Chemical recycling – Technopolymers 01-03-2023 - Arhive

Chemical recycling – Technopolymers

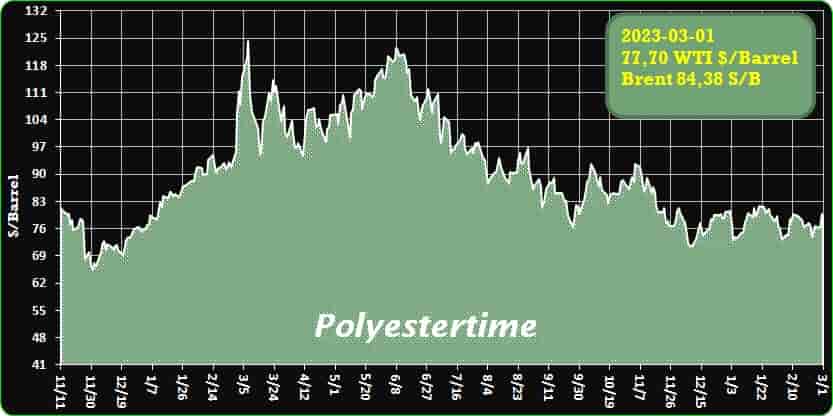

Crude Oil Prices Trend

Crude Oil Prices Trend Polyestertime

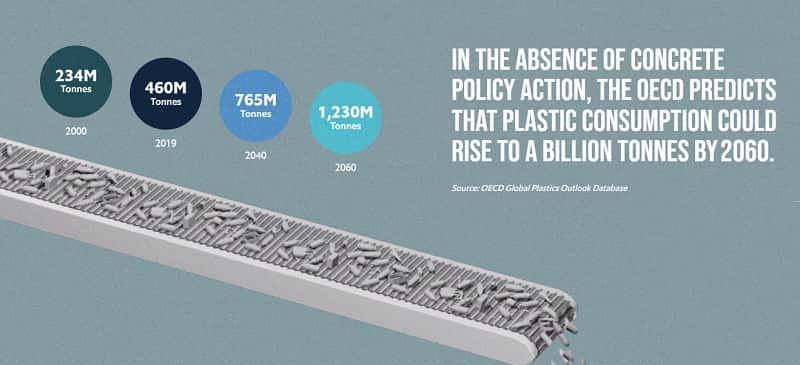

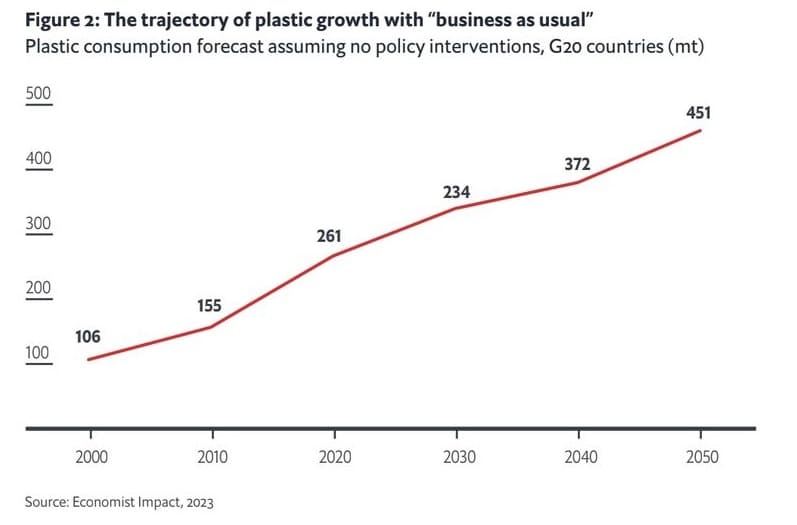

-Peak plastics: bending the consumption curve

Only bold and sweeping reforms will bend the plastic consumption curve. Achieving a reduction in plastic pollution will require all stakeholders–from the petrochemical companies to the consumers–to control the crisis. A piecemeal approach won’t work.

Executive Summary

The world will continue to drown in plastic waste unless a bold and comprehensive set of policy changes are agreed by the UN. To bring about peak plastic consumption, these policies would need to be at the most ambitious end of the spectrum being debated by UN treaty negotiators, which include governments, the petrochemical and consumer goods industries, and environmental groups. This is according to research by Back to Blue, an initiative of Economist Impact and the Nippon Foundation, which models the impact of a selection of policies being considered by world leaders as they draft a legally binding treaty to stem plastic pollution. Chemical recycling – Technopolymers

We model the impact of: a phased ban on problematic, unnecessary single-use plastic products (SUPPs); a mandatory extended producer responsibility (EPR) regime imposed on brands and retailers that introduce packaging to the market; and a tax on the production of virgin resin designed to redistribute the cost of negative environmental externalities. Our model tests whether any of these, alone or together, can achieve peak plastic consumption before 2050. The analysis is focused on the 19 countries of the G20.

Combined, the policies slow plastic consumption growth, but will not be enough to bring about a peak in plastic consumption by 2050, illustrating the scale of the challenge that lies ahead. Chemical recycling – Technopolymers

If the negotiators fail to agree on any policy interventions, we project that plastic consumption in the studied G20 countries will nearly double by mid-century.

