Sustainable-plastic – R-PET-pellet 21-01-2023 - Arhive

Sustainable-plastic – R-PET-pellet

-LyondellBasell Showcases Traditional and Sustainable Solutions at PlastIndia 2023

At PlastIndia 2023, LyondellBasell (NYSE: LYB) will introduce a comprehensive lineup of innovative circular and traditional polymer solutions under the theme of “We make your ideas possible”. The four innovation islands at LyondellBasell’s booth address today’s and tomorrow’s market trends in the field of mobility, packaging solutions, quality healthcare, and industrial and infrastructure. In addition to these market oriented solutions, a special focus topic will be the company’s sustainability strategy, combined with real-life examples of value chain collaboration projects with worldwide known consumer brands.

“After five years away since the last PlastIndia exhibition, we are excited to connect with customers in person and demonstrate the potential of LyondellBasell’s solutions and competencies in supporting our customers’ growth and success in this dynamic market”, said Ndiba Dioh, Sr. Director, Polyolefins AfMEI (Africa, Middle East & India) at LyondellBasell. Sustainable-plastic – R-PET-pellet

“We also look forward to sharing how our sustainability efforts are positioned to help our customers shape a more sustainable future.”

During PlastIndia, LyondellBasell will exhibit solutions and applications that help its customers improve fuel economy through light weighting of vehicles, reduce food waste through innovative packaging, achieve safer, high-quality solutions for healthcare and build a solid foundation for the development of infrastructure. The company’s presence will also highlight the pathbreaking high environmental stress crack resistance (ESCR) HDPE product range recently launched with our innovative Hyperzone technology in the blow molding, film and pipe segments. Products like the high performance Hexene LLDPE & LDPE grades, PP medical and melt blown grades, Non Pthalate PP grades, and Heterophasic & Random Terpolymers from LyondellBasell’s joint venture partners will also be showcased.

On display for the first time at PlastIndia will be sustainable solutions under the Circulen brand. Used in applications from suitcases to jerrycans and automotive interiors, the LyondellBasell Circulen product family supports the reduction of plastic waste through the use of recycled content, and a lower carbon footprint through the use of renewable-based content.

-Essity ranked one of the world’s most sustainable companies

Hygiene and health company Essity has once again been recognised as one of the world’s 100 most sustainable companies by Corporate Knights. The list was announced today during the World Economic Forum in Davos.

The Global 100 list represents the top 1% of companies in the world in terms of sustainability performance. Corporate Knights analyses and compares 6,720 publicly traded companies with a minimum gross revenue of US$1 billion against global industry peers. The ranking is based on 25 quantitative key performance indicators, including sustainable revenue, sustainable investment, taxes paid, carbon productivity, and racial and gender diversity.

“We are proud to once again be ranked as one of the world’s most sustainable companies. As a global company providing hygiene and health solutions to over a billion people every day, Essity makes a real impact when it comes to people and the environment. Our inclusion in Corporate Knight’s index demonstrates our commitment to responsible business practices throughout our value chain,” says Magnus Groth, President and CEO of Essity. Sustainable-plastic – R-PET-pellet

-Paraxylene prices in Asia continue to rise

Asian paraxylene spot prices continued their upward trend, helped by higher crude oil prices and an optimistic demand outlook, ICIS reported.

There was optimism about the growth in demand for polyester in the processing industry after the New Year holidays according to the Lunar calendar, which kept the mood up.

Paraxylene supply is expected to remain balanced or slightly limited, with a few planned maintenance stops in the future and with a steady stream of material exports from Asia to the US. Sustainable-plastic – R-PET-pellet

According to sources in the market, from January 1 to January 10, about 30 thousand tons of paraxylene were exported from South Korea to the United States.

On January 18, applications for March paraxylene shipments were at USD1,056 per tonne, CFR at major ports in Taiwan and/or China compared to transactions at USD1,023–1,024 per tonne, CFR at major ports in Taiwan and/or China on the previous day.

Earlier it was reported that an oversupply of paraxylene in Europe will continue to be a problem in 2023, as the launch of new production facilities in Asia is expected. Meanwhile, demand from European buyers for refining and sales is likely to remain low amid a gloomy macroeconomic outlook.

According to the ScanPlast review, in January-November 2022, the estimated consumption of PET in Russia amounted to 758.69 thousand tons, which corresponds to consumption for the same period a year earlier. Compared with November 2021, total estimated consumption increased by 4% and amounted to 78.77 thousand tons against 75.44 thousand tons last year.

-New behavioural “barrier-based” framework for sustainable plastic management

A new framework developed and tested by researchers at Ritsumeikan University claims to identify barriers and context-specific measures for plastic use and disposal.

Researchers from Ritsumeikan University say they have developed a new behavioural barrier-based framework, which can serve as a guide to policymakers, encourage better practices and improve the environment in a “context-specific manner.”

This frame is not restricted to plastic waste and can be applied to other waste-related problems requiring interventions for desirable behavioural changes, the University says.

To address plastic pollution, researchers from Ritsumeikan University have developed and tested a new framework called the Behavioural Barrier-Based Framework (BBBF).

The University says this method, which has been reported in an article made available online on 15 December 2022 and is set to be published in Volume 384 of the Journal of Cleaner Production on 15 January 2023, identifies suitable intervention methods from infinite possibilities in a context-specific manner. Sustainable-plastic – R-PET-pellet

The lead researcher of this study, Professor Takuro Uehara, from the Department of Policy Science, Ritsumeikan University, explained the study by saying: “This study proposes a new framework, the BBBF, for enabling policymakers to select effective intervention measures to promote people’s sustainable plastic use and disposal.”

