Textile-to-textile – In the latest Chemical Trends Report from CEFIC, the European Chemical Industry Council highlights that the EU chemical sector is grappling with greater impacts from the energy crisis compared to other regions 17-04-2024

Textile-to-textile

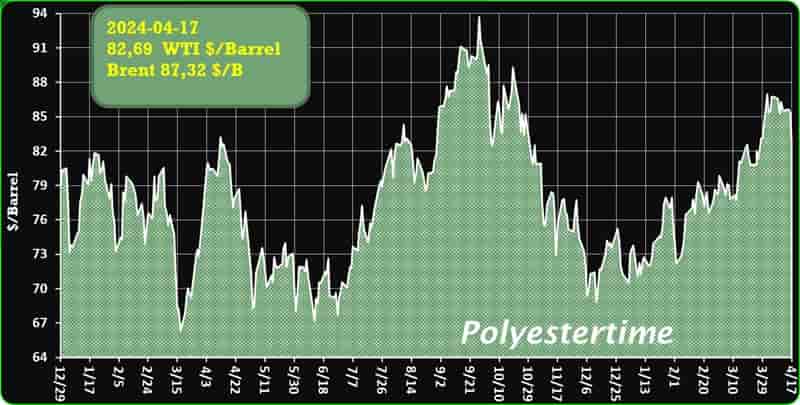

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

Europe’s textiles sorting industry in crisis; urgent EU action needed

The industry responsible for sorting discarded textiles for reuse and recycling is on the brink of collapse across Europe, with urgent alarms ringing from the Netherlands, Germany, and the UK.

Without immediate intervention, this crisis will escalate, causing irreversible economic and environmental damage.

Rising costs, dropping sales due to intense competition and legislative gaps are putting valuable reusable textile resources and the circular economy at risk. The combination of unsold second-hand clothing due to a global drop in sales and lacking business models for recycling, discarded textiles threaten to end up directly in the incinerator without being reused or recycled. Textile-to-textile

Mariska Boer, the President of EuRIC’s Textiles Branch, stated:”The prospect of incineration becoming the only remaining option if sorting discarded textiles becomes financially unviable is deeply alarming. All industry efforts to create a sustainable textile value chain in a circular economy would be in vain when textiles can no longer be collected and sorted in Europe. When second-hand clothing can no longer be supplied to countries that depend on it, this will have a massive economic impact both locally and within the EU.”

In the latest Chemical Trends Report from CEFIC, the European Chemical Industry Council highlights that the EU chemical sector is grappling with greater impacts from the energy crisis compared to other regions

According to Chemanager-online, structural challenges within the sector require immediate attention. Historically, the EU27 chemical industry has been losing ground in the global market, primarily due to its high energy costs. Textile-to-textile

This factor is particularly critical as it contrasts sharply with regions like the US and the Middle East, where energy is cheaper.

CEFIC points out that high energy prices are not the sole issue. Investment delays in Europe are also linked to regulatory ambiguities and unclear innovation support schemes, which together erode confidence in the EU’s industrial policies. This environment complicates conducting business in the EU. CEFIC emphasizes the need for a solid business framework as proposed in the Antwerp Declaration for a European Industrial Deal to attract investments. Textile-to-textile

Despite these challenges, there is a silver lining as confidence within the chemical sector is improving and the trade balance is stabilizing, possibly marking the end of destocking phases. Based on European Central Bank projections, inflation is anticipated to decrease from 5.4% in 2023 to 2.3% in 2024, signaling potential economic stabilization. However, CEFIC remains cautious, suggesting it might be premature to declare this a start of a recovery upcycle. Further insights are provided in graphs and the complete report on the CEFIC website.

Additionally, data from January 2024 shows a 5.9% drop in the output of the EU27 manufacturing sector compared to the previous year. Textile-to-textile

From wheat to Bioplastics

In a pioneering move for Europe’s green chemistry sector, Belgian company Futerro and French cooperative Tereos have teamed up to establish a biomanufacturing platform in Normandy. Futerro, a leader in producing lactic acid, lactide, and PLA (polylactic acid), and Tereos, a key player in the sugar, ethanol, and starch markets, have entered a strategic partnership aimed at creating a localized, sustainable supply chain. This involves converting dextrose extracted from eco-friendly French wheat into recyclable and compostable bioplastics at a facility planned for Port-Jérôme-Sur-Seine by 2027.

The agreement will see Tereos supply 150,000 tonnes of dextrose annually from its Lillebonne plant to Futerro’s adjacent biorefinery. Textile-to-textile

There, Futerro will transform the dextrose into bio-based products such as lactic acid, lactide, and PLA. This collaboration emphasizes a reduction in energy usage, particularly from fossil fuels, and strengthens the economic and environmental aspects of local production and logistics. Notably, the venture will utilize river transport and a pipeline system between the plants, significantly reducing road transport needs.

