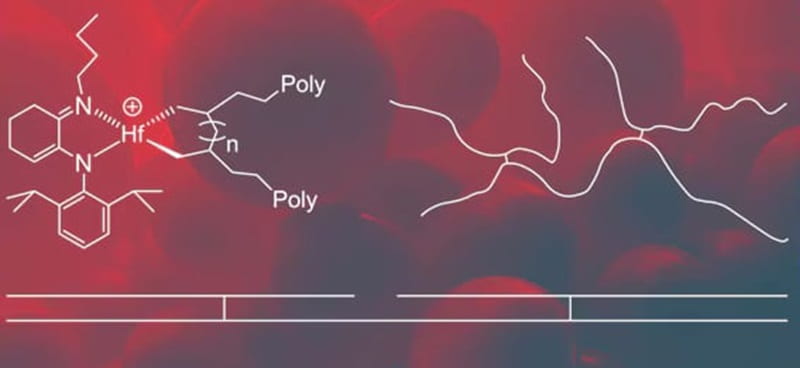

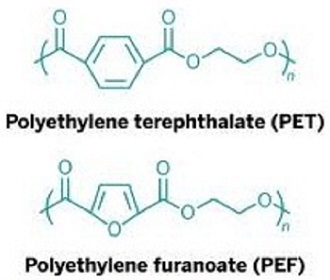

Bioplastics polylactic acid

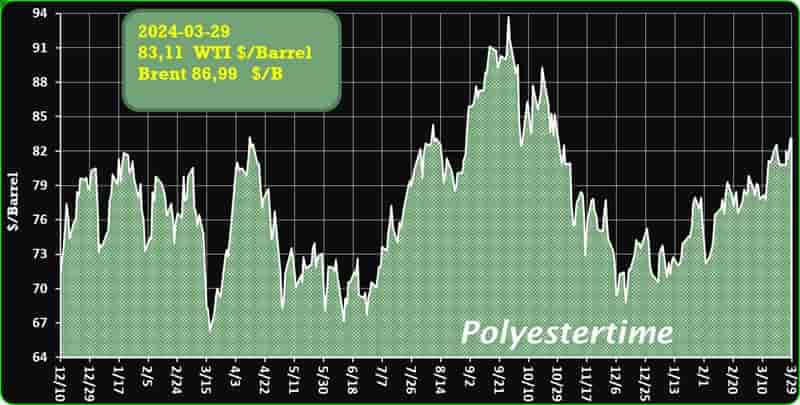

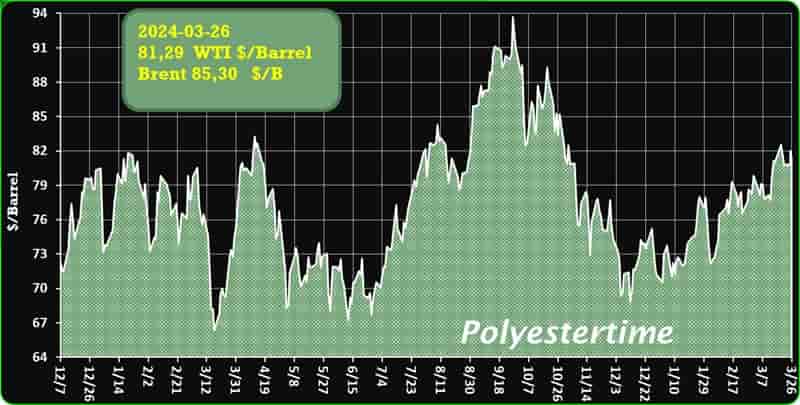

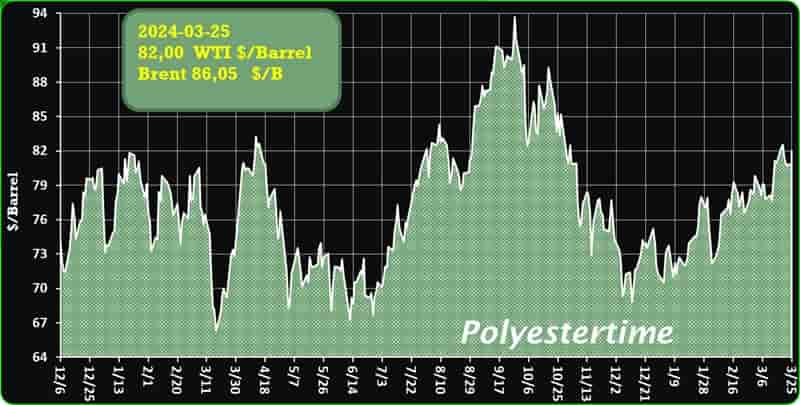

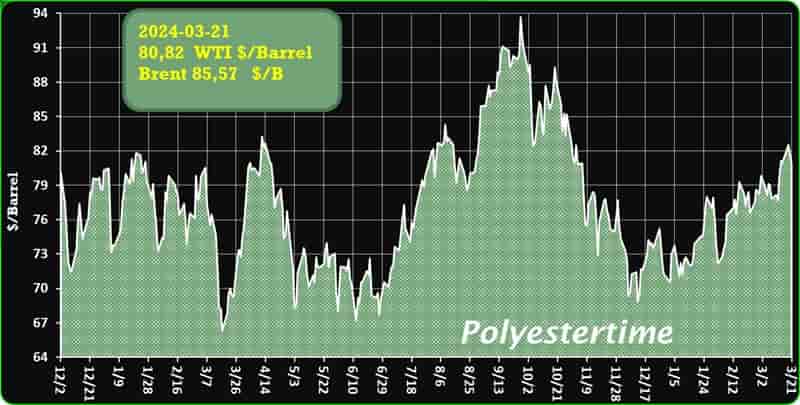

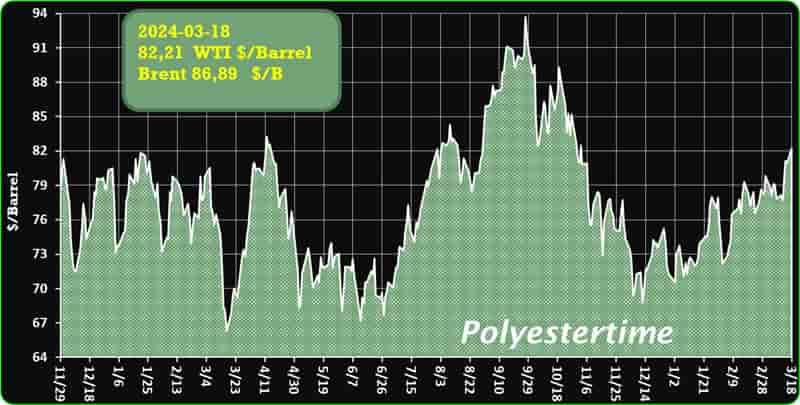

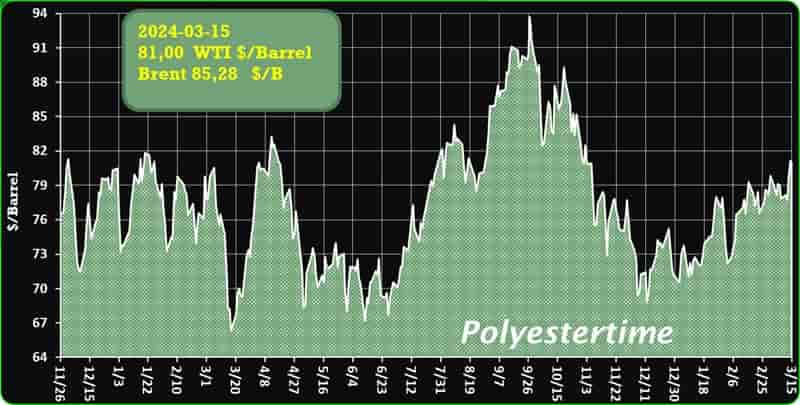

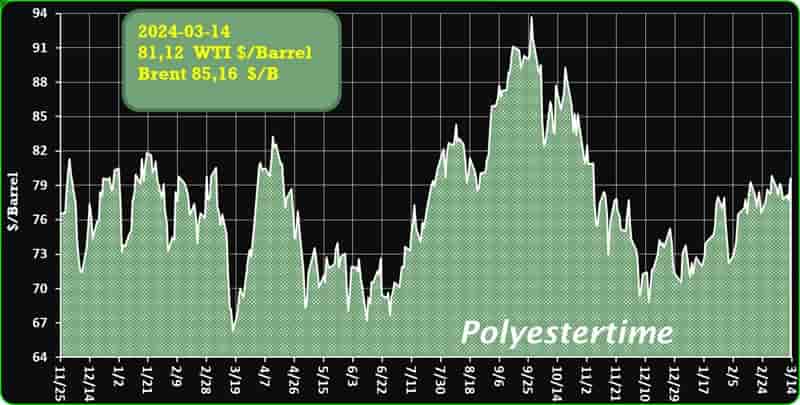

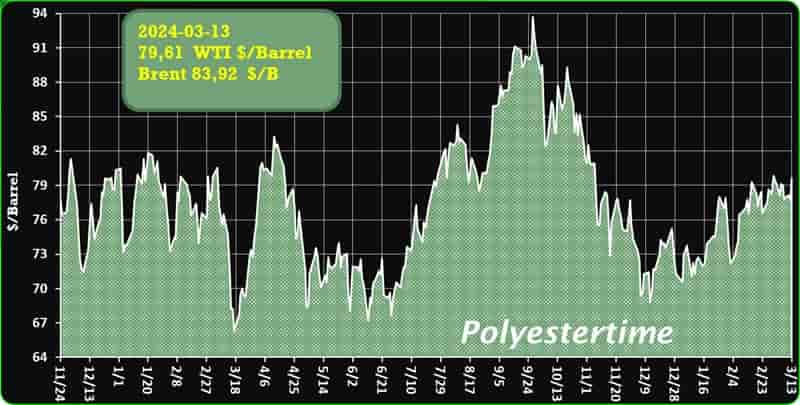

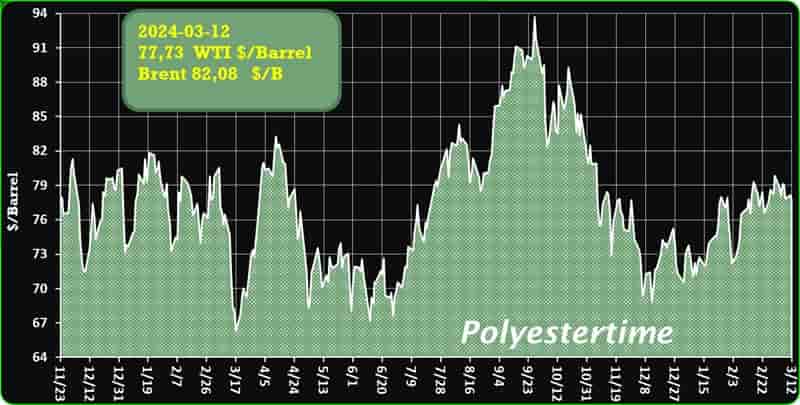

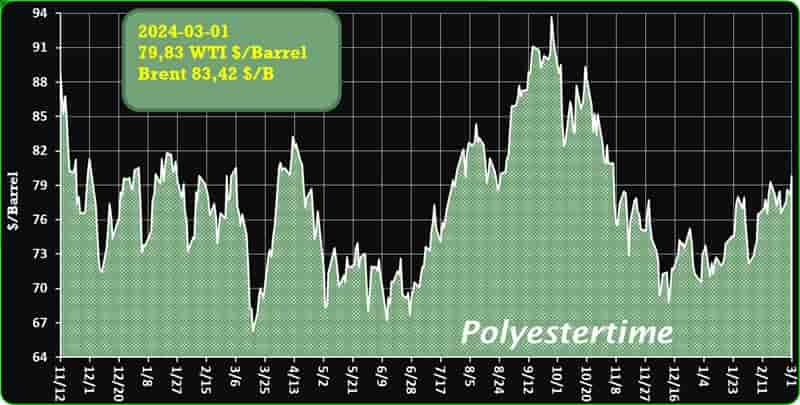

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

Sulzer supplying tech, gear to India’s debut bioplastics plant

