Carbon dioxide plastic – Balrampur Chini Mills, the Indian conglomerate, has unveiled its partnership lineup for the forthcoming polylactic acid (PLA) plant project 22-03-2024

Carbon dioxide plastic

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

LG Chem will showcase carbon dioxide-based plastic containers at Cosmoprof Bologna 2024, starting March 21 in Bologna, Italy, aiming to attract customers

Cosmoprof, a major event in the beauty industry, hosts around 3,000 cosmetics companies displaying various materials, packaging, ODM, and brands.

The company will reveal cosmetic containers made from Poly Ethylene Carbonate (PEC), an eco-friendly material developed in collaboration with COSMAX. PEC, derived from captured CO2 and ethylene oxide, signifies a leap in sustainable materials. LG Chem has developed catalysts and processes crucial for converting CO2 into plastic, achieving high productivity compared to existing CO2-based plastics.Carbon dioxide plastic

PEC finds applications in cosmetic and food packaging, and can be blended with other plastics for diverse uses, from flexible films to durable cases. With the cosmetics industry increasingly shifting towards eco-friendly packaging, LG Chem’s initiative aligns with global efforts to reduce carbon emissions, exemplified by regulations like the EU’s Carbon Border Tax.

An LG Chem spokesperson stated, “By leveraging PEC, a next-gen material synthesized from captured CO2, we aim to forge stronger ties with cosmetic partners and combat global warming.” This move underscores LG Chem’s commitment to sustainability and addresses the demand for environmentally responsible packaging solutions in the cosmetics sector. Carbon dioxide plastic

Balrampur Chini Mills, the Indian conglomerate, has unveiled its partnership lineup for the forthcoming polylactic acid (PLA) plant project

Sulzer, Alpine Engineering, and Jacobs have been selected as key technological collaborators for this initiative.

Sulzer, renowned for its expertise, will provide licensing for PLA production from sugarcane, a primary resource for Balrampur Chini Mills. Their role encompasses the entire process chain, from lactide synthesis to polymerization. Alpine Engineering will contribute fermentation, distillation, and purification technologies under a separate agreement. Meanwhile, Jacobs Solutions India will oversee Engineering, Procurement, and Construction Management (EPCM) services. This involves configuring and integrating lactic acid and PLA production facilities, alongside managing engineering for utilities and civil infrastructure to optimize energy efficiency. Carbon dioxide plastic

Stefan Barot, President of Balrampur Chini Mills’ Chemicals division, expressed excitement about the collaboration, highlighting the project’s significance in advancing sustainable innovation. This alliance aligns with the company’s commitment to environmental sustainability, in line with governmental directives.

The new PLA plant, anticipated to cost around 220 million euros, will boast an annual production capacity of 75,000 tonnes.

Strategically located near a group-owned sugar factory, it ensures access to raw materials and essential utilities, streamlining operations. This venture signifies a significant step towards sustainable manufacturing and underscores the company’s dedication to future generations. Carbon dioxide plastic

