Recycling sorting – Plastics – China 02-06-2023 - Arhive

Recycling sorting – Plastics – China

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

-STADLER, a German company specializing in recycling and sorting plants, has completed the installation of the first of three high-efficiency Materials Recovery Facilities (MRF) and Compost Refinement plants for TERNA ENERGY in Tripoli, Greece

TERNA Energy, a leading Greek renewable energy company and a subsidiary of the GEK TERNA Group, is committed to clean energy production, storage, and sustainable development. Through its integrated waste management projects, TERNA Energy aims to contribute to the circular economy.

STADLER was chosen as the strategic partner by TERNA Energy for the design and installation of MRFs in the Epirus region and now in the Peloponnese region. The newly completed facility in Tripoli showcases advanced automation and efficiency, capable of adapting to changing material composition. With outstanding recovery rates, the plant achieves above 90% recovery for the organic fraction, plastic containers, bottles, and paper, and 80% recovery for biofilms and PE film. The facility is also designed for easy maintenance with accessible components and motors.

The MRF receives mixed Municipal Solid Waste (MSW) and processes it to produce high-quality recyclates and organic materials. The recyclables, such as PET, HDPE, PP/PS, foils, paper, cardboards, ferrous and non-ferrous cans and containers, are sorted into automatic bunkers and baled. Recycling sorting – Plastics – China

The organic materials are processed in the compost refinement plant, generating two fractions of clean compost with different specifications and material size.

STADLER’s design team successfully addressed the challenge of managing the waste stream peculiarities in the Peloponnese region, which experiences high variations in seasonal consumption and packaging diversity due to tourism. The sorting process involves trommel screens, a STADLER STT5000 Ballistic Separator, and Pellenc ST COMPACT optical sorters integrated with high-speed conveyors. These optical sorters, known for their compact size, low energy consumption, and high performance, efficiently sort waste by material and color.

The project required close collaboration among TERNA Energy, STADLER, and technological partner Pellenc ST to ensure timely delivery. Despite a short timeframe and the need for the plant to run at full capacity from the first day of commissioning, the teams effectively coordinated their efforts. The successful partnership between STADLER and Pellenc ST, built on a strong relationship and smooth interactions, played a crucial role in the project’s success. Recycling sorting – Plastics – China

TERNA Energy expressed satisfaction with STADLER’s solid design, quality equipment, and effective project management throughout all phases. As part of the partnership, STADLER will design and build two additional MRF and Compost Refinement plants in Lakonia and Messenia, further advancing waste sorting capabilities in the Peloponnese region. STADLER will provide ongoing support through a local service team and a dedicated maintenance storage center. Together, these facilities will be the most advanced MRF sorting plants in Greece

-PepsiCo Unveils Its Most Environmentally Friendly Factory in Europe, Advancing the Circular Economy In a significant step toward addressing global food system challenges, PepsiCo has announced the opening of its most sustainable factory in Europe

The plant, located in Poland, exemplifies the principles of a circular economy and introduces innovative sustainability solutions.

Valued at EUR 300 million, this project represents PepsiCo’s fifth manufacturing facility in Poland. Its operations will cater to both the domestic market and export to more than 20 countries, including Germany, Czech Republic, Slovakia, and Hungary.

At the heart of the new plant lies a commitment to sustainability and circularity. The facility incorporates various eco-friendly practices throughout the entire life cycle of snack production. Notably, rainwater will be collected and reused, while rooftop solar panels will generate the plant’s energy, setting the stage for it to become climate neutral by 2035.

Furthermore, the factory boasts minimal utility consumption, and plans are underway to establish an onsite solar farm. Heat process water and rainwater will be effectively recovered for use within the facility’s utilities. Even the potato byproducts from the manufacturing process will find purpose, as the peelings are transformed into low carbon fertilizers through anaerobic digestor technology. These fertilizers are then returned to farmers, contributing to sustainable crop growth. Recycling sorting – Plastics – China

PepsiCo’s commitment to waste reduction is evident in the facility’s design and operations. The steam generation process is electrified, and the company maintains an electric fleet of cars for transportation, supported by dedicated charging stations.