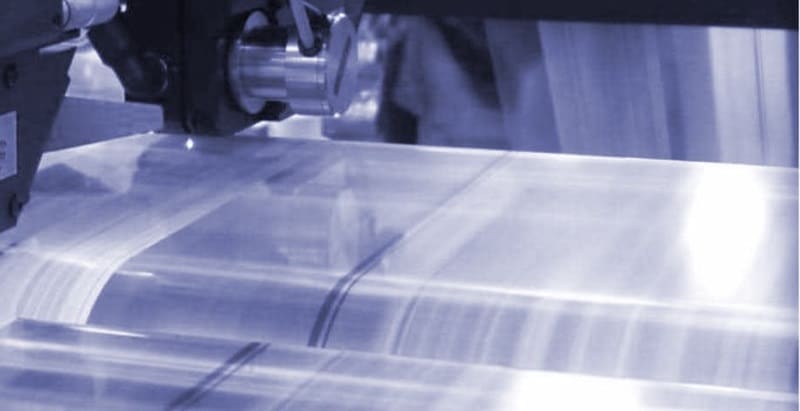

Sulzer Ltd., based in Winterthur, Switzerland, is set to provide cutting-edge polylactic acid (PLA) production technologies to Balrampur Chini Mills Limited (BCML) for India’s inaugural bioplastics facility. This state-of-the-art plant, situated adjacent to BCML’s sugar cane processing facility, aims to churn out 75,000 tons of compostable, entirely recyclable bioplastic annually, utilizing sugarcane as its primary feedstock. By leveraging the nation’s main agricultural crop, BCML seeks to significantly contribute to India’s sustainability goals.

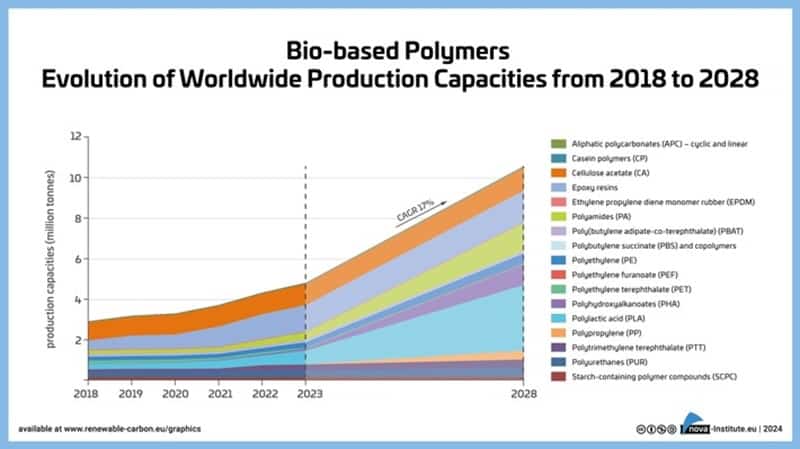

With single-use plastic pollution escalating globally, bioplastics adoption, especially in packaging, is being championed by many nations. Polylactic acid, a bio-based, compostable polymer derived from renewable sources like sugar cane, offers a promising solution. Bioplastics polylactic acid

Sulzer has meticulously developed and optimized the requisite technologies to facilitate this production process, meeting the escalating demand for sustainable products economically.

As a prominent player in India’s sugar industry, BCML boasts a crushing capacity of 80,000 tons per day across ten plants, underlining its commitment to sustainability. Notably, they’re already India’s top bioethanol producer and utilize sugar mill waste for power generation. Introducing bioplastic manufacturing aligns with BCML’s journey towards Net Zero, bolstering their resource efficiency and environmental stewardship.

Sulzer’s pivotal role in realizing this venture involves delivering manufacturing technologies for key process stages such as lactide synthesis, purification, and polymerization. Bioplastics polylactic acid

Renowned globally for supplying essential equipment in bioplastics production, Sulzer’s expertise permeates numerous PLA plants worldwide. Post-completion, their field service experts will provide support during commissioning and start-up procedures, ensuring seamless operations.

