Bottle Tethered Cap

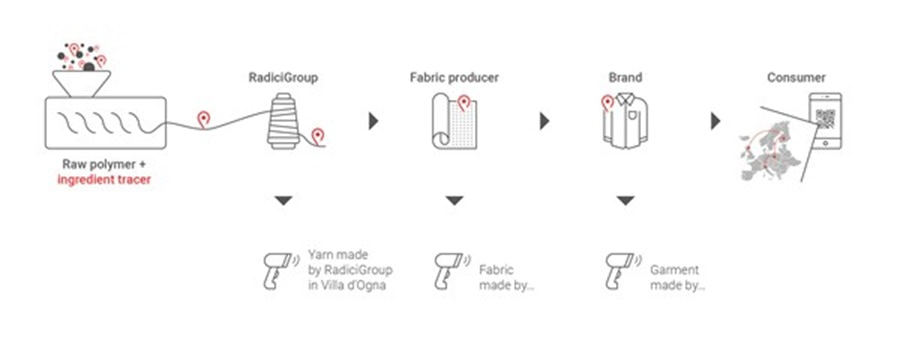

RadiciGroup is set to make a significant impact at Chinaplas 2024, held from April 23-26 at the National Exhibition and Conference Center in Shanghai, China

This event marks another year of RadiciGroup showcasing its innovations at this premier meeting platform for the Chinese plastic and rubber industries, a sector it has accompanied for over three decades. This year, RadiciGroup will occupy stand D38 in Hall 7.2, where it will highlight advancements across various industries including automotive, electrical/electronic, appliances, and consumer goods.

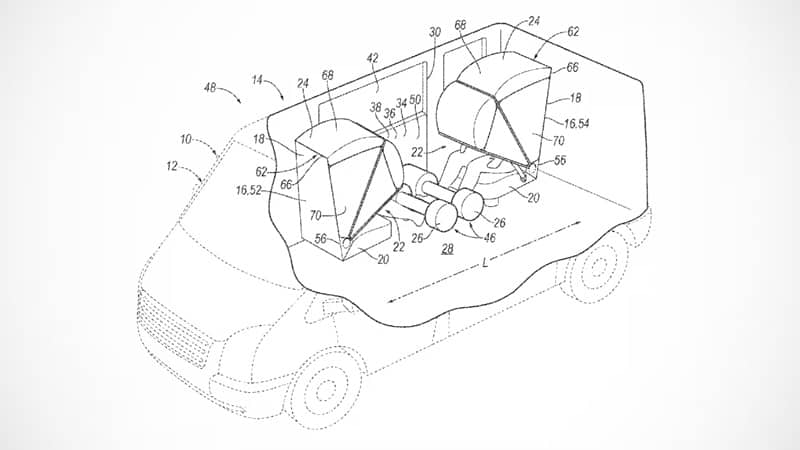

The automotive industry remains a crucial market for RadiciGroup in China, reflecting substantial volume and growth. Despite economic challenges, 2023 was a landmark year as Chinese automotive manufacturers surpassed global competitors. This achievement underscores the importance of RadiciGroup maintaining strong relationships with both local and international OEMs and TIERs, aiming to meet their evolving technical and environmental needs.

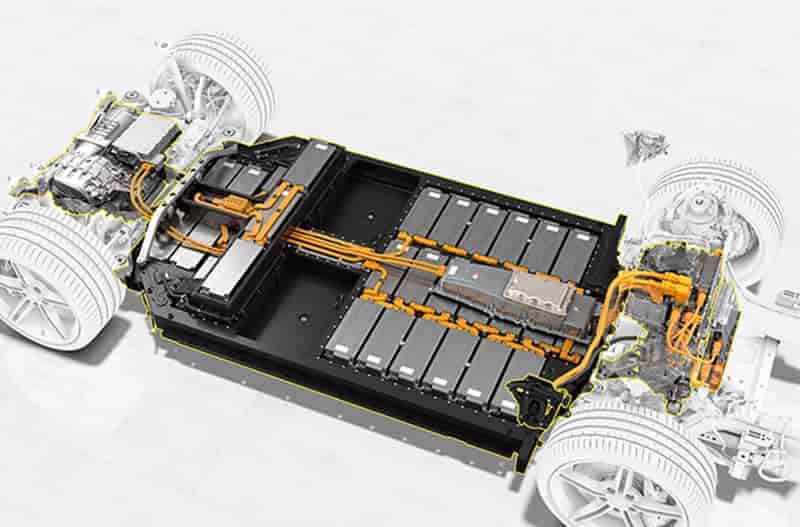

Alberto Sessolo, Country Manager China for RadiciGroup High Performance Polymers, expressed the company’s commitment to enhancing partnerships within the automotive sector. He emphasized their focus on innovative, sustainable solutions that uphold product quality and reliability. The shift towards electric vehicles highlights the need to lighten vehicle components by substituting metal with advanced plastic materials, an area where RadiciGroup is actively innovating.

RadiciGroup also continues to pioneer with its digital tool, RadiciGroup AutoInsight. This application allows users to explore automobile components in 3D, easily accessing information about the sustainable materials used. Designed for accessibility on various devices, it facilitates in-depth analysis tailored to diverse user expertise.

In 2023, RadiciGroup inaugurated a new production facility in Suzhou, China, now fully operational. This expansion, particularly in R&D and Marketing, reflects the company’s commitment to capturing emerging market trends and transforming them into innovative offerings.

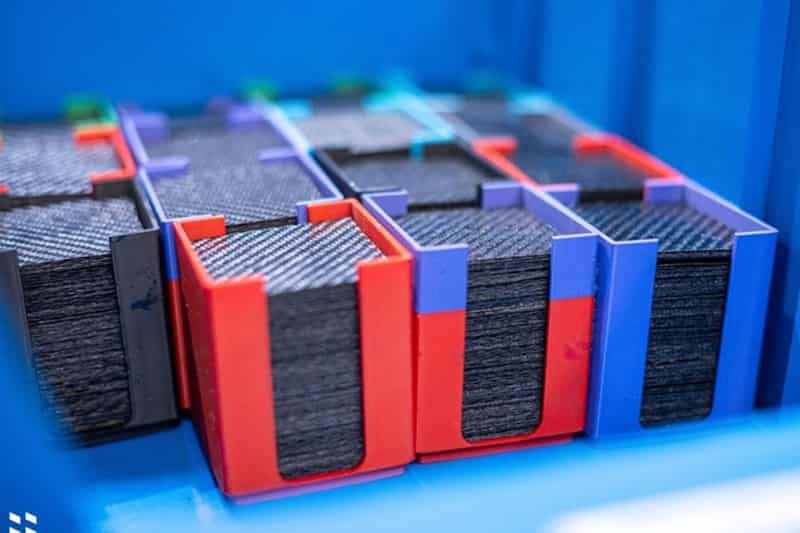

Another growing sector in China is the solar and photovoltaic panel industry, which mandates new constructions to incorporate these technologies. RadiciGroup meets these needs with materials like Radiflam® from its product line, which are designed to endure harsh conditions and are optimized for connectors.

