Sustainable Preforms

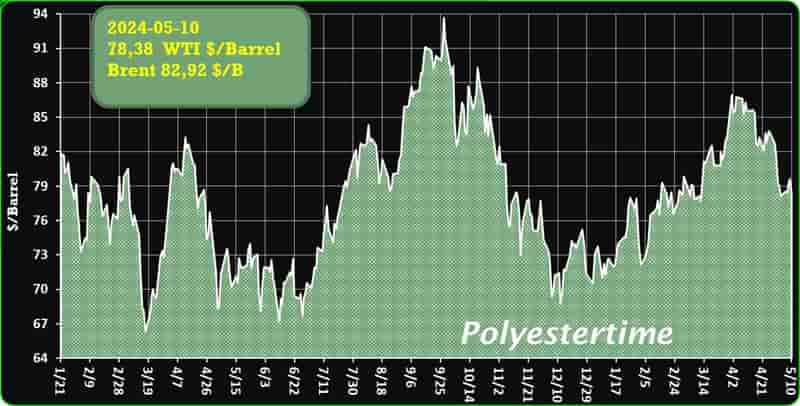

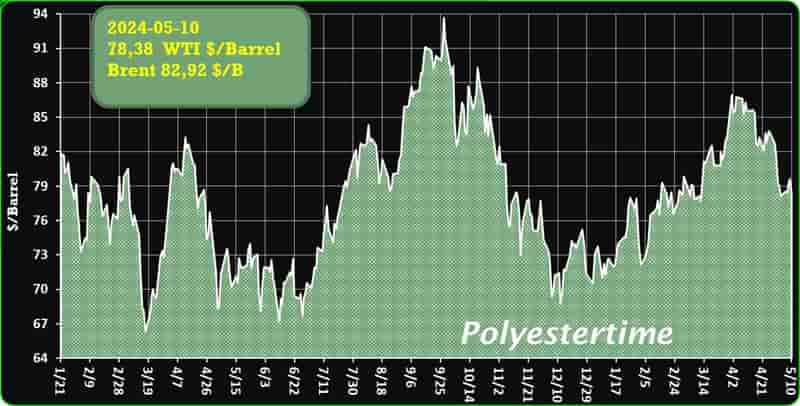

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

With the acquisition of Netstal Maschinen AG earlier this year, Krones has enhanced its capabilities, now offering an integrated solution for every stage of the plastics cycle

This addition enables Krones to deliver a complete system spanning from injection molding, involving MHT tools for PET production, to stretch blow molding with the Krones Contiform series. The suite also encompasses preform and container design, the MetaPure plastics recycling systems, and extensive digitalization solutions.

The launch of Prefero by Krones marks a significant development in its comprehensive system for producing, filling, and packaging PET containers, making Krones the sole provider covering the entire PET beverage industry’s value chain with its products.

Jochen Hirdina, Head of Plastics Technology at Krones, emphasizes the importance of integrated line concepts over mere assembly of machines. Sustainable Preforms

“Prefero aligns our line strategy with the plastics cycle, enhancing the synergy of our solutions,” he states, highlighting that this integration is crucial for leveraging digitalization opportunities.

Netstal will maintain its independence and continue offering its range of products for preforms, closures, packaging, and medical technology. While Krones focuses on complete PET systems through Prefero, Netstal specializes in production systems that combine injection molding machines with molds and peripherals. Hirdina notes that Netstal will also utilize the global Krones network to better serve its customers, aiming to maximize existing synergies. Sustainable Preforms

LyondellBasell has initiated a strategic review of its European operations, specifically focusing on its Olefins & Polyolefins and Intermediates & Derivatives divisions

The review will assess these sectors’ alignment with corporate strategies, which include growing and upgrading core operations, developing profitable circular and low carbon solutions, and enhancing performance and culture. This analysis aims to ensure that the European assets are optimized to support the company’s long-term goals.

Despite this reevaluation, LyondellBasell has confirmed the continuation of its recent investment projects. Notably, these include the construction of an industrial-scale chemical recycling plant using MoReTec technology in Wesseling, Germany, and the establishment of an integrated hub for plastic waste selection and recycling in Knapsack, Germany. These projects underline the company’s commitment to innovation and sustainability in its operations. Sustainable Preforms

Moreover, LyondellBasell maintains significant operations in Italy, with major petrochemical hubs in Brindisi and Ferrara. While the Brindisi hub saw the closure of a polypropylene plant last September, the Ferrara hub is slated for further investment in catalysis systems, highlighting ongoing development and adaptation in response to both market and environmental demands. Peter Vanacker, CEO of LyondellBasell, affirms that the strategic criteria guiding these decisions remain consistent, aiming for robust growth and sustainability. Sustainable Preforms

Sustainable Preform Injection Molding System

Husky Technologies’ HyPET®6e optimizes rPET processing, minimizes energy use, and simplifies operation for lower costs and a greener footprint.

Husky Technologies, a technology provider enabling the delivery of essential needs to the global community, announced the launch of its next-generation HyPET®6e platform. Building upon the technology of the company’s flagship PET preform injection molding system, HyPET®6e is the ideal combination of proven technology and innovation engineered to work together to deliver new standards in sustainable molding.

