The World Health Organization has recognized the swift emergence of antibiotic-resistant bacteria as a global threat, urging the urgent development of new antibiotics. Cationic polymers, a promising class of bioactive agents, induce bacterial cell death by physically disrupting their membranes. However, the polymerization processes must be carefully designed to optimize the therapeutic potential of cationic polymers.

Scientists, led by Texas A&M University, have made progress in addressing the threat of antibiotic resistance by developing a new family of polymers. These polymers can kill bacteria without disrupting the microorganisms’ membranes without inducing antibiotic resistance. Enzymatic recycling

The recently synthesized polymers hold potential in combating antibiotic resistance by offering antibacterial molecules that operate through a mechanism resistant to development by bacteria.

The Michaudel Laboratory, operating at the intersection of organic chemistry and polymer science, synthesized the new polymer. This involved designing a positively charged molecule that could be repetitively stitched to create a large molecule with the same repeating set motif using a catalyst named AquaMet. The catalyst’s unique capability to tolerate high concentrations of charges while being water-soluble proved crucial for this process. Enzymatic recycling

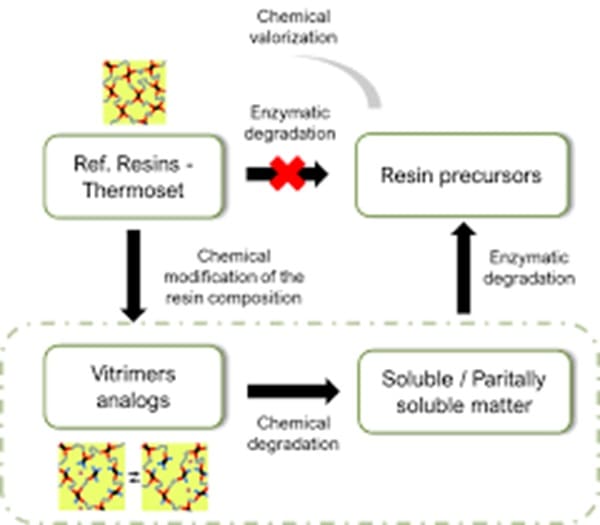

Bizente project evaluates enzymatic recycling for resins, composites

Among the latest advances are toxicity tests, used to evaluate the effect of different resins and plastic degrading on aquatic and terrestrial organisms, and thus determine the technology’s long-term sustainability.

The EU project Bizente, coordinated by the Aitiip Technology Centre (Zaragoza, Spain), is facing its last months of work. The 3-year research, aided by an international consortium made up of a dozen partners, has announced the development of an enzymatic technology for recycling thermoset composites, to give them a second life. Through protein engineering, Bizente has successfully molecularly modified enzymes and resins, making them suitable for controlled biodegradation in a bioreactor. Sectors such as aviation and construction could benefit. Enzymatic recycling

Among the latest advances are the toxicity tests being carried out by a group of scientists from the University of Cadiz (Spain), in collaboration with the rest of the project consortium, with the aim of evaluating the effect of different resins and plastic degrading products developed within the framework of the project on aquatic and terrestrial organisms, such as earthworms. The laboratory is studying these invertebrates as model organisms of great importance in the terrestrial ecosystem and as indicators of soil health. They are also beginning to work with artemia (brine shrimp), as they are considered the base of the trophic chain in aquatic systems.

In this way, the environments in which these materials could biodegrade are being recreated, and their degree of toxicity measured, taking into account possible anomalies in the different organisms. In the case of the worms, the observation examines whether external alterations occur, such as changes in weight, swelling, lesions, spasms, coiling, attempts to escape, lethargy and a host of strange behaviors, in addition to whether mortality is reached. Enzymatic recycling

World’s largest economy US holds strong despite challenges: CEBR

- In 2023, the world’s largest economy showcased resilience with a PPP-adjusted GDP per capita of $80,412, and growth rates of 2.1 per cent in 2022 and 2.2 per cent in 2023, despite aggressive rate hikes.

- Consumer spending, bolstered by employment, fuelled this growth, but cooling is expected due to fiscal reductions and interest rate effects.

In a year filled with economic hurdles, the world’s largest economy stood resilient, boasting an estimated Purchasing Power Parity (PPP)-adjusted GDP per capita of $80,412 in 2023. Despite the Federal Reserve’s aggressive interest rate hikes totalling a full percentage point, the nation’s economy surpassed expectations with a growth rate of 2.1 per cent in 2022, accelerating slightly to 2.2 per cent in 2023, the Centre for Economics and Business Research (CEBR) said in a recent report. Enzymatic recycling

Consumer spending, buoyed by employment strength, played a pivotal role in the year’s economic narrative. However, as 2024 approaches, the economic landscape appears more subdued. The delayed effects of interest rate hikes and reductions in fiscal spending are expected to cool consumer expenditure and overall economic momentum, as per the CEBR report titled ‘World Economic League Table 2024’.

Inflation, which moderated to an estimated 4.1 per cent in 2023, remains a focal point. Despite a downward trend, prices are projected to stay above the Federal Reserve’s 2 per cent target into 2024, keeping policymakers and consumers watchful.

