Automotive industry PA-Recycling – Every day a new idea for EV-cars 22-07-2023 - Arhive

Automotive industry PA-Recycling

Aquafil’s ECONYL® project is revolutionizing the textile industry by producing nylon with an almost infinite life while respecting the environment

Mr. Giulio Bonazzi President and CEO at Aqufil

This innovative vision of product design from a green perspective is setting new standards for sustainability.

Aquafil, an Italian company, manufactures ECONYL® yarn entirely from nylon waste, boasting exceptional ductility and durability. The yarn meets the needs of various industries, including fashion, clothing, textile flooring, and automotive sectors. Maria Giovanna Sandrini, the Brand and Corporate Communication Director, envisions a broader horizon for this product, emphasizing its regenerative potential and versatility.

The ECONYL® yarn is a voluminized continuous filament, known as BCF, which ensures strength and resilience. Its production process is unique, as it relies on chemical recycling of discarded carpets, fishing nets, fabric scraps, and pre-consumer nylon waste, closing the virtuous circle between sustainability and creativity. The yarn can be regenerated indefinitely while retaining the same characteristics as nylon sourced from fossil fuels, making it highly durable compared to other fibers.

Adopting Life Cycle Thinking, Aquafil evaluates the overall environmental impact of their products, from design to disposal. Automotive industry PA-Recycling

Identifying the extraction of raw materials, particularly caprolactam production, as the process with the greatest impact, the company has taken a forward-looking approach to reduce its environmental footprint significantly. ECONYL®’s environmental contribution is substantial, reducing global warming potential by 90% compared to conventional petroleum-based nylon.

Aquafil’s ambition goes beyond eco-friendly production; they aim to consolidate existing sustainable supply chains and create new ones, with the goal of generating 60% of ECONYL® branded and/or regenerated products as part of their total fiber turnover. Additionally, the company seeks to collect 35,000 tons of post-consumer waste for the creation of new recycled materials by 2025. Automotive industry PA-Recycling

A fundamental aspect of Aquafil’s approach is promoting eco-design practices. They believe that products should be designed with their end-of-life in mind, ensuring they are fully recyclable. In line with this philosophy, Aquafil launched the Born Regenerated to be Regenerable (Born R2R) program, engaging company partners to co-design future carpets that are easily removable and compatible with the ECONYL® regeneration system. This intelligent approach highlights that profitability should not come at the expense of environmental concerns.

Sandrini emphasizes the need for a synergistic system between companies and customers, rethinking product design to prioritize recyclability and regeneration. Automotive industry PA-Recycling

Mrs. Maria Giovanna Sandrini, Aquafil Brand & Communication Manager

Many products currently lack consideration for their life cycle, hindering effective recycling and regeneration efforts. Aquafil seeks to transform the industrial production landscape by embracing a truly sustainable and circular value chain.

Aquafil’s ECONYL® project stands as a beacon of hope for the future of eco-design, challenging the notion of waste as an inevitable outcome. Instead, they view waste as a design flaw and advocate for a paradigm shift towards products that are fully recyclable at the end of their life. By driving innovation and sustainability, Aquafil proves that profitability and environmental stewardship can go hand in hand, setting an inspiring example for the industry and beyond. Automotive industry PA-Recycling

Aisin, a renowned Japanese company specializing in vehicle components, has recently unveiled a groundbreaking electric car engine that promises to revolutionize the automotive industry

Developed in collaboration with the Tohoku Magnet Institute, an entity in which Aisin made strategic investments, this cutting-edge engine is powered by an innovative magnetic alloy known as Nanomet.

Offering unparalleled efficiency and environmental benefits, the Nanomet technology has the potential to reshape the future of transportation. Automotive industry PA-Recycling

At the heart of this groundbreaking engine lies the Nanomet, a nanocrystalline soft magnetic alloy that exhibits extraordinary flux density at high saturation and incredibly low iron loss.

