverages sector is growing, processors are increasingly turning to cheaper imports from Asia or using the virgin PET material.

In May, prices are expected to soften further as a result of continuing weak demand and competition from cheaper imported material.

Recycled low-density polyethylene (R-LDPE)

R-LDPE prices continued to drift downward in March as a result of low demand and competition from falling virgin LDPE prices. Natural film grade prices fell by €50-60/tonne with black extrusion pellets down by €40/tonne and translucent film pellets down by €30/tonne. The downward price trend continued into April, albeit at a slower pace.

Recyclers are maintaining production controls to avoid an excess stock position, yet availability of base material and recyclate still exceeds demand.

In March, the expected demand upturn failed to materialise as processors tended to buy only what was contractually required. Demand has however recovered in April, particularly for black extrusion pellets and dark film grades. R-PET-price – 3D-woven fabrics

-Boehringer Ingelheim inaugurates largest European biotechnology development center

The new €350m ($386m) biotechnology research center will help power Boehringer Ingelheim’s development of biopharmaceuticals, which account for around 50% of the company’s research pipeline.

The Biologicals Development Center (BDC) in Biberach an der Riß ‘significantly enhances Boehringer Ingelheim’s innovation power and biopharmaceutical development capabilities’ in the country.

The BDC has a gross floor space of 34,500 sqm, which equals five football fields.

The new facility is a highly complex building, offering modern workplaces for more than 500 employees who will develop Boehringer Ingelheim’s future biopharmaceutical substances. R-PET-price – 3D-woven fabrics

Scientists from multiple disciplines and three different development units will collaborate under one roof to research and develop antibodies and therapeutic proteins. They will have the capability to produce these substances from lab-scale to supply for clinical studies.

The new facility is part of Boehringer Ingelheim’s campus in Biberach, which is the company’s largest R&D and Biopharmaceuticals site with more than 7,000 employees.

The construction of the BDC is part of Boehringer Ingelheim’s strategy to make significant investments in its R&D pipeline, which amounted to €5bn ($5.5bn) in the last business year – equivalent to around 21% of total net sales. Nearly half (47%) of this investment was in Germany.

Headquartered in Ingelheim am Rhein, Boehringer Ingelheim is split into two main divisions – human pharma and animal health – alongside a smaller biopharmaceutical contract manufacturing division. R-PET-price – 3D-woven fabrics

In human pharma, the company’s pipeline covers some 90 clinical and pre-clinical projects, with more than 50 of these representing new molecular entities.

Biopharmaceuticals, highlights Boehringer Ingelheim, are highly complex drugs and at the same time one of the fastest growing drug segments of the pharmaceutical industry.

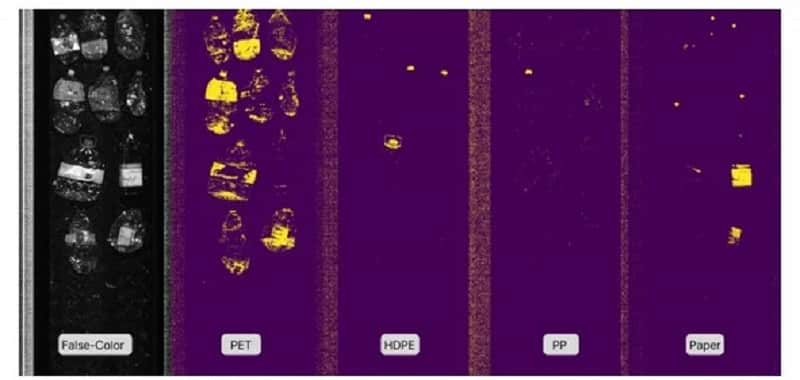

-This startup aims to improve recycling by capturing ‘chemical fingerprints’ with high-tech cameras

Metaspectral uses hyperspectral cameras to rapidly create a chemical fingerprint of plastic items, distinguishing between polyethylene terephthalate (PET), high-density polyethylene (HDPE), and polypropylene (PP) plastics. In some cases, their technology can also differentiate between low- and high-quality forms of the same plastics.

If you’re someone who recycles, you’ve experienced that paralyzed moment in front of a row of waste bins not knowing where your plastic fork and cup are meant to go.

Now imagine you had to accurately sort your plastic trash as it whizzed by on a conveyor belt at the rate of 3 feet per second. R-PET-price – 3D-woven fabrics

British Columbia’s Metaspectral is up for that challenge.

The startup has created technology using hyperspectral cameras and artificial intelligence (AI) to rapidly identify and sort plastics for recycling. While distinguishing between many plastics is essentially impossible with a regular camera that sees only red, blue and green, a hyperspectral camera can capture up to 300 frequencies of light.

“Each one of those 300 bounces back differently,” said Francis Doumet, Metaspectral CEO and co-founder. “It allows us to make up a chemical fingerprint off the material we’re looking at.”

The Vancouver-based startup recently received a $419,000 grant from a government initiative to curb plastic waste. It previously landed $300,000 from the same source, called the CleanBC Plastics Action Fund.

Metaspectral also closed a $4.7 million seed round in November.

