Bio-based-PP – PET-Al-polymerization 20-01-2023 - Arhive

Bio-based-PP – PET-Al-polymerization

Chinaplas 2023

Green, Smart, Advance are the 3 keywords the organisers chose for the 2023 edition of Chinaplas.

Green is the commitment for circular economy and sustainability. Smart can inspire innovations and enhance user experience.

Advance is the powerful tool for improving productivity and quality. At Chinaplas 2023, to take place from April 17-20, 2023 in Shenzhen World Exhibition and Convention Center (SWECC), Shenzhen, PR China, visitors are invited to immerse in these 3 hot technologies under one roof, helping inspire new ideas and explore new opportunities.

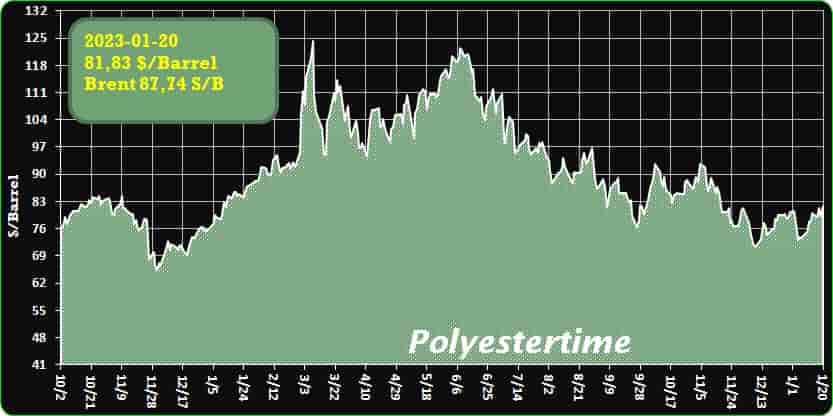

Crude Oil Prices Trend

Crude Oil Prices Trend Polyestertime

-Evonik Catalysts expand

s portfolio – focus on chemical recycling of PET

- Alkoxides from Evonik will now be produced and marketed under the umbrella of the Catalysts business line

- Transformation of the chemical industry requires innovative catalysts

- Sustainability and Next Generation Solutions are the focus of activities and are expected to become the growth drivers of the coming years

- Existing sales channels for alkoxides to remain in place continuing to serve our esteemed customers

Evonik is pooling its expertise and integrating its alkoxides business into the Catalysts business line. Bio-based-PP – PET-Al-polymerization

The extensive portfolio of heterogeneous catalysts is thus now complemented by homogeneous catalysts. An international network of production sites and the highly experienced alkoxides team will additionally strengthen the Catalysts business line, one of Evonik’s growth areas, from January 2023.

The chemical industry is undergoing a profound transformational process. Driven primarily by sustainability issues such as the circular economy, CO2 reduction or decarbonization, catalysts are at the heart of this transformation, as they are needed for approximately 80 percent of all chemical processes.

The internal integration supports transformation of the chemical industry as well as the Catalysts expansion strategy on the way to becoming a leading global catalyst supplier for the chemical industry. Bio-based-PP – PET-Al-polymerization

-Braskem evaluating production of bio-based polypropylene

In 2010, Braskem, the Brazil-based largest polyolefins producer in the Americas, first started to produce green plastics – bio-based PE – on an industrial and commercial scale. In the years that followed, its I’m Green portfolio of bio-PE grades became an established presence in the market. Now, over a decade later, Braskem announced it is launching a new project aimed at supporting brand owners’ and OEMs’ transition to a more sustainable use of raw materials. Bio-based-PP – PET-Al-polymerization

The company will evaluate an investment in producing a second bio-based material; in this case, carbon-negative bio-based PP.

Production would be in the U.S., home to the largest ethanol industry production in the world and therefore able to offer the ample technology, infrastructure, and supply availability needed for a project in the polymers’ value chain.

The project would utilise Braskem’s proven, proprietary technology to convert bioethanol into physically segregated bio-based polypropylene at an industrial scale. As well, Braskem is exploring partnership opportunities for this project with several clients, brand owners, and suppliers.