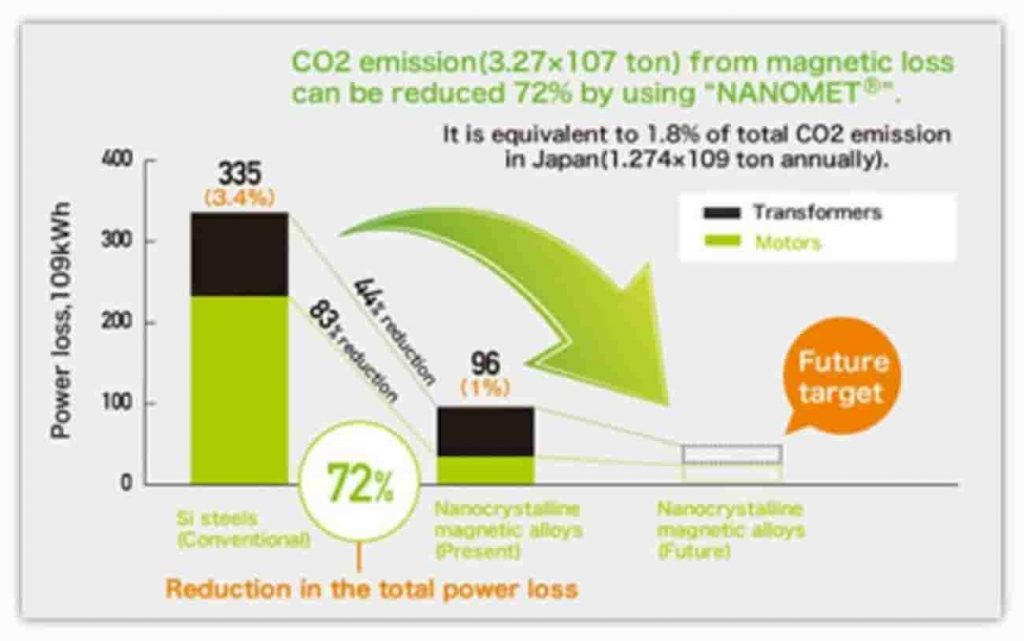

Unlike traditional motors for electric vehicles that rely on electromagnetic steel plates, Nanomet slashes energy losses by a staggering 50%. This substantial reduction in energy loss translates to a remarkable 3% overall improvement in efficiency. More significantly, the lower power loss directly contributes to a staggering 72% decrease in CO2 emissions, making it a game-changer in the fight against climate change.

The development of Nanomet was spearheaded by the Materials Research Institute of the Tohoku Magnet Institute and is manufactured by TMI, a company born within the renowned Tohoku University in Sendai. This groundbreaking alloy is utilized in both the motor core and the stator, ensuring that its efficiency gains are effectively integrated throughout the engine’s design. Automotive industry PA-Recycling

With such remarkable advancements, Aisin swiftly embarked on the task of designing engines that could be efficiently manufactured and eventually brought to market. Their ambitious timeline targets the introduction of these revolutionary engines by the year 2029, which will find applications not only in fully electric vehicles but also in plug-in hybrid models. The widespread adoption of Nanomet-powered engines holds the potential to drive substantial reductions in greenhouse gas emissions across the automotive industry, thereby contributing significantly to global efforts to combat climate change.

However, the potential of Nanomet technology extends beyond the realm of transportation. Aisin envisions its application in various other sectors that require enhanced energy efficiency. Automotive industry PA-Recycling

Beyond zero-emission mobility, Nanomet could revolutionize energy consumption across diverse industries, contributing to a more sustainable and greener future.

The seamless collaboration between Aisin and Tohoku Magnet Institute indicates the possibility of future partnerships with prominent automakers, like Toyota, known for their strong commitment to environmental sustainability. Aisin’s history of supplying high-performance engines to electric Lexus models, such as the RX, suggests a possible integration of Nanomet-powered engines in Toyota’s upcoming electric vehicles.

