Recycled-Polyester – Plastic-waste 28-11-2022 - Arhive

Recycled-Polyester – Plastic-waste

Recycled Polyester – Petrochemicals

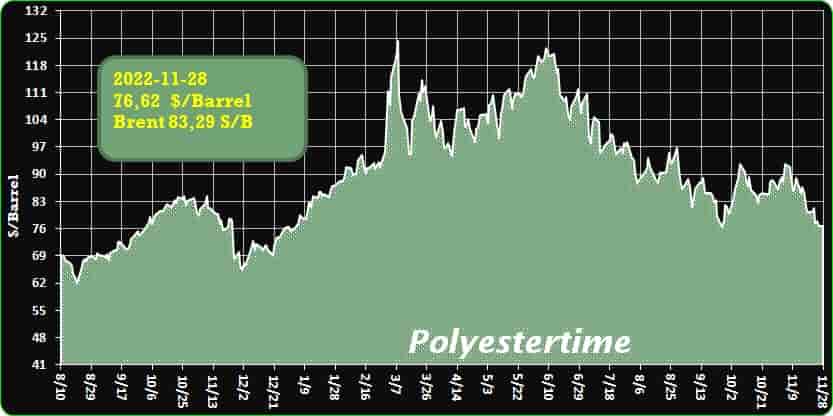

Crude Oil Prices Trend

Crude Oil Prices Trend Polyestertime

-Pyrowave electrifies microwave-based plastic recycling

Pyrowave, a Montreal-headquartered firm, is looking to make its mark in the plastics recycling industry with its use of energy efficient, electric microwaves to produce an almost pure, traceable plastic polymer that broadens the recycling market.

Founded and led by CEO Jocelyn Doucet, the company spent a decade of “intense R&D and investments” to bring its technology to scale. Recycled-Polyester – Plastic-waste

It transforms polystyrene waste, like Styrofoam, into its root chemical called a monomer. The monomer can then be recycled into an end product.

The company offers an alternative to mechanical recycling that faces the challenge of non-removeable additives like pigments and fillers, limiting their market. Pyrowave’s microwave technology resets the plastic to its original shape and removes additives to output something “that has identical application as the virgin material,” Doucet said.

“Now you really fully reset the clock of the polymer.”

Doucet hopes to deliver environmentally-friendly recycling that runs on clean electricity, thus reducing oil consumption and greenhouse gas (GHG) emissions, and supports the circular economy.

The Pyrowave process

Recycling begins in the liquification tank, where plastic waste is liquefied to remove contaminants like labels and additives. The liquid plastic waste is transferred to a reactor, where microwaves reach around 300C to break up polystyrene chains and release the styrene monomer.

The liquid monomer is purified in a distillation column to reach 99.8 per cent purity, compared to 50 to 60 per cent purity from other methods.

Unlike other recycling methods, Pyrowave stands out for its use of electricity, said Doucet.

“Being able to use electrical energy to break up the polymer chain, it’s more energy efficient and you have a lower carbon footprint, because you’re using eventually renewable energy instead of burning something . . . That’s why we’re really focused on electrification of the chemical industry.”

Before it installs its recycling system, Pyrowave conducts a sensitivity analysis to determine the impact from the electricity grid. The cleaner the grid in a particular area, the cleaner the recycling process will be. Doucet claims Pyrowave’s recycling process can significantly reduce GHG emissions in countries with clean grids, like Canada or France.

Producing one kilogram of styrene monomer with Pyrowave’s electric technology slashes GHG emissions by 40 to 45 per cent, compared to producing one kilogram of virgin styrene monomer from fossil fuels.

Even regions without the cleanest grids still benefit, as the microwave technology is energy efficient and only needs to reach about half the temperature required for typical pyrolysis.

Pyrowave is competitive and cost-effective for virgin styrene manufacturing, Doucet said, and decouples the manufacturer from fluctuating crude oil prices.

Traceable plastics for a circular economy

Another benefit to Pyrowave is that it produces traceable plastic.

This assures consumers the plastic they buy has the quantity of recycled plastic material promised on the label, Doucet said. It provides more assurance than certificates or corporate claims, he said, which closes the opportunity for greenwashing.

