Biodegradable plastic – R-Carbon-fiber 30-05-2023 - Arhive

Biodegradable plastic – R-Carbon-fiber single-cell energy density 240Wh/kg

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

-New research reveals that biodegradable plastic used in clothing does not degrade as quickly as anticipated

Plastic pollution has become a critical environmental issue, with millions of tons entering the environment annually, including a significant amount ending up in our oceans. These plastics break down into harmful microplastic particles that pose a threat to wildlife as they can be ingested.

While discarded bottles and bags are commonly recognized as plastic waste, the synthetic fibers found in our clothing, such as polyester, nylon, and acrylic, present an equally concerning problem. Each year, over 60 million tons of plastic fabric are produced, a substantial portion of which ultimately finds its way to landfills.

One promising solution to combat this crisis is the utilization of “biodegradable” plastics. These plastics are designed to naturally decompose into gases and water, which are then released back into the environment without causing long-lasting harm. However, recent research conducted by the Scripps Institution of Oceanography in San Diego, California, indicates that a popular bioplastic material known as polylactic acid does not degrade in the environment as rapidly as initially hoped. Biodegradable plastic – R-Carbon-fiber

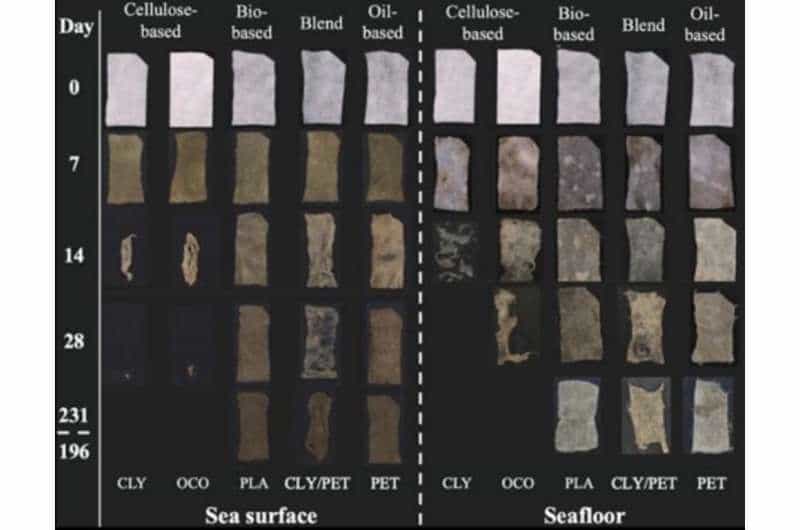

In their study, the researchers suspended fiber samples made of both bio-based and oil-based plastic materials, as well as natural fibers like cotton, in coastal waters and on the seafloor. Over time, they observed these individual fibers under a microscope to monitor their decomposition. While cotton fibers started breaking down within a month, synthetic fibers, including bioplastics like polylactic acid, showed no signs of degradation even after being submerged in the ocean for 400 days. single-cell energy density 240Wh/kg

The issue of plastic pollution stemming from clothing poses a particular challenge. Clothes are often not recycled or designed to be recyclable, and they release tiny plastic fibers into the environment through gradual wear and tear. These clothing fibers can reach the oceans through various pathways. For instance, garments that end up in the sea may undergo physical breakdown caused by wave action or friction with sand particles, resulting in the release of fibers as the fabric deteriorates.

Even the act of wearing clothes leads to the discharge of plastic fibers into the environment, some of which may eventually settle in the ocean. Additionally, during the laundering process, fibers become dislodged and are carried through drains, potentially finding their way into the sea. Biodegradable plastic – R-Carbon-fiber

Given that clothing fibers inevitably find their way into the environment regardless of our actions, it is crucial to seriously consider the fate of these fibers once they are released.

Credit: Royer et al. (2023)

-Elon Musk, CEO of Tesla, announced in an interview with the Wall Street Journal that the company intends to disclose the location of its upcoming assembly plant by the end of 2023

While Mexico has already been chosen as the next destination for a Gigafactory outside the United States, there is another factory in the works.

