Recyclable polymers cellulose – Pact Collective and Eastman have achieved a significant milestone: the approval of colored PET waste from Pact members and consumers for use in Eastman’s methanolysis process 07-05-2024

Recyclable polymers cellulose

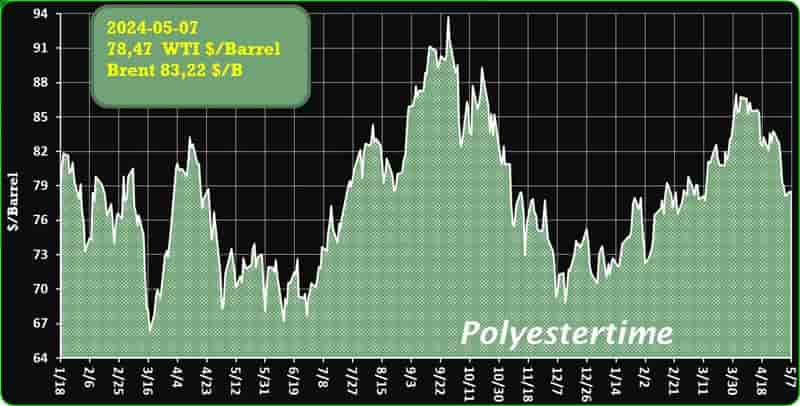

Crude Oil Prices Trend

Researchers have innovated a method to create recyclable polymers from plant cellulose, addressing the urgent need to mitigate plastic pollution

Published in ACS Macro Letters, this breakthrough utilizes cellulose, a plentiful plant biomass component, ensuring no interference with food production land. The Hokkaido team transformed two cellulose-derived molecules, levoglucosenone (LGO) and dihydrolevoglucosenone (Cyrene), into diverse polysaccharide polymers through novel chemical processes, paving the way for various applications.

The project’s main hurdles involved mastering the polymerization reaction and achieving material stability for practical use while maintaining recyclability. Recyclable polymers cellulose

The resultant polymer films exhibited unexpected high transparency, suggesting suitability for specialized uses in optics, electronics, and biomedicine, rather than flexible products like plastic bags.

This development adds to the growing field of ‘bioplastics,’ with some already on the market. However, the team’s contribution opens new avenues, particularly given the vast potential structural variations. Collaborations with experts in computational chemistry, AI, and automated synthesis are sought to further explore these possibilities.

The overarching goal is to foster a sustainable cycle of polymer production from biomass, complete with efficient recycling, contributing to a greener future. Recyclable polymers cellulose

This initiative represents a significant stride in creating alternative materials that align with environmental conservation efforts and the global shift towards renewable resources.

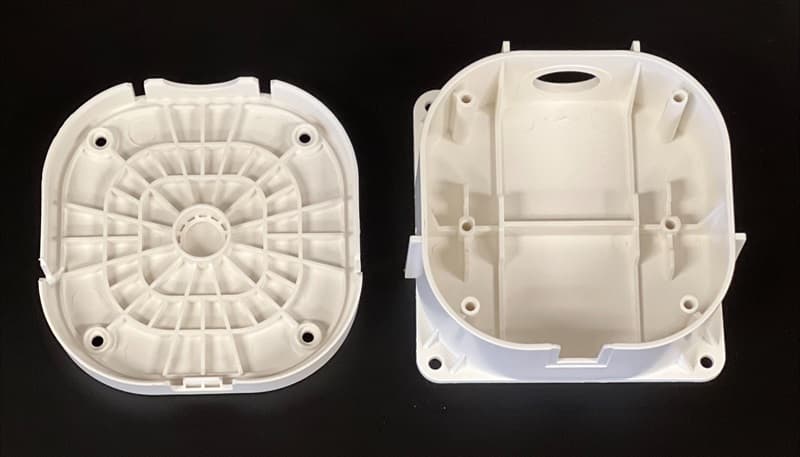

At the upcoming NPE 2024 event, Sirmax North America is set to exhibit its extensive collection of flame-retardant polypropylene (PP) compounds

These halogen-free materials, which boast UL Yellow Card certification, are gaining traction as a greener substitute for polyvinyl chloride (PVC), especially in electrical and electronics applications. The showcase, scheduled for May 6-10 in Orlando, Florida, will feature the Dafnelen and Dafneglass families—unfilled and glass-reinforced FR PP compounds, respectively. These products offer robust mechanical, electrical, and thermal properties, meeting stringent industry standards. Recyclable polymers cellulose

The demand for Sirmax’s FR PP compounds is on the rise in the U.S., as the market shifts away from halogenated alternatives. This trend is further fueled by the withdrawal of a key competitor from the FR PP compound market. Sirmax’s offerings include a variety of colors and grades, such as the Dafnelen line with a UL V0 flame retardant rating and the Dafneglass line, suitable for automotive and household appliances, with glass loadings ranging from 10% to 30%.

Sirmax’s U.S. country manager, Lorenzo Ferro, emphasizes the company’s readiness to cater to market demands with these versatile and high-performance FR PP options. Sirmax also collaborates with clients to tailor FR products for specific applications, including meter sockets, sensor housings, and power tools, among others. Recyclable polymers cellulose

This commitment to customization and environmental sustainability positions Sirmax as a leader in the industry, poised to meet the evolving needs of a market moving towards non-halogenated, eco-friendly materials.

