Unrecyclable plastics – The Complex Reality of Plastic Recycling: Beyond the Hype 24-10-2023

Mura Technology is opening its first commercial-scale HydroPRS advanced plastic recycling plant in Teesside, UK, processing ‘unrecyclable’ flexible and rigid mixed plastics into recycled hydrocarbon feedstocks for repeated plastic production.

Located at the Wilton International industrial site, the site reportedly has the capacity to produce 20ktpa of recycled liquid hydrocarbon products and expand its production capacity by over three times its initial size in the future. It is said to have created 150 jobs during its build and commissioning phases and now expects to offer up to 50 direct jobs and a further 100 surrounding related infrastructure to support operations.

The company anticipates that its offtake partners will receive their first delivery of recycled hydrocarbon products from the Teesside facility early next year. Unrecyclable plastics

HydroPRS is a process designed to complement mechanical recycling and produce recycled plastic feedstock to manufacture new plastics, in turn facilitating a circular economy. It makes use of supercritical water, or water under high pressure and temperature, and converts films, pots, tubs, trays, and other post-consumer, multi-layered plastics into stable hydrocarbon feedstocks.

Independent Life Cycle Assessments have been carried out at Teesside and suggest that the process saves 80% of carbon emissions by diverting these ‘unrecyclable’ plastics away from incineration. Apparently, materials can undergo unlimited cycles of the HydroPRS recycling process, which would cut down on single-use plastics and drive circularity within the plastics industry. Unrecyclable plastics

For every tonne of plastic waste produced, HydroPRS is also said to save up to five barrels of oil and create products with an equivalent or lower Global Warming Potential.

Local mayor Ben Houchen will deliver a speech at the opening of the facility. Also set to attend are Marco ten Bruggencate, commercial VP for EMEA at Dow and President of Plastics Europe; Benny Mermans, vice president of Sustainability at Chevron Phillips Chemical (CPChem); Jinsuk Kim, managing director of LG Chem Europe; Doug Kelly, vice president of Technology at KBR, Mura’s License and Engineering Partner; and Dr Paul Davidson, Director of UK Research & Industry’s Smart Sustainable Plastic Packaging Challenge delivered by Innovate UK. Unrecyclable plastics

Dr Steve Mahon, CEO of Mura Technology, said: “The opening of our first-of-its-kind, next generation recycling facility is a groundbreaking achievement and the culmination of four years of dedication.

“Our HydroPRS process is unlocking a new market for plastic waste, creating value and keeping both plastic and carbon in circularity. The technology works alongside existing mechanical recycling to ensure no plastic types are considered ‘unrecyclable’ and require incineration or landfilling.

“With support from our partners, the Teesside site will be the first in Mura’s global roll-out, helping in the fight against the plastic pollution and global warming crises and acting as a launchpad for the 1,000,000 tonnes of annual recycling capacity that Mura plans to have in operation and development in this decade.” Unrecyclable plastics

Partnerships with blue-chip companies like KBR, CPChem, LG Chem, and igus GmbH are helping Mura pursue global scaling for the HydroPRS process. Its collaboration with Dow has resulted in plans to construct a HydroPRS advanced recycling facility in Böhlen, Germany, scheduled to begin operations in 2025.

In similar news, Swedish Plastic Recycling’s Site Zero plant site, which aims to recycle all kinds of plastic packaging without emitting CO2, has scheduled its own grand opening on 15th November 2023. The company expects its opening to commence a ‘new era’ for the recycling of plastics. Unrecyclable plastics

Joint Swiss-German survey finds inflation expected to drop worldwide

Insights

- Though inflation expectations worldwide remain above central banks’ target, a further fall in the expected inflation rate for the rest of this year compared with previous quarters is evident, a Swiss-German survey found.

- The overall average expected inflation rate this year is 6.2 per cent.

- High inflation rates worldwide are expected in the coming years.

Though inflation expectations worldwide remain well above central banks’ target, a further decline in the expected inflation rate for the rest of this year compared with previous quarters is evident, according to the Economic Experts Survey (EES) of the Leibniz Institute for Economic Research at the University of Munich (ifo Institute) and the Institute for Swiss Economic Policy. Unrecyclable plastics

The overall average expected inflation rate this year is 6.2 per cent. This is the median of average expected inflation rates at the country level, ifo Institute said on its website.

Though inflation expectations worldwide remain above central banks’ target, a further fall in the expected inflation rate for the rest of this year compared with previous quarters is evident, a Swiss-German survey found. The overall average expected inflation rate this year is 6.2 per cent. High inflation rates worldwide are expected in the coming years.