The bio-based PP would be a drop-in solution that has the same technical properties and recyclability found today in Braskem’s current PP portfolio, with the additional benefit of a negative carbon footprint.

-Toyobo : wins Chemical Society of Japan Award for Technical Development for 2022; helping realize a circular economy with an eco-friendly aluminum catalyst for polyester polymerization

Toyobo Co., Ltd. has received the 2022 Award for Technical Development by Chemical Society of Japan (CSJ) for its work in the “Development and Industrialization of Novel Aluminum Catalysts for Polyethylene Terephthalate.” The CSJ, Japan’s biggest chemical society, has presented this award, which recognizes outstanding achievements in developing technology in Japan’s chemical industry, annually for the past 71 years.

In 2002, Toyobo developed the world’s first aluminum catalyst, TOYOBO GS Catalyst®, for manufacturing polyethylene terephthalate (PET) resins, although general PET polymerization catalysts were composed of heavy metal such as antimony.

In 2017, Toyobo signed a licensing contract* involving specific polymerization technologies and related patents with Thailand-based Indorama Ventures Public Company Limited, the world’s largest PET resin manufacturer, as part of its efforts to tap the global market. PET resins produced using TOYOBO GS Catalyst®, containing no heavy metals, are eco-friendly. Bio-based-PP – PET-Al-polymerization

Also, these resins are less likely to deteriorate during repeated melting processes due to their excellent thermal stability; therefore, they are well suited for recycling.

Amid heightened global environmental awareness, recovery and reuse systems mainly for PET bottles have been rapidly established, and then PET resin recycling is expected to expand beyond bottles to fibers, films and molded items. Against this backdrop, the award was presented to Toyobo after CSJ gave high marks to TOYOBO GS Catalyst® as an innovative catalyst fundamentally improving the thermal stability and quality of PET resins, thus contributing to promote recycling. It was also evaluated that Toyobo has achieved global industrialization of the catalyst.

-Toray Develops Eco-Friendly PET Film Offering Excellent Applicability and Adhesion for Water-Based and Solvent-Free Coatings in Printing, Mold Release, and Adhesive Processing

Toray Industries, Inc., announced today that it has developed a polyethylene terephthalate (PET) film that combines excellent applicability and adhesion for water-based and solvent-free coatings and can eliminate solvent-derived carbon-dioxide emissions. The company looks to produce the film at a domestic plant by end-March 2024 to help popularize eco-friendly film products for which decarbonization during manufacturing is desirable. These items include release, adhesive, printing, packaging, and automotive films.

The environmental impacts of organic solvents in regular PET film processing have become problematic in view of global warming becoming a prime issue in recent years as a result of air pollution and carbon dioxide emissions. Bio-based-PP – PET-Al-polymerization

This situation has driven the development of coatings free of such volatile organic compounds (VOCs) as toluene, xylene, and ethyl acetate. Such coatings eliminate carbon dioxide emissions derived from solvents. Advances include coatings in which water replaces these compounds in mold release agents, adhesives, and printing inks, as well as solvent-free versions employing monomers to dilute ingredients. Still, VOC-free coatings have downsides. They include appearance defects such as peeling when applied on PET films. Other issues are poor adhesion between coated layers and PET films after drying, resulting in lifting and peeling that reduces durability.

Toray’s new PET film has both good applicability for water-based paints and good adhesion to films after it is dried. This was achieved by forming an ultra-thin layer with nanosized dispersion of hydrophilic components with high affinity to water and hydrophobic components with high affinity to the resin on the surface of the film.

This film has demonstrated outstanding applicability and adhesion for an array of water-based offerings from paint manufacturers. Coating and adhesion is also excellent with solvent-free coatings, which are also VOC-free.

PET film processing generally emits carbon dioxide from coating and drying printing inks, release agents, and adhesives, as well as from consuming electricity in curing, releasing organic solvents into the atmosphere through incineration, and disposing of solvent effluents and waste. The film makes it possible to use VOC-free paints and thus eliminate the carbon dioxide emissions associated with organic solvents.