As the world becomes increasingly focused on transitioning to cleaner energy solutions, Nanomet emerges as a transformative force in the quest for sustainable transportation. Its potential to significantly enhance efficiency while reducing CO2 emissions has sparked excitement and anticipation within the automotive industry and environmental circles alike. Automotive industry PA-Recycling

In conclusion, Aisin’s innovative electric car engine featuring the revolutionary Nanomet magnetic alloy showcases a remarkable breakthrough in energy efficiency and environmental sustainability. With its ability to slash energy losses by 50% and improve overall efficiency by 3%, Nanomet holds the promise of significantly reducing CO2 emissions by a staggering 72%. Aisin’s ambitious plans to introduce these engines into the market by 2029 signal a paradigm shift in the automotive industry towards greener and more sustainable mobility solutions. Automotive industry PA-Recycling

Moreover, the potential applications of Nanomet technology in diverse industries highlight its importance as a critical step towards a more energy-efficient and environmentally conscious future. With the potential collaboration of major automakers like Toyota, the widespread adoption of Nanomet-powered engines could pave the way for a cleaner, greener, and more sustainable transportation landscape.

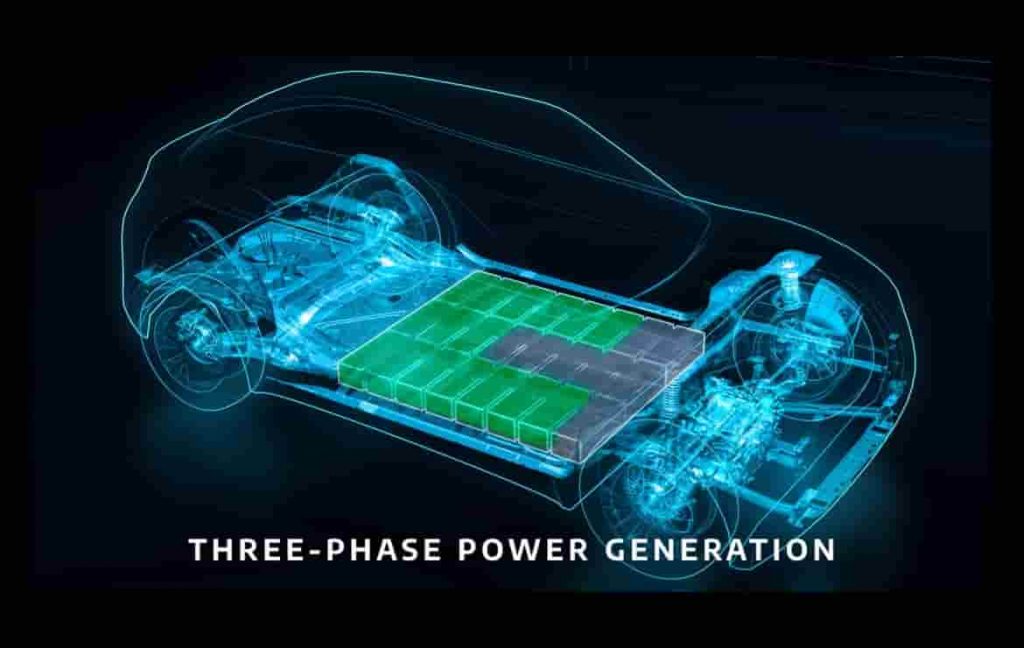

Stellantis, in collaboration with French Saft, has recently unveiled a groundbreaking battery technology named Ibis (Intelligent battery integrated system)

This innovative battery promises to revolutionize the world of electric cars by reducing costs, increasing efficiency, and boosting driving range.

At the heart of Ibis is its unique integration of an inverter and charger directly into the Li-ion battery components. By mounting the inverting boards as close as possible to the battery, the control system can now produce alternating current directly, which powers the electric motor. This significant change in design not only reduces the space required inside the vehicle but also leads to a substantial reduction in weight. As a result, production costs are lowered, which ultimately translates to more affordable prices for electric cars in the dealership. Moreover, the increased efficiency and reduced weight also contribute to improved reliability and extended driving autonomy. Automotive industry PA-Recycling

The team at Stellantis is currently focused on developing a prototype electric car equipped with the Ibis battery technology for rigorous testing on their group’s test tracks. Their ambitious goal is to bring these cutting-edge innovations to the market by the end of the decade. This demonstrates their commitment to pushing the boundaries of electric vehicle technology and providing consumers with enhanced driving experiences.