Environmental sustainability continues to be a priority for RadiciGroup, evidenced by its promotion of Renycle®, a line of recycled polyamides. The environmental impact of these products is measured using the Life Cycle Assessment (LCA) method, considering all stages from raw material sourcing to final production, all conducted locally to reduce CO2 emissions. This is part of RadiciGroup’s broader strategy to minimize ecological footprints, facilitated by their LEED Gold certified production plant equipped with a photovoltaic system.

Throughout Chinaplas 2024, RadiciGroup’s team will be available at their stand to discuss these innovations and explore new collaborative opportunities. A special event will also highlight the latest additions to their product portfolio, particularly focusing on Renycle® and sustainability initiatives, signaling RadiciGroup’s ongoing dedication to environmental responsibility and innovation in the industry.

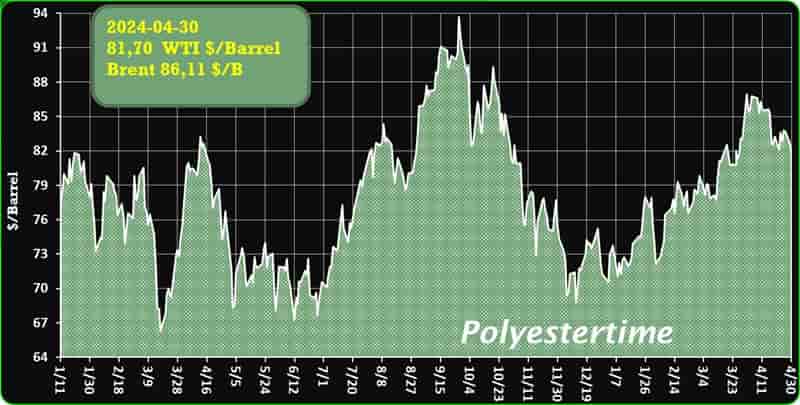

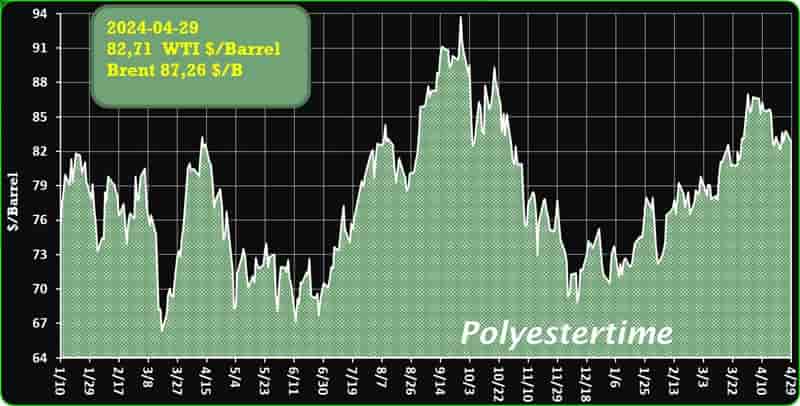

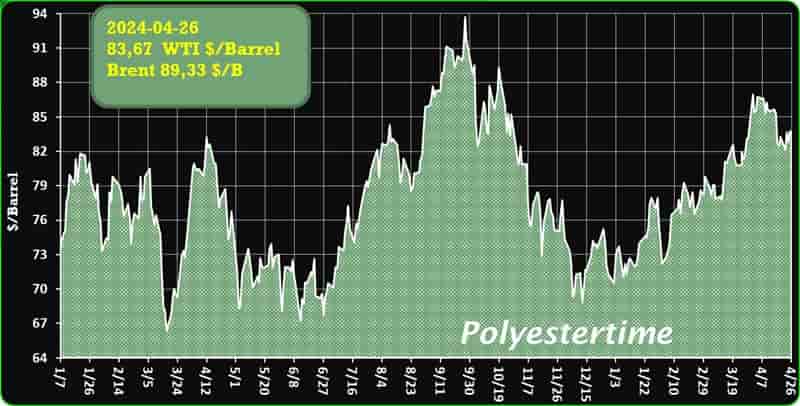

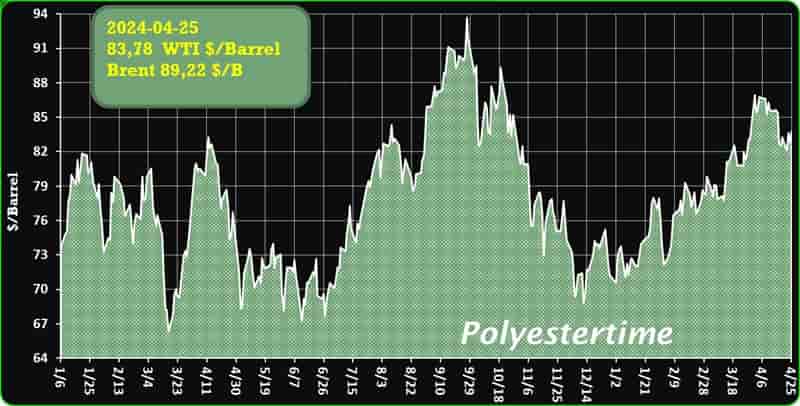

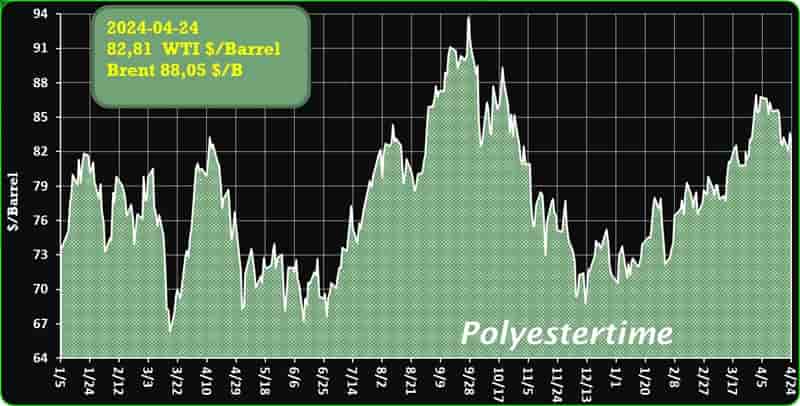

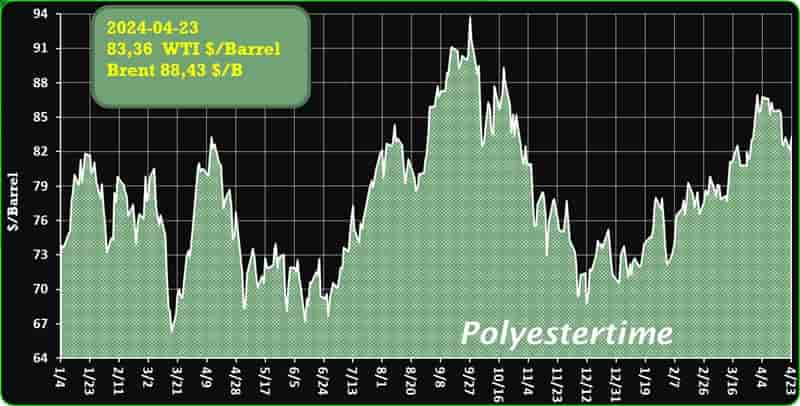

