Electric cars – Introducing Winter Proof: the solution to the cold weather dilemma faced by electric car batteries 12-04-2024

Electric cars

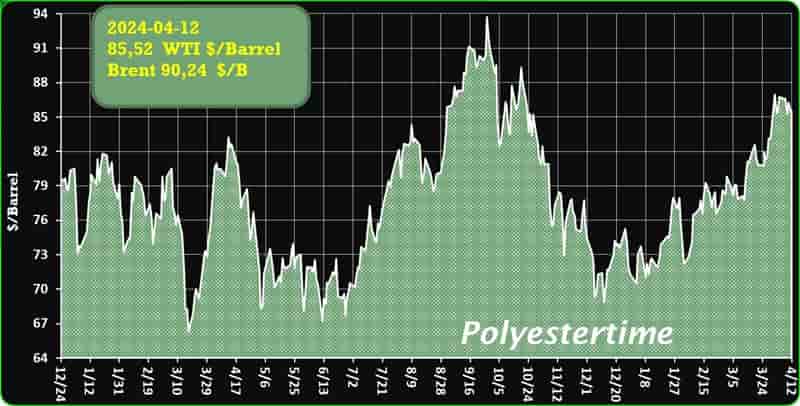

Crude Oil Prices Tren

Crude Oil Prices Trend by Polyestertime

Borealis invests €4.5M in Porvoo cracker to increase production of circular materials

Borealis is injecting a hefty €4.5 million into enhancing the cracker furnaces at its olefins unit in Porvoo, Finland, aiming to ramp up production of Base Chemicals (ethylene and propylene) using more renewable and recycled materials.

This move aligns with Borealis Strategy 2030, advancing towards a circular economy. The investment, set for completion by 2025, follows a similar upgrade last year at the Stenungsund facility in Sweden. Electric cars

Porvoo’s steam cracker, with an annual capacity of 430 kilotons of ethylene and 263 kilotons of propylene, is central to a petrochemical complex, cracking feedstock like naphtha and propane into smaller molecules. The investment focuses on modifying three out of ten cracker furnaces, increasing annual production by 120 kilotons from renewable and recycled sources, certified by ISCC Plus for sustainability.

Wolfram Krenn, Borealis Executive Vice President Operations and Base Chemicals, emphasizes the investment’s role in driving sustainability and circularity.

Borealis, a leader in polyolefin solutions, caters to various industries globally, boasting 6,000 employees and a €216 million net profit in 2023.

OMV, based in Vienna, owns 75% of Borealis, with the remaining 25% held by the Abu Dhabi National Oil Company. Electric cars

Klöckner Pentaplast launches 100% recycled PET trays

Klöckner Pentaplast debuts 100% recycled PET trays, offering businesses a cost-effective solution amidst eco-tax and plastic legislation challenges.

Representing a milestone in food packaging, the Luxembourg-based company introduces trays crafted entirely from post-consumer tray-derived recycled PET (rPET).

While current trays integrate reclaimed PET, Klöckner Pentaplast’s Tray2Tray initiative elevates sustainability by exclusively using recycled tray material for new tray production. Thomas Kure Jakobsen, kp’s food packaging president, hails this innovation as a testament to their pioneering spirit and technological prowess. Electric cars

He emphasizes the significance of blending expertise with technology to achieve such milestones.

Presently, a mere 30% of recycled PET serves food tray production, with a considerable portion lost in the linear system, resulting in the wastage of valuable rPET material annually.

Klöckner Pentaplast’s 100% rPET trays signal a transformative shift in the packaging landscape, showcasing the potential unleashed through innovation and sustainable practices. Electric cars

Veolia has announced it has successfully commissioned a recycled PET plant in Tsuyama, Japan

This innovative facility, a joint venture between Veolia, Mitsui & Co., Ltd., and Seven & i Holdings Co., Ltd., represents a significant leap forward in the global movement towards a circular economy.

Commissioned by Veolia, a French multinational with a legacy in waste management, the plant is poised to transform the landscape of PET (polyethylene terephthalate) recycling. With an annual production capacity of 25,000 tonnes of food-grade recycled PET resin, the Tsuyama plant is not just a marvel of modern recycling technology; it’s a testament to the collaborative spirit of international sustainability efforts. Electric car

The ‘Circular PET’ plant stands on the premise of recycling low-grade used PET bottles, which account for over half of Japan’s PET bottle waste volume. These are the bottles often discarded with caps, labels, or residual liquids still intact. The facility’s cutting-edge processes will convert these bottles into high-quality, food-grade resin, suitable for creating new PET bottles.

This initiative is not only a triumph for environmental stewardship but also for economic pragmatism. By recycling PET, the plant will reduce CO2 emissions by an estimated 27,500 tons annually compared to virgin production. This is equivalent to taking thousands of cars off the road each year, a milestone in the fight against climate change.

The strategic location of Tsuyama, in Okayama Prefecture, was chosen for its proximity to sources of post-consumer PET bottles and its accessibility to major markets where the recycled resin will be sold. The plant’s operation aligns with Japan’s ambitious goals to reduce plastic waste and increase recycling rates, serving as a model for other nations to follow. Electric car

Introducing Winter Proof: the solution to the cold weather dilemma faced by electric car batteries

SK On and Samsung are leading the charge in this field, aiming to revolutionize the market with advanced, cold-resistant models in the coming years.