“We’re able to track systematically every drop of styrene monomer and physically count it into the final product. And this is really the breakthrough we bring to the table. We’re able to demonstrate that with the proper technology, you’re able to do physically segregated, traceable recycled content. Recycled-Polyester – Plastic-waste

“So at the end of the day when the consumer buys product with our styrene monomer, they know 100 per cent of the molecules are actually physically in the product. It’s not just an allocation or an accounting scheme.”

Doucet said the technology can increase recycling rates for plastic that would have been otherwise incinerated or left to decompose in landfills. He pointed to a seven to 10 per cent recycling rate as a problem of markets, not technology.

Plastic waste imbued with additives offers limited recycling options such as being used for car parts. Pyrowave’s process produces near virgin-quality product, opening up the market, creating more demand and reducing water and energy consumption.

The Michelin partnership

Pyrowave partnered with French tire giant Michelin to produce approximately 1,000 passenger car tires with three tons of recycled styrene.

Doucet said Michelin chose Pyrowave because of the traceability of the plastic waste, aiding Michelin’s commitment to using 40 per cent recycled material by 2030.

It is the result of a partnership forged in 2020 when Michelin invested an undisclosed sum into Pyrowave.

Pyrowave “industrialized” its operation with Michelin, Doucet said, licensing the process to the tire maker.

Doucet said Pyrowave impressed industry figures at the Advanced Recycling Conference in Germany with its lifecycle assessment. Pyrowave was “one of the few companies that showed the real numbers . . . Most organizations have been very happy to see that for the first time, companies can show hard numbers that have been generated through full-scale performance.”

Funding and future

The company is continuing to gain traction, with “exponential” growth over the past two years, Doucet said. Tougher regulations for recycled content in products, especially in Europe, has helped drive its business.

Doucet said it is a “signal” for the plastics industry to adopt new technology.

Pyrowave is also catching on Asia, he said, due to new regulations and influence from Asian business leaders who see a market shift.

Doucet said Pyrowave is raising funds to finance growth for the next five years.

He said the firm has received “tens of millions” of dollars to develop the technology. Pyrowave has achieved commercial scale with less money than its competitors because of its modular approach, he said, making it cash efficient. Recycled-Polyester – Plastic-waste

Pyrowave also plans to expand to other markets and applications. Announcements planned for 2023 include a new platform for new materials. There is also a plan to move beyond plastic polymer recycling to other applications, and a core focus on having impact on climate change, the “challenge of this century.”

-NATO, EU to step up non-lethal aid to Ukraine over winter woes

As Russian missile strikes on Ukraine’s power, heating, and water supplies risk leaving a majority of the country vulnerable during winter, Europeans have started looking into how to provide Kyiv with more emergency equipment.

Ukraine is experiencing “waves of deliberate missile attacks on cities and civilian infrastructure, depriving Ukrainians of heat, light, and food”, NATO Secretary-General Jens Stoltenberg told reporters on Friday (25 November), calling it a “horrific start to the winter for Ukraine”. Recycled-Polyester – Plastic-waste

In recent weeks, Russia’s focus in Ukraine has shifted from territorial gains towards large-scale bombing campaigns targeting Kyiv and other cities across the country.

While winters in Ukraine tend to be very cold, with temperatures plunging well below 0°C, the coming season is expected to be especially challenging as Russia appears set to continue its attack on the country’s power, water and heating infrastructure.

Speaking to reporters in Brussels, Stoltenberg confirmed “NATO has been delivering fuel, medical supplies, winter equipment”, thanking members for the contributions provided.

The NATO chief also added he would call for more non-lethal aid to secure power generators, winter clothing and other needed non-lethal equipment when alliance foreign ministers meet in Bucharest next week.

Stoltenberg also said NATO members would discuss sending more equipment to enable Ukraine to counter drone operations, in response to Russia’s increasing use of Iran-made unmanned kamikaze weapons used to hit civilian targets.

“Over the longer term we will help Ukraine transition from Soviet-era equipment to modern NATO standards, doctrine and training,” he added in regard to military assistance provided by the alliance.

Next week’s NATO meeting will take place ahead of a donor conference hosted by French President Emmanuel Macron in Paris on 13 December focused on humanitarian aid to Ukraine, and efforts by the EU to transport power grid equipment to the country.