However, the potential of Ibis does not stop at electric cars.

The battery system is also being considered for use in stationary energy storage systems. Saft plans to offer energy storage solutions that optimize the use of installed energy, minimizing environmental impact. The architecture of the Ibis battery makes maintenance more manageable and significantly increases the power output of these stationary systems while simultaneously reducing their environmental footprint. Automotive industry PA-Recycling

Ned Curic, the Chief Engineering & Technology Officer of Stellantis, emphasized their commitment to innovation and research that caters to the real needs of electric vehicle buyers. The primary focus is on enhancing driving range, habitability, and accessibility while simultaneously reducing the environmental impact through greater efficiency.

By harnessing the power of the Ibis battery system, Stellantis envisions a decisive leap in their efforts to provide advanced, user-friendly technologies accessible to all. The integration of an inverter and charger into the battery represents a substantial leap forward in electric vehicle technology, marking a significant milestone for the entire industry. Automotive industry PA-Recycling

The future implications of this battery system are vast and promising. As electric vehicles become more accessible to a broader range of consumers due to lowered production costs, there will likely be an accelerated shift away from traditional internal combustion engines, leading to a more sustainable transportation landscape. The increased driving range and reduced environmental impact of Ibis-equipped electric vehicles will further cement the transition towards eco-friendly transportation.

Furthermore, the potential application of Ibis in stationary energy storage opens up opportunities for more efficient and sustainable energy management systems. This could play a crucial role in supporting the integration of renewable energy sources, such as solar and wind, into the power grid, thereby reducing reliance on fossil fuels and advancing the global pursuit of a greener energy future. Automotive industry PA-Recycling

In conclusion, the Ibis battery system developed by Stellantis and Saft stands as a beacon of hope for the electric vehicle industry and the sustainable energy sector as a whole. With its integrated inverter and charger, the Ibis battery paves the way for more efficient, reliable, and affordable electric cars, while also offering significant benefits to stationary energy storage solutions. As Stellantis continues to refine and commercialize this revolutionary technology, the world edges closer to a greener and more sustainable future for transportation and energy consumption.

Advancing the Circular Economy: Universal Recycling Quality Specifications Urged by Eunomia

Introduction

In a recently published report, Eunomia, in collaboration with the Alliance to End Plastic Waste, has stressed the urgent need for the plastics industry to develop and adopt universal quality specifications for mechanical recyclates. The report identifies the industry’s significant challenge in meeting recycling targets, primarily due to the insufficient supply of recycled plastic that meets the required quality standards for essential packaging applications. With the European Commission proposing to raise recycled content targets in the Packaging and Packaging Waste Regulation, the demand for improved recyclate quality becomes even more critical. Automotive industry PA-Recycling

To accelerate the circular economy and increase the availability of high-quality recyclates, the report puts forth essential recommendations for industry players to adopt.

Recommendations for Promoting Adoption of Quality Specifications

- Engaging Stakeholders: To ensure industry-aligned quality guidelines for packaging applications, the report recommends engaging brand owners, retailers, and other stakeholders throughout the value chain. By collaborating with various parties, the technical work on target quality guidelines can be finalized, fostering mutual understanding and support. Automotive industry PA-Recycling

- Conducting Industrial Trials: The report suggests conducting industrial trials for key applications to validate the appropriate recyclate quality required for specific packaging types. These trials will aid in defining accurate quality standards, ensuring that recyclates meet industry requirements and adhere to design guidelines for sorting and recycling facilities.

- Contributing to Certification Initiatives: Industry players are encouraged to actively participate in ongoing certification initiatives, such as forthcoming standards from CEN and CENELEC. Leveraging collective knowledge from these initiatives will expedite industry acceptance and adoption of quality standards.