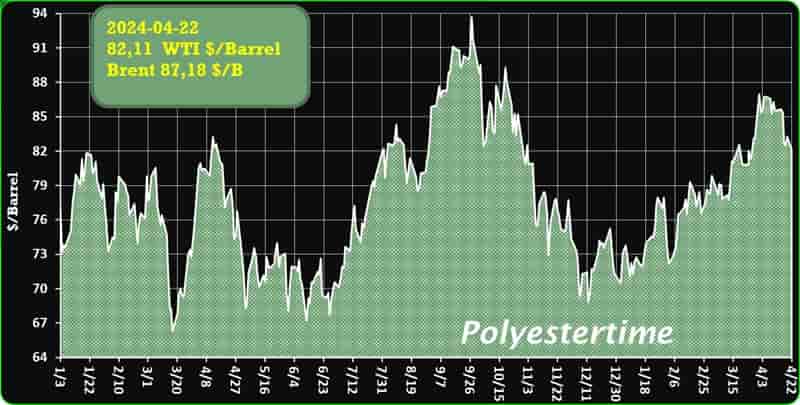

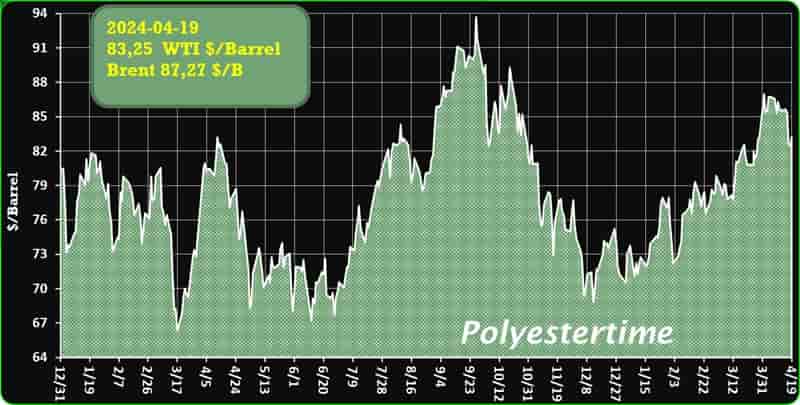

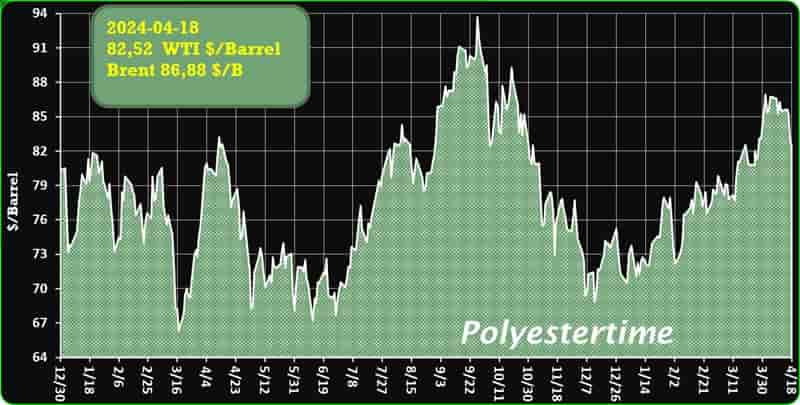

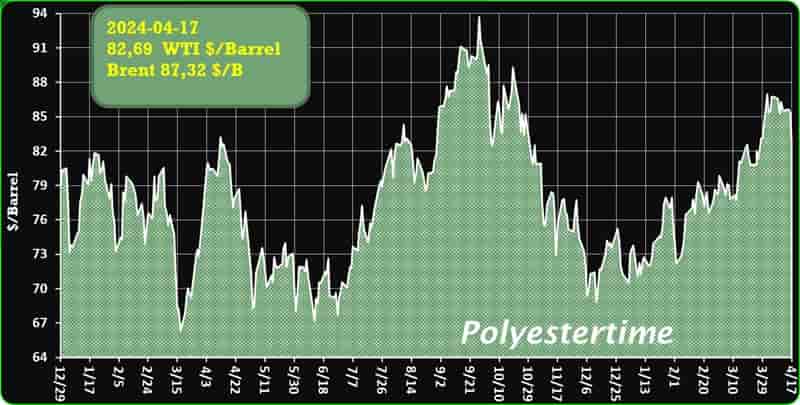

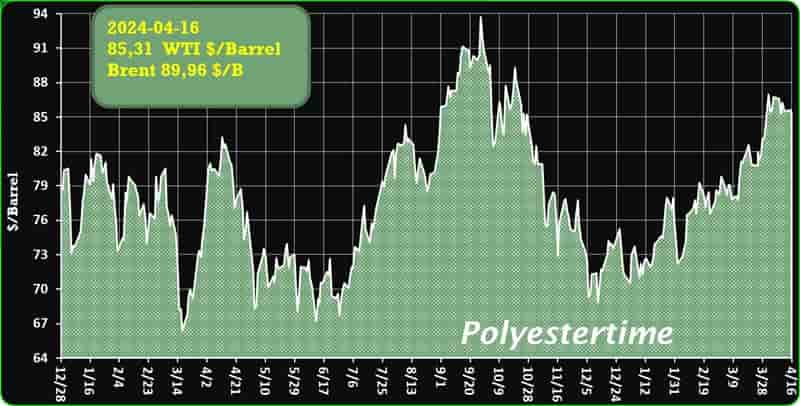

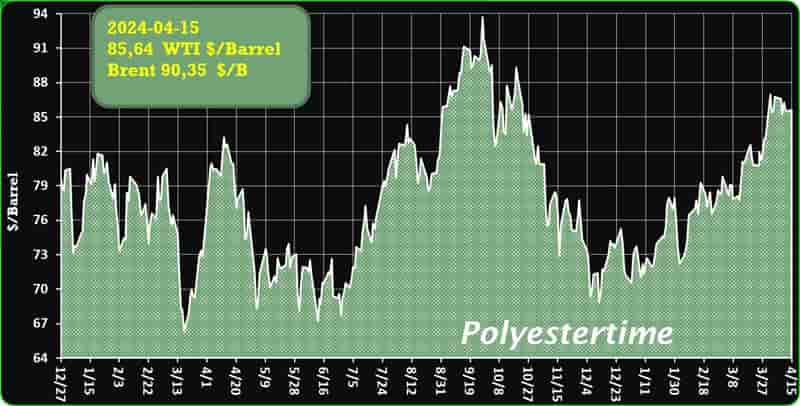

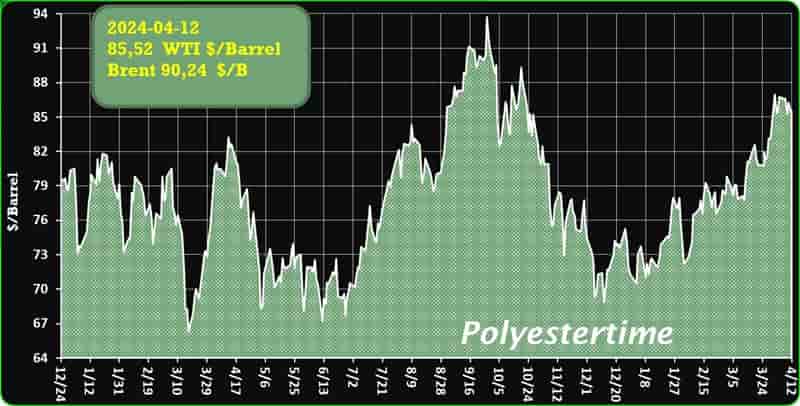

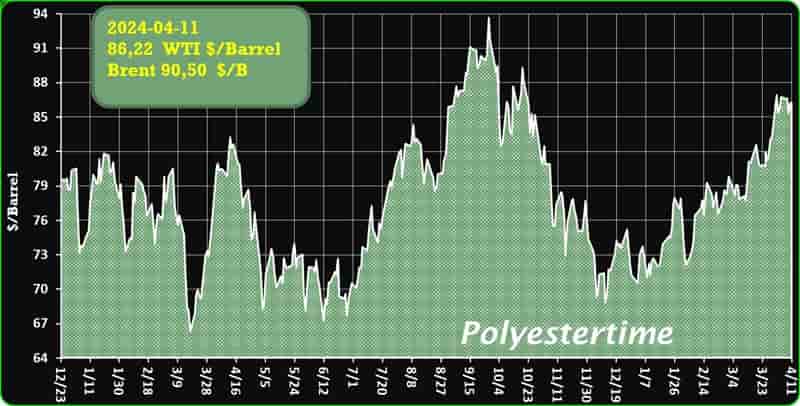

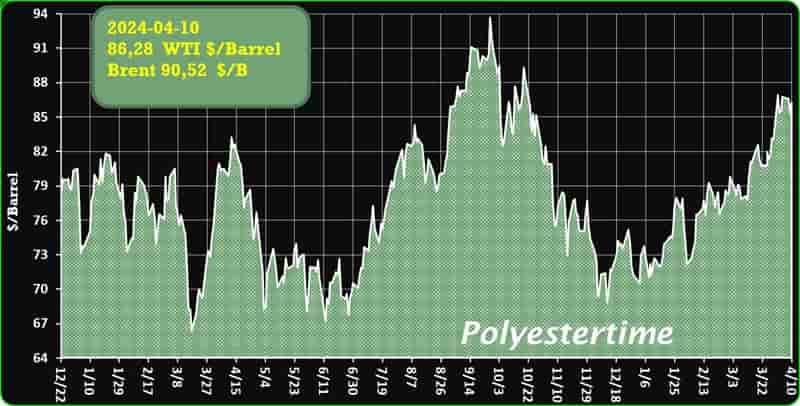

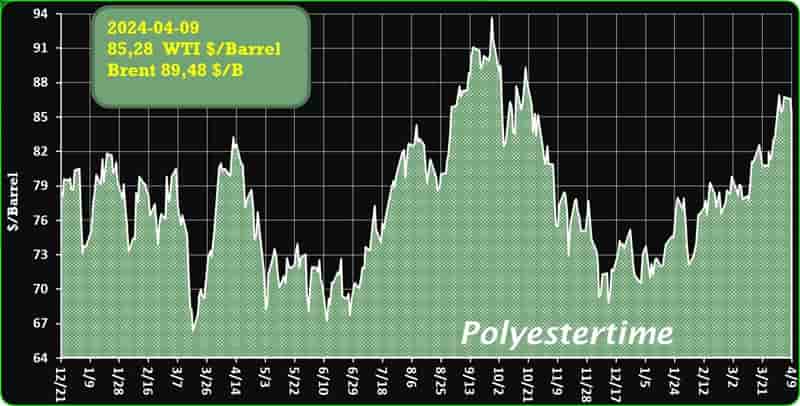

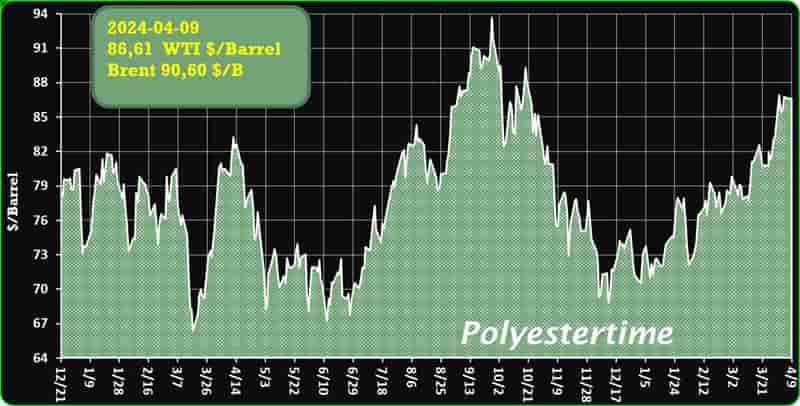

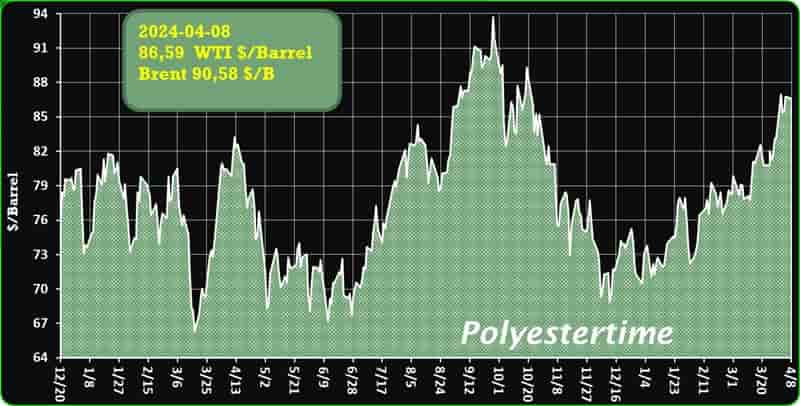

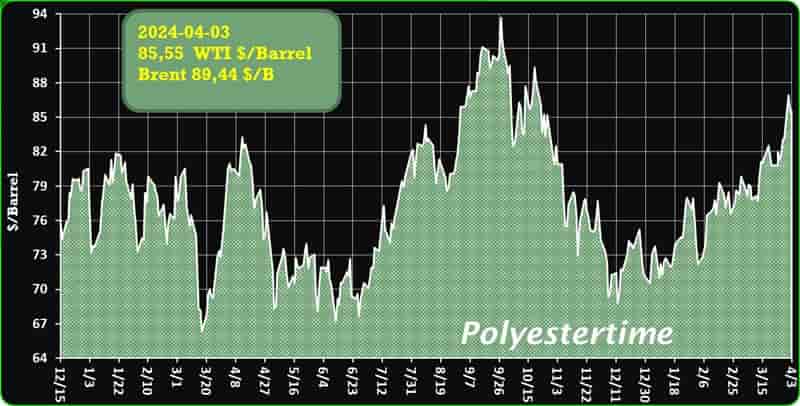

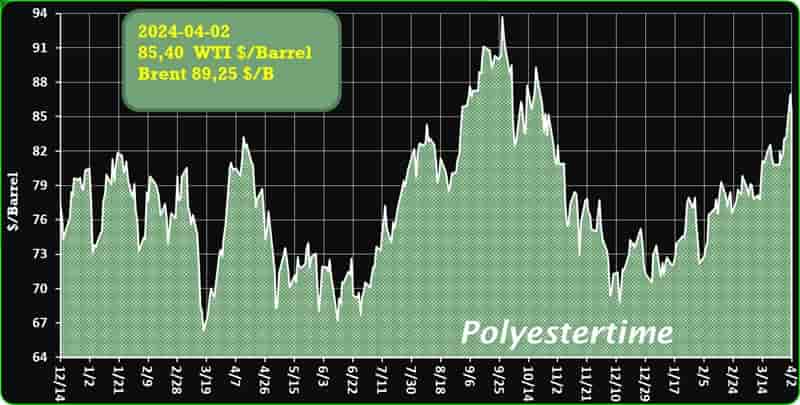