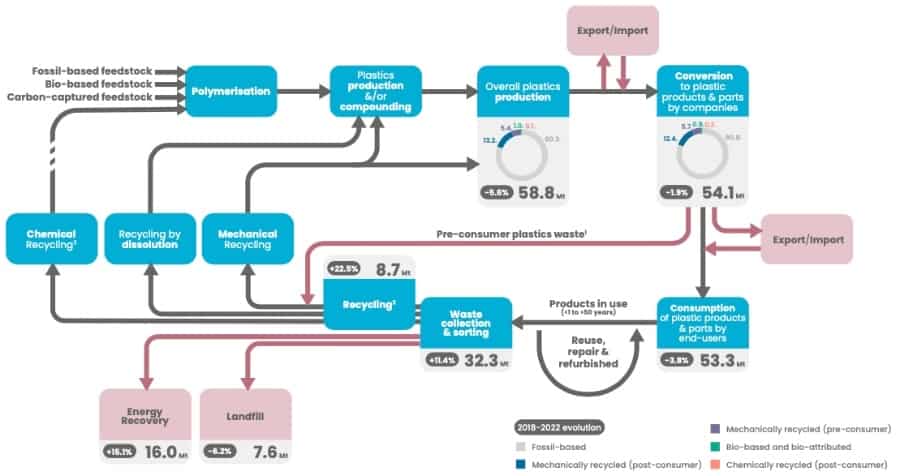

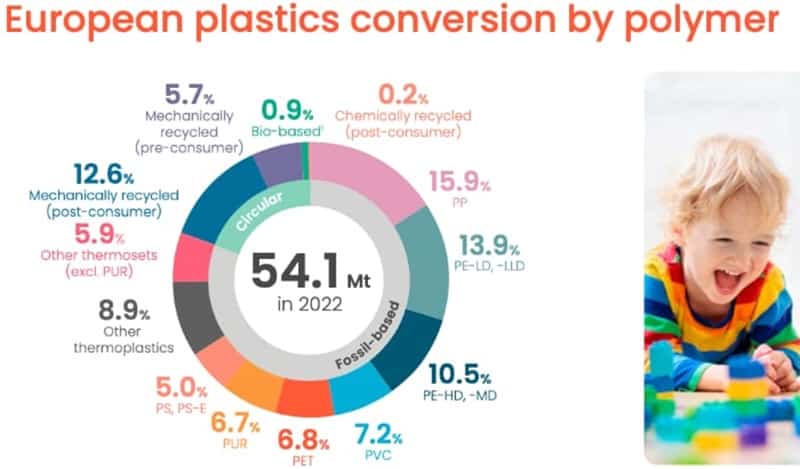

PlasticsEurope has released its biennial report on plastic circulation in Europe, shedding light on production, transformation, and recycling trends

The 2024 edition, titled “The Circular Economy for Plastics: A European Analysis,” delves into various facets including production, transformation, consumption, waste management, recycling, and use of recycled materials in Europe as of 2022. Notably, this report marks the inclusion of data on biobased plastics and chemical recycling for the first time.

Analysts highlight that circular plastic, comprising recycled, biobased, or carbon capture materials, constitutes approximately 13.5% of newly manufactured plastic products in Europe, amounting to 7.3 million tonnes, with 6.8 million tonnes being post-consumer recycled. This signifies significant progress, positioning the industry halfway towards the target outlined in the ‘Plastics Transition’ roadmap, aiming for 25% of plastic from circular sources in new products by 2030. The use of recycled plastics has surged by nearly 70% compared to 2018. Carbon dioxide plastic

Despite this progress, challenges persist. While 26.9% of plastic waste generated in 2022 was recycled, surpassing landfill disposal for the first time, incineration remains prevalent, with waste-to-energy plants processing 16 million tonnes, a 15% increase since 2018. Mechanical recycling dominates, contributing 13.2% of processed products, while biobased and chemical recycling represent minor shares.

Virginia Janssens, Managing Director of Plastics Europe, underscores the urgent need to address these challenges, emphasizing the necessity of transitioning towards circularity. She stresses the importance of chemical recycling alongside mechanical recycling, particularly for applications demanding high-quality plastics. However, she notes that regulatory clarity and support from policymakers are imperative to incentivize investments and accelerate the adoption of chemical recycling. Carbon dioxide plastic

The report also reveals disparities across sectors, with packaging, construction, and agriculture demonstrating stronger demand for recycled materials compared to automotive or electrical and electronics industries. Despite progress, achieving EU recycling targets for plastic packaging remains a challenge, necessitating a concerted effort towards embracing innovative recycling solutions and clearer legislative frameworks.

Toray Plastics launches Torayfan with certified-circular resins

Toray Plastics has introduced Torayfan polypropylene film made with ExxonMobil’s certified-circular resins, a move advancing the packaging industry towards a circular plastic economy. Carbon dioxide plastic

Leveraging ExxonMobil’s Exxtend technology for advanced recycling, Toray’s decision underscores its commitment to plastic circularity and customer value. Chris Nothnagle, Toray’s senior director of new business development, highlights the significance of choosing certified-circular resins, which not only diverts plastic from landfills but also ensures accountability through mass balance accounting.

Toray’s technologically advanced film maintains quality and performance standards expected by customers, utilizing ExxonMobil’s resin without requiring requalification due to its virgin-quality nature. Carbon dioxide plastic

ExxonMobil’s advanced recycling process, certified by the International Sustainability and Carbon Certification (ISCC) PLUS, facilitates the production of high-quality packaging film crucial for efficient manufacturing.