The pursuit of sustainability aligns with PepsiCo’s pep+ (PepsiCo Positive) ambition, emphasizing waste reduction across the value chain. Silviu Popovici, CEO of PepsiCo Europe, expressed gratitude to associates and partners who contributed to this milestone and reimagined the future of food through the new environmentally sustainable facility.

Having been a part of Poland’s market for over three decades, PepsiCo’s presence continues to grow. The new plant will create 450 jobs, further contributing to the country’s economy. With a focus on local communities, PepsiCo collaborates with Polish farmers under the global PepsiCo Sustainable Farming Programme, sourcing over 200,000 tonnes of sustainably grown potatoes annually. This volume is set to increase by an additional 60,000 tonnes per year by 2025, and the farming program will expand to encompass 19,000 acres (7,700 hectares) and over 80 farms.

PepsiCo’s commitment to Poland is echoed by Mark F. Brzezinski, the US Ambassador to Poland, who highlighted the company’s enduring investment and expansion in the country.

The plant’s grand opening on May 31 was graced by Polish Prime Minister Mateusz Morawiecki and US Ambassador Mark Brzezinski. The event brought together more than 150 government officials, local authorities, project partners, and PepsiCo employees to celebrate this milestone in sustainable manufacturing. Recycling sorting – Plastics – China

-Closed Loop Partners has secured a $10 million investment for its Plastics Recovery and Recycling Fund, courtesy of Sumitomo Mitsui Banking Corporation (SMBC), a Japanese banking institution

The investment is aimed at advancing the recovery and recycling of polyethylene (PE) and polypropylene (PP) plastics in the United States and Canada.

The Closed Loop Circular Plastics Fund, a part of Closed Loop Partners’ circular economy strategy, focuses on resin types such as PE, PP, and flexible plastics that require additional investment to maintain a continuous flow of materials and meet the demand for recycled materials in the industry.

The fund will provide catalytic debt and equity financing, which will stimulate further investments in recovery and recycling initiatives and infrastructure that address bottlenecks in the recycling system.

Jennifer Louie, Head of the Closed Loop Infrastructure Group at Closed Loop Partners, emphasized that these new platforms can encourage greater financial participation, thereby accelerating projects, infrastructure development, and innovations necessary to close the loop on plastics. Recycling sorting – Plastics – China

Launched in 2021, the Closed Loop Circular Plastics Fund has already made several investments in private companies and public organizations. It has supported projects that enhance collection infrastructure, enabling technologies, sortation capabilities, and re-manufacturing of PE and PP plastics.

The fund’s performance will be evaluated based on a combination of financial and impact outcomes, including the amount of PE and PP impacted and the reduction or avoidance of greenhouse gas emissions.

Masayuki Takanashi, Chief Sustainability Officer of Sumitomo Mitsui Financial Group, expressed their commitment to sustainability and forming partnerships that leverage their presence in Japan and the Asia Pacific region. They will be part of the Closed Loop Circular Plastics Fund’s impact-driven efforts to accelerate infrastructure development, equipment deployment, municipal services, as well as innovation and enabling technologies for flexible films and specific types of plastic.

Closed Loop Partners envisions a future for plastics within a circular economy framework that reduces the reliance on virgin resources, promotes design innovation and material science, and encourages reuse and new product delivery models. To date, the company has successfully kept 4.8 million tons of materials in circulation and contributed to the avoidance of 10.1 million tons of carbon dioxide equivalent emissions.

Investing in increased plastics recovery, material reduction solutions, scalable reuse systems, and new materials can address a market with significant revenue potential. Additionally, plastic recovery and recycling divert millions of tons of plastics from landfills and the environment. Recycling sorting – Plastics – China

According to a report by the Organization for Economic Co-operation and Development, plastic waste is projected to triple by 2060, underscoring the urgency of such investments.