- Providing Implementation Guidelines: Clear and systematic guidelines should be offered to facilitate the implementation of quality specifications. This will support industry players in their efforts to work towards aligned global standards, thus enhancing overall recycling efficiency. Automotive industry PA-Recycling

Benefits of Implementing the Measures

By following these recommendations, the plastics industry can address the pressing challenges of insufficient high-quality recyclates. This, in turn, will significantly increase the utilization of recycled content in plastic products, making substantial progress towards achieving sustainability goals and reducing the environmental impact of plastic waste.

Addressing Industry Challenges

Andy Grant, the technical director at Eunomia Research & Consulting, highlighted that a significant barrier to advancing the plastics circular economy lies in achieving a clear agreement on the specifications of materials that recyclers can produce and the industry can use. The report’s approach aims to bridge this gap by fostering collaboration and establishing universal quality guidelines for plastic recyclates.

Optimizing Recycling Infrastructure

The report emphasizes the need to optimize sorting and recycling infrastructure to ensure that recyclates meet brand owner requirements and align with design guidelines for various facilities. Automotive industry PA-Recycling

This will not only increase the availability of high-quality recyclates but also contribute to the rapid development of sorting infrastructure and complementary recycling technologies.

The Alliance’s Contribution

Martyn Tickner, chief advisor of the Technical Solutions Centre at the Alliance, expressed the plastics industry’s ambitious recycling targets, necessitating swift development of sorting infrastructure and the deployment of complementary recycling technologies.

The Alliance is committed to supporting this transition and believes that the rapid adoption of quality standards throughout the value chain is a crucial step in this process.

Conclusion

Eunomia’s report serves as a call to action for the plastics industry to embrace universal recycling quality specifications. Automotive industry PA-Recycling

By aligning industry players on standardised quality guidelines for mechanical recyclates, the circular economy can be accelerated, promoting the use of high-quality recycled content in plastic products. Collaborative efforts and implementation of the report’s recommendations will pave the way for a sustainable future, reducing plastic waste’s impact on the environment. With the industry’s commitment and cooperation, the vision of a circular economy can become a reality, benefitting both businesses and the planet.

US Electric Vehicle Battery Recycling Promoted by Inflation Reduction Act

In a surprising twist, the US Inflation Reduction Act (IRA) is revolutionizing electric vehicle (EV) battery recycling efforts in North America and posing a formidable challenge to China’s dominant position in the field. Within the IRA lies a little-known clause that states any EV battery materials recycled within the US will automatically qualify as American-made for subsidies, irrespective of their origin.

This qualification has far-reaching implications for automakers, as it opens the door to lucrative EV production incentives when they opt for recycled battery materials sourced domestically. Automotive industry PA-Recycling

Experts and industry officials, interviewed by Reuters, have pointed out that this clause is fueling an unprecedented boom in US factory construction, spurring automakers to explore more recyclable battery alternatives, and possibly complicating matters for buyers in developing countries seeking to purchase used EVs.

Currently, China reigns supreme as the global hub for EV battery recycling, with the market projected to reach a staggering $18 billion by 2028. The valuable minerals, such as lithium, cobalt, and nickel, extracted from these batteries, are worth approximately 1,000 to 2,000 euros per car. With the increasing production of EVs, the demand for these minerals is likely to outstrip supply. However, the good news is that these minerals can be recycled multiple times without losing their potency.

Capitalizing on the incentives provided by the IRA, numerous US recycling plants are already under construction. For instance, Li-Cycle, a Canadian battery recycling firm, secured a $375 million US government loan to build a plant in New York, set to open later this year. According to the company, this funding played a pivotal role in accelerating their investment decision. Similarly, Redwood Materials, the recipient of a $2 billion US government loan, is planning to establish a battery material recycling and remanufacturing complex in Nevada. Automotive industry PA-Recycling

The IRA treats recycled battery materials as “urban mined” or locally sourced, rather than acquired through conventional mining methods. This approach has prompted US companies to prioritize recycling efforts over their European counterparts, who have predominantly focused on mandating minimum percentages of recycled materials in future EV batteries. However, recycling firms like Ascend Elements and Li-Cycle are planning to build plants in Europe within the next few years and will rely on funding and incentives available in the region.