Toray’s new technology is also compatible with Ecouse®Lumirror™ offerings employing recycled PET materials. Ecouse is a brand for recycled materials and products that Toray began rolling out worldwide in 2015. Lumirror is a biaxially oriented polyester film. The company can help lower environmental impact by providing total solutions for PET film manufacturing through processing for printing, mold release, adhesion, and other coatings. Bio-based-PP – PET-Al-polymerization

Under the Toray Group Sustainability Vision and “TORAY VISION 2030”, the company helps to resolve environmental, resources, and energy issues through business. It will continue to develop advanced materials to materialize its corporate philosophy of contributing to social progress by delivering new value.

-EMS CHEMIE : Stiff and strong specialty polyamides reduce energy consumption in manufacturing and use (EMS-GRIVORY K-Messe 2022, EMS-GRIVORY)

Stiff and strong specialty polyamides reduce energy consumption in manufacturing and use

Energy cost reductions from metal replacement

The energy supply situation in Europe is an issue for concern and is driving up costs for electricity and natural gas. From August 2021 until August 2022 the electricity prices in Switzerland and Germany increased by more than 550% (Fig. 1). This dramatic increase in energy costs is forcing manufacturers to analyse and optimize their complete energy management in production. Bio-based-PP – PET-Al-polymerization

High energy costs promote use of polymer materials

EMS specialty polyamides are well known to trade experts and are recognised and valued for metal replacement. Along with weight savings, which in the car industry go hand in hand with a reduction of CO2 emissions, these materials also make a reduction of up to 60% in manufacturing costs possible. Metal die-cast components, on the other hand, are manufactured at high temperatures and are therefore, very energy-intensive (Fig. 2). The energy requirements for the manufacture of metal alloys as basic materials is substantially higher than for the manufacture of polymer materials. This is a significant reason for the sharper increase in metal prices compared to polymer materials in the past months. This energy-driven cost increase also makes use of high-performance polymers additionally attractive in comparison to metal.

Main potential for savings at the start of the development phase

65 – 75% of manufacturing costs are already defined during the design phase, i.e. at the start of a development project. This makes it essential that design engineers create a range of design variants and materials used for comparison reasons. In the following example of a water meter, the savings potential in three development phases is illustrated (Fig. 3).

Potential for cost saving taking a water meter as example

Phase 1, choice of material and design: Grivory HT1VA-4 FWA is used to replace brass for the insert of a water meter. The maximum operating conditions are 16 bar pressure and 70°C for an intended life expectancy of at least 20 years. With a part weight of 340 g (brass), this is a medium-sized water meter. Using Grivory HT instead of brass, the manufacturing costs can be reduced by 50% and the part weight by 75%. Additional energy savings can be achieved which, with the current energy prices compared to 2021, is a very significant from a part cost point of view.

Phase 2, design optimisation: Using Moldflow simulation and Finite Element Analysis, component geometry is defined according to the effective requirements and wall thicknesses are reduced to a minimum resulting in a shorter cooling time. As a practical rule, the cooling time in seconds (tc) is taken as 2 – 3 x (max. wall thickness in mm)2. Flow channels are optimised for perfect flow behaviour and unnecessary filling energy or filling pressure is avoided.

For a trade expert it is clear that the steps described here are ideally taken at the start of the development process, but it is always worth applying them to ongoing applications to achieve the maximum optimisation potential and additional energy cost savings from material and process innovation. Bio-based-PP – PET-Al-polymerization