Efficiency is key – these Korean companies are pushing boundaries to ensure batteries maintain peak performance even in freezing temperatures. Winter Proof batteries are designed to defy the challenges of cold weather, ensuring consistent efficiency during the toughest months.Electric cars

Renowned globally, SK On supplies batteries to industry giants like Volkswagen Ford Group and Hyundai, while Samsung is gearing up for solid-state battery production by 2027. The need for improved performance is evident; traditional lithium-iron-phosphate batteries can lose up to 70% of their range in sub-zero conditions.

The new Winter Proof models boast a 16% increase in charging capacity and a 19% energy boost, with rapid charging capabilities. Samsung’s solid-state battery, expected in 2027, promises even faster charging, greater energy retention, and compact size.

With plans to achieve 80% battery recharge in just 15 minutes by 2026 and a 20-year lifespan by 2029, the industry is driving towards a future dominated by electric vehicles. While challenges persist, investments in alternative battery technologies signal a promising shift away from traditional fuel reliance. Electric cars

The transition to electric vehicles is complex, but advancements like Winter Proof and solid-state batteries represent significant steps towards a sustainable automotive future.

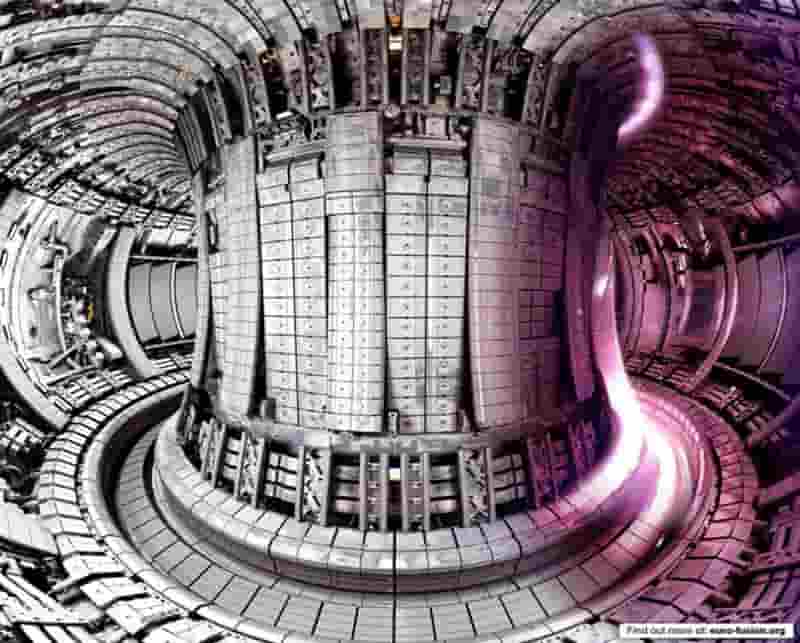

In the early 2030s, Eni is set to pioneer the first industrial-scale fusion nuclear power plant

This announcement was made by Francesca Ferrazza, who leads Eni’s fusion group, during a Senate Environment Committee hearing.

Eni is a key player in the Commonwealth Fusion System (CFS) project, a United States initiative born from MIT’s spinoff, which utilizes magnetic confinement for fusion.

The Italian energy company is contributing to the construction of the inaugural Cfs-Sparc pilot plant, anticipated to be operational by the mid-2020s. Electric cars

Following this, the Cfs-Arc, Eni’s first industrial plant to be integrated into the power grid, is scheduled for the early 2030s.

The company also has plans to establish additional power plants later in the decade.

BMW has struck a significant deal with Rimac Technology to advance battery technology for its future electric vehicles post-2025

This collaboration marks a substantial milestone for both companies, with Mate Rimac, founder of Rimac Technology, describing it as their largest and most ambitious project to date.

While specific details of the partnership remain undisclosed, the focus will be on co-developing and co-producing innovative high-voltage battery solutions for BMW’s upcoming electric models. Mate Rimac has hinted at their prior involvement with BMW, noting that Rimac has been developing battery systems for the German company for the past two years. Electric cars

The agreement signals Rimac’s evolution from a niche supplier to a key player in high-volume manufacturing for the automotive industry. Notably, a significant portion of Rimac’s Croatian campus is now dedicated to producing batteries exclusively for BMW.

However, the implications of this partnership on BMW’s existing battery supply framework remain uncertain. It’s unclear whether Rimac will refine the chemistry and production processes of BMW’s new cylindrical cell batteries or if BMW plans to incorporate additional battery types. Electric cars

As Mate Rimac reflects on his journey from converting a 1984 BMW 3 Series into an electric car to collaborating with BMW today, he sees it as a perfect symmetry. This partnership signifies Rimac’s readiness to undertake large-scale projects for leading automotive brands, marking a pivotal moment in Rimac Technology’s growth.

Stellantis CEO Carlos Tavares, speaking at the annual Freedom of Mobility Forum, emphasized hydrogen’s potential as a sustainable alternative to electric vehicles (EVs), citing advantages in economy, charging speed, and vehicle integration

However, he flagged a major hurdle: the steep cost of hydrogen technology, currently twice that of EVs. Electric cars

Tavares expressed concerns over the affordability of hydrogen vehicles, suggesting they might be viable for corporate fleets but not yet for the average consumer. He stressed the urgency of addressing cost barriers to broaden access to hydrogen mobility.

Meanwhile, Stellantis Italia’s Davide Mele warned about the competitive landscape, particularly with the emergence of Chinese automotive firms enjoying a 30% cost advantage over European counterparts. This poses a threat to the sustainability of Italy’s automotive supply chain, impacting projects like the electric Fiat 500 and Italy’s global market competitiveness. Electric cars

Though hydrogen offers promise for a greener future, cost and competitiveness hurdles loom large. Overcoming these challenges is crucial to realizing the potential of hydrogen mobility.

Electric cars