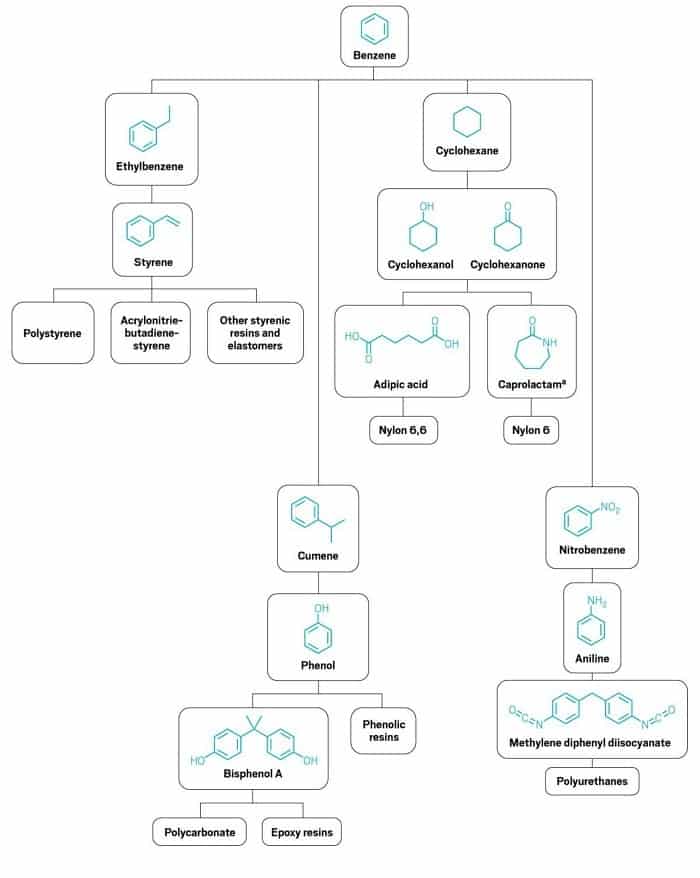

Cyclohexane Prices Decline in Feb 2024, Takes Support from Feedstock and Low Demand

The Dutch market saw prices of Cyclohexane marginally depreciate by approximately 2% during the middle of the first quarter of 2024, despite prices of feedstock Benzene witnessing a surge of approximately 14% during the same timeframe.

The prime reason for the depreciation in the prices of Cyclohexane is largely attributed to the reluctance amongst residential investors and declined demand for office spaces as bankruptcies increase amongst construction firms. Bioplastics polylactic acid

With capital market interest rates on the rise, investment confidence in commercial real estate continued to remain low, which consequently led to the cancellation of construction projects. Thereby having a detrimental impact on the demand for Cyclohexane, as demand from the downstream paints and coating industries subdued.

Investment volume in the real estate market fell by 53% in 2024 with further depreciations anticipated towards the end of 2024 and institutional volume (consisting of pension funds and insurers) fell by 70% in 2023 with depreciations likely expected towards the termination of 2024. Bioplastics polylactic acid

Despite positive effects seen across the Dutch construction sector so far, as evidenced by the stabilization of property prices, the outlook remains largely uncertain.

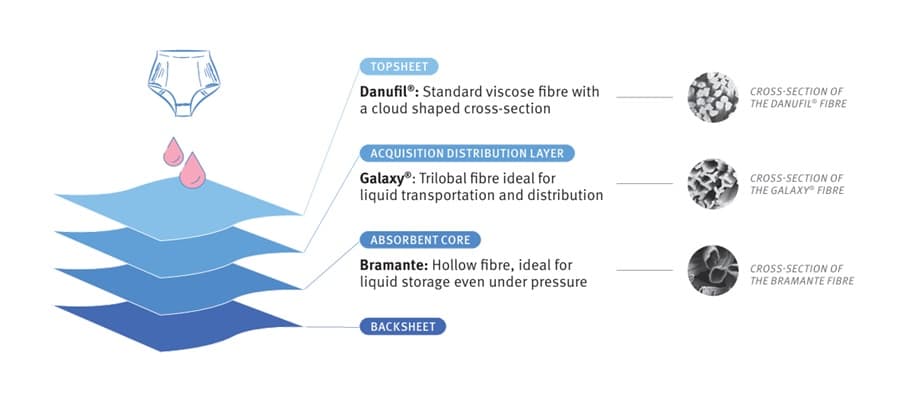

Lenzing faced a challenging year in 2023, grappling with subdued demand and escalating raw material and energy costs

Despite maintaining a relatively stable revenue of €2.52 billion, compared to €2.57 billion in 2022, the company suffered an overall loss of –€593 million, a significant downturn from –€37.2 million the previous year. CEO Stephan Sielaff expressed disappointment at the lack of market recovery and emphasized the importance of resilience-building measures.