“The plastics industry is at a pivotal moment, and as industry leaders we must deliver by proactively developing circular solutions to address plastic waste management,” said Robert Domodossola, Husky’s President of Systems and Tooling. Sustainable Preforms

“Our new HyPET®6e platform meets this need as it’s designed so that all system components are integrated to work together to deliver on the unique requirements of sustainable molding, including superior rPET capability, enhanced energy efficiency, and closed-loop quality control, while simplifying operation and still delivering the lowest total production cost.”

More…

NPE2024: Sabic showcasing progress in plastic innovation for a more sustainable future

- Under the theme of “Collaborating to Create the Future,” SABIC’s presence at NPE2024 showcases plastic innovations and work across the value chain in multiple industries.

- SABIC emphasizing value of its plastics as enablers for transformation – to a circular, electric and more sustainable future.

- Booth reinforces company’s strong commitment to local supply and application development support to power innovation.

SABIC, a global leader in the chemical industry, is highlighting at NPE2024 (Booth #S19005; May 6-10 at the Orange County Convention Center in Orlando, Florida) a wide range of solutions that demonstrate the value of plastics for a more sustainable future. Under the theme “Collaborating to Create the Future,” the company is presenting innovative solutions that are available today and others that are on their way to broader adoption. Sustainable Preforms

This includes examples of the company’s work with manufacturers and others across the value chain on circular plastic solutions available under its TRUCIRCLE™ program and new approaches with plastics under its BLUEHERO™ initiative that can help in the shift to electrification.

“Since the last NPE in 2018, SABIC has taken giant strides forward in creating pathways for plastics to make valued contributions toward resolving critical global challenges and driving circularity,” Sami Al-Osaimi, executive vice president, Polymers, SABIC, said.

More…

PURE LOOP, a member of the EREMA Group, is celebrating its success in the US market at NPE 2024

The company, which launched its ISEC repelletizing system at NPE 2015, is showcasing the ISEC evo 302 E at stand W4471 with live demonstrations of its recycling capabilities.

Manfred Dobersberger, Managing Director, highlights the importance of NPE and the ISEC system’s global success in repelletizing various polymers. Sustainable Preforms

The ISEC evo’s design benefits from years of experience in handling complex recycling requirements, including challenging materials like PVC and glass-fiber reinforced plastics.

The ISEC evo features a patented double feed ram system and a single drive shaft for the shredder and extruder, ensuring gentle material treatment and minimal contamination risk. The technology has led to significant sales growth in the US, with the ISEC evo 702 being a notable sale, boasting a throughput capacity of up to 3,300 pounds per hour.

PURE LOOP’s success in North America is attributed to strong partnerships with local sales networks and close collaboration with EREMA North America. The company’s service hub in Ipswich offers customer trials and support. Sustainable Preforms

Dobersberger also points out the potential in textile recycling, with PURE LOOP’s FibrePro:IV technology focusing on PET fiber-to-fiber recycling. At NPE, visitors can experience the ISEC evo 302 E’s performance firsthand, reflecting PURE LOOP’s commitment to showcasing efficient recycling solutions. Dobersberger expresses enthusiasm for demonstrating the technology’s broad application range alongside the Austrian and US teams.

CJ Biomaterials, Inc., a division of South Korea’s CJ CheilJedang and a leading producer of polyhydroxyalkanoate (PHA) biopolymers, unveiled a new semi-crystalline PHA (scPHA) biopolymer, the PHACT S1000P, at NPE 2024 in Orlando, Florida

This product is certified by TUV OK for home and industrial composting and by the US FDA for food contact, demonstrating its suitability for a broad range of environmentally sensitive applications. Sustainable Preforms

The PHACT S1000P represents an advancement in the PHA market, expanding the applications where CJ Biomaterials can provide solutions, especially where biodegradation is essential. It offers superior rigidity and high-heat stability, ideal for processes like injection molding, thermoforming, and other conversion technologies. The biopolymer is also certified as marine and soil biodegradable, enhancing its appeal in sustainable packaging and other eco-friendly products.

Max Senechal, Chief Commercial Officer at CJ Biomaterials, emphasized the product’s versatility and biodegradability across various environments, including anaerobic, aquatic, and compost settings. He noted that this launch follows the company’s introduction of its amorphous PHA (aPHA) in 2022, which differs by being softer and more rubbery. The addition of PHACT S1000P to their portfolio allows the company to meet diverse technical needs by blending their main PHA types. Sustainable Preforms

CJ Biomaterials is also scaling up its production capacity in Pasuruan, Indonesia, to meet growing market demand, reflecting its commitment to advancing sustainable biopolymer technology globally.

— For KARL MAYER GROUP, Turkey is an extremely important market with numerous longstanding business connections and promising growth potentials. Accordingly prepared, the global player travels as an exhibitor to ITM at Tüyap Fair and Congress Center in Istanbul. Sustainable Preforms

“In response to the economic challenges in the Turkish textile industry, we are intensifying our commitment to our local customers. We have founded a subsidiary in Bursa to provide even better support for our services. Our proximity to the market also helps us to optimise our production solutions to meet the needs of our customers. Our focus remains on providing advanced, efficient, high-performance machines that use digital solutions to increase productivity and reduce operating costs. We are here at ITM to assist our customers through the current difficult times and help them emerge stronger. This is also a personal concern of mine. I have built up close relationships with many customers over the years. Their success is very near and dear to my heart,” says Arno Gärtner, CEO of the KARL MAYER GROUP. Sustainable Preforms

More…

PET bottle packaging – DOMO Chemicals responds to surging demand in China with new TECHNYL® polyamide production plant 09-05-2024

Sustainable Preforms