The median is used because expected inflation rates vary widely by region, with some dramatically higher in individual countries and regions such as Africa than in the rest of the world. Unrecyclable plastics

The average rate of 6.2 per cent expected in the current quarter is significantly lower than the expected rate of 7 per cent in the second quarter this year.

Short-term inflation expectations are therefore falling, but remain at a high level worldwide. Experts also expect high inflation rates worldwide in the coming years.

In the long term up to 2026, inflation expectations will also remain high at 4.5 per cent. However, long-term inflation expectations have decreased compared with the results of the previous quarter (4.9 per cent).

Inflation expectations vary widely among the world’s regions. For 2023, experts expect the lowest inflation rates in North America (4.1 per cent). Unrecyclable plastics

Mexico’s Alpek suspends construction at the PTA and PET plant in Texas due to inflationary cost pressure

Mexico-based Alpek, one of the largest petrochemical companies in the Americas, has decided to temporarily suspend construction at its Corpus Christi Polymers (CCP) project in Texas due to rising costs. The decision comes shortly after the announcement of the closure of a filament plant in Mexico due to profitability challenges. Alpex has already obtained consent from its partners for this project for the temporary suspension of construction at the CCP project. Unrecyclable plastics

The CCP project offers the most efficient and innovative production of polymers such as purified terephthalic acid (PTA), and polyethylene terephthalate (PET). PTA accounts for the majority of the total annual capacity of the project, followed by PET. The project uses innovative processes and products for technical advantages compared to the competing packaging materials in its versatility. The CCP was originally scheduled to commence commercial production in 2025.

Reports said that the construction and labour costs have surpassed the initial expectations due to a sustained period of high inflation. Hence, CCP and its partners decided to pause the project temporarily. The promoter, partners, and financiers are expected to meet in the near future to decide the re-commencement of the construction work and commercial production. Sources said that the project will be adequately preserved to restart construction in the near future. Unrecyclable plastics

The Complex Reality of Plastic Recycling: Beyond the Hype

InnoVent Renewables Launches a Solution to Global Waste Tire Challenge

Exclusive technology converts tires into valuable fuels & chemicals

InnoVent Renewables announces its formation with a corporate mission to drive renewable energy forward by mitigating the global environmental challenge of waste tires. InnoVent Renewables launched as a U.S.-based technology and operations company with a proprietary continuous pyrolysis technology that converts waste tires, plastics, and biomass into valuable fuels and chemicals. Unrecyclable plastics

Each year more than 1 billion tires are disposed of globally, and North America alone disposes of 100+ million tires annually. Decomposition of tires is slower than other waste resulting in a serious health hazard (mosquitos, pests, water borne diseases, and chemical leaching into soil); and burning tires in pits or cement kilns is far more hazardous as it emits toxic emissions in the air. The exclusive pyrolysis technology is unique in that it’s continuous, which is a much higher efficiency compared to batch processing. It utilizes the gas to preheat the tires, thereby making it a Net Zero energy process. During the process valuable chemicals are recovered from the products, producing high quality fuels.

“We are thrilled to formally launch InnoVent Renewables and plan to ramp-up operations into early 2024,” noted InnoVent Renewables CEO Vibhu Sharma. “Our investors, strategic advisors, and management team are all fully committed to our success as we address the global challenge of waste tires. Unrecyclable plastics

We firmly believe our proven process, deployed at scale globally, will have a huge positive impact on our climate and fill a clear environment need.”

With a solution to this environmental challenge, InnoVent has assembled a team of world class executives each with more than 25 years of energy and chemical industry experience to drive early-stage growth. With current operations in Houston (USA), Pune (India), and Monterrey (Mexico), the company has aggressive growth plans across North America and Latin America, with future expansion opportunities in Europe, the Middle East, and Asia-Pacific. Unrecyclable plastics