To counter these challenges, Lenzing implemented a performance improvement program expected to yield €100 million in annual savings, with half of the benefits realized in 2023. Capital expenditure in 2023 amounted to €283.6 million, following a substantial €698.9 million in 2022, primarily focused on enhancing production capabilities and reducing emissions in facilities like Nanjing, China, and Purwakarta, Indonesia. Bioplastics polylactic acid

Despite the setbacks, Lenzing maintained its commitment to sustainability, earning recognition from rating agencies like CDP and EcoVadis. Looking ahead, while the International Monetary Fund (IMF) revised its 2024 growth forecast to 3.1%, global economic risks persist, including geopolitical tensions, inflation, and market volatility, notably in the Chinese real estate sector.

Consumer sentiment remains subdued due to inflation and stagnant incomes, impacting the clothing market crucial to Lenzing. Nonetheless, the company anticipates improved earnings in 2024, banking on gradual market normalization and continued strategic initiatives. Bioplastics polylactic acid

European Benzene Prices Pulled up by the Increased Production Cost

Hamburg (Germany): Benzene prices in the European market remained unchanged from the previous week following a series of significant increases.

The previous weeks saw a sharp rise in prices due to increased demand from industries using styrene, phenol, and other solvents, as well as rising production costs domestically. The surge in demand for aromatics and styrene affected Benzene prices, with manufacturers having to maintain higher prices to balance supply and demand and cover production costs. Bioplastics polylactic acid

The price quotations of Benzene in the European market were observed at USD 1,230 per MT, FOB Hamburg, for the week ending March 8th, 2024.

The Manufacturing PMI increased slightly to 42.5 in February 2024 from the initial estimate of 42.3, indicating a contraction in the manufacturing sector.

Production declined, and new orders decreased at a faster rate due to lower domestic and international sales, resulting in fewer backlogs and job cuts. Bioplastics polylactic acid

The Port of Hamburg is resilient in the face of potential supply chain disruptions caused by an upcoming strike by the German Union of Locomotive Drivers (GDL).

A study by the German Federal Logistics and Mobility Office (BALM) showed positive trends in container transport by water and rail, with an increased share of rail freight.

More…

Biocircular Data Center, the first project in the world starts in France

France heralds the initiation of the world’s pioneering Biocircular Data Center project through a collaboration between Data4, a prominent European data center operator and investor, and the University of Paris-Saclay. Set into motion in early 2024, this groundbreaking endeavor aspires to craft the globe’s premier biocircular data center.

Convening a diverse, interdisciplinary team, the project endeavors to erect a prototype capable of repurposing the heat generated by data center infrastructures. This recycled heat aims to benefit local communities and adjacent industrial sectors. Bioplastics polylactic acid

Spearheaded by experts from institutions like Centrale-Supélec, AgroParisTech, Inrae, and the ICMMO Laboratory of the University of Paris-Saclay, along with private entities such as Blue Planet Ecosystems, the endeavor unfolds at Data4’s Marcoussis campus near Paris.

The project’s agenda encompasses research, development, and testing of innovative solutions to harness and repurpose data center heat. By leveraging natural processes like photosynthesis, the aim is to capture CO2 emissions effectively.

Algae cultivation emerges as a potent tool, boasting a carbon capture capacity 20 times greater than trees, ultimately yielding sustainable energy sources such as biofuels and biogas. Bioplastics polylactic acid

Patrick Duvaut, vice-president of the University of Paris-Saclay, underscores the efficacy of this carbon capture method, which surpasses traditional tree-based approaches. Linda Lescuyer, Innovation Director of Data4, highlights the project’s dual focus on promoting healthier food practices and facilitating the energy transition. The partnership with the University of Paris-Saclay reflects a shared commitment to foster a circular energy economy, propelled by cutting-edge scientific research.

