r-PET Bottles – Japanese researchers have unveiled a groundbreaking bioplastic that combines durability with rapid seawater degradation, offering hope for ocean cleanup efforts 15-04-2024

r-PET Bottles

- Bottle Environmental Impact – Origin Materials has achieved a significant milestone in the production of biobased intermediates at its Origin 1 commercial plant in Sarnia, Canada 08-04-2024

- New enzyme technology for environmentally friendly plastic recycling

r-PET Bottles

Japanese researchers have unveiled a groundbreaking bioplastic that combines durability with rapid seawater degradation, offering hope for ocean cleanup efforts

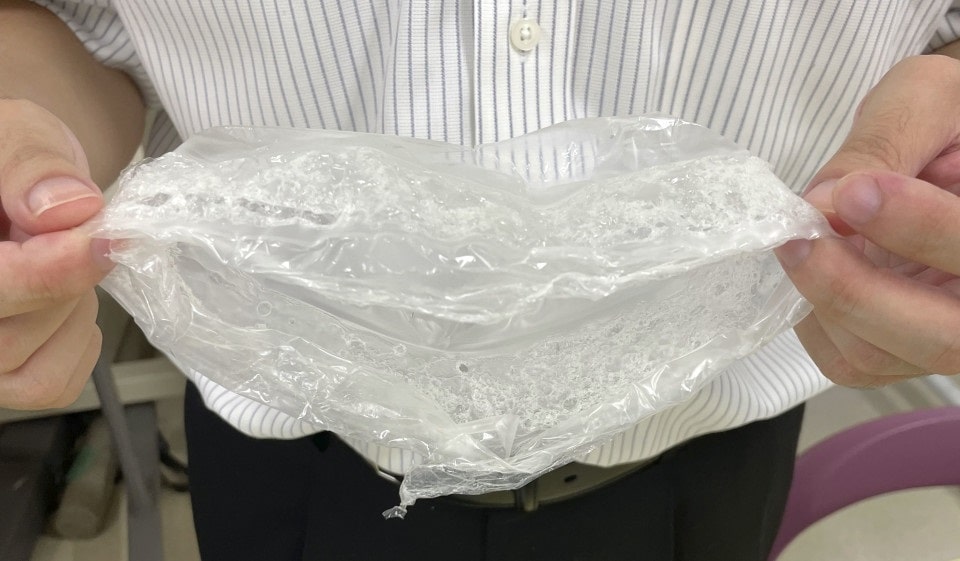

Made from polylactic acid derived from starches like sugarcane and corn, the material represents a significant step in combating the 30 million tons of plastic waste polluting oceans worldwide.

While traditional polylactic acid suffers from brittleness and production challenges, the team overcame these limitations by leveraging a bacteria’s plastic-producing capabilities. Through genetic modification, they achieved mass production of an enhanced degradable polylactide known as LAHB.

By blending LAHB with conventional polylactic acid, they achieved transparency, enhancing its versatility.

The Japanese government aims to boost bioplastic usage to 2 million tons by 2030, viewing this innovation as a pivotal step in their biomanufacturing initiative.

Seiichi Taguchi, a key figure in the project, believes this development will not only aid in mitigating global warming but also marks the industrialization of bioplastics.

With this advancement, the prospect of cleaner oceans and reduced reliance on petroleum-based plastics becomes increasingly attainable.

Microplastics are contaminating our water; IISc has now found a solution to the problem

Microplastics, a global water contamination crisis, faces a promising solution from researchers at the Indian Institute of Science (IISc). Their innovative hydrogel, boasting a unique polymer network, effectively removes and degrades these minuscule plastic particles.

Microplastics, omnipresent in water bodies worldwide, threaten ecosystems and human health. Despite efforts using filtering membranes, these solutions often falter due to clogging. Led by Professor Suryasarathi Bose, the IISc team engineered a sustainable hydrogel with an Interpenetrating Polymer Network (IPN) architecture. Infused with nanoclusters of a copper substitute polyoxometalate (Cu-POM), this hydrogel efficiently binds and degrades microplastics under UV light.

The hydrogel, comprising chitosan, polyvinyl alcohol, and polyaniline layers, exhibits remarkable adsorption and degradation capabilities. Mimicking real-world scenarios, the team crushed plastic products to generate common microplastics. Tracking their removal and degradation, they found the hydrogel excelled, especially at near-neutral pH levels.

Additionally, the hydrogel proves durable under varying temperatures, hinting at its potential for large-scale deployment. Once its lifespan concludes, it can transform into carbon nanomaterials for heavy metal removal.

Future endeavors involve collaborating to develop scalable devices for widespread microplastic cleanup. The IISc’s breakthrough heralds a sustainable remedy to combat waterborne microplastic pollution, safeguarding ecosystems and human well-being alike.