The initiative is set to infuse over €500 million into the local economy, generate about 1,150 new jobs, and support a substantial number of existing jobs at Tereos. This partnership not only promises significant environmental benefits by promoting decarbonization and sustainable logistics but also bolsters the regional workforce and economy through innovative agricultural and industrial advancements.

Early April 2024, Asian and European PET Prices contrast with US PET Prices

During the initial days of April, the global Polyethylene Terephthalate (PET) resin market displayed a varied sentiment, with both the Asia-Pacific and European markets mirroring similar trends. Conversely, the US market maintained a stable stance. The trend of PET prices was influenced by downstream demand and the fluctuating crude oil prices amid geopolitical concerns. Textile-to-textile

In the United States, the PET market maintained its steady course, a trend that took root in late March. This stability followed a notable increase in the third week of March, which was subsequently balanced by a 2.3% decline in the feedstock Mono Ethylene Glycol (MEG) prices. With ample inventory in MEG feedstock, Ethylene Oxide, and moderate demand from downstream industries, particularly the PET bottle and packaging sector, prices found equilibrium. Despite a 4% rise in Crude Oil prices, the impact on MEG prices remained minimal, thanks to modest fluctuations in crude oil inventories. The overall scenario in the US, including refinery operations at more than 88% capacity and a slight decrease in daily crude oil imports, influenced the commercial crude oil storage dynamics. Moreover, a marginal rise in inflation signalled potential challenges ahead, primarily driven by higher oil and raw material prices and increased transportation rates observed in March. Textile-to-textile

South Korea’s LG Chem Ltd. has partnered with Ansan City in Gyeonggi Province to recycle waste vinyl into plastic raw materials, according to a report by Kedglobal

This collaboration was formalized with the signing of a memorandum of understanding (MOU) aimed at promoting a circular economy and transforming Ansan’s waste vinyl into sustainable resources. The agreement, signed on Tuesday, underscores the mutual commitment to establishing a system for the circulation of plastic resources.

Annually, Ansan generates about 15,000 tons of waste vinyl, a number that continues to rise. Under this new agreement, Ansan City will supply waste vinyl to LG Chem’s upcoming pyrolysis oil factory in Dangjin, South Chungcheong Province, which is expected to commence operations this year. This facility will specialize in chemical recycling, a process that converts waste vinyl into plastic raw materials. Textile-to-textile

LG Chem’s initiative is set to not only reuse local waste materials but also to produce various eco-friendly products utilizing the recycled vinyl from Ansan.

This partnership reflects a strategic move towards sustainability and resource efficiency, leveraging technological innovations in chemical recycling to address environmental challenges.

Circular from the start

Recycling start-up to promote circularity in automotive components

Over the past year, the news from the plastics recycling industry has been, for the most part, sombre. Textile-to-textile

The low prices of virgin materials have attracted producers away from the use of recycled plastic, which has led to the shuttering of recycling plants across Europe.

Now, bucking this trend is a young, dynamic startup in Modena, Italy, called Circular Identity, which is convinced that now is the time to act. Textile-to-textile

“We envision a world where plastic waste is transformed into high-quality safety-critical components, reducing the negative impact of plastic waste on the environment and creating a more sustainable future for generations to come,” is how the company put it. Sustainable Plastics spoke with one of the co-founder owners of the company, Pierrick Cassin, a plastics recycling veteran who is well aware of the challenges ahead.

Exploring options for UK textile-to-textile recycling

Study will take lessons from first fully scaled automated textile sorting facility in Sweden.

Tomra Textiles and Circle-8 Textile Ecosystems have entered into a collaborative agreement to advance the first automated textiles sorting and pre-processing facility for non-reusable waste textiles in the UK. Textile-to-textile

The companies will conduct a feasibility study for an automated textile sorting and pre-processing facility, emphasising solution and process designs that can be scaled.

The explorative collaboration agreement is focused on the UK market where despite higher average re-use levels compared to the rest of Europe, an estimated 700,000 tons of non-reusable textile waste is still generated every year.

As a key member of ACT UK, a consortium set up to industrialise textile sorting in the country in 2023, London-based Circle-8 is working with stakeholders along the textile value chain to realise a circular textiles ecosystem. It will now draw on Tomra’s experience and know-how to develop solution designs for a future automated sorting and pre-processing facility for non-reusable textiles in the UK. Textile-to-textile

Tomra, headquartered in Oslo, Norway, was the main technology provider to the world’s first fully scaled automated textile sorting facility, SIPtex, in Malmö, Sweden and the Swedish research project has provided valuable lessons for optimising and reconfiguring Tomra’s technology for the industrial-scale sorting of post-consumer garments.

Textile-to-textile