Barrierfilm rPETRecycling CircularEconomy 26-03-2021 - Arhive

Barrierfilm rPETRecycling CircularEconomy

Crude Oil Prices Trend

-Scratch-Resistant PP for Complex Interior Automotive Applications

Compounder Polykemi and subsidiary Rondo Plast launch first of new PP-based compound and sustainable variants that boast both high scratch resistance and UV stability.

A new family of scratch resistant PP compounds focused on complex interior automotive applications has been developed by Sweden’s specialty compounder Polykemi AB (U.S. office in Evansville, Ind.) and its fully-owned subsidiary Rondo Plast AB, a provider of quality assured and recycled plastics based on PP, ABS, PBT, nylon 66, and PC/ABS.

The first newly developed PP-based material of the new Complus Concept family is virgin raw material based compound Polyfill PP EP317R UV, which boasts both high scratch resistance and UV stability, together with excellent mechanical properties and reportedly unlimited coloration possibilities. These features are said to make the material an optimum choice for interior automotive applications.

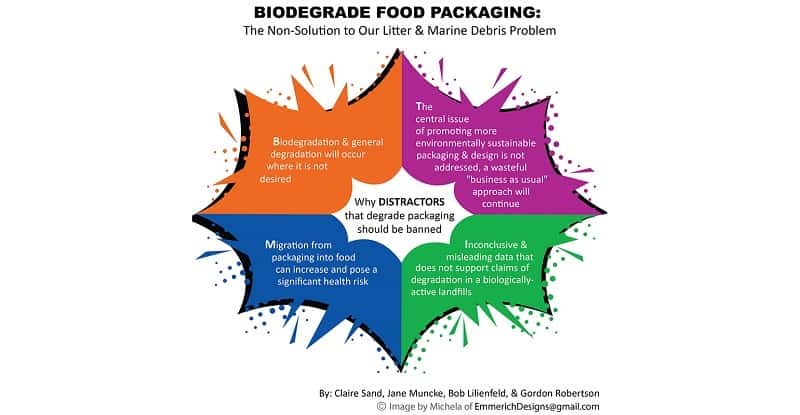

-Are Biodegradable Additives for Food Packaging a Solution? No, They Make It Worse

We know that biodegradable additives in packaging are the wrong solution to the plastics problem, so why are they still on the table?

As we all know, packaging plays a major role in achieving a more sustainable food system. However, consumers hear of and sometimes encounter rivers clogged with packaging, islands in oceans made of garbage, and discarded packaging littering the roadside. Barrierfilm rPETRecycling CircularEconomy

We all would like this ill-disposed packaging to “just go away!” And, we do have the technology to make it disappear. Yes, this packaging in the oceans, rivers, lakes, and streets can easily be degraded, and we can have more space in our landfills if we add degradable technology to packaging. Right? Wrong!

-Berry to expand nonwovens production in Europe

Berry Global, a leading global nonwovens manufacturer, announced its second investment for 2021 in the wipes segment to support the long-term consumer behavior shift towards infection prevention, amplified by the Covid-19 pandemic, said Nonwovens-industry. Barrierfilm rPETRecycling CircularEconomy

The investment, located in Europe, will increase Berry’s production footprint in support of its global customers, with total investments reaching over USD110 million in nonwoven materials for products such as hard surface disinfectant wipes. Prior to the demand surge of 2020, the European impregnated wet wipes segment, for home cleaning and disinfecting, was growing at the rate of 5% in the 2014 to 2019 time frame. Covid-19 has increased heightened focus on sanitation and personal hygiene for infection prevention, suggesting permanent consumer trends away from the chore of cleaning to a health and safety priority.

“We strategically partner with many of the world’s leading brands with wipe materials, ensuring our investments align with demand for today and for the future. The reliability of our capacity and scale are paramount to our customer support and the trusted relationships we desire to maintain,” says Curt Begle, president of Berry’s Health, Hygiene, and Specialties Division.

-Renewable Styrenic Polymers Launched

Ineos Styrolution offers its first specialty thermoplastics based on renewable styrene.

The fist specialty thermoplastics based on renewable styrene monomer from leading global styrenics supplier Ineos Styrolution, Aurora, Ill., are said to offer 74% lower greenhouse gas emissions when compared to styrene made from fossil fuel.

Styrolux ECO and Styroflex ECO resins are a range of thermoplastic styrene-butadiene copolymers (SBC), said to offer identical product characteristics as the conventionally produced Styrolux/Styroflex copolymers. Styrolux/ -flex ECO is available in two grades in commercial quantities: Styrolux/-flex ECO B60 in which100% of the fossil-based styrene is replaced by renewable styrene; and, Styrolux/-flex ECO B30 in which 50% of the fossil-based styrene is replaced by renewable styrene. Barrierfilm rPETRecycling CircularEconomy

-Avantium secures new offtake contracts for planned FDCA flagship plant

Avantium N.V., a leading technology company in renewable chemistry, announces that its subsidiary Avantium Renewable Polymers (“Avantium RNP”) has signed two additional conditional offtake agreements for the supply of PEF resin to manufacture bottles and films, bringing the total now to four such contracts. The partners involved include specialty chemical company Toyobo (Japan), specialty polyester film producer Terphane (USA), the beverage bottling company Refresco (Netherlands), and a major global food & beverage brand owner. Barrierfilm rPETRecycling CircularEconomy

Avantium RNP aims to commercialise its proprietary plants-to-plastics YXY® Technology, which is used to produce FDCA (furandicarboxylic acid) – the main building block of the high-performance, plant-based and fully recyclable polymer PEF (polyethylene furanoate). Avantium has demonstrated the technology in its pilot plant in Geleen and the company plans to open, dependent on a positive Final Investment Decision (FID), the world’s first commercial FDCA plant in 2023.

