Battery recycling

The renewable energy sector faces a critical challenge: energy storage. Solar and wind are intermittent sources of energy. It needs to be supported by a robust energy storage system to provide reliable and continuous energy to the grid. To truly transition away from fossil fuels, we need efficient and sustainable ways to store this captured energy for use. Lithium-ion (Li-ion) batteries have emerged as the frontrunners in this race, powering everything from electric vehicles (EVs) to portable electronics and potentially serving as the backbone of large-scale grid storage. However, their reliance on critical raw materials and the environmental impact of improper disposal raise concerns about their long-term sustainability. This is where battery recycling comes in, transforming the future of energy storage and ushering in a green revolution. Battery recycling

The global demand for Li-ion batteries is expected to skyrocket in the coming years, driven by the EV revolution and the increasing adoption of renewable energy. Battery energy storage systems (BESS) will have a CAGR of 30 per cent, and the GWh required to power these applications in 2030 will be comparable to the GWh needed for all applications today. This surge presents a significant challenge. Mining the raw materials needed for Li-ion batteries, such as lithium, cobalt, and nickel, can be environmentally destructive and often involves unethical labour practices. The world’s highest lithium stores are in Brazil, Chile, Argentina, and Australia. Mining utilises much of the water in these arid regions, leaving the area parched of its precious water resources. Sulfuric acid and sodium hydroxide used in lithium extraction penetrate the soil and water, poisoning ecosystems and endangering species. Battery recycling

Two flamingo species in Chile are said to be endangered due to lithium mining

More…

CARBIOS Active: Enzymatic Solution for Compostable PLA in Food Contact Substances

In a world striving for sustainability, the recent achievement of CARBIOS Active represents a significant leap forward. Its inclusion in the U.S. Food and Drug Administration (FDA) Inventory of Effective Food Contact Substances marks a monumental step in the harmonization of packaging innovation with ecological consciousness. This groundbreaking technology promises to redefine the standards of packaging materials, providing a 100% compostable solution at ambient temperatures. Battery recycling

Unpacking CARBIOS Active’s Impact

Polylactic Acid (PLA) packaging incorporating CARBIOS Active stands out not only for its compostable qualities but also for its capacity to support Food & Beverage brands in their sustainability commitments. Integrated directly into the plastic conversion processes, the enzyme fosters the creation of a new PLA generation. This material leaves behind no toxic residues or microplastics, embodying the ideal of a circular economy.

The encapsulated enzyme is integrated into manufacturing PLA packaging. It stays inactive during product use, maintaining mechanical properties. Upon collection with biowaste and composting, the enzyme activates for complete disintegration and biodegradation, resulting in non-toxic compost and soil enrichment.

“With the FDA’s clearance, we anticipate a surge in demand within North America for CARBIOS’ biodegradation solution. This is a testame nt to our team’s dedication,” affirms Emmanuel Ladent, CEO of CARBIOS. Battery recycling

More…

Avient Introduces Versaflex™ TF Adhesive Tpes For Textile Fabrics

Avient Corporation, a premier provider of specialized and sustainable materials solutions and services, is proud to introduce its new Versaflex™ TF Adhesive Thermoplastic Elastomer (TPE) solutions for adhesive films in laminations with nylon and polyester textile fabrics. These new solutions help textile fabric laminations to be soft, stretchable, and breathable, enabling a uniform thickness and overall appearance in athletic apparel such as sportswear and underwear. Battery recycling

Avient Introduces Versaflex™ TF Adhesive TPE Solutions for Athletic Textile Fabrics

Versaflex TF Adhesive TPEs offer easy processing and shaping, resulting in a strong adhesion between the TPE adhesive film and high-elastic fabrics. These solutions can support the strength and elasticity of the fabric for superior shape recovery of up to 99% after 300% elongation over 1 minute while also providing excellent washability in various washing machines and modes at temperatures up to 60 °C. This new TPE technology can provide a cost-effective alternative to TPU adhesive films and traditional glue.

“We are seeing a steady increase in the demand for fitness clothing, as people are becoming more health-conscious,” said Matt Mitchell, Director, Global Marketing, Specialty Engineered Materials at Avient. “This trend has created a need for functional and comfortable fabrics that are also visually appealing. With the new Versaflex TF Adhesive TPEs, manufacturers can create close-fitting bodywear textiles that offer consumers a more comfortable exercise experience. Additionally, this technology caters to the growing market for seam tapes.” Battery recycling

More…

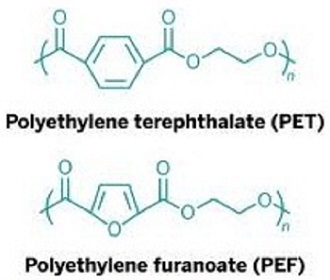

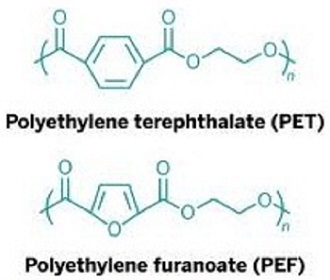

Tapping into PEF’s potential

Dutch company Avantium is on the verge of commercial production of recyclable bioplastic compatible with PET.

Avantium, a renewable chemistry company based in the Netherlands, plans to open a plant later this year that will enable commercial-scale production of a plant-based plastic that can be incorporated into packaging and recycled in traditional polyethylene terephthalate (PET) recycling streams.

Avantium’s YXY plant-to-plastics technology catalytically converts plant-based sugars into a chemical building block that can be used in a variety of chemicals and plastics, including polyethylene furanoate (PEF), a polymer used either as a replacement for PET or as a high-barrier liner in PET bottles. Battery recycling

PEF’s oxygen barrier properties are 10-times greater than PET, and its carbon dioxide barrier properties are 16-times greater, according to the company. The improved barrier properties can lead to a longer shelf life for foods and beverages, and they maximize the taste and fizziness of soft drinks.

“PEF is a new polymer—it’s new to the world,” Avantium CEO Tom van Aken says. “It is something that has not been produced at commercial scale before. We have been working on this since 2005.”

More…

Indicor, LLC., a top diversified industrial firm offering specialized technologies crucial to various niche markets, has announced the acquisition of AGR International

AGR stands as a prominent provider of quality and process control technologies for global beverage packaging clients. Battery recycling

AGR’s offerings encompass technology and services vital for global glass and plastic packaging clients, ensuring the fulfillment of quality, productivity, and sustainability objectives. Their portfolio includes laboratory and inline equipment, along with automated process systems, facilitating customers in meeting quality management demands for container manufacturing and brand ownership.

Doug Wright, CEO of Indicor, expressed enthusiasm about the acquisition, highlighting AGR’s market leadership, critical solutions, strong customer relationships, and dedication to meeting quality and sustainability requirements. He emphasized that this move aligns with Indicor’s strategy of prudent capital deployment, aiming to enhance long-term financial gains by collaborating with leading businesses. Battery recycling

Following the acquisition, AGR’s management team will maintain leadership from its headquarters in Butler, PA. There will be no changes to AGR’s name, brands, or operational structure post-transaction. Sudha Jebadurai, AGR’s President, will continue to steer the business forward.

Plastic Waste recycling – Experience meets quality: EREMA sets standards in PET recycling 13-03-2024

Battery recycling