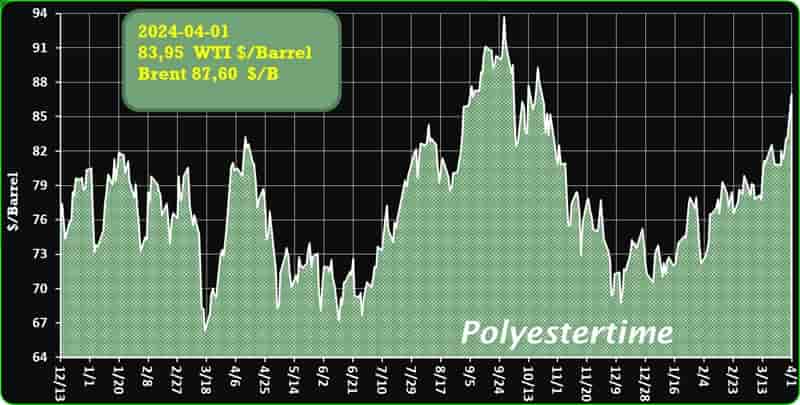

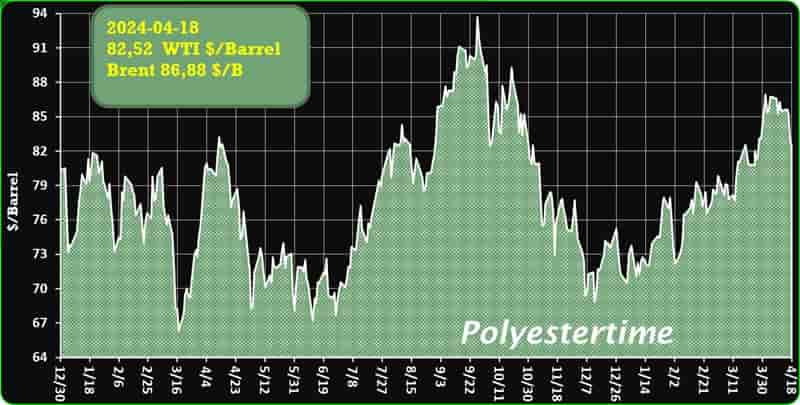

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

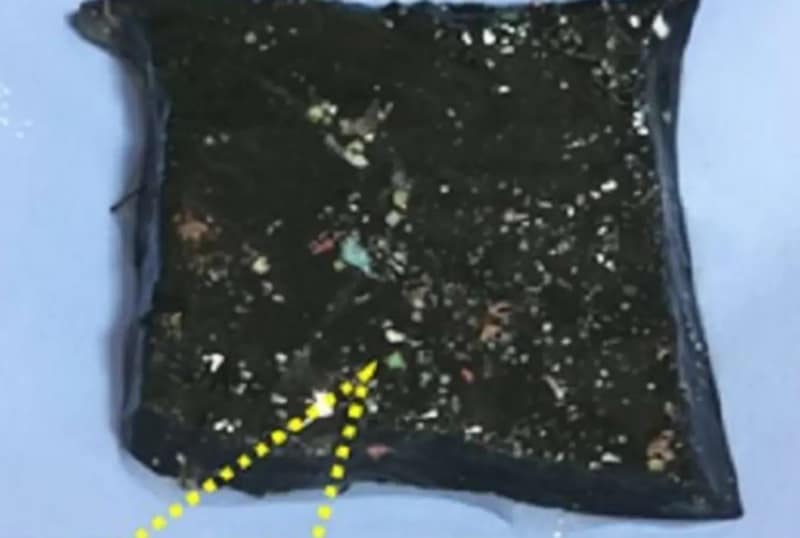

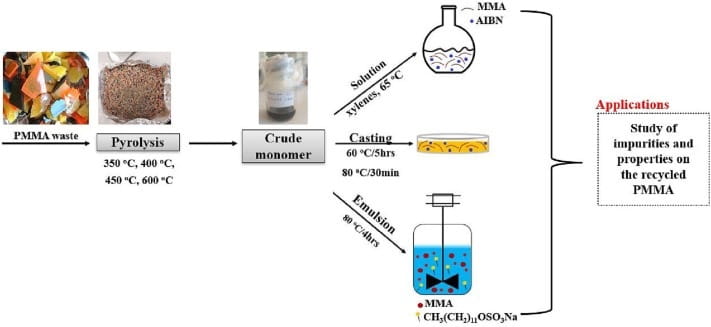

Sinopec recently inaugurated the world’s largest single-unit production capacity PTA project at its Yizheng Chemical Fiber Co., Ltd., located in Jiangsu Province

PTA, an essential intermediate and key raw material for PET resin, is integral to manufacturing plastic bottles, fibers, films, and packaging materials, thus playing a vital role in everyday life.

