Plasticisers – Energy storage – H2 28-02-2023 - Arhive

Plasticisers – Energy storage – H2

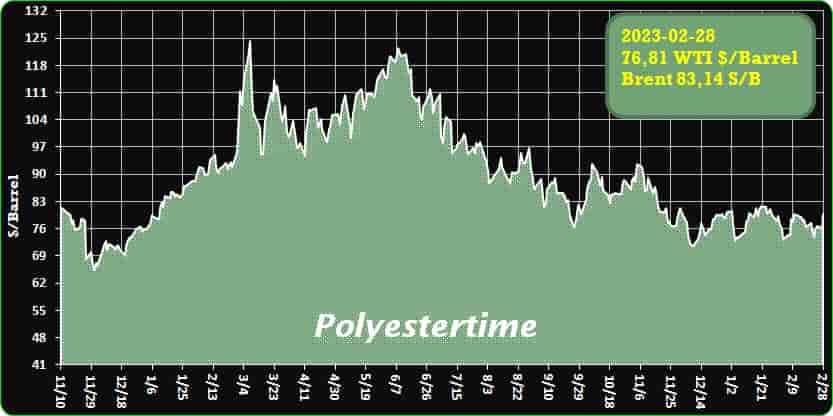

Crude Oil Prices Trend

Crude Oil Prices Trend Polyestertime

-How safe are plasticisers?

Demand for renewably-sourced plasticisers on the rise

Plasticisers have a reputation. These additives, while crucial to many applications, have been a source of unrest as unsettling reports of the detrimental health effects of some plasticisers emerged. At the same time, it is fair to say that no other type of additive has been studied so intensively as plasticisers have been – mainly because of the ubiquity of their use. They are, in fact, among the most commonly used additives in the industry. Plasticisers are used in applications varying from medical and the automotive industry to fashion, building and construction. Plasticisers – Energy storage – H2

They offer flexibility and pliability to thermoplastic resins such as PVC; and serve to enhance processability and mouldability. Depending on the application and resin, they are used at levels that can be significantly higher than other additives – up to as much as 60% by weight. The global market for plasticisers is therefore huge: valued at $14.7 billion in 2020, it is projected to reach $22.0 billion by 2030, growing at a CAGR of 4.1% from 2021 to 2030.

As these additives are not bound to the polymer matrix, plasticisers are known to migrate out of plastics, into the environment, both outdoors as well as inside. For example, studies have found phthalates in indoor dust. As well, phthalates can potentially disrupt the endocrine system and have been linked to certain cancers and metabolic disorders. Their use is very strictly regulated in Europe. Plasticisers – Energy storage – H2

-Avantium and Origin Partner on PEF

Avantium is partnering with Origin Materials to accelerate the mass production of furandicarboxylic acid (FDCA) and plant-based, fully recyclable plastic, polyethylene furanoate (PEF).

The partnership will combine Avantium’s proprietary YXY process with Origin’s patented technology platform that turns carbon found in sustainable wood residues into building-block chemicals such as chloromethylfurfural (CMF), which can be used to make FDCA.

The company has already started to build a commercial-scale FDCA plant in Delfzijl, the Netherlands, while Origin reached mechanical completion this month on its first commercial manufacturing plant for CMF and derivatives in Sarnia, Canada, with start-up expected in the second quarter of 2023. Plasticisers – Energy storage – H2

Under their collaboration, Avantium has granted Origin a non-exclusive license to use certain parts of its YXY process – including certain patent rights – for enabling the conversion of CMF derivatives into FDCA at a 100,000 t/y plant. Avantium added that it will also develop a “bridge” between the companies’ respective technologies.

Origin paid Avantium €5 million upfront last year and will also pay a milestone fee of €7.5 million, as well as subsequent license fees upon achieving certain development milestones.

“The technologies of both companies are highly complementary and will also enable the use of non-edible, renewable feedstocks for the production of FDCA and PEF, meeting the expectations of brand owners and consumers worldwide,” said Avantium CEO Tom van Aken.

The partners have also entered into a conditional offtake agreement whereby Avantium will sell FDCA and PEF to Origin Materials from its FDCA pilot plant in Geleen, the Netherlands, in 2023 and from the Delfzjil plant once it goes into commercial operation in 2024. Plasticisers – Energy storage – H2

-Enea in the European energy storage research network

Create the first European network of research infrastructures on energy storage, to encourage the growth and diffusion of renewable sources.

This is the objective of the StoRIES project in which Enea, Cnr, Eni and 43 other partners from 17 European countries participate, including the German research center Karlsruhe Institut Fur Technologie in the role of coordinator.

The four-year project is funded with 7 million under the European Horizon 2020 program and involves research institutions, technological institutes, universities, industries, members of the European Energy Research Alliance (EERA) and associations, including the European Storage Association of Energy (EASE). Plasticisers – Energy storage – H2

Enea will participate with eight infrastructures including a hi-tech laboratory to develop innovative materials for medium temperature thermal storage, a solar park among the largest in the world for the research and construction of molten salt concentration plants and a supercomputer in capable of performing up to 1.4 trillion mathematical operations per second (1.4 PetaFlop).

-Stellantis – Tavares: “We need LFP batteries to produce affordable electricity”

Stellantis intends to follow the example of several competitors, using a type of battery for electric cars that is less expensive than the devices that are predominant today.