Last week, the European Commission announced it will provide temporary cold-weather shelter, generators, and electricity grid-repair kits to Ukraine to help it tide over the winter ahead.

EU member states have also been asked to prepare for additional refugee inflows from Ukraine during the winter if there is a surge in attacks, the bloc’s Crisis Management Commissioner Janez Lenarčič said last week.

“We are encouraging member states to put enough resources in place to face this kind of increased needs”, Lenarčič said.

The World Health Organisation has warned the attacks on infrastructure could have “life-threatening” consequences and estimated that millions could leave their homes as a result.

This comes as Russian officials have begun openly admitting to targeting Ukraine’s civilian utilities. Recycled-Polyester – Plastic-waste

Russian Defence Ministry spokesman Igor Konashenkov claimed this week they were linked to Ukraine’s military command and control system and the aim was to disrupt the flows of Ukrainian troops, weapons, and ammunition to the front lines.

“Taken as a whole, this raises serious problems under international humanitarian law, which requires a concrete and direct military advantage for each object attacked,” UN human rights chief Volker Turk said, adding that the Russian strikes on critical infrastructure were problematic.

More…

-Cambi and Sasol innovate to move up the waste hierarchy through thermal hydrolysis

Cambi has signed a large contract with Wood, a global leader in consulting and engineering, to supply Sasol with two full-scale thermal hydrolysis process (THP) systems for treating industrial biological sludge at Sasol’s Secunda Operations (SO) in South Africa.Sasol and Cambi commenced a commercial trial at SO in 2021 using a small-scale THP unit. Extensive laboratory tests and integration checks demonstrated the feasibility of refunneling industrial biological sludge into Sasol’s coal-to-liquids (CTL) gasification process and identified the optimal process parameters for full-scale application.

“We are excited about this project, as it will enable us to improve our waste management by moving up the waste hierarchy while improving ambient air quality.

This will enable Sasol to move away from incineration and, at the same time, to derive syngas from biosludge. We recognise the link between our activities and the need to act responsibly by holistically managing the impacts of our operations through world-class innovation,” said Simon Baloyi, Executive Vice President for Energy Operations and Technology at Sasol. Recycled-Polyester – Plastic-waste

“Today’s contract is important for Cambi, marking our first full-scale THP project for industrial substrates outside of Norway. The project is unique in the world and introduces a new, sustainable way to process large streams of biosludge. The swift progress from demonstration to full-scale adoption shows that THP makes business sense in many settings and is testimony to Sasol’s solid commitment to reducing carbon emissions. We look forward to seeing the full-scale solution in operation as soon as possible”, remarked Eirik Fadnes, CEO at Cambi.

This innovative project will reroute biosludge from incineration to the gasification process, thereby reducing point source emissions. It will be the world’s first full-scale installation where thermal hydrolysis is used to enable the conversion of biosludge into hydrocarbon fuels and chemicals.

The THP equipment supply contract follows an engineering design project carried out by Cambi earlier this year in close collaboration with Wood, who were commissioned to deliver the full sludge refunnelling solution.

For Cambi, the project is ready to go into the manufacturing phase. The two THP systems are scheduled for commissioning in 2024.

-Frame France & Germany plunged into recession..!? Game Begun?

Several parties have predicted that many countries will be pushed into a recession by the end of 2022 due to the slow pace of economic growth in the world and that superpowers such as the United States will be pushed into a recession in the first half of 2023. Many parties have predicted that superpower countries like America will be pushed into recession in the first half of 2023. Which countries are stuck in recession..? Private sector activity in Europe’s two major economies slowed in November, pushing them into decline. Thus it is said that both these countries are already plunged into recession like Britain and have not declared it officially. Recycled-Polyester – Plastic-waste

France’s PMI index fell to 48.8 points for the first time since the coronavirus, according to S&P Global Flash Purchasing Managers’ Index data. Generally, a PMI index above 50 points means growth and below 50 points means decline.

With this, France’s PMI index fell to 48.8 points, while Germany’s PMI index fell to 46.4 points. It is noteworthy that both these countries have recorded a recession than the level predicted by economists. At the same time, as the whole of Europe enters the Winter, fuel shortages, inflation, and production decline will reach their peak, which will affect not only the economy of France and Germany but also the economic condition of Europe as a whole.