This process transforms plastic waste into raw materials at a molecular level, significantly reducing greenhouse gas emissions compared to fossil-based feedstocks.

The partnership between Toray and ExxonMobil aims to explore new opportunities for deploying certified-circular resins in common packaging applications, promising substantial benefits for consumers and brand owners keen on participating in the circular economy.

Toyota’s CEO, Akio Toyoda, has sent shockwaves through the automotive industry, unveiling plans for an engine that could upend the electric vehicle (EV) sector

Toyoda’s assertion of an engine set to “destroy the entire electric vehicle industry” has sparked intrigue and debate. Carbon dioxide plastic

Central to Toyoda’s stance are his apprehensions about the rush towards electric vehicle adoption. He contends that a swift transition could yield dire economic and environmental consequences. Toyoda predicts exorbitant costs not only in development and manufacturing but also in the necessary infrastructure. This, he argues, could render cars unaffordable for many and potentially lead to energy shortages in nations, with minimal environmental gains due to increased CO2 emissions from battery production.

Using Japan as a case study, Toyoda highlighted the potential electricity shortfall during peak seasons if all vehicles were electrically powered. Estimates suggest Japan could face costs ranging from 14 to 37 trillion Yen for such a transition, approximately 110-290 billion euros. Carbon dioxide plastic

This announcement has ignited a contentious industry dialogue. Some view Toyota as a prudent guardian against rash electrification, while others accuse the company of hindering progress to safeguard its interests.

Toyoda’s pledge of a groundbreaking engine symbolizes a broader discourse on mobility’s future. Its impact on the market and the validity of Toyoda’s concerns remain uncertain. Ultimately, the market’s response will determine whether innovation and sustainability can reconcile economic and environmental imperatives.

New Energy Blue, a US-based biofuel and biochemicals developer, has launched New Energy Chemicals, a subsidiary with Dow as a key client

This new arm will supply Dow with biobased ethylene for eco-friendly plastics production.

Utilizing crop residues, New Energy Chemicals will produce biobased fuels and chemicals. By late 2025, its biomass refinery in Mason City, Iowa, will churn out 16 to 20 million gallons yearly of low-carbon cellulosic ethanol and 120,000 tons of clean lignin. Lignin holds significant value as a fossil fuel substitute, particularly in decarbonizing steel production. Carbon dioxide plastic

The produced ethanol will be sent to Texas for conversion into bio-based ethylene, which will then travel via pipeline to Dow’s Gulf Coast facilities. Here, it will be used in renewable plastics manufacturing, catering to burgeoning markets like packaging.

Dow’s adoption of New Energy Blue’s bio-based feedstocks is set to receive ISCC Plus certification, ensuring sustainability and carbon traceability. This certification allows Dow to incorporate agriculture-based ethylene into its production process, enabling its clients to track bio-based materials within their supply chains. Carbon dioxide plastic

The LYCRA Company, renowned for pioneering innovative and sustainable apparel solutions, joins the Performance Days seminar on textile recycling

The event, hosted by Accelerating Circularity, focuses on polyester recycling from textile waste, exploring commercial-scale systems.

Jean Hegedus, The LYCRA Company’s Director of Sustainable Business Development, participates as a panelist at Performance Days in Munich, Germany, from March 20 to 21. Hegedus will feature in the Recycled Polyester Database Launch session, facilitating discussions from 3 to 4:30 p.m. daily in the Reality Zone. This platform connects polyester recyclers and fabric producers incorporating textile feedstocks. Carbon dioxide plastic

Panelists will address challenges associated with textile waste utilization and solutions, followed by breakout sessions enabling direct interaction between brands, retailers, and providers.

Since 2021, The LYCRA Company has led in specialty polyester fibers development, offering COOLMAX® and THERMOLITE® EcoMade fibers entirely sourced from textile waste.

These high-quality fibers, available in staple, filament, and insulation forms, find application in various fields from performance wear to outdoor apparel.

The company introduced “Waste for Good” campaign last year, advocating circularity in the industry through COOLMAX® and THERMOLITE® EcoMade technologies.

Hegedus appreciates Accelerating Circularity for highlighting the importance of transitioning to textile waste, especially as recycled bottles face imminent supply shortages, urging the industry towards closure of its loop. Carbon dioxide plastic

Carbon dioxide plastic