When asked about the most exciting country to establish a Tesla plant, Musk confirmed that Mexico has been selected, with a site already identified. Additionally, he mentioned that another location will likely be chosen later in the year. The interviewer suggested India as a potential option, to which Musk responded positively, expressing interest in the country. single-cell energy density 240Wh/kg

Currently, Tesla operates multiple car manufacturing facilities worldwide, including two in the United States, one in Germany, and one in China. Mexico is slated to become the next host of a Gigafactory. While opening a factory in India would provide Tesla with access to a cost-effective labor force, no official confirmation has been made. Musk also recently met with French government officials, including President Emmanuel Macron, to discuss the possibility of Tesla investing in France. Biodegradable plastic – R-Carbon-fiber

Although he indicated that Tesla will invest in the European country at some point, specific details were not disclosed.

Tesla’s Fremont and Shanghai facilities are currently operating at maximum capacity, while the Berlin and Austin plants are still in the process of scaling up production. Despite this, the company witnessed a 37 percent surge in US registrations during the first quarter of 2023, with 155,360 new Tesla EVs hitting the roads. This positive trend sets the stage for Tesla’s goal of producing 1.8 million units globally by the end of the year.

With four operational car-making facilities worldwide, one under construction, and another on the horizon, Tesla continues to make impressive strides in its 20-year history.

Credit : InsideEVs

-Gotion High-Tech launches new L600 LMFP Astroinno battery; single-cell energy density of 240Wh/kg

China-based Gotion High-Tech launched its L600 Astroinno lithium manganese iron phosphate (LMFP) battery cell and pack at the 12th Gotion Technology Conference. This manganese-doped LMFP Astroinno battery features a gravimetric energy density of 240Wh/kg, a volumetric energy density of 525Wh/L, a cycle life of 4000 times at room temperature, and a cycle life of 1800 times at high temperatures, according to Dr. Cheng Qian, Executive President of the International Business Unit of Gotion High-Tech.

Volumetric cell-to-pack ratio has reached 76% after adopting the L600 cell, and the system energy density has reached 190Wh/kg, surpassing the pack energy density of current mass-produced NCM cells, said. single-cell energy density 240Wh/kg

“It is due to the high energy density of Astroinno battery that we can enable a range of 1000km without relying on NCM materials”. Biodegradable plastic – R-Carbon-fiber

According to Dr. Cheng, after ten years of in-house research on lithium manganese iron phosphate (LMFP) materials, Gotion High-Tech solved the challenges of Mn dissolution at high temperatures, low conductivity, and low compaction density through utilizing co-precipitation, doping encapsulation technology, new granulation technology and new electrolyte additives.

Gotion High-Tech’s breakthroughs in LMFP, on the one hand, are due to the forward-looking materials deployment of the company, which obtained the “New Product Certificate of IFP1865140-15Ah Prismatic LMFP Battery” in 2014, and received the “New Product Certificate of LMFP Carbon Composite Cathode Materials for Lithium-ion Batteries” in 2016; on the other hand, the achievement is also attributable to the company’s R&D efforts worldwide.

Its research institution in Cleveland, Ohio has developed a new electrolyte for LMFP, which has greatly improved the cycle and storage performance at high temperatures. With its in-house LMFP materials and electrolytes, Gotion High-Tech successfully developed the Astroinno L600 battery cell.

The LMFP Astroinno L600 battery cell is scheduled to begin mass production in 2024, said Dr. Cheng. Biodegradable plastic – R-Carbon-fiber

According to Dr. Cheng, in addition to the upgrade and innovation of the battery material system, there are also several technical breakthroughs and innovations concerning the Astroinno battery pack developed based on the new battery cell.

The Astroinno battery pack adopts sandwich-structure double-sided liquid cooling technology and a minimalist design approach, which reduces the number of structural parts of the battery pack by 45% and lowers the weight of structural parts by 32%.

The minimalist electrical design enables the length of the battery pack wiring harness to drop from 303 meters to 80 meters—only 26% of that of previous battery packs—but the volumetric cell to pack ratio has reached 76% and the pack energy density has reached 190Wh/kg, outperforming the energy density of NCM batteries currently on the market.