Plastic chemicals are more numerable and less regulated than previously thought

A recent report by PlastChem reveals that less than 6% of over 16,000 chemicals associated with plastic production are regulated globally, highlighting a significant regulatory gap. PlastChem, a project funded by the Norwegian Research Council, aims to address potential harm from plastics and polymers. The report underscores the proliferation of hazardous compounds from plastic production, use, and waste, with inadequate regulatory measures to safeguard against them.

Houston, Texas, known as the “Energy Capital of the World,” with over 600 oil and gas facilities, is particularly implicated. These facilities contribute to plastic production, compounding the issue of chemical exposure. Bioplastics polylactic acid

Key findings of the report include:

- Identification of 16,325 chemicals related to plastic production.

- Only 6,276 chemicals have publicly available data, with less than 6% being regulated.

- Chemicals categorized into hazardous, less hazardous, watch list, and not hazardous groups.

- Concerns raised about the health impacts of plastic-related chemical exposure, with substantial healthcare costs attributed to plastics.

PlastChem advocates for increased transparency in disclosing chemicals by industry and government, targeted regulations focusing on specific chemical groups, and integration of research findings into global policies like the UN Global Plastics Treaty draft.

While the American Chemistry Council acknowledges the need for greater transparency, they raise concerns about the report’s methodology. However, experts like Karen Reubenheimer emphasize the importance of clear data to address the unseen pollution caused by unregulated chemicals. Bioplastics polylactic acid

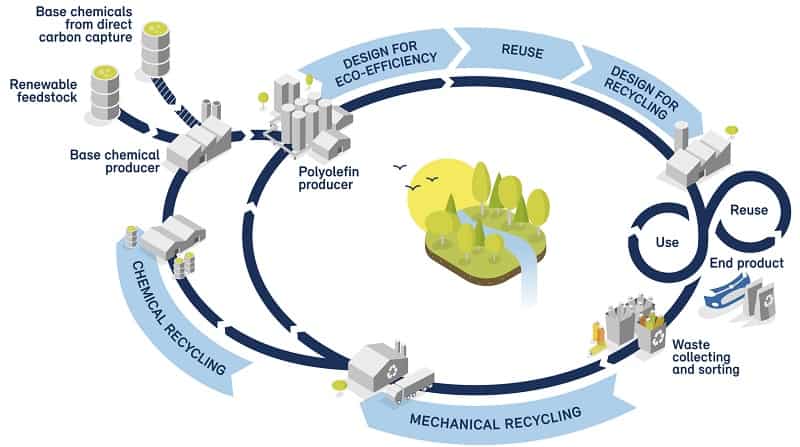

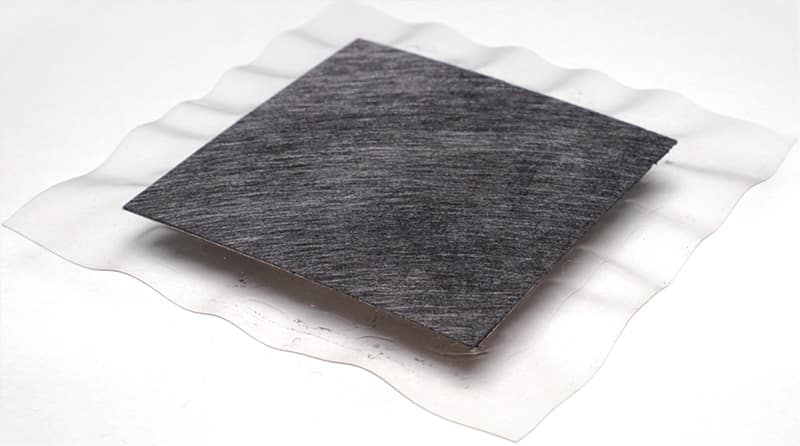

Shell Chemicals and Braskem have collaborated to introduce certified bio-attributed and bio-circular propylene and polypropylene to the U.S. market

This initiative responds to the increasing consumer demand for sustainable plastics. Braskem, a leader in bio-based materials, will leverage these feedstocks to manufacture bio-attributed and bio-circular polypropylene. This move targets various sectors such as packaging, film, automotive, and consumer goods, offering more eco-friendly options.