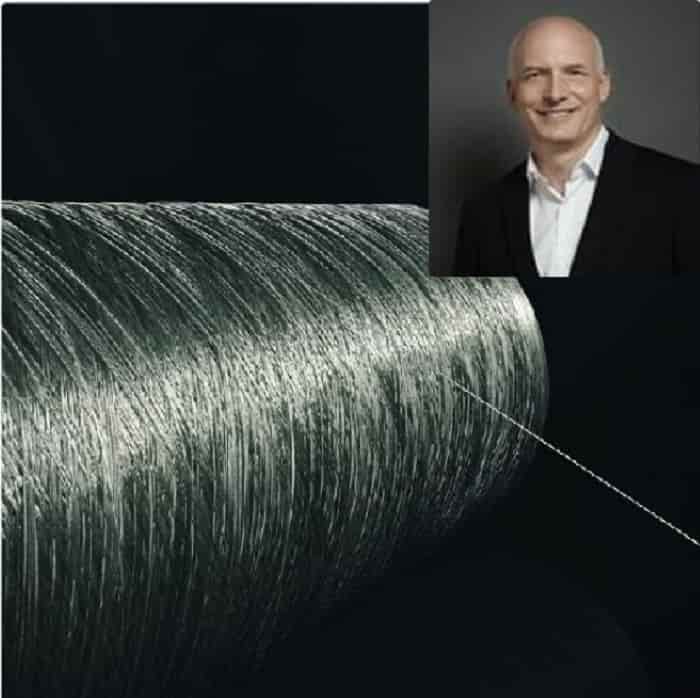

-HeiQ AeoniQ™ Turns Into A Piece Of Garment For The First Time By HUGO BOSS

HeiQ announces that the German premium fashion company HUGO BOSS reveals today the first product made with HeiQ AeoniQ™ fiber – a seamless high-performance Polo Shirt.

With that, the company marks a milestone within the partnership that will enable the replacement of synthetic fibers to reduce their impact on the planet.

The product is crafted with 87% HeiQ AeoniQ™, a revolutionary cellulosic yarn created from certified wood pulp, one of the many renewable raw materials it can be made of, featuring the same performance attributes as polyester.

This new style is part of the BOSS Green collection line, designed for urban environments with BOSS’ renowned performance-driven qualities and worn by Italian tennis player Matteo Berrettini. Bio-based-PP – PET-Al-polymerization

The first Innovation drop of the Polo Shirt is available in limited quantities in the global eCom of HUGO BOSS. [https://www.boss.com/boss-heiq-aeoniq-polo-shirt-for-him].

For Carlo Centonze, HeiQ CEO, “this first drop by HUGO BOSS makes the dream of replacing polyester for a more sustainable alternative tangible while keeping all the features that made synthetic fibers so widespread. Until today we called HeiQ AeoniQ™ a project. From now on it is a brand that delivers the promise of sustainability and true circularity for the benefit of the Planet.”

For HUGO BOSS, the exciting partnership with HeiQ represents yet another important milestone on its journey towards becoming the leading premium tech-driven fashion platform worldwide. Consistent with their bold mission statement ‘We Love Fashion, We Change Fashion,’ this game-changing technology will enable HUGO BOSS to further push innovation and sustainability across their brands’ offerings, thereby driving measurable impact for the environment and society alike.

Textile industry change starts here

HeiQ AeoniQ™ is a more sustainable, circular, and closed-loop cellulosic textile yarn.

-Reliance raises MEG prices in India

Reliance Industries Ltd (RIL), India’s energy and petrochemical giant and the country’s largest producer of polyvinyl chloride (PVC), january 16 raised its monoethylene glycol (MEG) price offer to USD535 per tonne for the second half of January for the Indian market, a source close to the company told ICIS. Bio-based-PP – PET-Al-polymerization

Terms of delivery cfr India.

So, on January 13, spot prices of MEGs in the market in Asia closed at the level of USD525-530 per ton, CFR CMP (the main ports of China).

Earlier it was reported that Reliance Industries announced the nomination of the contract price of MEG for the first half of January in the amount of USD530 per ton.

MEG, along with terephthalic acid (TPA), is one of the main raw materials for the production of polyethylene terephthalate (PET).

According to the ScanPlast review, in January-November 2022, the estimated consumption of PET in Russia amounted to 758.69 thousand tons, which corresponds to consumption for the same period a year earlier. Compared with November 2021, total estimated consumption increased by 4% and amounted to 78.77 thousand tons against 75.44 thousand tons last year.

Bio-based-PP – PET-Al-polymerization