In other words, without adopting the NCM battery system, Gotion High-Tech’s Astroinno battery pack has achieved a range of 1000km for the first time in the industry, and achieves more than 1800 cycles of 18-minute fast charging. single-cell energy density 240Wh/kg

In addition, intrinsic safety is also the main advantage of Astroinno battery pack: the thermal decomposition temperature of the materials it used is much higher than that of ternary materials, which makes the materials intrinsically safe. The in-house thermal insulation materials can withstand a high temperature of up to 1200°C, which is equivalent to putting a layer of heat-insulating skin on the battery cell surface, and it provides four layers of ultimate safety protection through rapid heat exhausting channels set for extreme circumstances and active safety BMS. Biodegradable plastic – R-Carbon-fiber

Credit : Gotion High-Tech

-A few months ago, China confirmed the sale of a quantum computer to an undisclosed buyer, making it the third country, after the United States and Canada, to commercialize these revolutionary machines

Although the sale actually took place the previous year, it was recently made public with limited details about its specific use.

This development has sparked intense competition among major industry players such as Google, IBM, Intel, and Microsoft, as well as renowned research centers like MIT and Harvard. The advent of quantum computers marks one of the most significant battlegrounds in the field of information technology. single-cell energy density 240Wh/kg

So, what exactly is a quantum computer? Unlike traditional computers, quantum computers leverage the principles of physics and quantum mechanics to process data, utilizing qubits as their fundamental unit instead of classical bits. Qubit stands for quantum bit and possesses unique properties derived from quantum physics. These include data superposition, enabling parallel and non-sequential computations, entanglement, which correlates two qubits to accelerate computational processes, and quantum interference, an effect of superposition that allows control over qubit measurements by exploiting the wave nature of particles. Biodegradable plastic – R-Carbon-fiber

To understand the origins of this technology, we must reflect on the past few decades when the pursuit of computer advancements was guided by Moore’s Law. This law postulates that the complexity of microcircuits, measured by the number of transistors on a chip and their calculation speed, doubles every 18 months. This relentless drive towards greater power in ever-shrinking processors eventually reached the limits of classical mechanics. To overcome these limitations, scientists turned their attention to the realm of quantum physics. single-cell energy density 240Wh/kg

Explaining the intricate workings of a quantum computer in detail is a highly complex task, and for the sake of avoiding excessive technicality, we will provide a concise overview. Quantum computers operate based on the principles of superposition and entanglement, leveraging qubits to perform intricate calculations in parallel at an unimaginable speed compared to traditional computers. They can complete highly complex computations in seconds that would take hours, months, or even years on conventional systems.

This is where the crucial element of cooling comes into play. Quantum technology is highly sensitive to heat and requires near-absolute-zero temperatures (-273°C) to function optimally. Therefore, the development of effective cooling solutions is of paramount importance for the rapid and widespread advancement of quantum computers.

The potential applications of quantum computers span across various fields. Machine learning will greatly benefit from their immense processing and calculation capabilities, making automatic machine learning significantly faster. Similarly, artificial intelligence will experience faster calculations, driving advancements in the field. Quantum computers also hold promise in chemistry and biochemistry, enabling the generation of new fertilizers, battery chemicals, tailor-made drugs, and personalized medicine. Other areas where quantum computing can revolutionize industries include the development of highly durable and high-performing materials, optimization of mathematical calculations, and simulations in the realm of information technology. Biodegradable plastic – R-Carbon-fiber