These are lithium-iron-phosphate (LFP) batteries, which are less expensive than NMC cells (nickel, manganese and cobalt) but characterized by a lower energy storage capacity.

“We need LFPs and we will have LFPs because, in terms of costs, they guarantee the possibility of making affordable cars for the middle classes,” said Chief Executive Officer Carlos Tavares, during the conference call on the annual financial results.

No timing. However, the Portuguese manager did not provide more precise details on the timing of the adoption of the new technology for the electrics of the various brands of the group, nor on where the LFP batteries will be purchased. Plasticisers – Energy storage – H2

At the moment, the group is focusing on NMC chemistry for the three gigafactories that the Acc joint venture with Mercedes-Benz and TotalEnergies intends to open in Europe between 2024 and 2026.

The first, in Douvrin (France), will start producing the first prototypes already in the second half of this year to then start series production at the beginning of next.

However, LFPs are now seen as a solution to higher raw material prices as they do not contain the expensive nickel, cobalt and manganese. Not surprisingly, more and more companies are using them.

Tesla, for example, buys them from the Chinese Catl and uses them in the basic versions of the Model 3 and Y. Similar destinations have been chosen by various Chinese brands, such as Xpeng, Nio or MG. Plasticisers – Energy storage – H2

fter all, according to the analyzes of Benchmark Minerals, it is still China that dominates the production of lithium-iron-phosphate batteries, with over 99.5% of supplies and 97% of manufacturing capacity planned until 2030.

Also for this, Ford has chosen the Chinese Catl to build a new plant for the production of LFP batteries in Michigan capable of refueling 400,000 vehicles a year starting from 2026.

-China’s first integrated methanol-to-hydrogen and hydrogen refueling service station now in operation

China Petroleum & Chemical Corporation (Sinopec) officially launched China’s first methanol-to-hydrogen and hydrogen refueling service station in Dalian, China. An upgrade from the previous fueling station offering oil, gas, hydrogen, electric charging services, the integrated complex can produce 1,000 kilograms of hydrogen a day, with a purity of 99.999%. Plasticisers – Energy storage – H2

Sinopec’s hydrogen production plant has the advantages of covering a small area, having a short construction time, and having a green, environmentally friendly production process. The new Service Station can save costs on hydrogen production, storage and transportation by more than 20% compared to traditional hydrogen refueling stations; it is intended to become a pilot model to lead the development of China’s hydrogen energy industry. Plasticisers – Energy storage – H2

China produces the most methanol in the world, accounting for 60% of the global total. The storage and transportation cost of methanol is also much lower than hydrogen, making methanol-to-hydrogen an attractive hydrogen production technology.

-Commodity resin prices on the rise at the start of 2023

Commodity resin markets started 2023 with a bang, with four of those materials seeing higher prices during January and at least two more in February.

North American prices for PVC and polystyrene resins both increased in February.

PVC prices moved up an average of 1 cent per pound for the second consecutive month, according to market sources contacted by Plastics News. Availability of PVC remained somewhat tight again in February, as construction industry buyers began to make purchases ahead of spring construction. Plasticisers – Energy storage – H2

The January hike ended a streak of six consecutive monthly price drops for PVC, including a 6-cent decline in December. PVC prices finished 2022 down a net of 31 cents. Residential construction in the U.S. has slowed as interest rates increased.

U.S. housing starts for January came in at an annualized rate of a little less than 1.34 million. That number essentially was flat vs. December but down more than 27 percent vs. the same month in 2022.

Prices for both solid and expanded PS were up 3 cents in February after being flat in January. The February price hike was linked to price fluctuations for benzene feedstock, which is used to make styrene monomer.

Market prices for benzene were up 47 cents in February to $3.58 per gallon, an increase of a little more than 15 percent. Prices for the material had been up 4 cents in January, but that amount wasn’t enough to lift PS prices. Plasticisers – Energy storage – H2

-Volkswagen is going to ramp up recycled materials in its EVs

Volkswagen is going to put recycled materials in the rest of the ID. series that have already been mass-produced in the ID. Buzz.

The Volkswagen ID. Buzz’s interior is made up of a sizable amount of recycled materials, and those materials will be gradually introduced in the ID.3, ID.4, ID.5, and ID.7.

For example, many of the Buzz’s interior components are made of recycled ocean plastic, or 63 (yes, VW is precise) 500 ml PET bottles. Plasticisers – Energy storage – H2

The Buzz’s seat cover’s outer material is made of Seaqual yarn, which is made of 10% collected marine debris and 90% recycled PES yarn – a durable synthetic yarn made from polyester. VW says Seaqual yarn saves 32% of emissions compared with conventional surface materials.

VW says that seat covers are made of ArtVelours Eco – which is made from a blend of natural and recycled materials, including recycled polyester, natural latex, and jute; the recycling share is 71%.

The Buzz’s headliner and floor covering are made from 100% recycled polyester, and the carpet’s insulating layer also contains recycled plastics. Other components, such as the underbody cladding and the wheel housing liners, also contain recycled plastic.

The Buzz’s doors, instrument panel, and steering wheel clip no longer feature chrome because it’s bad for the environment. Plasticisers – Energy storage – H2

Chrome production uses toxic chemicals that can be harmful to human health and the environment, and when chrome plating is applied, it requires the use of acids, solvents, and other hazardous chemicals. VW replaced the Buzz’s chrome with a liquid paint with a chrome look that has a bio-based binder.