Polyamide6,6 Automotive – Escalating trend of virgin PSF replacing recycled PSF 02-04-2024

Polyamide6,6 Automotive

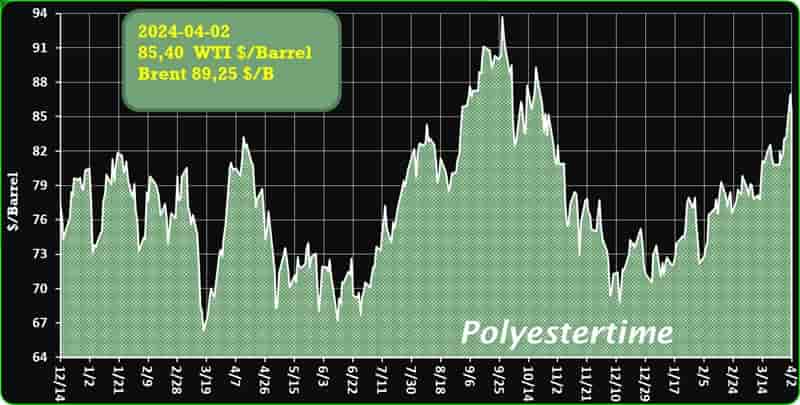

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

Pushing the Limits of Large PET Containers at NPE2024

Cypet Technologies, known for its cutting-edge one-stage injection stretch-blow molding (ISBM) machines, is unveiling its latest advancements in large PET products. Among these innovations are expanded sizes and designs of handled and stackable PET containers, including some groundbreaking offerings:

• In Mexico, a pioneering PET agricultural solution emerges in the form of a 434-mm-long, 40-mm wide tube with a pointed base for easy insertion into soil, manufactured in 16 cavities. With precise engineering, its base seamlessly interlocks with another identical part, allowing for the creation of sturdy structures reaching 2 meters in height.

• Introducing Cypet’s inaugural 60-L stackable industrial container featuring twin built-in handles, catering to a market dominated by 20-L counterparts. Polyamide6,6 Automotive

• Additionally, Cypet showcases three previously unseen containers: a PET jar with a lightweight blown neck achieved by molding a dome above and then trimming it with a spin trimmer; a 20-L container designed for edible oils and chemicals boasting a four-high stackability, an improvement from the previous three-high configuration; and a series of PET jars ranging from 1.3 L to 2.2 L with a distinctive deep groove grip.

Cypet continues to redefine possibilities in PET container manufacturing, expanding horizons and meeting diverse industry demands. Polyamide6,6 Automotive

The 2024 Plastics Recycling Conference kicked off in Grapevine, Texas, sparking dynamic discussions on industry trends like policy, investment, and recyclability design

From March 25-27, this annual event drew 2,500 participants and featured a bustling exhibit hall with over 240 booths.

The inaugural session, titled “The State of Plastics Recycling,” moderated by Nina Bellucci Butler, CEO of Stina, engaged industry leaders including Steve Alexander, CEO of The Association of Plastic Recyclers, Jon Vander Ark, CEO of Republic Services, and Scott Saunders, GM of KW Plastics. Topics ranged from economic pressures to sustainability goals, the interface between recycling operators and consumer goods companies, and strategies to enhance recycling efforts. Polyamide6,6 Automotive

Saunders emphasized consumer demand for increased recycling, stressing the urgency for cities to initiate recycling programs to supply materials for industry investments. Alexander underscored the importance of collaboration between industry and communities, advocating for consumer education and improved access to recycling facilities.

Flexibility in plastic packaging emerged as a central theme, with Vander Ark exploring chemical recycling solutions for composite materials arising from e-commerce. Despite challenges like contamination, industry leaders remain optimistic about recycling innovation and market potential. Polyamide6,6 Automotive

Looking ahead, the conference promises further insights into resin markets, collaborative initiatives, and advancements in film and flexible recycling. As the industry evolves, collective action is essential to address pressing environmental concerns and foster sustainable practices1.