-Unmasking the Illusion: China’s Economic Rebound Narrative Revealed Microsoft Start’s Watchlist Ideas

In an article for the Financial Times, Ruchir Sharma, president of Rockefeller International, challenges the prevailing belief in China’s economic rebound, highlighting its lack of support from underlying economic realities. Sharma points to various indicators of weakness, including a meager 1.5% growth in corporate revenue during the first quarter, an 8% decline in imports in April, and credit growth in the previous month that fell short of expectations by half. He explains that since 2008, China’s economic model has relied heavily on government stimulus and mounting debt, which has now reached its limit. Sharma cautions against the excessive optimism of Western observers regarding China’s rebound narrative, warning that it could lead to substantial losses for investors in the range of hundreds of billions of dollars. He concludes by emphasizing the urgency of exposing this façade before its repercussions worsen.

Consequently, the following list explores companies that might be affected by China’s economic weakness. Recycling sorting – Plastics – China

Over the past year, this list has witnessed a negative performance of -3.58%. In comparison, the FTSE MIB Index has risen by 8.19% during the same period. The beta of this list, which measures volatility, is moderately low at 0.90. The list’s beta is calculated by equally weighting the average beta of the stocks within it. The list comprises 40.00% of Consumer Cyclicals shares, 40.00% of Technology shares, 10.00% of Energy shares, and 10.00% of Financials shares.

The performance of the list is determined using a fair weighting methodology. It is generated through web analysis and the utilization of algorithms to identify potentially relevant titles related to the topic. The list is intended for educational purposes and includes titles that may be suitable for a watchlist. It should not be regarded as a basis for investment or trading decisions. Microsoft does not endorse using the provided data and information as a guide for making investment choices. Recycling sorting – Plastics – China

-Addressing Plastic Pollution: Beyond the Limits of Recycling

The UNESCO headquarters in Paris is hosting the second meeting on a potential global treaty to combat plastic pollution this week. While recycling has often been hailed as a solution to tackle plastic waste, recent studies indicate that this approach comes with its own risks and is inadequate in the face of skyrocketing plastic production.

The magnitude of plastic pollution continues to escalate relentlessly. According to OECD data, the world now generates twice as much plastic waste as it did two decades ago, reaching a staggering 353 million tonnes in 2019. The vast majority of this waste ends up in landfills, incinerated, or improperly managed, meaning it is either left as litter or inadequately disposed of. Shockingly, only 9 percent of plastic waste is actually recycled.

Expanding plastic recycling may appear to be a logical means of transforming waste into a valuable resource. However, recent research highlights that recycling plastic poses its own environmental and health hazards. The recycling process generates significant levels of microplastics and harmful toxins, which can be dangerous for people, animals, and the environment. Recycling sorting – Plastics – China

Microplastics, plastic particles measuring up to 5mm, have been found in alarming quantities as a result of the recycling process. Erina Brown, a plastics scientist and lead author of a recent study published in May 2023, revealed the disturbing findings of her research on the microplastic runoff produced by recycling centers. Brown’s study focused on a UK recycling facility that utilized substantial amounts of water for sorting, shredding, and separating plastics before converting them into pellets for resale. Her findings indicated that approximately 6 percent of all plastics entering the facility were released as microplastics into the water, even with filtration systems in place. Brown emphasized the inadequacy of sewage treatment facilities in filtering microplastics, which often leads to their inadvertent application to fields as fertilizer or their entry into local waterways, ultimately spreading to even remote areas such as the Arctic seas.