The new PTA facility stands out as one of the most complex in the petrochemical sector. Embracing advanced technologies, Sinopec has implemented short-process, intelligent manufacturing, and eco-friendly production methods, positioning itself as a leader in the industry. Bottle Tethered Cap

The plant has an impressive annual production capacity of 3 million tonnes.

This scale aims to meet the growing demands across various sectors, including apparel, food, housing, transportation, and environmental health, reflecting Sinopec’s commitment to innovation and sustainability.

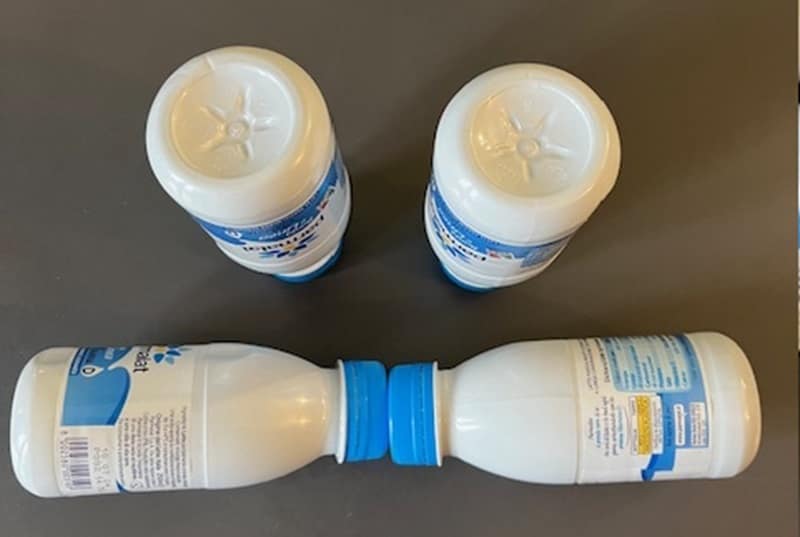

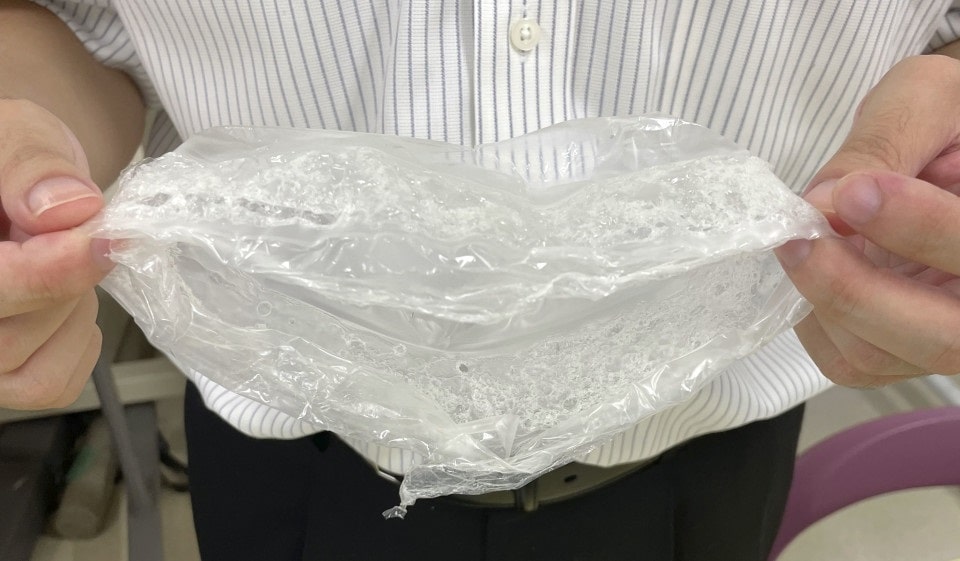

The conversion of Corvaglia Closures Eschlikon’s product line to 90% tethered caps is nearly complete, aligning with a 2019 EU directive mandating such designs for beverage bottles by July 3, 2024

Tethered closures, which remain attached to the bottle after opening, aim to reduce litter and environmental impact.

Based in Thurgau, Switzerland, Corvaglia has been at the forefront of designing and manufacturing these innovative caps, starting development before the directive was even announced.

As an early adopter in the European market, Corvaglia has established a strong presence in the tethered cap segment, attracting major brand owners with its effective solutions. The company’s Eschlikon facility has progressively shifted towards producing these caps, with over 80% of its output now complying with the EU requirements as of March 1, 2024. Approximately 10% of its production is destined for non-EU countries and remains untethered, while the balance is expected to transition by July. Bottle Tethered Cap

Corvaglia has a longstanding commitment to minimizing plastic waste, a principle embedded in its operations long before the tethered cap initiative.

The latest cap designs continue this tradition by cutting down on material use and energy consumption, thereby reducing CO2 emissions associated with beverage packaging.

This transition not only complies with regulatory demands but also underscores Corvaglia’s dedication to environmental sustainability. Bottle Tethered Cap

