rPET Carbon Capture – “ADNOC Announces Plans to Create One of the Most Extensive Carbon Capture Initiatives in the MENA Region” 09-09-2023

rPET Carbon Capture

Amut Advances PET Recycling Initiatives in South America

In a significant stride toward bolstering plastic recycling efforts in South America, Amut, a prominent manufacturer based in Novara, has clinched a substantial order from the Peruvian conglomerate, San Miguel Industrias (SMI). SMI stands as a major player in the production of PET and rPET preforms as well as bottles across South and Central America. This collaboration signals a promising step towards a more sustainable future for the region.

Amut, renowned for its expertise in designing and fabricating extrusion and recycling plants for plastic materials, is set to embark on a groundbreaking venture. Under the patronage of SACE and UniCredit, who have orchestrated a non-recourse discount operation amounting to a staggering 16 million euros, Amut will erect three state-of-the-art bottle recycling facilities in Peru, Guatemala, and Colombia. This move represents a pivotal moment in the quest for environmental sustainability, with PET plastic recycling at its forefront. rPET Carbon Capture

Mauro Drappo, the CEO of Amut, underscores the company’s unwavering commitment to sustainability, particularly evident in their production of PET recycling plants tailored for food-grade applications. He elaborates on the intricate process that embodies a circular economy for PET bottles and more, commencing from the initial collection of containers, progressing through meticulous selection, and culminating in the recycling of plastic materials, thus granting them a second lease of life. This holistic approach epitomizes the spirit of circularity, where resources are efficiently utilized and waste is minimized.

Enrica Delgrosso, the Regional Director North West of SACE, affirms the vital role that their organization plays in facilitating such endeavors. In times marked by instability and uncertainty, companies can rely on SACE’s support, encompassing a plethora of insurance-financial products and accompanying services.rPET Carbon Capture

These resources are instrumental in nurturing Italian exports, which have consistently functioned as an economic driving force. The collaboration between SACE, UniCredit, and Amut, therefore, not only champions sustainability but also underscores the importance of fostering economic growth through responsible business practices.

Amut, with its roots dating back to 1958, boasts a rich history of providing cutting-edge extruders and complete production lines for a diverse range of products. These include sheets, stretch films, waterproofing membranes, pipes, and profiles. The company’s repertoire extends further into the realm of recycling, as they specialize in conceiving and constructing plants tailored to recycling plastic materials sourced from bottles and containers made of PET, HDPE, PP, and PE film. Their portfolio also encompasses waste recycling plants dedicated to reclaiming post-consumer and industrial materials. By offering comprehensive solutions in plastic recycling, Amut stands as a steadfast proponent of sustainability in an era where the need for responsible resource management has never been more pressing.rPET Carbon Capture

The collaboration between Amut and San Miguel Industrias (SMI) represents a paradigm shift in South America’s approach to plastic recycling. With three cutting-edge recycling plants on the horizon, Peru, Guatemala, and Colombia are poised to become beacons of sustainability in the region. These facilities will not only address the pressing issue of plastic waste but also contribute to job creation and economic development. As Amut’s CEO Mauro Drappo aptly puts it, these plants will breathe new life into discarded plastic materials, ushering in a circular economy that promotes responsible consumption and production.

In conclusion, Amut’s recent venture with San Miguel Industrias (SMI) is a testament to the power of collaboration in driving sustainability initiatives forward. With an unwavering commitment to recycling PET and promoting a circular economy, Amut, supported by SACE and UniCredit, is poised to make a lasting impact on South America’s environmental landscape.rPET Carbon Capture

Through the construction of three state-of-the-art recycling plants, the region is taking bold steps towards reducing plastic waste, fostering economic growth, and embracing responsible resource management. This alliance serves as a beacon of hope in an era where environmental consciousness is more critical than ever before.

“ADNOC Announces Plans to Create One of the Most Extensive Carbon Capture Initiatives in the MENA Region”

ADNOC Commits to Developing One of MENA’s Largest Carbon Capture Initiatives ADNOC has officially greenlit a momentous initiative to establish one of the most substantial carbon capture projects in the Middle East and North Africa (MENA) region, as reported by Process-worldwide. This groundbreaking venture, known as the Habshan Carbon Capture, Utilization, and Storage (CCUS) project, is set to possess the capability to apprehend and securely store 1.5 million metric tonnes of carbon dioxide (CO2) annually, deep within subterranean geological formations. The announcement stands as a vital component of ADNOC’s overarching carbon management strategy, designed to forge a distinctive framework that unites all emissions sources and sequestration locations. This united effort aims to accelerate the realization of ADNOC’s and the United Arab Emirates’ decarbonization objectives.rPET Carbon Capture