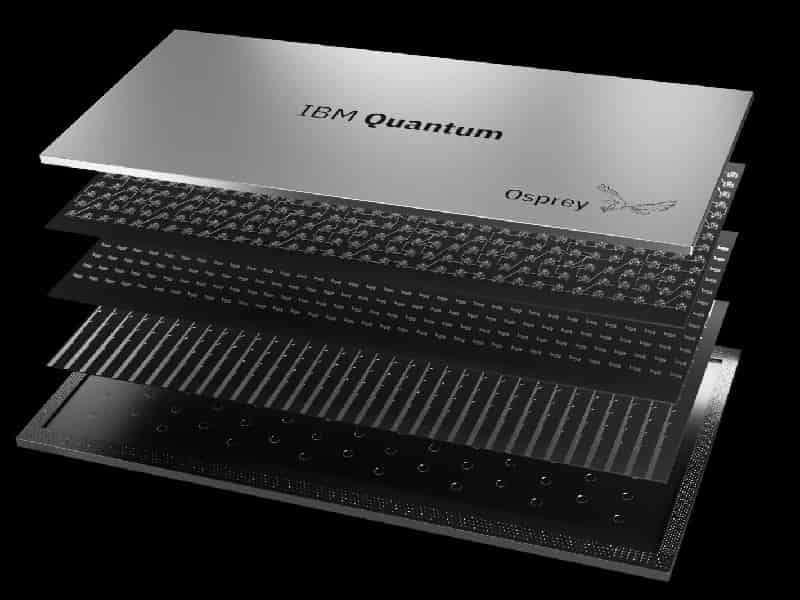

Notably, IBM unveiled Osprey, the most powerful quantum computer to date, last autumn. Boasting 433 qubits, it surpasses its predecessor Eagle by a factor of three and even outperforms Sycamore, Google’s quantum computer that achieved the milestone of quantum supremacy. IBM claims that Osprey will revolutionize complex calculations, delivering unprecedented speed and efficiency. Its construction process involved the utilization of superconducting materials optimized for operation at the aforementioned ultra-low temperatures. single-cell energy density 240Wh/kg

In summary, the advent of quantum computers signifies a major leap forward in computing capabilities. With their unique properties and extraordinary processing power, these machines are poised to revolutionize various industries and drive innovation to unprecedented heights. Biodegradable plastic – R-Carbon-fiber

Credit : IBM Quantum Osprey

-GUESS : US Clothing Giant Expands in Russia, Consolidating Business

According to recent reports from Kommersant, American fashion brand Guess is making an unconventional move in the sanctioned country of Russia by reacquiring its stake from a local partner. This deal, which experts have deemed unusual for the fashion market in Russia, highlights Guess’s commitment to expanding and consolidating its business in the country. single-cell energy density 240Wh/kg

Guess purchased its 30% share back from Vyacheslav Shikulov, its Russian partner, for a sum of 8 million ($8.5 million). With the approval of the US Treasury Department, the clothing manufacturer and retailer now holds 100% ownership of its Russian operations. This move aligns with a “put option” agreement signed by both parties in 2015, allowing Shikulov to sell his stake by December 31, 2025. Biodegradable plastic – R-Carbon-fiber

In November 2022, Shikulov exercised this option, prompting Guess to seek permission from the Office of Foreign Assets Control (OFAC) within the US Department of the Treasury to proceed with the buyback. By completing this acquisition, Guess stands out from the majority of Western companies exiting Russia, as they typically opt to sell their assets to local investors. Industry experts speculate that this deal could indicate Guess’s concerns about the future of its operations in Russia. single-cell energy density 240Wh/kg

Despite the challenges faced by foreign brands in Russia, Guess experienced a 24% increase in revenue in 2022, amounting to 4 billion rubles ($49.9 million), according to available data. Many foreign businesses have been under increasing pressure from their governments, resulting in a significant number of exits from the Russian market in the past year. These companies have often incurred substantial losses upon exiting. For instance, Japanese retailer Uniqlo recently decided to sell most of its stores in Russia after incurring multimillion-dollar losses. Similarly, Swedish brand H&M suffered losses of approximately $363 million, while Spanish conglomerate Inditex, owner of renowned brands like Zara, Bershka, and Massimo Dutti, faced losses of about $300 million. Other companies such as Decathlon, Moncler, and Hermes also reported substantial financial setbacks due to their operations in Russia. single-cell energy density 240Wh/kg

In contrast, Guess’s decision to expand and consolidate its business in Russia demonstrates a unique approach, showcasing its confidence in the market despite the challenges faced by other Western companies.