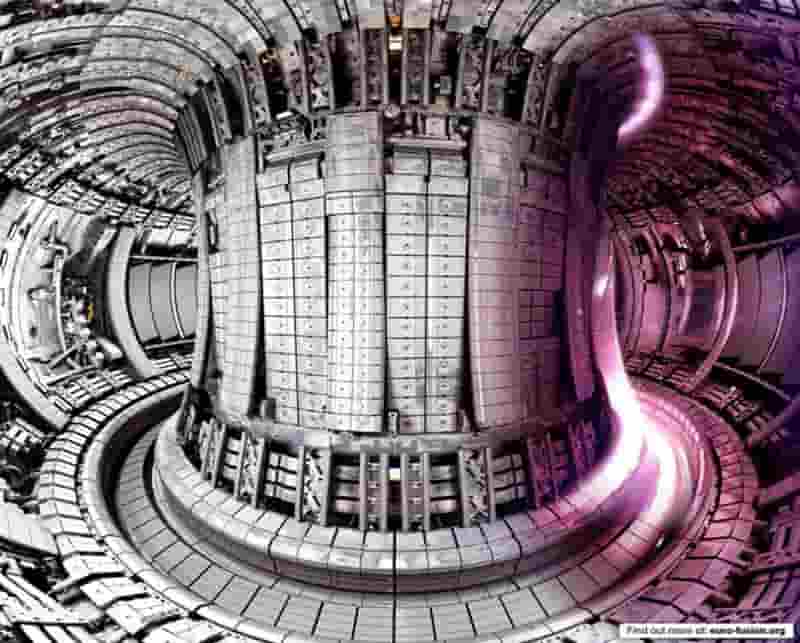

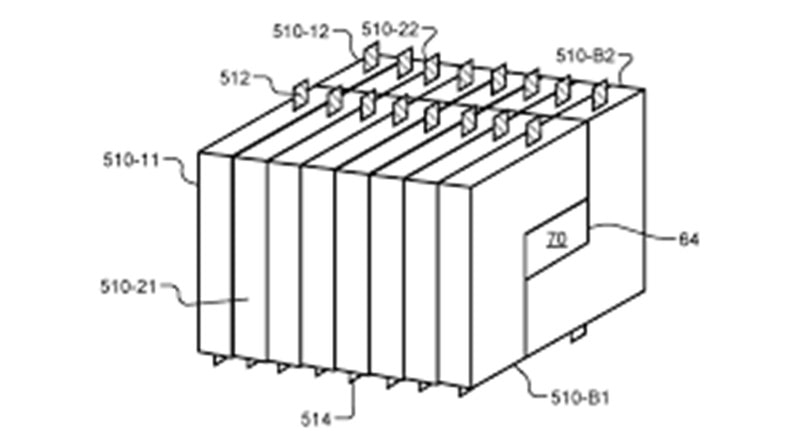

Avantium and TNO partner to manufacture electrolyser test stations for green hydrogen production

Avantium N.V., a leader in renewable and circular polymer materials, announced its partnership with The Netherlands Organisation for Applied Scientific Research (TNO) to manufacture Proton Exchange Membrane (PEM) electrolyser test stations, crucial for green hydrogen production. Bottle Tethered Cap

This collaboration grants Avantium access to TNO’s advanced technical knowledge and software for single-cell and multi-cell lab-scale electrolysis test stations.

Avantium will leverage this expertise to manufacture, develop, and globally distribute these test stations, enhancing its green hydrogen technology offerings.

Avantium R&D Solutions is known for its innovative R&D products and services in sustainable chemistry, particularly electrolysis for green hydrogen.

TNO, recognized for its research in energy, sustainability, and technology, has significantly advanced the efficiency and cost-effectiveness of electrolysis processes through ongoing development of PEM electrolysis test stations. Bottle Tethered Cap

Both organizations aim to advance these test stations further, combining Avantium’s innovative manufacturing and commercial strategies with TNO’s technical prowess. Richard Braal from TNO highlighted the partnership as a step towards intensified collaboration in accelerating the chemical industry’s energy transition.

KBR has entered into an exclusive alliance with GeoLith SAS to globally distribute GeoLith’s pioneering Direct Lithium Extraction (DLE) technology, Li-Capt®

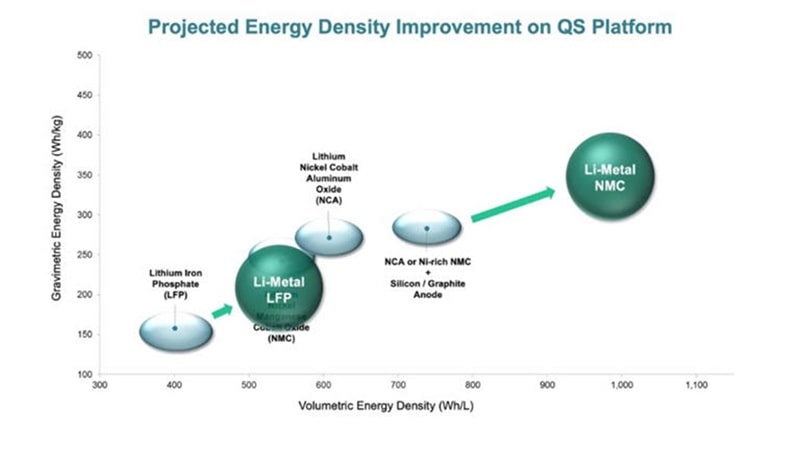

This innovative technology facilitates zero-emission lithium production from previously untapped sources such as geothermal and oil well brines. As the exclusive global licensor, KBR will integrate this technology with its battery material solutions, including the high purity lithium production technology, PureLiSM.

This collaboration will provide customers with comprehensive solutions to produce battery-grade lithium carbonate or lithium hydroxide monohydrate, crucial for advanced electric vehicle batteries. Bottle Tethered Cap

Jay Ibrahim, KBR President of Sustainable Technology Solutions, expressed enthusiasm about partnering with GeoLith to enhance lithium availability for the booming lithium-ion battery market, supporting the shift towards electrification and a net-zero carbon future. He highlighted KBR’s expertise in evaporation and crystallization technologies as vital for developing sustainable mobility.

Jean-Philippe Gibaud, CEO of GeoLith SAS, also emphasized the importance of robust partnerships in promoting electrification. He praised the Li-Capt® technology for its zero-emission process and exceptional efficiency and selectivity in lithium extraction.

KBR’s technical proficiency in mineral recovery and purification is built on over seventy years of experience in developing technologies that adhere to strict environmental standards. Bottle Tethered Cap

Germany’s Recycled Polypropylene Industry: A Model of Resilience

In the dynamic world of recycling, Germany’s recycled polypropylene industry stands as a testament to resilience and adaptability. Despite market volatility and logistical challenges, the industry has maintained a steady course, showcasing its robustness.

March 2024 began with an unexpected rise in recycled polypropylene prices, despite a decrease in the cost of propylene, its raw material. This anomaly was attributed to farmers’ protests, which disrupted trade routes and logistics. However, the industry’s response was swift and measured, with only minor price adjustments reflecting the market’s ability to navigate disruptions. Bottle Tethered Cap

As the month progressed, the market remained stable, thanks to a well-balanced supply and demand equation. The packaging sector, in particular, continued to receive ample supplies from full warehouses, underscoring the industry’s strong foundation.

Mid-March saw a surge in demand from the packaging and other industries, leading to a brisk trading pace and a slight uptick in prices.

This reflected the market’s sensitivity to the interplay between available supply and consumer needs. Bottle Tethered Cap

By the end of March, the market had achieved a stable stride, with demand from the packaging and textile sectors being met by increased production. This equilibrium ensured that companies dependent on recycled polypropylene could operate without interruptions.

Entering April, the market’s stability persisted, with prices remaining unchanged from March’s end. The price for recycled polypropylene natural pellets in Hamburg was USD 1760/MT as of April 12th, indicating a market that had weathered challenges and emerged stronger.

Germany’s recycled polypropylene market is a clear indicator of the industry’s capacity to withstand upheaval and swiftly adjust to its customers’ evolving demands.