This study proposes a new framework, the BBBF, for enabling policymakers to select effective intervention measures.

The proposed framework has a four-step process. Step one involves setting policy targets. Step two identifies desirable behavioural changes to attain the policy targets. Step three identifies critical barriers to desirable behavioural changes.

Finally, step four involves interventions that will directly impact policies by inducing desirable behavioural changes.

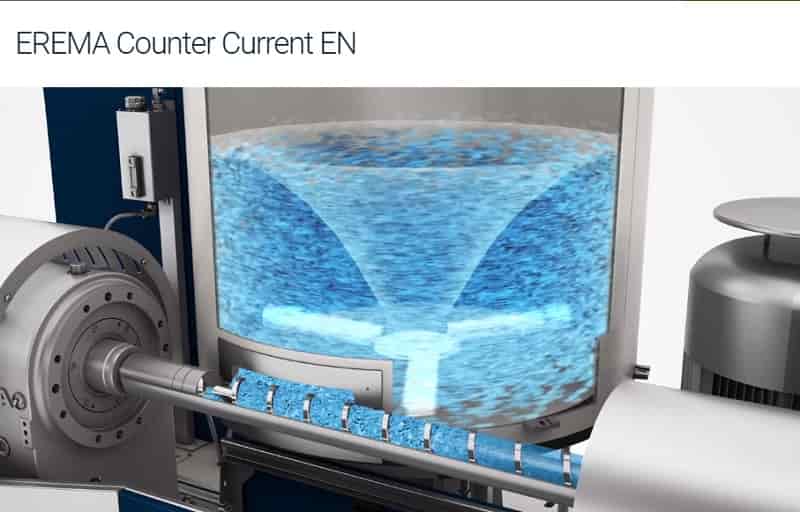

-RCS Group increases R-PET pellet output

German waste-disposal and recycling company RCS has increased its capacity of recycled polyethylene terephthalate (R-PET) food-grade pellets (FGP) with the addition of a second EREMA bottle-to-bottle unit, said the company.

The second unit will bring the company’s FGP capacity up to 70,000 tonne/year according to a release from the company, based in Werne, Germany.

The pellets produced via this second unit have both European Food Safety Authority (EFSA) and US Food and Drug Administration (FDA) approval for use in food-contact applications such as beverage bottles.

Alexander Rimmer, managing director said of the company’s decision to invest in a second unit: “The demand for R-PET is increasing, the quality of the pellets has exceeded our expectations and the entire process from planning to installation and commissioning has been faultless”. Sustainable-plastic – R-PET-pellet

We remind, RCS Group was awarded a sustainability certificate from the Fraunhofer Institute, because the recycling of PET bottles saves more than 100,000 t of CO2 equivalents, 45,000 t of fossil resources and 733,000 MWh of energy every year.

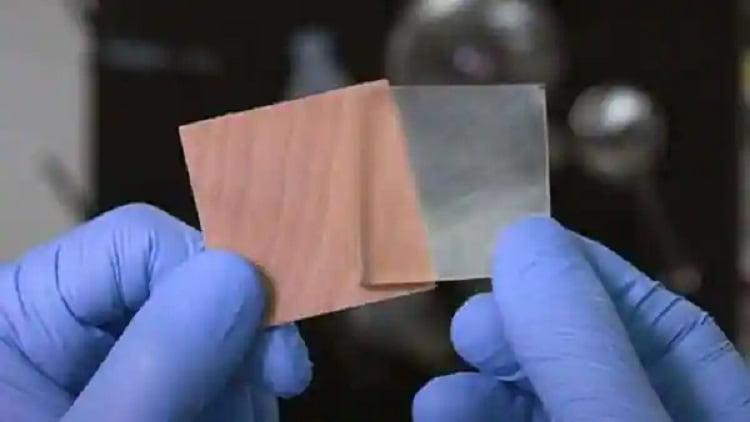

-PureCycle to Build Europe’s First Polypropylene Recycling Facility

The plant will be located in Belgium at Europe’s second-largest seaport and will have initial capacity of 130 million pounds

PureCycle Technologies continues to expand its global reach. The advanced recycling company and the Port of Antwerp-Bruges jointly announced today plans to build PureCycle’s first polypropylene (PP) recycling facility in Europe at the port’s fast-growing NextGen District in Belgium.

The new plant is expected to have annual capacity of 59,000 metric tons (130 million pounds), with plentiful expansion opportunities. The 14-hectare (35-acre) plot can support up to four processing lines with an anticipated total capacity of approximately 240,000 metric tons (500 million pounds) per year. Sustainable-plastic – R-PET-pellet

PureCycle is currently engaged in feedstock sourcing and financial planning with the intent to secure a final project timeline by mid-2023. Plant construction is expected to begin in 2024 once the permitting process has been completed.

PureCycle holds a global license to commercialize a solvent-based purification recycling technology developed by Procter & Gamble. The proprietary process removes color, odor, and other contaminants from recycled feedstock, resulting in ultra-pure PP suitable for any market, said PureCycle.

NextGen District is described as a global hub for businesses seeking to advance the circular economy. The district is located at the Port of Antwerp-Bruges, Europe’s second largest seaport, in proximity to Europe’s largest integrated petrochemical cluster. PureCycle was awarded a “concessionaire” contract during NextGen’s competitive bidding process.

Sustainable-plastic – R-PET-pellet