-Catalytic Techniques for Upcycling Plastic Waste

Current plastic recycling is limited, typically involving mechanical processes that often result in “downcycled” products with inferior properties relative to plastics in their unprocessed, virgin forms. Furthermore, the plastics that do end up recycled comprise less than 20% of the total plastic produced to date—most of our plastic waste ends up in a landfill or dumped in the natural environment, leading to ever-increasing pollution and a persistent and disruptive impact on ecosystems.

Given the urgent need to improve upon existing plastic recycling methods, more researchers are turning toward chemical routes for plastic reclamation.1 Closed-loop chemical recycling depolymerizes plastics into their constituent monomers or oligomers, which can be used to resynthesize the same plastics with virgin-like material properties. However, this is commercially unattractive when virgin monomers from fossil resources are so cheap. Chemical recycling – Technopolymers

-SK Materials and ExxonMobil team up for blue ammonia

SK Holdings Materials, a South Korea-based company specialising in material technology, has signed an agreement with ExxonMobil, a US energy and petrochemical company, with the main aim of introducing blue ammonia to SK Materials in Korea, said Offshore-energy.

The company noted that ExxonMobil plans to build a facility to produce blue ammonia in Baytown, Texas, USA, and SK Materials plans to support the transition to clean energy in the domestic coal power generation market by introducing blue ammonia and supplying it as a power generation fuel in time for co-fired power generation in Korea.

SK Materials said it also plans to expand cooperation with ExxonMobil to develop a carbon reduction solution business. Chemical recycling – Technopolymers

-Taro Plast crosses the Atlantic

Agreement signed to acquire Delta Polymers, a US company active in the compounding and distribution of engineering plastics.

Taro Plast continues its growth plan through acquisitions, this time overseas. After taking over the Celanese activities in Ferrara last year in hotmelt polyesters and thermoplastic co-polyesters , the Parma-based company has signed an agreement to acquire the US Delta Polymers, together with the Amplas Compounding division, specialized in the formulation of compounding and distribution of technopolymers.

The acquisition of 100% of the two companies, in the intention of the parties – the Squeri and Beaupre families – should be concluded in the month of March. No financial details of the deal have been provided. Chemical recycling – Technopolymers

“The acquisition is in line with our strategy of establishing an active presence in the US market, to better serve our global customers at a local level – comments Andrea Squeri (pictured), CEO of Taro Plast -. The request from US market share for our recently enhanced product portfolio, including the TPC Pibiflex and Riteflex brands, has increased and we are delighted to benefit from the experience of the Delta Polymer team to bring our expertise and know-how to the North American market.” .

Founded in 1978, with headquarters in Soragna, in the province of Parma, Taro Plast operates with four plants in Italy in the production of polypropylene-based compounds, thermoplastic elastomers (SBS, SEBS, TPV and TPC) and technopolymers, destined for application sectors such as automotive, home appliances, power tools and housewares, E/E, construction and furniture. It employs almost 190 people for a turnover of 170 million euros in the 2022 financial year. Chemical recycling – Technopolymers

-New Pyrum plant to expand ties with Michelin, BASF

The 20ktpa facility in Homburg to free up capacity in existing plant for ELTs from Luxembourg

Dillingen, Germany – Waste tire pyrolysis company Pyrum Innovations AG has selected the city of Homburg in the German state of Saarland for its next end-of-life tire (ELT) recycling plant. Chemical recycling – Technopolymers

In a statement 16 Feb, the company said Homburg City Council had unanimously voted in favour of the sale of a city-owned property to Pyrum and thus for the construction of a new pyrolysis plant.

-Danone to invest US$65M to establish new bottle production line in Florida

Food and beverage company Danone North America has announced that it will invest up to US$65 million over the next two years to create a new bottle production line in Jacksonville, Florida.

The investment will support Danone North America’s long-term growth strategy and will deliver key benefits across the U.S. business, including advancing operational excellence, enabling flexibility in bottle design, accelerating the company’s sustainability goals, and driving cost efficiencies. Chemical recycling – Technopolymers

Shane Grant, Group Deputy CEO, CEO Americas said: “We are delighted to announce this investment in our North American business, which will allow us to capitalize on consumer demand in key beverage categories including coffee creamers, plant-based creamers, and ready-to-drink coffee, while also supporting our long-term growth agenda.

“This investment will help us keep our products on our customers’ shelves and give more American consumers the Danone products they love.”

-Curbing our insatiable appetite for plastics – yes, but how?

New study: ’Bold and comprehensive set of policies’ alone can stem plastic waste crisis

According to the findings of a new study from Back to Blue, an initiative of Economist Impact and The Nippon Foundation, the efforts currently being explored by the UN to halt the growth in plastic consumption and to ‘bend the curve’, will not achieve their goal by 2050. Chemical recycling – Technopolymers

Entitled Peak Plastics: Bending the consumption curve, the report confirms that an ‘urgent, global effort is needed to stop the flood of plastic pollution at its source’, as David Azoulay, of the Center for International Environmental Law, pointed out.

The entire lifecycle of plastics […] must be addressed by the future, legally binding UN treaty to end plastic pollution, he said.

Chemical recycling – Technopolymers