Harnessing state-of-the-art technology, this project will augment ADNOC’s carbon capture capacity to 2.3 million metric tonnes annually, which is equivalent to eliminating over half a million gasoline-powered vehicles from the streets each year. The development will be overseen, operated, and maintained by Adnoc Gas on behalf of ADNOC and encompasses carbon capture units situated at the Habshan gas processing facility, an extensive pipeline infrastructure, and an intricate network of wells designed for CO2 injection. In parallel news, Abu Dhabi National Oil Co (ADNOC) has increased its acquisition offer for Covestro AG to approximately 11 billion euros (USD 12.3 billion). According to insider sources, ADNOC’s latest proposal values Covestro at roughly 57 euros per share, a notable increase from the initial mid-50 euro per share range. Covestro had previously declined ADNOC’s initial takeover bid last month, citing its perceived undervaluation. While a Covestro spokesperson chose not to comment on the matter, ADNOC has not yet responded to a Reuters request for comment. rPET Carbon Capture

Pacur chooses Eastman’s Eastar Renew as the material for its medical device packaging

Pacur, a custom sheet extruder based in Wisconsin, has announced its selection of Eastman’s Eastar Renew 6763 for the production of rigid, thermoformed, sterile barrier medical device packaging. This decision aligns with Pacur’s commitment to sustainability and their dedication to a more circular future by diverting plastic waste away from landfills.

The materials within Eastman’s Renew polymer portfolio are manufactured using ISCC-certified circular content via mass balance allocation. This approach allows Pacur to use resins with certified circular content, supporting their innovation agenda focused on sustainable solutions. Jason Eckel, Pacur’s Senior Vice President of Sales and Marketing, emphasized the importance of investing in next-generation sustainability solutions as a key element of their innovation agenda.rPET Carbon Capture

Eastar Renew 6763 is created through Eastman’s molecular recycling technology, which is virtually indistinguishable from Eastar 6763 copolyester in terms of durability, safety, and performance. Molecular recycling plays a pivotal role in introducing circular polymers into the healthcare industry, promoting the collection and recycling of previously unrecyclable polymers and contributing to the reduction of plastic waste. By choosing Eastar Renew, Pacur can certify the diversion of plastic waste from landfills to produce new packaging. The percentage of recycled content is accurately tracked through an ISCC-certified mass balance accounting method, ensuring transparency and accountability.

Furthermore, Eastman is set to launch the world’s largest material-to-material molecular recycling facility in Kingsport, Tenn., later this year, further enhancing their efforts in this field. rPET Carbon Capture

Pacur’s use of Eastar Renew 6763 in sterile barrier packaging products is made possible by their ISCC PLUS-certified facility, which was achieved in 2022. ISCC PLUS is a globally recognized third-party certification system that tracks sustainable feedstocks throughout the supply chain, ensuring the sustainability of Pacur’s operations.

Prashant Gamatex rejoices in the successful sale of 1,000 high-speed sectional warping machines

Prashant Gamatex is celebrating a remarkable milestone by marking the sale of 1000 high-speed sectional warping machines. As a prominent member of the Prashant Group, an alliance of India’s leading engineering companies specializing in weaving preparation and logistics, Prashant Gamatex stands as a testament to their enduring commitment to excellence. Since its inception in 1975, the Prashant Group has expanded its global presence substantially.

The Prashant Group’s reputation is firmly rooted in its core values of innovation, quality, automation, and exceptional service. These principles have been instrumental in propelling the group to numerous accomplishments, all driven by their unwavering dedication to exceeding customer expectations.rPET Carbon Capture

Headquartered in Ahmedabad, Prashant Group recently hosted a ‘Customers Meet’ in Surat to commemorate the sale of 1000 High-Speed Sectional Warping Machines in the Surat region. This prestigious event attracted over 700 prominent entrepreneurs from Surat’s textile industry, all of whom have relied on Prashant for their weaving preparation machinery for many years.

As the textile industry has diversified its production lines, Prashant Group has expanded its product range to meet the evolving needs of both natural and man-made fiber sectors, as well as the filament sector. During this business gathering, the company presented details about its latest machines, including products such as Techtronic for the Technical Textiles Sector, Robowarp as the ideal solution for sample to medium production in yarn-dyed shirting (Cotton, P/V, and P/W Suiting & Furnishing), Innovative Nitro technology offering ecological and green solutions in Indigo Dyeing, as well as High-Speed Polyester and Viscose Filament Sizing machines, and Warp printing technology with Loom Printer for the Filament industry.rPET Carbon Capture

Thanks to continuous advancements in technology and automation, Prashant Group has maintained its competitive edge in terms of quality and cost-effectiveness. Their market share has consistently grown, both in domestic and export markets.