Many companies are striving to create “closed-loop supply chains,” where recycled minerals are utilized to produce new batteries locally.

This strategy aims to reduce dependence on Chinese imports and maintain control over the entire supply chain. Despite this ambition, China is still ahead in the battery recycling race. The country has recently introduced more stringent standards and increased research support for recyclers, criticizing the IRA as “anti-globalization” and accusing the US of “unilateral bullying.” Automotive industry PA-Recycling

On a global scale, over 80 companies are actively engaged in EV recycling, with more than 50 startups securing at least $2.7 billion in corporate investments over the past six years. The volume of EV batteries available for recycling is expected to increase over tenfold by 2030. Considering the average lifespan of electric vehicle batteries to be around 10 years or more, it is estimated that by 2040, 40% of battery materials used in new EVs could originate from recycled stocks.

At present, the US and Europe have limited recycling capacity, but concerted efforts to improve recycling processes and enhance recovery yields are already underway. Companies like Ecobat in Texas have developed methods to recover approximately 70% of battery-cell lithium during the recycling process. As technology advances, yield levels are expected to improve to an impressive 90% to 100%. The EU is also planning to mandate minimum amounts of recycled lithium, cobalt, and nickel in EV batteries within eight years, which will further bolster recycling efforts within the region. Automotive industry PA-Recyclingv

However, one major challenge facing the industry is sourcing old EVs for recycling. Many of Europe’s older fossil-fuel-powered cars are either sold overseas or scrapped, making it difficult to track and recycle their EV batteries. Some automakers are exploring strategies like leasing EVs to retain control over the batteries. Nonetheless, keeping valuable battery minerals in Europe could potentially limit the availability of affordable transportation options for developing countries.

In conclusion, the US Inflation Reduction Act is sparking a surge in EV battery recycling efforts in North America, challenging China’s longstanding dominance in this domain.

The automatic qualification of US-recycled battery materials as American-made for subsidies serves as a powerful incentive for automakers to explore recyclable battery options and support local recycling initiatives. While China currently maintains its lead, the global market for EV battery recycling is projected to experience significant growth, with Europe also gearing up to bolster its recycling capacity. Efforts to establish closed-loop supply chains and improve recycling processes are vital in meeting the escalating demand for EV batteries while reducing reliance on imports. Automotive industry PA-Recycling

Graphene Makes PE Stretch Film Ultrathin and Strong

Film manufacturer Packseven is rolling out a recyclable polyethylene stretch film made with Gerdau’s graphene masterbatch that reduces virgin resin use by 15% to 30%.

Graphene technology is to thank for the commercialization of a new type of stretch film that is significantly thinner and more durable than conventional alternatives. The new graphene-enhanced stretch film, from film manufacturer Packseven, incorporates the Poly-G graphene masterbatch from Gerdau Graphene. Automotive industry PA-Recycling

The companies, both based in Brazil, claim Packseven’s new product is the world’s first commercial stretch film enhanced with graphene, an exceptionally strong material featuring an atomic monolayer of carbon atoms arranged hexagonally in a honeycomb-like structure.

When blended with plastics, graphene lends its strength to the polymer matrix and greatly strengthens the blended plastic. Graphene improves physical and mechanical properties like puncture-resistance and increases barrier properties against liquids and gasses. It also protects against weather, oxidation, and ultraviolet light, and boosts electrical and thermal conductivity. Automotive industry PA-Recycling

Packseven’s graphene-enhanced stretch film is expected to be available for sale in the third quarter of 2023, launching in Brazil.

Additionally, “The Poly-G masterbatch used to create Packseven’s product is currently available in Brazil and Japan. In Japan, Gerdau Graphene has a strong partnership with Sumitomo to commercialize the product,” Alex Correa, CEO of Gerdau Graphene, tells us.

Poly-G can be exported to US plastics manufacturers, he adds.

Advantages of graphene masterbatch enhancement.

Incorporating graphene into plastic films offers plastics companies and their customers transportation, storage, and packaging benefits vs. conventional films.

Initial testing of Packseven’s ultra-thin stretch film shows that the film can pack 120% more material without breaking, vs. other stretch films.