The company’s technology currently is being used by one of B.C.’s main recyclers to sort between polyethylene terephthalate (PET) plastic used to make items like water bottles and high-density polyethylene (HDPE) plastic used for goods such as milk bottles and food containers. R-PET-price – 3D-woven fabrics

Its system can also distinguish between purer, high-quality PET items and PET that’s mixed with other materials, making it lower quality.

The new grant will support research to differentiate between homopolymer HDPE that’s typically found in milk jugs and copolymer HDPE often used for detergent, shampoo and automotive oil containers.

-Maire Tecnimont has suspended contracts in Russian projects

Maire Technimont is terminating contracts with contractors and subcontractors for the design, procurement and services at the site (EPSS) of the Amur Gas Chemical Complex for polyethylene and polypropylene and linear alpha-olefins plants, the company said in a statement.

In 2020, Maire Tecnimont signed a contract for “Design, Procurement and On-Site Services (EPSS) for polyethylene and polypropylene and linear alpha olefins at the Amur Gas Chemical Complex (AGCC, a joint venture between SIBUR and China’s Sinopec).

Due to the geopolitical situation and the sanctions imposed on Russia, Maire Tecnimont and the Amur Gas Chemical Complex agreed to suspend work until April 2023.

The company clarifies that now it is undergoing re-registration of contracts with subcontractors and suppliers for the customer and termination of other contracts with subcontractors and suppliers. R-PET-price – 3D-woven fabrics

Maire Tecnimont also announced that in 2022 the contract with Kazanorgsintez for the engineering and purchase of equipment for the LDPE/EVA autoclave plant was suspended.

In August 2021, subsidiaries of the Italian engineering company Maire Tecnimont S.p.A. received a contract for the construction of a new Kazanorgsintez plant for the production of high-pressure polyethylene (LDPE)/ethylene-vinyl acetate (EVA) at the existing WWTP complex in Kazan (Tatarstan, Russia).

The capacity of the new enterprise should be 100 thousand tons of LDPE / EVA per year.

-The 3D woven fabrics market size is expected to grow from US$ 120.87 million in 2022 to US$ 266.34 million by 2028; it is estimated to grow at a CAGR of 14.1% from 2022 to 2028

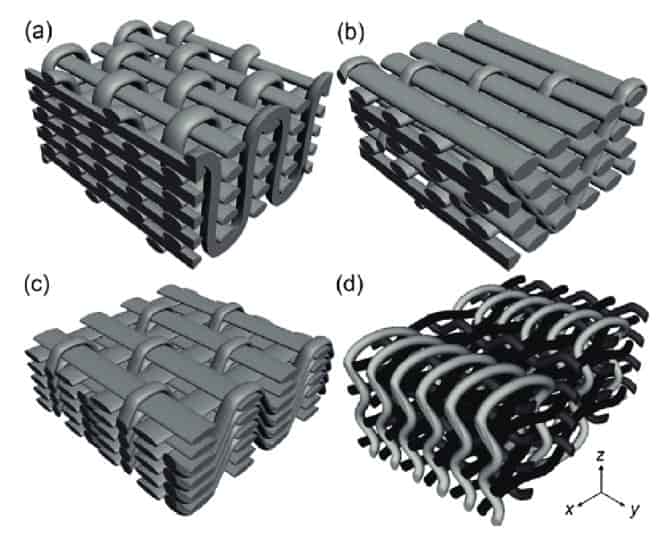

3D woven fabrics are made with three-dimensional structures that are produced by interlacing yarns or fibers in three directions (x, y, and z). These fabrics have a unique and complex structure, which makes them useful in a wide range of applications, such as aerospace, automotive, building and construction, and other industries.

The woven process of 3D woven fabrics involves interlacing two sets of yarns or fibers at right angles to each other, forming a two-dimensional plane. Then, a third set of yarns or fibers is woven through this plane at a 90-degree angle to create the third dimension. This creates a solid, stable structure with excellent mechanical properties. The global 3D woven fabrics market is mainly driven by the increasing demand for 3D woven fabrics from automotive and aircraft industry. Moreover, the market growth is fueled by a rise in the utilization of carbon fiber in various end-use industries. R-PET-price – 3D-woven fabrics

The higher utilization rate of carbon fiber in end-use industries such as aerospace, automotive, building and construction, and defense and military has broadened the scope of carbon fiber 3D woven fabrics. Automotive is one of the fastest-growing sectors across the globe and will expand rapidly in the coming years. Rise in preference of lightweight vehicles to improve efficiency and fuel economy is boosting the sector. Further, the increasing use of 3D woven fabrics in the automotive sector is expected to offer lucrative opportunities for the 3D woven fabrics market growth during the forecast period.

Based on application, the 3D woven fabrics market is segmented into ballistics, aircraft, transportation, building & construction, and others. The aircraft segment registered a larger share of the 3D woven fabrics market in 2022. 3D woven components exhibit high strength and wear capabilities compared to aluminum and steel alternatives.

They allow weight reduction in existing airframe and structural components and have the ability to weave complex 3D shapes, such as turbine blades, without any worry about delamination. R-PET-price – 3D-woven fabrics

The adoption of 3D woven fabrics in aerospace manufacturing is increasing globally. Constant cross-section 3D Pi structures in the fabrics have been developed over the last decade and are being used in current developments worldwide. Solid 3D structures are being considered and developed for more technical aerospace applications where their interlaminar sheer properties are expected to improve composite performance further.