Flexible packaging materials get cheaper, but still above 2020 levels

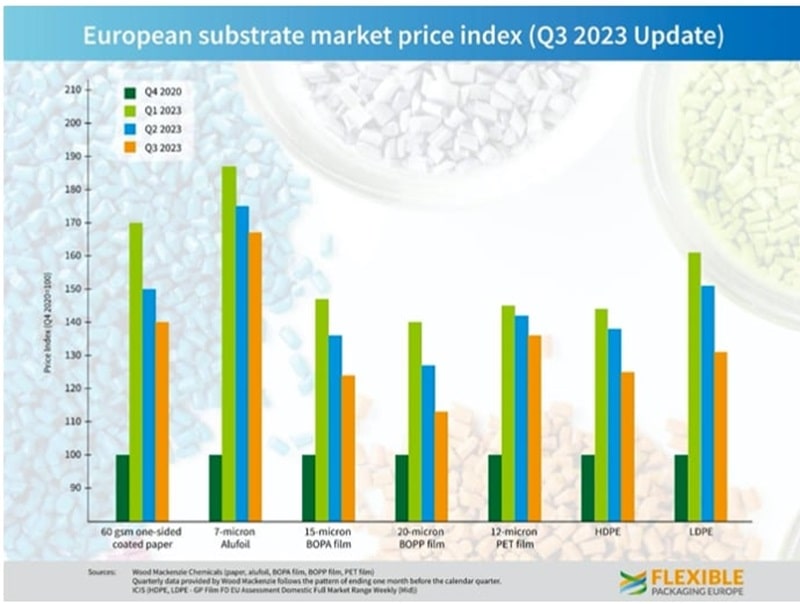

A new report from Flexible Packaging Europe reveals that the prices of flexible packaging materials have fallen more in the third quarter of 2023, but they are still higher than before the crisis.

The report, based on a survey by the European association, shows that the prices have been dropping since the start of the year, after reaching a record high last year.

However, they have not yet returned to the levels of the fourth quarter of 2020, which is the baseline for comparison. Unrecyclable plastics

The report says that most prices went down by 10% to 20% in the third quarter, compared to the second quarter.

For example, HDPE and LDPE prices went down by 10% and 14%, and ended the quarter with a price index of 125 and 131, respectively.

The index was 100 in the fourth quarter of 2020.

Some prices decreased less than others.

The price of sixty gram single-coated glossy paper went down by 7% and reached 140, while the price of 15 micron BOPA film went down by 8% and reached 124.

The price of 20 micron BOPP film went down by 11% and reached 113, which is close to the original price. Unrecyclable plastics

The price of 12 micron PET film only went down by 4% and reached 136. David Buckby, a senior analyst at Wood Mackenzie, thinks that the prices are falling because of low orders, low demand from some European customers, and low stocks.

He also says that some markets have too much production capacity, which was increased a lot in the past years. Buckby says that some prices may keep falling in the fourth quarter, but some products may become more stable.

Guido Aufdenkamp (in the photo), the executive director of FPE, says that the future is unclear: “Many customers do not want to buy packaged foods and there are too many stocks in the supply chain. Unrecyclable plastics

This makes the demand for flexible packaging low in the short term”. He also says that inflation is going down, but not as fast as some people expected.

He reminds that even though these big drops in prices are good for reducing inflation, the prices of flexible materials are still much higher than before Covid and they change a lot. He says that this makes their customers and suppliers very careful, but they hope that demand will increase in 2024.

What happens to waste tire after pyrolysis?

Pyrolysis is a thermochemical process that involves the decomposition of organic materials, such as waste tire, in the absence of oxygen and at high temperatures. During this process, the tire waste is heated in a controlled environment, leading to the breakdown of its chemical structure.

Stages of Pyrolysis:

Pyrolysis of waste tire can be divided into three main stages:

1. Preheating:

The waste tire is initially heated gradually to a specific temperature range, typically between 300 to 400 degrees Celsius.

This preheating stage helps to evaporate any moisture present in the waste tire and prepare it for further decomposition. Unrecyclable plastics

2. Pyrolysis or Decomposition:

Once the waste tire reaches the desired temperature, pyrolysis occurs. At this stage, the long chains of polymers in the waste tire break down into smaller molecules, including oil-gases and solids.

3. Condensation and Collection:

After the pyrolysis process, the oil-gas products are usually cooled rapidly by the cooling system(DOING waste tire pyrolysis system has a multi cooling system with high oil yield), causing them to condense into liquid oil and gas. The solid can be discharged from the pyrolysis reactor. These products are then collected and subjected to sell or further process.

– Gaseous Products: Various hydrocarbon and volatile gases, such as methane, ethane, propane, and butane, are released as byproducts of pyrolysis. These gases can be used as sources of energy or further processed for pyrolysis reactor heating or other applications.

– Liquid Products: The decomposition of waste tire results in the formation of a liquid product known as pyrolysis oil or pyrolysis liquid. This oil is rich in hydrocarbons and can be used for industrial plants heating. Or it can be refined by the pyrolysis oil distillation machines to diesel and for agricultural machinery.

Unrecyclable plastics