The Chairman of the group, Mr. Prakash Shah, along with Directors Mr. Apurva Kapadia and Ms. Amoli Shah, joined their technical and marketing teams at the event to express their gratitude to all customers for their unwavering support and patronage. Customers reciprocated with expressions of complete satisfaction regarding the performance of their machines, further elevating the significance of this celebratory occasion.

Sinochem International Expands Presence In Aramid Fiber Industry Chain

Sinochem International made its debut at the China International Optoelectronic Exposition (CIOE2023), showcasing its entire line of para-aramid products. These innovative solutions are tailored to meet the specific needs of the optical communication industry, serving as non-metallic reinforcement materials for optical-fiber cable applications. rPET Carbon Capture

Optical communication cables constitute a critical foundation for high-speed information networks. In the era of new-generation communication technology, optical transport networks demand higher speeds, increased capacity and longer reach. Therefore, optical communication cables need to have superior performance attributes, including elevated strength, enhanced modulus, extended lifespan, reduced weight, minimal creep, and heightened resistance to corrosion.

Sinochem International’s proprietary para-aramids are used as non-metallic reinforcing materials for optical-fiber cables, offering a compelling alternative to traditional materials like glass fibers or steel wires. They significantly augment the overall performance of optical-fiber cables while enhancing the reliability of communication signal transmission.

Aramid is recognized globally as one of the three high-performance fibers. It has an outward appearance resembling ordinary spun fibers. rPET Carbon Capture

But compared with steel wire, aramid exhibits a strength of 5-6 times and a toughness of 2 times, while weighing only one-fifth. These fibers excel in various aspects, including high strength, elevated modulus, resistance to high temperatures, tolerance to acidic and alkaline environments, insulation properties, anti-aging characteristics, and an extended lifecycle. In the realm of optical communication cables, they have rightfully earned their place as one of the industry’s specified non-metallic reinforcement materials.

Solvay Set to Showcase Full Spectrum of Advanced Polymers and Specialty Chemicals at Semicon Taiwan 2023

Solvay, a renowned global provider of specialty materials, has disclosed its participation in Semicon Taiwan 2023, where it intends to unveil its comprehensive range of materials tailored for the worldwide and local semiconductor manufacturing industry. The company will be showcasing its materials portfolio at the Taipei Nangang Exhibition Center from September 6 to 8, with a dedicated booth at Q5848. The spotlight will be on cost-effective and eco-friendly material solutions spanning advanced polymers, slurry abrasives, gases, and wet chemicals. These solutions are meticulously engineered to address the intricate demands of manufacturers in this dynamic market, elevating chip performance with exceptional purity, enduring chemical stability, and optimized resistance to elevated temperatures and plasma.rPET Carbon Capture

Andrew Lau, Senior Executive Vice President of Solvay’s Specialty Polymers Global Business Unit, expressed the company’s dedication to Taiwan’s market players, serving both local and global semiconductor industries. He emphasized Solvay’s commitment to sharing cutting-edge material innovations that enhance profitability and sustainability throughout all semiconductor manufacturing phases, aligning with the industry’s roadmap for next-generation processes.

Leveraging its extensive technical industry expertise, Solvay has established itself as a frontrunner in specialty polymers and chemicals for the semiconductor industry. These materials have proven their resilience in the challenging conditions of advanced semiconductor processes. Designed to meet the most stringent performance requirements, they foster efficiency and assist manufacturers in reducing their environmental footprint across each process stage, encompassing front-end-of-line (FEOL), back-end-of-line (BEOL), testing, and assembly.rPET Carbon Capture

Solvay’s booth will prominently feature structural and internal components molded from KetaSpire® PEEK, Torlon® PAI, Halar® ECTFE, and Solef® PVDF, illustrating the value of Solvay’s specialty polymers in FEOL processes such as dry and wet etching, cleaning, chemical vapor deposition (CVD), chemical mechanical planarization (CMP), and lithography. Additionally, Tecnoflon® FFKM for O-rings and seals, Fomblin® PFPE as a lubricant in vacuum pumps, and Galden® PFPE for efficient heat transfer in chillers will receive special attention.