-Gneuss Kunststofftechnik: Efficiency increase in PET-recycling by retrofitting existing melt filter

Spanish PET bottle-to-bottle recycler sees major efficiency improvements by replacing melt filter – against a background of government rules prescribing the proportion of recycled polymer, the plastics strategy of the EU and the commitment of many market leaders to responsible use of polymers, the conversion or modification of extrusion lines represents an important trend. The German manufacturer of Filtration Systems, Gneuss, has seen a surge of interest among customers looking to retrofit their extrusion lines, despite the Covid-19 Crisis.

The expectations that Nosoplas placed on the retrofit with a Gneuss Rotary Filter have been completely fulfilled. Immediately after commissioning the units, a drastic reduction in in material loss due to back flushing was observed and, at the same time, the quality of the rPET granulate produced was noticeably improved.

RSFgenius back flushing filters as optimum retrofit solution for PET bottle flake recycling Barrierfilm rPETRecycling CircularEconomy

The processing of PET Bottle Flakes presents particular challenges for Melt Filtration Systems. On the one hand, the post-consumer material source typically has a relatively high contamination level, on the other hand, the quality requirements (fine filtration) are very high – especially when the material is to be put back into transparent bottles for beverages.

Amsterdam and Brussels: AVTX), a leading technology company in renewable chemistry, reports its 2020 full-year results.

Key business progress during 2020 Barrierfilm rPETRecycling CircularEconomy

Avantium Renewable Polymers made progress towards a Final Investment Decision (FID) concerning the construction of the planned FDCA (furandicarboxylic acid) flagship plant, but not all conditions for a positive FID were met by the end of 2020: Avantium announced this morning that to date it has signed conditional offtake agreements with specialty chemical company Toyobo (Japan), specialty polyester film producer Terphane (USA), the beverage bottling company Refresco (Netherlands), and a major global food & beverage brand owner, representing in total 30% of the FDCA flagship plant capacity;

Avantium Renewable Chemistries achieved the successful start-up and commissioning of the plantMEG™ (mono-ethylene glycol) demonstration plant;

The COVID-19 pandemic delayed on-site projects with customers and impacted new system orders for Avantium Catalysis; the Catalysis contract research services business did, however, grow during the period.

-Levissima Launches 100% Recycled Plastic Bottle In Italy

Levissima, part of Gruppo Sanpellegrino, has launched mineral water bottles made with 100% recycled PET plastic (rPET) in Italy.

The launch is part of the brand’s ongoing commitment to a more sustainable world and achieving a circular economy. Barrierfilm rPETRecycling CircularEconomy

The first bottles of natural mineral water made from 100% recycled PET plastic include 0.75- and 1-litre non-carbonated formats.

Earlier, Levissima launched the bio-based PET in the non-alcoholic drinks segment in Italy.

New Legislation

The use of up to 100% recycled PET bottles and tubs for food use is now possible after a new Italian legislation came into force in January 2021, extending the existing limit set at 50%.

The term rPET refers to a polymer obtained through the recovery and recycling of used PET.

The material is identical in terms of quality, safety and resistance to traditional PET and can also be recycled almost infinitely.

-Barrier film found to have limited recycling compatibility by RecyClass

An independent laboratory testing of an unprinted LDPE-based multilayer film manufactured by UBE has found limited compatibility with PE flexibles recycling streams. Barrierfilm rPETRecycling CircularEconomy

The AIMPLAS technology centre carried out the analysis on UBE’s Performance PA SC15 according to the RecyClass Recyclability Evaluation Protocol for PE films. Subsequent approval is limited to a certain type of polyamide (PA) copolymer and, therefore, cannot be extended to the whole family of polyamides.

UBE’s technology features barrier properties provided by a PA inner layer. The compatibility of the structure is ensured with LLDPE-based tie layers grafted with maleic anhydride (MAH).

The results obtained from the testing demonstrate that the technology has limited compatibility with the existing European industrial recycling processes for PE flexibles, given specific conditions. One of the key requirements is the melting temperature of the PA 6/6.6 copolymer barrier, which must not be higher than 192 deg C. Additionally, the technology in question must have specific tensile modulus and elongation properties and the PA layer can represent a maximum of 15 per cent of the total weight of the film. Furthermore, a minimum of 10 per cent by weight of LLDPE-based tie layers grafted with at least 0.06 per cent MAH needs to be incorporated into the structure.

-Agreement for the recycling of compostable materials

Novamont and Iren will develop new management models for compostable bioplastic packaging in organic treatment plants.

The bioplastics producer Novamont and the multi-utility Iren have signed a three-year collaboration agreement in the field of integrated waste collection systems, with the aim of reducing non-recyclable waste at source and fully implementing the objectives of the circular bioeconomy. Barrierfilm rPETRecycling CircularEconomy

The first step of the agreement is the development of a technical-economic model for the management of compostable bioplastic packaging and of the pre-treatment waste of the organic fraction within the integrated anaerobic digestion and composting plants, using optical selection technologies in order to maximize recovery.

The agreement also provides for the organization of dedicated flows (also of an experimental nature) of organic fraction with disposable compostable products from markets, catering establishments and large events.

Barrierfilm rPETRecycling CircularEconomy