Graphene-enhanced stretch films are more resistant to being punctured by sharp objects, as well. Automotive industry PA-Recycling

The graphene-enhanced film’s durability translates into reduced consumption of stretch film per pallet and safer packing and loading. Its improved strength and durability also make it possible to significantly reduce the thickness of the film.

Thus virgin plastic use is reduced, resulting in a higher-performance, more sustainable low-weight film. Furthermore, the virgin resin reduction drives down post-consumer polyethylene waste.

The enhanced film is recyclable, too. “The re cyclability of the final polymer product is unaffected by the addition of graphene to the polymer mix,” Correa says.

Graphene masterbatch’s ROI cost benefits. Automotive industry PA-Recycling

Gerdau piloted the Poly-G masterbatch in a series of industrial applications in its own factories prior to commercializing the additive. In one pilot, a graphene-enhanced film for construction-nail packaging was tested.

Introducing Pirelli P Zero E: The Revolutionary Tires Engineered for Electric Vehicles

Pirelli, renowned for its dominance in the world of motorsport, has once again raised the bar in tire technology with its latest innovation – the P Zero E. Unveiled at the prestigious Goodwood Festival of Speed alongside its counterparts, the P Zero R and P Zero Trofeo RS, the P Zero E is specifically designed to cater to the growing market of electric cars. Pirelli boldly claims that this tire is a “champion of performance and sustainability,” proving that eco-conscious driving doesn’t have to compromise on safety or excitement.

One of the most remarkable features of the P Zero E tires is their composition, consisting of an impressive 55% natural and recycled materials Automotive industry PA-Recycling

This groundbreaking achievement showcases Pirelli’s commitment to minimizing the environmental impact while still delivering exceptional driving dynamics. For environmentally conscious drivers who seek exhilarating performance without harming the planet, the P Zero E tires are the perfect match.

With Pirelli being the exclusive tire partner at the Goodwood event, the P Zero E shares the stage with the P Zero Rs, tailored for supercars, and the P Zero Trofeo RS, designed for hypercars. Pirelli’s illustrious history in motorsport spanning almost four decades demonstrates the brand’s expertise and dedication to tire innovation, continuously pushing the boundaries of automotive performance. Automotive industry PA-Recycling

Pirelli’s foresight in anticipating the forthcoming Euro 7 anti-pollution regulations led them to address tire emissions as well. Consequently, the development of the P Zero E took into account not only its performance but also its environmental impact. Bureau Veritas, a global leader in certification and compliance verification, has meticulously verified and certified the tires’ composition, confirming the use of 55% natural and recycled materials. Moreover, Pirelli’s extensive study of the tire’s lifecycle revealed a remarkable 24% reduction in CO2 emissions compared to the previous generation of tires, further corroborated by Bureau Veritas. Automotive industry PA-Recycling

Pirelli’s commitment to sustainability is undoubtedly commendable. While other tire manufacturers are also striving to produce eco-friendlier compounds, Pirelli’s P Zero E represents a significant leap forward in the industry. The findings from this groundbreaking endeavor are expected to pave the way for even higher percentages of recycled and natural materials in future tire models. Drivers seeking greener alternatives can easily identify these eco-conscious tires through the distinctive “Elect” marking on the sidewall.

The Pirelli P Zero E stands as a testament to the company’s dedication to innovation, performance, and sustainability. As the automotive landscape embraces electric mobility and stricter environmental regulations loom, Pirelli has set a precedent for the tire industry. Their pioneering efforts in creating high-performance eco-friendly tires not only cater to the needs of the present but also leave a lasting impact on the future of mobility.

In conclusion, the P Zero E tires exemplify a remarkable synergy between sustainability and driving excellence. Pirelli’s vision of a cleaner, greener automotive world has materialized in these groundbreaking tires, setting new benchmarks for the industry and inspiring a generation of drivers committed to both performance and preserving the planet. Automotive industry PA-Recycling

PET-to-PET EV-Car – Are plastic bale prices nearing bottom? 21-07-2023

Automotive industry PA-Recycling