Mark Nikolich, Vice President of Olefins and Polyolefins at Braskem North America, emphasized their commitment to sustainable solutions, highlighting the significance of partnerships with forward-thinking suppliers like Shell. Shell, in turn, is proud to contribute to the supply chain of everyday products through bio-attributed and bio-circular feedstocks, aligning with their strategy to lower emissions and achieve net-zero status by 2050. Bioplastics polylactic acid

Their collaboration in Europe further underscores Braskem’s dedication to carbon neutrality and circular economy goals. Meanwhile, Shell has set ambitious emission reduction targets, aiming for a 50% decrease by 2030 compared to 2016 levels.

The introduction of mass balance, independently verified by a third-party certification body, allows the attribution of bio-circular and bio-attributed content to specific end products. This accounting process, widely adopted across industries, facilitates the integration of traditional and novel feedstocks, supporting the transition towards a more sustainable plastics industry. Bioplastics polylactic acid

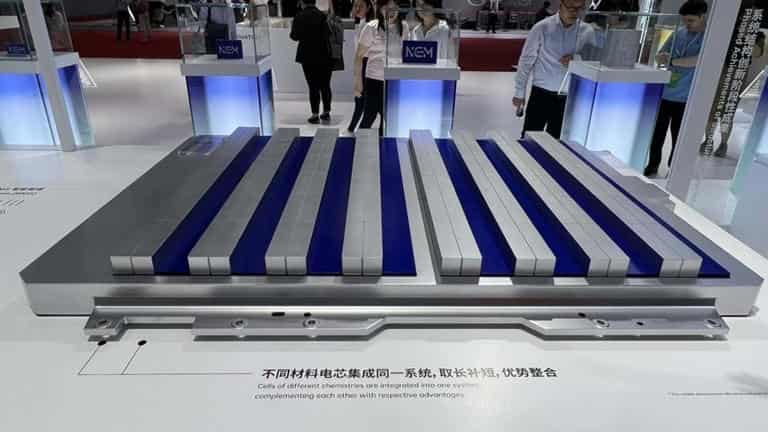

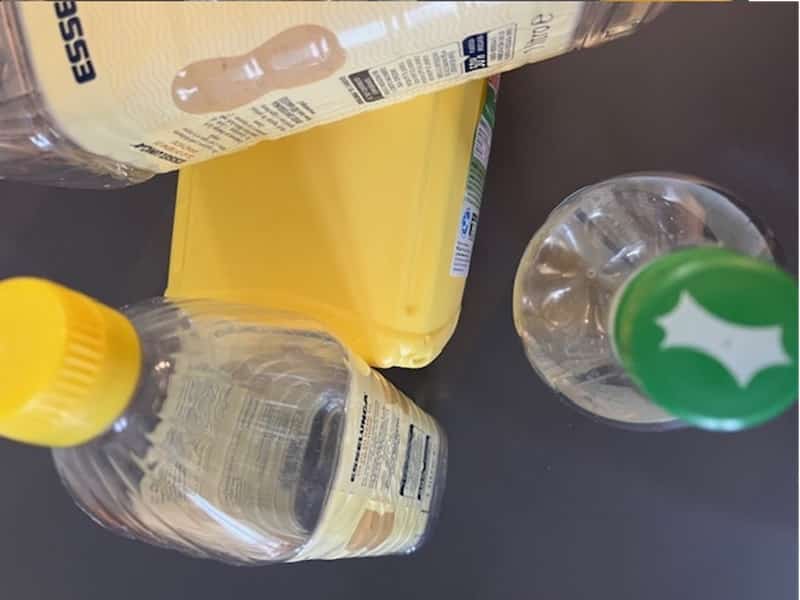

Bottle waste recycling – Battery costs have plummeted, with Goldman Sachs foreseeing a corresponding drop in electric car prices 18-03-2024

Bioplastics polylactic acid