“Electric Cars and Environmental Impact: A Detailed Study Reveals the True Picture”

In the ever-expanding landscape of European and global transportation, electric cars have become a well-established reality. However, a recent study by the VDI, the Association of German Engineers, has shed light on the environmental impact of electric cars compared to conventional ones, examining various parameters. Enzymatic recycling

The study reveals that currently, Battery Electric Vehicles (BEVs) face a disadvantage due to the substantial carbon dioxide emissions associated with battery production. The “break-even point” for CO2 emissions between an electric car and a conventional one is shifted over the years and mileage. While electric cars compensate for emissions during operation by producing no exhaust emissions, this only partially offsets the environmental impact linked to vehicle production.

The VDI’s expert group conducted a detailed study comparing the ecological balance of electric cars, plug-in hybrids, and conventionally fueled diesel and gasoline vehicles in the German market. Results show that electric cars in this category reach an emissions equilibrium after approximately 90,000 km. Looking further, up to a mileage of 200,000 km, electric and hybrid cars outperform diesel and gasoline cars in terms of carbon footprint. Enzymatic recycling

However, it’s crucial to note that electric cars, like hybrids, carry a significant CO2 burden from their inception. This is primarily attributed to production in Asia, where most battery cells originate, causing substantial greenhouse gas emissions during transport. To address this, the VDI President, Joachim Damasky, suggests a solution: a substantial and rapid expansion of renewable energy production, green battery development, and sustainable fuel for existing vehicles.

For electric cars to truly become environmentally friendly, Damasky proposes producing them as close to the factories as possible, minimizing transportation emissions and utilizing cutting-edge fuel technologies. This approach could potentially lower the emissions break-even point, currently set at 90,000 km, encouraging more motorists to embrace the environmentally friendly aspects of electric vehicles. Enzymatic recycling

Breakthrough in Solid-State Batteries: A More Powerful and Affordable Future

Researchers at MIT and German engineers have developed innovative solid-state batteries with crystallized electrolytes. The pursuit of innovation in batteries is driven by two key priorities: performance and cost. The market demands increasingly powerful products while also seeking affordable energy storage solutions for the anticipated rise of economical electric vehicles. Enzymatic recycling

While lithium-ion batteries continue to improve in energy density and production cost reduction, the U.S. Department of Energy believes additional technologies are crucial for a definitive leap into the future. This is where MIT and the University of Munich researchers come into play.

Led by Jennifer Rupp from MIT, the team collaborated with German engineers from the Faculty of Engineering in Munich. Enzymatic recycling

They created a new battery type utilizing solid-state electrolyte cells and lithium metal anodes instead of conventional graphite.

The groundbreaking aspect of this new battery lies in its solid electrolyte, derived not from traditional ceramic type but from a liquid containing lithium oxide, crystallized through a novel synthesis process.

Advantages of the New Production Method:

As reported in Angewandte Chemie, the solid electrolyte, produced through lithium ion crystallization, enables the creation of high-performance batteries at lower costs, ensuring safer energy storage without the formation of dendrites and without containing flammable elements. Enzymatic recycling

These results have attracted the interest and funding support of the U.S. National Science Foundation, highlighting the potential of these innovative production methods. Thanks to the collaborative efforts of MIT and the University of Munich, solid-state batteries might be a step closer to reality.

China Launches Trials for World’s Largest Plant Converting Coal-to-Ethanol

In a groundbreaking development, southeastern China has witnessed the initiation of test operations at the world’s largest coal-based ethanol production facility. With an impressive annual capacity of 600,000 tonnes, this pioneering plant marks a departure from conventional practices by harnessing coal, rather than crops, as the primary raw material for ethanol production.

Ethanol, valued as both a basic chemical and a petrol additive, stands out as a renewable energy source with properties akin to petrol. This move represents a significant stride in China’s endeavor to alleviate pressure on food sources while concurrently reducing dependence on fuel ethanol imports. Enzymatic recycling

The strategic choice of coal, specifically low-grade coal abundantly available in China, breaks away from traditional ethanol production methods that often involve corn or sugar cane. This shift addresses the critical concern of potential competition between ethanol production and the global food supply, a concern amplified by China’s escalating grain prices. In response to these challenges, China, endowed with vast coal reserves, seeks to carve out a sustainable and secure pathway by diverting from traditional raw materials, potentially saving millions of tonnes of grain annually.

The ramifications of this new production pathway extend beyond the realm of food security, encompassing broader implications for China’s energy security and the chemical industry supply chain. Enzymatic recycling

Postponement of Italian Plastics Tax to July 2024

Italy has once again delayed the implementation of the Single-Use Plastics Consumption Tax (MACSI), marking the sixth extension. The Italian Parliament, in its year-end Budget Law, granted another postponement for the tax on single-use plastic products, originally scheduled to take effect on January 1, but now rescheduled to commence on July 1, 2024, along with the ‘sugar tax’. Enzymatic recycling

Initially approved in the 2020 Budget Law, the Italian plastics tax imposes a levy of 450 euros per ton (0.45 euros per kg) on single-use plastic packaging made from virgin plastic, including films and preforms. The scope of the tax excludes compostable plastics compliant with UNI EN 13432, recycled plastics, and all medical devices and pharmaceutical packaging.

Despite six consecutive delays, the enforcement of the regulation is still pending the issuance of guidelines by the Director of the Customs and Monopolies Agency (ADM) to define the application rules.

The continual postponements raise questions about the readiness and consensus on the implementation of the plastics tax in Italy. Enzymatic recycling