This will not only affect the economy of France and Germany but also the economic condition of the entire of Europe. British Chancellor of the Exchequer Jeremy Hunt announced last week that Britain is already in recession. While no country has yet officially declared that it has gone into recession, Britain has admitted that it has gone into recession.

Following this, Germany and France, which are currently the largest economies in the European Union, have entered into recession. With leading economies going into recession, other countries that depend on these countries will suffer more.For example, while Europe is the most important trading country for India’s textile industry, France and Germany have entered into recession, making it very difficult to get new orders, which may reduce production and lay off workers in the indian textile industry.

-Why the UK needs to stop exporting plastic waste

The world produces a vast amount of plastic. Global plastic production increased from 2 million metric tons in 1950 to 348 million metric tons in 2017. Yet much of this plastic is wasted: 86% of the world’s plastic waste in 2016 was either incinerated, sent to landfill or leaked into nature. Recycled-Polyester – Plastic-waste

Many countries use international trade to manage their plastic waste. The justification for this is that plastic waste can be treated in destinations with better capacity for waste treatment. The UK, lacking capacity itself, exports 60% of its plastic waste abroad. But in a recent report, the House of Commons Environment, Food and Rural Affairs Committee – the group of MPs responsible for improving and protecting the environment – have called on the government to stop the export of UK plastic waste by the end of 2027.

The movement of hazardous waste is controlled by an international agreement called the Basel Convention. It requires the consent of the receiving country, accurate labelling of waste, and notification when plastic waste has been treated for waste to be exported legally. The Convention has recently increased the range of plastics that fall within its remit.

China has long been the world’s leading plastic waste importer. But in 2017 its government banned plastic waste imports, citing concerns over the low quality of material received. This has displaced vast quantities of plastic waste. The UK now exports most of its plastic waste to Turkey, Indonesia, Vietnam, Malaysia and the Netherlands.

Passing the burden

The import of plastic waste is a valuable source of foreign exchange for many countries. But these countries often have limited waste treatment infrastructure.

Uncontrolled imports can therefore lead to the volume of plastic waste received exceeding the capacity of a country to cope with it. It also displaces its ability to treat its own domestic waste. The result is more plastic waste than can be safely handled and high levels of mismanagement.

Once a country has received the waste, monitoring of the treatment process is also scarce. A Greenpeace investigation in 2021 found evidence of plastic waste from the UK and Germany dumped illegally across 10 sites in southwestern Turkey.

But mismanaged plastic waste is one of the main causes of plastic pollution in nature. One report estimates that 56% (239 million metric tonnes) of global annual plastic waste production by 2040 will be subject to mismanagement.

Exporting plastic waste also raises ethical questions. It allows exporting nations to forgo their responsibility to deal with their own plastic waste while claiming to be managing their waste responsibly. Recycled-Polyester – Plastic-waste

Upstream solutions

A more systemic and responsible way of dealing with plastic waste is to reduce plastic consumption. The Committee’s report recommends measures that focus on reducing plastic waste at source, rather than improving the ability of waste treatment infrastructure to manage a greater capacity of waste.

The key suggestion was to accelerate the introduction of Extended Producer Responsibility schemes. Extended Producer Responsibility is an approach that aims to make companies bear a greater proportion of the cost of disposing the plastic they use for products put on the market. These schemes will apply to all companies in the UK who put at least 1 tonne of plastic packaging on the market each year by 2030, encouraging them to reduce their production of plastic waste. This can be achieved through innovations to “design out” plastics or by transitioning to a circular economy where plastic materials are reused or fully recycled.

The Committee’s report recommends the establishment of a plastic reuse task force, composed of representatives from industry and consumer groups. The group would coordinate strategies including incentives to adopt business models that encourage the reuse of plastic materials, single-use plastic charges, mandatory reporting on a company’s plastic footprint, and public campaigns to raise the profile of reuse schemes.

Deposit-return schemes also help and are already in progress in the UK. In 2023, Scotland will launch a national programme where people will pay a 20p deposit when they buy a drink in a plastic bottle or can, which will be repaid when the empty container is returned.