While over two-thirds of UN member states agreed to develop a binding agreement on plastic pollution by 2024, with the current discussions being part of that process, some environmental groups argue that the proposed action plan primarily focuses on reusing, recycling, and shifting towards alternative materials. Critics contend that these strategies downplay the urgent need to reduce plastic consumption and are concessions to the global plastics and petrochemicals industry. Recycling sorting – Plastics – China

Microplastic release is not the sole concern associated with recycling plastics. Recycling processes involve working with unregulated toxic chemicals. Plastics contain up to 13,000 different chemicals, with a UN report indicating that around 3,200 of them possess hazardous properties that can harm human health and the environment. Furthermore, many of these chemicals have never been thoroughly assessed for their toxicity. The lack of global regulation and transparency in the market prevents consumers from knowing which plastics contain toxic chemicals. When recycled, the unknown composition of products combined with heating exacerbates the risk posed by these chemicals. Consequently, recycled plastics pose even greater health risks to workers in recycling centers and can contain higher levels of toxic substances compared to their virgin counterparts, including items such as kitchen utensils, children’s toys, and food packaging. Moreover, these toxic chemicals find their way into the food chain, even contaminating eggs in proximity to plastic recycling facilities.

While global plastic waste recycling is projected to increase to 17 percent by 2060, according to OECD figures, this approach fails to address a fundamental issue: most plastics can only be recycled once or twice before reaching a dead end.

Contrary to the belief that recycled plastics can be transformed back into plastic bottles if of high quality, the reality is that plastics gradually downgrade in quality during the recycling process. They are “down-cycled” into items like drain pipes or fleece clothing that cannot be further Recycling sorting – Plastics – China

-Following in Elon Musk’s footsteps, Jamie Dimon, CEO of JP Morgan, has also made a visit to China

Speaking at the JP Morgan Global China Summit in Shanghai, Dimon addressed the strained relations between the United States and China.

The recent incident involving a Chinese spy balloon over American skies, coupled with the ongoing tensions with Taiwan, has intensified the situation. Dimon emphasized the need for a genuine commitment to improve relations between the two countries. He also cautioned that the prevailing uncertainty would not only impact foreign direct investment but also erode confidence among Chinese investors, as reported by Bloomberg.

While Dimon acknowledges the role of the Chinese government in the tensions, he remains optimistic, stating, “Disputes regarding security and trade between the US and China can be resolved. However, simply shouting at each other across the Pacific won’t make it possible. I hope we can reach a genuine commitment,” according to CNBC’s report citing Reuters sources. Recycling sorting – Plastics – China

The CEO of JP Morgan expressed a preference for de-risking East-West economic relations rather than pursuing a large-scale decoupling.

Dimon also addressed concerns about the slowdown of the Chinese economy. He highlighted alarming data on youth unemployment, which reached its highest level since the surveys began in 2019, surpassing 20% in May. Dimon stressed the importance of trust in fostering growth in China.

Recent economic indicators have cast doubt on the Chinese government’s target of achieving 5% growth in 2023. While the Chinese economy experienced a strong rebound in the first quarter, subsequent data revealed a decline in property investment, credit, industrial profits, and retail sales falling short of analysts’ expectations. Additionally, the contraction in industrial activity, reflected in the official index of purchasing managers in the manufacturing sector dropping to 48.8 points in May from 49.2 in April, further adds to the challenges faced by China.

Dimon’s previous visit to China was marred by criticism in November 2021 when he made a joke about Chinese politicians, suggesting that JP Morgan would outlast the Communist Party. However, relations have improved since then, as evidenced by the meeting between Dimon and Chen Jining, the party secretary of Shanghai. The Chinese politician expressed a desire for JP Morgan to continue investing in China. Dimon affirmed that his bank would serve as a bridge to Shanghai for foreign companies. These statements align with Elon Musk’s sentiments, who has emphasized the shared commercial interests between the United States and China. Recycling sorting – Plastics – China

Chinese Foreign Minister Qin Gang, after welcoming Tesla’s CEO, also extended his welcome to foreign companies, expressing hopes for a relationship based on “mutual respect” between the two powers.