Solvay will also unveil a range of materials with enhanced sustainability credentials. Novel bio-based polymer chemistry addresses ambitious environmental objectives. Non-fluorosurfactant (NFS) Tecnoflon® FKM and sustainably produced Tecnoflon® FFKM elastomers exhibit excellent plasma resistance for dry etch seal fabrication and an expansive service temperature range while generating extremely low particles. Furthermore, Halar® ECTFE grades offer a more sustainable alternative to PFA and PTFE in wet process applications. rPET PET Recycling

Many of Solvay’s specialty polymers extend into wafer handling, duct coating, filters, piping, tubing, and BEOL processes, covering wafer level packaging (WLP), probing, and testing. The portfolio is complemented by dedicated specialty chemicals, including cleaning gas for etching, Interox® hydrogen peroxide (H2O2) for optimized wet etching, and Cypure® PH3 cylindered phosphine dopant gas. All these process chemicals, including low global warming potential fluids, uphold the highest standards of purity, quality, and consistency in the market.

In line with Solvay’s commitment to ensuring the long-term supply security of its specialty chemicals, the company has invested in a new joint venture plant for electronic-grade H2O2 production. This essential chemical agent for wafer cleaning will be manufactured at the Tainan Technology Industry Park, with commissioning planned for the fourth quarter of 2023, boasting an initial capacity of 30,000 tons per year. This venture builds upon Solvay’s experience with existing H2O2 plants in Asia, Europe, and the United States, adhering to rigorous international standards for quality, sustainability, and environmental safety.rPET Carbon Capture

It’s worth noting that Solvay, a pioneer in high-performance and sustainable polyamide 6.6 polymers, continues to drive innovation within its portfolio. The company recently introduced a specialized grade of Rhodianyl, composed of 100% pre-consumer recycled polyamide, produced at its Santo Andre plant in Brazil.

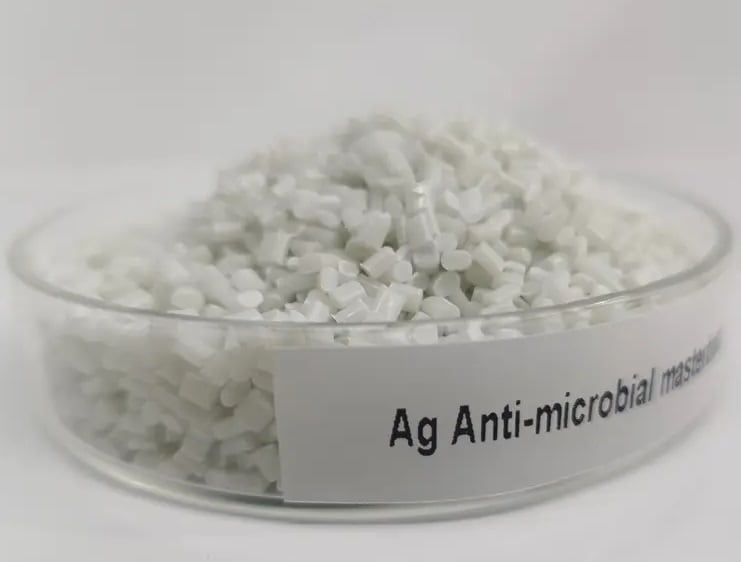

This report presents a comprehensive overview of the Antibacterial Masterbatch market, including market share, size, growth, analysis, and forecast for the period 2023 – 2030 with 8% CAGR

The “Antibacterial Masterbatch Market” report draws on various inferences to analyze the challenges within the industry. The final draught highlights the industry’s typical problems as well as the businesses facing them. This report is of 127 pages. The Antibacterial Masterbatch market is expected to grow annually by 8% (CAGR 2023 – 2030).

The global Antibacterial Masterbatch market is experiencing significant growth, driven by a number of factors including increasing demand, technological advancements, and favorable government regulations. One of the key growth drivers of the market is the increasing demand for Antibacterial Masterbatch products from various end-user industries. Additionally, advancements in technology have led to the development of more efficient and cost-effective Antibacterial Masterbatch products, further fueling market growth.rPET Carbon Capture

However, there are also a number of challenges that the market faces. One of the major challenges is the high cost of Antibacterial Masterbatch products, which makes them unaffordable for some end-users. Additionally, the lack of standardization and technical expertise in the industry can also hinder market growth.

Overall, the global Antibacterial Masterbatch market is expected to continue its growth trajectory in the coming years, driven by increasing demand and advancements in technology. However, the market will need to overcome the challenges it faces in order to realize its full potential.

rPET Carbon Capture