The stable prices as April progresses underscore the resilience and efficiency of market participants1. Bottle Tethered Cap

Versalis, Eni’s chemical division, has successfully completed the acquisition of Tecnofilm S.p.A., securing full ownership following regulatory approval

Tecnofilm, a family-operated entity based in the Le Marche region, specializes in manufacturing functionalized polyolefins and thermoplastic compounds, which are primarily used in the footwear and technical goods industries. Established in 1972, Tecnofilm has diversified its offerings over the years, providing a variety of compounds and functional polymers for multiple industrial uses. The company’s commitment to innovation is evident in its continuous investment in research and development, leading to several patents. In 2015, Tecnofilm was recognized as an “Innovative SME” by the Italian Business Register, and in 2016, it joined ELITE, a Borsa Italiana platform aimed at supporting outstanding companies’ growth. Bottle Tethered Cap

Adriano Alfani, CEO of Versalis, stated that this acquisition enhances the company’s strategic focus on specialization within its business segments. By incorporating Tecnofilm, Versalis aims to broaden and refine its product portfolio by integrating additional processes in elastomer-based compounding, specifically targeting industrial applications and the footwear market. Alfani highlighted the synergy between Tecnofilm and Finproject, another company within Versalis’s portfolio, emphasizing the complementary nature of their operations in the compounding supply chain.

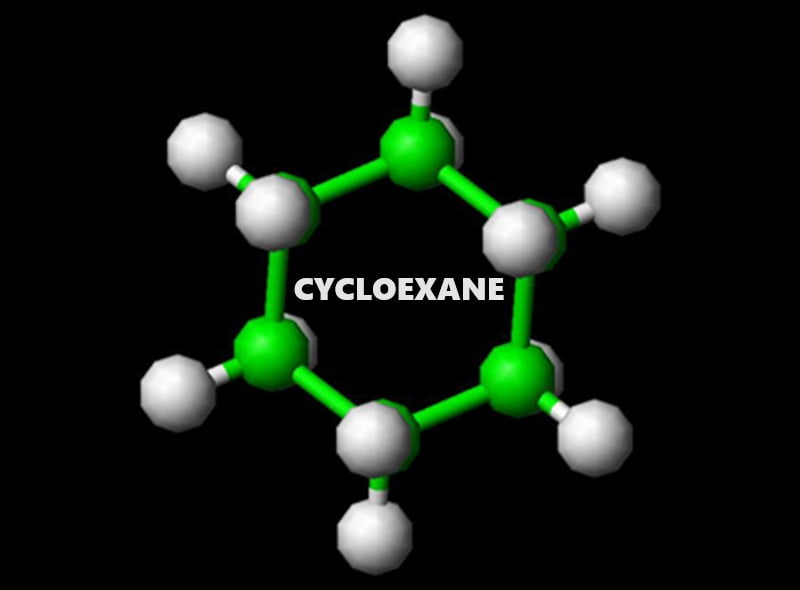

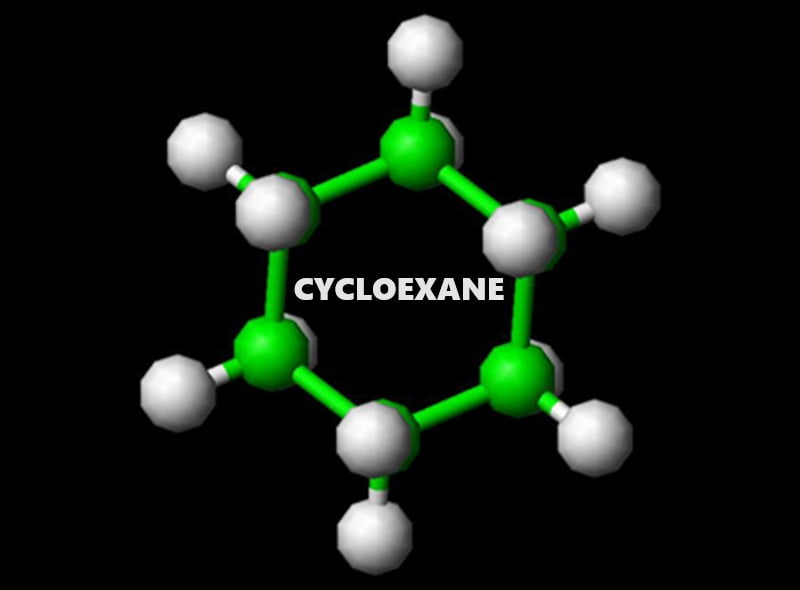

Cyclohexane Market Sees Price Surge Amidst Unfavorable Demand

In the first half of April 2024, the chemical industry observed a surprising trend: the price of Cyclohexane, a key solvent and intermediate in the production of nylon, increased by approximately 3%. Bottle Tethered Cap

This price hike comes at a time when production costs have escalated, yet demand from the downstream paints and coatings industry remains markedly low.

Industry experts attribute the rise in Cyclohexane prices to several factors. Primarily, the cost of benzene, a major feedstock for Cyclohexane, has seen an uptick due to tightened supply chains and increased crude oil prices. Additionally, operational costs have soared with energy prices reaching new heights, further compounding the financial pressure on Cyclohexane producers.

Contrastingly, the paints and coatings industry, which significantly relies on Cyclohexane, is experiencing a slump. Bottle Tethered Cap

The sector has been hit by a decrease in construction activities and a shift in consumer preferences towards eco-friendly alternatives. This has led to an inventory build-up, causing a mismatch between supply and demand dynamics.

The current situation poses a challenge for Cyclohexane manufacturers. They are caught in a bind between recovering increased production costs and maintaining competitive pricing to stimulate demand. Some producers are considering scaling back production to prevent further price inflation and balance the market. Bottle Tethered Cap

More…

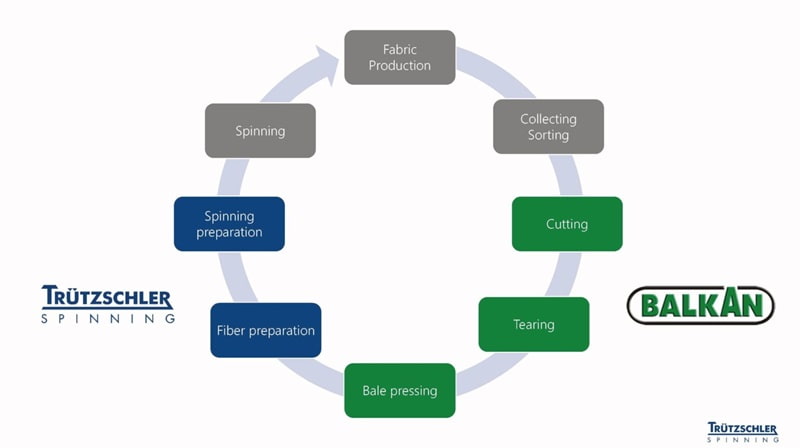

Textile-to-textile – In the latest Chemical Trends Report from CEFIC, the European Chemical Industry Council highlights that the EU chemical sector is grappling with greater impacts from the energy crisis compared to other regions 17-04-2024

Bottle Tethered Cap