In January 2024, the U.S. witnessed an unprecedented surge in scrap PET imports, reaching a staggering 52.5 million pounds – more than double the amount imported in January 2023

This influx coincided with a year that already set records for post-consumer resin imports. The situation has created what one reclaimer aptly described as a “brutal” scenario.

Paul Bahou, president of Global Plastics Recycling in California, lamented how the influx has depressed sale prices for reclaimers in the state. Many are now selling at cost just to secure orders. The reasons behind this surge are multifaceted: a global economic slowdown in China, coupled with increased shipping availability, has fueled the imports. Meanwhile, California’s processors find themselves caught in a bind: while scrap PET bales are being snapped up by Mexican reclaimers, they struggle to find enough inbound material. Polyamide6,6 Automotive

Sally Houghton, executive director of the Plastic Recycling Corporation of California, aptly called it a “perfect storm situation.” California reclaimers are paying more for bales and then selling their output of RPET (recycled PET) at lower prices due to fierce competition from imports. It’s a challenging market for them.

The surge in January 2024 follows a remarkable year in 2023, during which recovered PET imports surged by 33%, reaching a new high of 450 million pounds. The driving force behind this increase was a spike in RPET imports from southeast Asia, particularly Thailand, which jumped from 20 million pounds in 2022 to 51 million pounds in 2023. Canada also contributed, sending 21% more RPET than the previous year. Interestingly, the RPET entering the U.S. is primarily in flake form, processed abroad but in high demand by U.S. end users – a twist for a commodity that was once a major export1 Polyamide6,6 Automotive

Escalating trend of virgin PSF replacing recycled PSF

Recently, the trend of virgin PSF replacing recycled PSF has been escalating.

The price difference between virgin PSF and recycled PSF is low, leading to more downstream spinners switching from recycled PSF to virgin PSF.

In some factories, as many as one-third to half of the downstream spinners are making this switch.

The trend of this substitution is particularly seen in Hebei, followed by North Jiangsu.

Additionally, some factories in Jiangyin, Wujiang, and Sichuan have also reported instances of such substitution, around 20%. Polyamide6,6 Automotive

While there is still some lack of precise data, but sales of recycled PSF have shown a declining trend this week.

Why is this happening?

For example, on Feb 29, 2024, CCFGroup virgin PSF price was 7,405yuan/mt, with processing fees of 4,350yuan/mt, making the total cost 11,755yuan/mt.

Jiangsu-origin polyester yarn 32S price was at 11,650yuan/mt, resulting in a loss of 105yuan/mt.

Meanwhile, a large recycled plant in Hebei (Hebei Jinyi) offered 1.4D HTLS close virgin PSF at 7,350yuan/mt after-tax ex-works, with processing fees of 3,500yuan/mt, making the total cost 10,850yuan/mt. Polyamide6,6 Automotive

Hebei-origin polyester yarn 32S made of close virgin PSF was 10,200yuan/mt, resulting in a loss of 650yuan/mt.

Nylon filament new orders weak, but processing fees improves

Entering the second half of March, nylon textile filament market, which was thriving at this time last year (many specifications in 1 month or even longer of pre-sales), is now lukewarm. Although it is now in the traditional peak season for nylon filament, the order taking has fallen short of expectations. New orders taken by filament plants are generally not as active, resulting in increasing equity inventory. Even sun-protection related products, which were popular in 2023, are showing signs of stagnation, with no significant increase in demand. However, despite the lackluster performance in new orders, processing fees for nylon filament have improved overall. Polyamide6,6 Automotive

The improvement in processing fees is reflected in several aspects:

1. Pre-holiday presales prices with minimal pressure for post-holiday deliveries

Before the Chinese New Year holiday, from late January to early February, downstream stocked up nylon filament until the end of March or partly until mid to late April, with nylon filament priced based on the basic cost of CPL at 14,000-14,200yuan/mt. The February contract settlement of CPL rose slightly by 105yuan/mt compared to the previous month’s price, but the settlement in March is expected to be significantly lower than the pre-holiday stocking price. Polyamide6,6 Automotive

In 2023, the European Union marked a notable turnaround in its trade performance, boasting a trade surplus of €38 billion (about $40.9 billion), as per Eurostat data

This is a stark contrast to the previous year’s €436 billion deficit ($469.8 billion). The shift can be attributed to a 16% decrease in non-EU imports, particularly in energy products (down by 34%) and manufactured goods (down by 21%), driven by both lower prices and reduced volumes.

The EU’s transformation from deficit to surplus in just a year underscores significant economic shifts. Notably, Luxembourg exhibited robust intra-EU trade, with 90% of its imports originating from fellow member states, highlighting its deep integration into the EU market. Conversely, Czechia emerged as a major intra-EU exporter, with 82% of its total exports destined for other EU nations, emphasizing its pivotal role within the bloc’s export landscape. Polyamide6,6 Automotive

Conversely, Ireland displayed the lowest intra-EU import share, at a mere 39% of its total imports, primarily due to its reliance on non-EU trading partners, notably the US and the UK. This underscores the diversity of trade patterns within the EU and the varying degrees of integration among its member states.

Polyamide 6,6 in Automotive Applications: A Sustainable Shift

Introduction

The automotive industry is undergoing a transformative shift towards sustainability. As concerns about environmental impact and resource scarcity grow, manufacturers are seeking alternatives to traditional petroleum-based polymers. One such promising material is polyamide 6,6 (PA 6,6), which offers a balance of performance, durability, and eco-friendliness. Polyamide6,6 Automotive

Why Polyamide 6,6?

- Superior Mechanical Properties: PA 6,6 exhibits excellent tensile strength, impact resistance, and fatigue endurance. These properties make it ideal for critical components in automobiles.

- Heat Resistance: PA 6,6 can withstand high temperatures, making it suitable for engine parts, exhaust systems, and under-the-hood applications.

- Chemical Resistance: It resists oil, fuel, and other automotive fluids, ensuring longevity and reliability.

- Lightweight: PA 6,6 contributes to weight reduction, enhancing fuel efficiency and reducing emissions. Polyamide6,6 Automotive

Recent Advances

1. Interior Components

- Seatbacks: PA 6,6-based materials are used in seatbacks, providing comfort and structural integrity.

- Door Panels and Dashboards: These components benefit from PA 6,6’s impact resistance and dimensional stability.

- Trunk Liners and Headliners: PA 6,6 ensures durability and aesthetics in these areas.

2. Exterior Applications

- Bumpers and Grilles: PA 6,6 withstands impacts and harsh weather conditions.

- Wheel Covers: Lightweight PA 6,6 wheel covers enhance aerodynamics.

- Electrical Components: PA 6,6 insulates wiring and connectors.

3. Environmental Impact Polyamide6,6 Automotive

- PA 6,6 reduces greenhouse gas emissions throughout its life cycle.

- It is biodegradable, addressing end-of-life disposal concerns.

Challenges and Future Prospects

While PA 6,6 has made significant strides in automotive applications, challenges remain:

- Cost: PA 6,6 can be expensive compared to traditional plastics.

- Property Requirements: Meeting stringent aviation industry standards remains a hurdle.

- Supply Chain: Ensuring a reliable supply of biopolymers is crucial.

Conclusion

Polyamide 6,6 is poised to revolutionize the automotive sector. As automakers embrace sustainability, PA 6,6 will play a pivotal role in shaping the cars of the future. From steering wheels to engine components, this versatile material is driving positive change on our roads. Polyamide6,6 Automotive

Remember, as we drive towards a greener future, polyamide 6,6 is steering us in the right direction!

Polyamide6,6 Automotive