Plastic waste is a global problem

The recommendations made by the Committee are a positive step forward and would place the UK in a position of international leadership on tackling plastic pollution. But plastic value chains are transnational and waste is generated at each stage. This reduces the effectiveness of isolated national action. Recycled-Polyester – Plastic-waste

National policies often do not have the reach or influence to tackle the global causes of plastic pollution. Research that I co-authored found that isolated policies including national bans on plastic products are ineffective in reducing the generation of plastic waste. Fragmented national policies can also create loopholes in international policy that inadvertently reroutes plastic waste towards the destinations least equipped to deal with it.

But earlier this year, 173 countries formally adopted a UN resolution to start negotiations for a global legally binding agreement to end plastic pollution by the end of 2024. The World Trade Organisation has also launched an initiative to explore how trade policies can be used to reduce plastic pollution. International cooperation over plastic waste policy, along with the legal power of the Basel Convention, offers hope of a coordinated global response to plastic pollution that avoids policy fragmentation.

Environmental groups are critical of the trade in plastic waste. The Committee’s recommendation to ban UK plastic waste exports by 2027 is therefore an ambitious and welcome step forwards in tackling plastic pollution. But without global action, isolated national policies will not deliver change on the scale required to end this controversial trade.The Conversation

-Contract prices of injection molding PC rose in Europe by EUR170 per ton in the fourth quarter

Contract prices for injection polycarbonate (PC) in Europe rose by EUR170 per tonne in the fourth quarter compared to the previous quarter due to high electricity costs seen in the third quarter,ICIS reported.

Weak buying interest was restrained by a sharp increase in prices. PC orders in the automotive and construction sectors remained low due to weak macroeconomic forecasts.

Demand for polycarbonate for casting is still considered higher than for polycarbonate for extrusion.

Pc supply remains sufficient, although most local manufacturers have drastically reduced production volumes. Recycled-Polyester – Plastic-waste

The price difference between European and Asian polycarbonate has made imports from China, South Korea and Saudi Arabia more attractive this quarter.

This has allowed some European buyers to buy more goods in these regions and reduce their dependence on local sellers.

According to theScanPlast review, in January-September 2022, the total estimated consumption of PC granulate in the Russian market (excluding imports and exports to Belarus) increased by 2% and amounted to about 64.3 thousand tons against 63.3 thousand tons a year earlier.

-WM and Dow run curbside recycling pilot scheme for plastic films in Illinois city

WM and Dow are collaborating to facilitate curbside recycling of hard-to-recycle plastic films in a pilot scheme taking place in the US city of Hickory Hills, Illinois.

Only 1.9% of US households currently have access to curbside plastic film recycling, according to The Recycling Partnership. As such, it has the lowest overall recycling rate of any plastic material. Once the recycling programme is operating at full capacity, it is hoped that 120,000 metric tons of plastic film will be diverted from landfills every year.

Plastic packaging such as bread bags, cling film, and dry-cleaning bags are thought to be compatible with the current pilot. It is currently said to reach around 3,500 households, and other cities across America are expected to adopt the scheme in the future.

“By providing residential customers with a simple, curbside option for recycling plastic films, we will not only help our customers more easily manage their used plastic film products, but also meet the rising demand for recycled content products,” said Jim Fish, president and CEO at WM. Recycled-Polyester – Plastic-waste

“We see tremendous untapped potential to recycle and reuse plastic film, which many of our residential customers struggle to properly dispose.”

WM plans to invest $800 million into recycling infrastructure from now until 2025 – this is set to include sorting technology for plastic films. Meanwhile, Dow is reportedly working towards the incorporation of recycled content into its product solutions and aims to deliver three million metric tons of circular and renewable solutions by 2030.

“Enabling a circular economy requires broad stakeholder collaboration, innovation, and investment throughout the value chain to continue to more rapidly develop and advance solutions at scale,” added Jim Fitterling, chairman and CEO at Dow. “Through our collaboration with WM, we’re determined to launch new programs that grow recycling infrastructure and access nationwide, creating a more comprehensive system where films and flexible plastics form a key pillar of our circular product offerings.”

The news comes after Dow announced the expansion of its Project REFLEX flexible packaging recycling initiative to Egypt and Guinea following a successful pilot phase in Nigeria; and its introduction of the R-Cycle digital product passport to its pouch-to-pouch mechanical recycling concept for flexible packaging, working alongside HP Indigo, Reifenhäuser, Cadel Deinking, and Karlville.

Recycled-Polyester – Plastic-waste