NatureWorks, a manufacturer of polylactic acid (PLA) biopolymers made from renewable resources, has made significant progress on the construction of their new fully integrated Ingeo™️ PLA biopolymer manufacturing facility in Nakhon Sawan Province, Thailand. As a fully integrated PLA complex, the plant will include three manufacturing facilities: lactic acid fermentation, lactide monomer production, and polymerization. The facility will have an annual capacity of 75,000 tons of Ingeo biopolymer and produce the full portfolio of Ingeo grades. This effort reflects the company’s commitment to expanding customer access to fully biobased, low-carbon biomaterials with unique performance attributes valued by global downstream packaging and fiber markets. Returnable PET-bottles

“The construction of our new facility is a significant undertaking that represents NatureWorks’ continued investment both in the Asia Pacific region and in the expansion of the biobased materials market,” said Steve Bray, VP of Operations at NatureWorks. “We have seen a rise in demand for Ingeo biopolymers throughout the Asia Pacific region, and this new complex will allow us to continue to sustainably and efficiently supply our markets with the highest quality biopolymers.”

The construction of this new facility will support rapid growth in multiple different markets including 3D printing, nonwovens for hygiene, compostable coffee capsules, tea bags, flexible packaging, and sustainable food serviceware. Construction is on track to support projected start-up activities and full production in 2025.

Ingeo biopolymer produced at this site will be made from sugarcane, an annually renewable feedstock that is locally abundant and will be sourced from farms within a 50-kilometer radius of the Nakhon Sawan site. Returnable PET-bottles

“Over the last decade, the global materials market increasingly prioritized the use of biobased, sustainably sourced materials in order to reduce the impact on climate and facilitate climate-friendly processes like food scrap diversion from landfill to compost through the use of compostable materials,” said Jill Zullo, CEO at NatureWorks.

“The market’s evolution has redefined the scope of what we can accomplish, allowing us to think bigger when it comes to our manufacturing expansion. This new facility will enable us to meet growing consumer demand and continue providing unparalleled service to our international customer base.” Returnable PET-bottles

Thai Acrylic Fibre Co.,Ltd. (TAF) To Showcase Regel™ And Other Sustainable Innovations In Textile Exchange Conference

Thai Acrylic Fibre Co.,Ltd. (TAF), one of the world’s largest acrylic fibre producers, is excited to announce its participation in the upcoming Textile Exchange Conference 2023 at Booth 145. Set to take place from October 23 to October 27 at the O2 InterContinental in Greenwich, London.

The Textile Exchange Conference brings together industry leaders, innovators, and experts from across the fashion, textile, and apparel industry, serving as a premier global platform to collaboratively explore challenges and solutions to overcome the climate crisis.

At the conference, TAF will be showcasing their latest innovation – Regel™ – recycled acrylic fibre. With its impressive MSI (Material Sustainability Index) scores, and outstanding LCA (Life Cycle Assessment) credentials, Regel™ is setting new standards for sustainability within the textile industry. Returnable PET-bottles

Regel™, recycled acrylic fibre, has been developed with a strong focus on sustainability that offers a practical solution for a variety of textile applications. Its MSI scores and LCA demonstrate the reduced environmental impact throughout its life cycle and its potential to contribute to a supply chain, marking a significant step in the industry towards more eco-friendly textile production. Regel™ also retains the warmth, comfort, vibrant shades, and durability for which acrylic fibers are renowned through innovative “Regel technology”.

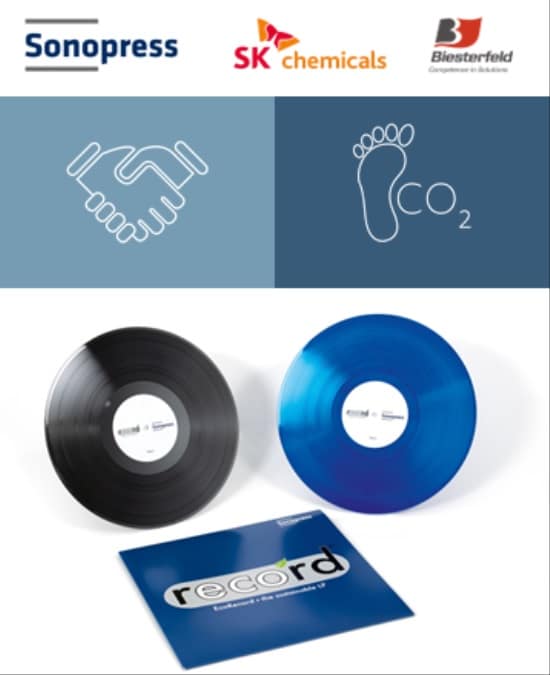

Sonopress and SK Chemicals agree on cooperation in the field of 100% recycled PET distributed by Biesterfeld Plastic for the EcoRecord Long-Playing Record

Leading storage media manufacturer Sonopress has developed a revolutionary new form of long-playing record that dramatically reduces the environmental impact of the manufacturing process. Neither natural gas nor steam are needed to press the discs, and in test operations the energy savings were up to 85% compared to the conventional process. For the production of the novel “EcoRecord” LP, recyclable polyethylene terephthalate (PET) is used as the base material instead of polyvinyl chloride (PVC), which can also be 100% recycled PET from SK Chemicals provided by SK Chemicals’ long-standing international distribution partner Biesterfeld Plastic. This allows a significant reduction in carbon emissions – while ensuring the same physical properties and safety as existing PET. Returnable PET-bottles

Sonopress and SK Chemicals are thus actively leading the way in reducing carbon emissions by closely cooperating in the production of music long-playing records made from 100% recycled materials. SK Chemicals announced that it has used 100% of its recycled PET (CR-PET) for Sonopress’ new EcoRecord long-playing records.

The term CR refers to “Circular Recycling” or “Chemical Recycling” technology, which enables infinite reuse by breaking down plastic waste to the molecular level and reprocessing it back into raw materials. Compared to “mechanical recycling,” in which plastic waste is cleaned or shredded for reuse (in flake form), it has the advantage of maintaining high-value physical properties and safety.

Sonopress’ EcoRecords, which can be made of 100% recycled PET-CR, was jointly developed by SK Chemicals and its long-term strategic international Distribution Partner Biesterfeld Plastic, after signing a memorandum of understanding with Sonopress.

By using PET-CR in Sonopress’ EcoRecord music records, greenhouse gas emissions can be significantly reduced compared to the previous petroleum-based PET, which meets the needs of consumers who prefer environmentally friendly products. Accordingly, Sonopress plans to expand the use of SK Chemicals’ PET-CR to other product groups, starting with this mass-produced packaging. Returnable PET-bottles

In addition to Sonopress applications, SK Chemicals is using the CR material for Jeju Samdasoo’s RE:Born and has launched the “6℃ Eco Toothbrush” with recycled materials in collaboration with KNK, a company specializing in toothbrushes. The company is also expanding the scope of recycled materials by launching textiles made of recycled materials developed in collaboration with environmentally friendly social enterprises such as “Art Impact” and “Project 1907.”

Eung-soo Kim, Executive Vice President and Head of SK Chemicals’ Green Material Business, said, “In March, we acquired assets related to the recyclable recycled PET raw materials business in Shuye, China, and established SK Shantou to lay the foundation for a stable supply of recycled plastic raw materials.” He added, “Based on this, SK Chemicals plans to expand its recyclable recycled product groups to various industrial materials in the future.” Returnable PET-bottles