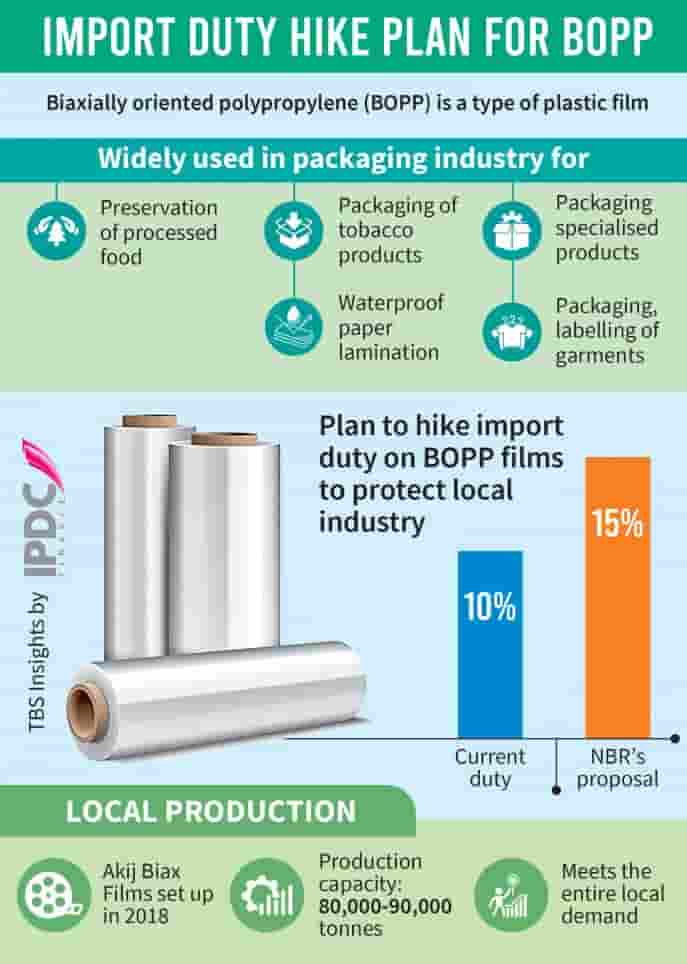

-Import costs of flexible films used in packaging may rise

The import cost of flexible films used in packaging and labelling various products, such as foodstuffs, garments, beverages, medicines and tobacco, is expected to increase in the next fiscal year.

According to finance ministry officials, the government plans to propose an increase in customs duty on the import of biaxially oriented polypropylene (BOPP) films from the current 10% to 15% in the upcoming national budget to provide protection to the local industry.

In 2018, Akij Group set up a plant for the first time in the country for producing packaging films, which are used as raw materials by various industries.

With a fresh investment of Tk1,000 crore, the new venture of the conglomerate has a production capacity of 80,000-90,000 tonnes, which is sufficient to meet the entire local demand. Recycling sorting – Plastics – China

Akij Biax Films Ltd currently manufactures three types of products used in packaging: BOPP, biaxially-oriented polyethylene terephthalate (BOPET), and cast polypropylene (CPP).

However, officials at the local manufacturer argue that an increase in the import duty alone will not yield the expected results. They emphasise the need to prevent the sale of raw materials imported under the bond facility in the local market, as it poses the biggest threat to the local industry.

M Hossain Iraz, director (operation) at Akij Biax Films, told The Business Standard, “The government action is certainly important in creating competition between local production and imports.”

“When the cost is high due to the imposition of additional duties on imports, the possibility of a misuse of the bond facility will also increase. In this case, without strict government monitoring, the good initiative will not pay off,” he added.

According to officials, following an application by Akij Biax Films, the Bangladesh Trade and Tariff Commission analysed the hardships of the raw material importer and producer.

The commission says that while the company has the production capacity to meet local demand, the protection provided to this industry is insufficient, given the current import taxes imposed on raw materials and finished goods, as well as the value related to duty.

Recycling sorting – Plastics – China