Credit : Guess

-Vartega, a specialist in carbon fiber recycling based in Denver, Colorado, has expanded its operations by inaugurating a new facility spanning 82,000 square feet

The company celebrated this significant milestone on May 23 with a ribbon-cutting ceremony at the Pecos Logistics Park in Denver. The state-of-the-art facility will empower Vartega to substantially increase its production capacity and meet the rising demand for recycled carbon fiber. single-cell energy density 240Wh/kg

CEO and founder Andrew Maxey, along with the company’s 35 employees, marked this occasion alongside Dale Brosius, the CCO of IACMI in Knoxville, Tennessee, and Rama Haris, the Senior Manager of Advanced Industries at the Colorado Office of Economic Development and International Trade. During his speech at the event, Maxey emphasized Vartega’s unwavering commitment to a sustainable future and a circular economy through carbon fiber recycling. Biodegradable plastic – R-Carbon-fiber

Reflecting on the journey that brought Vartega to this juncture, Maxey expressed his astonishment at the remarkable individuals and perspectives that have contributed to the company’s success. He acknowledged the ever-evolving technology in the industry, which challenged Vartega to discern the genuine needs of the market rather than relying solely on perceived needs. This approach enabled the company to develop a material that addresses an immediate and deliberate demand in the industry. Maxey also highlighted that the construction of a manufacturing facility of this magnitude surpassed his original expectations, but in a profoundly positive way.

In the face of a growing market and heightened competition, Vartega has embraced a collaborative strategy. Maxey believes that by working with competitors, his company can not only create value for them but also gain insights and ideas in return. Rather than solely focusing on expanding Vartega’s market share in carbon fiber recycling, Maxey and his team prioritize enlarging the overall market. This philosophy has led to unexpected partnerships and collaborations, fostering a proactive approach to tackling the issue of carbon fiber waste. Biodegradable plastic – R-Carbon-fiber

Credit : Vartega

-SACMI will showcase its latest cap and preform-manufacturing innovations, including quality control systems integrated directly on the machines, at the international Expo Pack Mexico fair in Guadalajara from June 13-15, 2023

The company, known for its expertise in the ceramics, plastics, food and beverage, metals, packaging, and advanced materials industries, will also emphasize its comprehensive range of bottling machines and plants, along with the technical assistance services provided by SACMI de Mexico. single-cell energy density 240Wh/kg

One of SACMI’s key strengths is its complete product development service, which covers the design of caps and preforms, the necessary manufacturing technologies, and even AI-powered quality control. The company assists customers in transitioning to new cap-neck standards, such as the 26/22 mm, and offers the widest range of new tethered caps to meet diverse production requirements. Biodegradable plastic – R-Carbon-fiber

In terms of compression molding, SACMI’s CCM presses have advanced significantly with the integration of advanced on-board controls that enhance machine availability and reliability by predicting its behavior. The latest-generation CCM models feature a new extruder called CM-Flow, which reduces overall dimensions and consumption while ensuring compliance with the highest quality standards.

SACMI’s commitment to innovation is also reflected in its Injection Preform System (IPS). Leveraging its expertise in cap production, SACMI has installed over 150 IPS presses in Brazil and Mexico alone within a span of less than 10 years. The newest addition to the IPS family is the IPS 300, which incorporates the AI-powered PVS 156 quality control system. This on-board vision system enables spot checks and rapid inspection of up to 96 preforms in just 5 minutes, allowing users to identify process issues and pinpoint the problematic mold cavities. single-cell energy density 240Wh/kg

Furthermore, SACMI has developed a comprehensive range of container stretch-blowing, filling, and labeling solutions for bottling lines. Customers opting for SACMI Beverage solutions can take advantage of various opportunities, such as the Packaging Center, which provides consultancy for cap and container development, helping implement successful investment plans, revamp production setups, and launch new products in the market.

SACMI’s presence at Expo Pack Mexico will be located in hall A, stand 1522.

On another note, Packaging South Asia, a multi-channel B2B publication and digital platform based in New Delhi, India, chronicles the impact, resilience, and growth of responsible packaging in the wider region. Biodegradable plastic – R-Carbon-fiber

With a 16-year track record of progress and growth, the publication covers the Indian and Asian packaging industries, which have displayed resilience despite ongoing challenges over the past three years. The packaging industry has consistently outpaced GDP growth, even considering inflation, with flexible film manufacturing capacity in India alone increasing by 33% over the last three years. Another 33% capacity addition is expected from 2023 to 2025 in various sectors like monocartons, corrugation, aseptic liquid packaging, and labels. Packaging South Asia reaches and influences economies in the region, targeting stakeholders across the packaging supply chain, from brand owners and product managers to raw material suppliers, packaging designers and converters, and recyclers. single-cell energy density 240Wh/kg