China Polyamide Prices remain Weak due to the Ease in Feedstocks Coupled with Low Demand

The pricing pressure from low-cost feedstocks, Caprolactam and Adipic Acid, has kept the prices of Polyamide 6 and 66 low in the Chinese market in recent weeks. The Polyamide market in China is encountering difficulties due to ample supply and declining demand from downstream industries, creating a challenging environment for producers and traders. There has been no noticeable increase in stocking activity before the holiday period. Traders are maintaining stable prices, with moderate demand supporting average levels for PA66. As a result, the cost of Polyamide 6 (Medium Viscosity) decreased by 1.3% on a FOB Dalian basis, and Polyamide 66 remained stable, reflecting the broader market conditions.

Supply of Polyamide in China remains abundant, with production levels exceeding current demand. This oversupply situation is partly a result of increased production capacities in the region, driven by early-stage maintenance companies that have progressively resumed operations, weekly production is on the upswing, leading to mounting supply pressure. Despite efforts to align production with demand, the market remains flooded with Polyamide, putting pressure on prices.

Demand for Polyamide from downstream industries such as textiles, electrical, and others has been weakening.

Versalis, Technip Energies to integrate technologies for plastic waste recycling

Italian company Versalis has announced signing an agreement with Technip Energies, a France-based engineering and technology company for energy transition.

Through this collaboration, the companies intend to develop a “theoretically endless plastic recycling loop”.

The joint project will support the production of new virgin polymers that can be used for a wide range of applications. Recyclable polymers cellulose

Both the companies will integrate their technologies for developing a technological platform for advanced chemical recycling of plastic waste.

Versalis, a chemical company of Italy’s oil supermajor Eni, will provide its ‘Hoop’ technology.

The company describes its Hoop technology as a pyrolysis process that helps in recovering mixed plastic waste with high performance.

This Hoop technology will be integrated with Technip Energies’ ‘Pure.rOil’ and ‘Pure.rGas’ purification technologies. Recyclable polymers cellulose

Morocco has emerged as the European Union’s (EU) top automotive supplier, surpassing giants like China, Japan, and India

The nation’s success is attributed to its modern manufacturing facilities, skilled workforce, and competitive production costs. In the previous year, Morocco produced over 535,000 vehicles, primarily from its northern region, contributing $13.7 billion to its economy—a 30% increase from 2023.

Strategically located just 14 kilometers from Spain, Morocco serves as a gateway between Europe and Africa. Recyclable polymers cellulose

This advantageous position, coupled with robust trade connections, has propelled Morocco to the forefront of the African automotive industry. The city of Tangier, in particular, has become a significant Mediterranean business hub, bolstered by the dynamic Tangier Med port and its trade agreements.

The Moroccan government’s regulatory measures, including the Investment Charter and the Industrial Acceleration Plan 2014-2020, have attracted numerous companies, fostering an environment ripe for investment. Major brands like Neo Motors, Snop, Renault, Dacia, and Stellantis account for 88% of the country’s vehicle production, underscoring Morocco’s integration into the global economy through free trade. Recyclable polymers cellulose

Committed to development and inclusivity, Morocco is addressing the gender gap, with the automotive sector achieving 63% integration, aiming for 80% by 2030. Additionally, aligning with environmental goals, Morocco is increasing its electric car production, targeting a 40% share of its total automotive output, as part of its strategy to reduce reliance on hydrocarbons.

Pact Collective and Eastman have achieved a significant milestone: the approval of colored PET waste from Pact members and consumers for use in Eastman’s methanolysis process

This breakthrough addresses the challenge posed by multicolored PET received at material recovery facilities (MRF), which often cannot be mechanically recycled due to color discrepancies. Eastman’s innovative methanolysis technology transforms this waste into high-quality copolyesters and PET, known as Eastman Renew materials, ideal for the beauty industry and comparable in quality to virgin materials. Recyclable polymers cellulose

Tara Cary, Eastman’s cosmetics packaging segment manager, expressed enthusiasm about the collaboration: “Our partnership with Pact Collective represents a shared commitment to a sustainable future for the beauty industry. Through methanolysis, we’re not just overcoming challenges but transforming them into opportunities, paving the way for beauty packaging waste to become a valuable resource.”

As a nonprofit organization, Pact Collective leads beauty packaging take-back initiatives at retail and consumer levels, ensuring responsible waste management. Pact’s Executive Director, Carly Snider, highlighted the significance of Eastman’s technology: “Eastman’s methanolysis offers a promising alternative for our collected materials, diverting them from waste-to-energy routes and potentially increasing post-consumer recycled content for future beauty packaging.” Recyclable polymers cellulose

Through this collaboration, Pact Collective and Eastman are driving positive change, transforming waste into valuable resources and advancing sustainability in the beauty industry.

CARBIOS secures feedstock for PET biorecycling plant with Hündgen

French biotech company CARBIOS has signed a key agreement with German waste management specialist Hündgen Entsorgungs to supply CARBIOS’ upcoming polyethylene terephthalate (PET) biorecycling plant.

This marks a significant step towards CARBIOS’ first commercial plant in Longlaville, France, which is currently under construction and expected to be operational by the end of 2026. Recyclable polymers cellulose

The agreement outlines Hündgen’s commitment to supply 15,000 tonnes (t) per year of post-consumer PET flakes, sourced and processed from household light packaging waste in Germany.

This PET waste will be transformed into usable biorecycled materials through CARBIOS’ innovative enzymatic depolymerisation technology.

CARBIOS’ technology offers an advancement in PET recycling.

Unlike traditional methods, CARBIOS said it can process a wider range of PET waste, including coloured, opaque packaging, and even polyester textiles.

This translates to greater flexibility and cost-effectiveness for CARBIOS, as it is not limited to high-demand clear plastic bottles. Recyclable polymers cellulose

Recyclable polymers cellulose