Enzymes-breaks-down-PET – Plastic-recycling 26-03-2022 - Arhive

Enzymes-breaks-down-PET – Plastic-recycling

-Plastics waste – no problem; scientists develop enzymes to break down PET in weeks

With an admissible lifespan of around 450 years, plastics, the wonder material of the sixties and seventies, have become a cause of major concern for the entire world due to irresponsible dumping of its waste, which has started posing a very real environmental threat to our planet.

According to reports, around 275 million tonnes of plastics waste is generated each year around the world of which a quantity between 4.8-12.7 million tonnes finds its way into the sea, thus causing air, water, and soil pollution. Policymakers across the world have been drafting rules for several years with a ban on single-use plastics in many countries and extended producers’ responsibility (EPR) among others, to reduce irresponsibly dumping of plastics waste into the environment. Unfortunately, no visible progress has been achieved yet. Enzymes-breaks-down-PET – Plastic-recycling

But now, scientists have developed enzymes that can break plastics waste in a matter of weeks. Reports said that researchers at the University of Portsmouth, United Kingdom, succeeded in engineering a better-performing version of enzymes called ‘MHETase’ to form a super enzyme that digests hard plastics like polyethylene terephthalate (PET) at six times the speed.

In 2016, scientists in Japan had discovered a bacterium with a natural appetite for PET plastics, using enzymes to break it down in a matter of few weeks. Later a better performing version of this enzyme was discovered in 2020 which was called ‘PETase’. Now, when PETase is combined with a super enzyme called ‘MHETase’, PET plastics can be digested at six times the speed of the previous version of enzymes.

“Over the past five years, scientists have succeeded in getting some breakthroughs, demonstrating how enzymes can be used to break down common plastics such as the PET which finds application in a water bottle to shampoo containers. In pursuit of a circular economy for plastic waste, scientists have now discovered a new enzyme that further breaks down one of the key plastic building blocks left behind by this process, leaving thereby simple molecules that can be repurposed for use in new products,” said the report.

In this process, two chemical building blocks of PET have left ethylene glycol (EG) and terephthalic acid (TPA), and one is more problematic than the other. While EG is a chemical with many applications – it’s a part of the antifreeze used in cars, TPA does not have many uses outside of PET. Most importantly, TPA has nothing that most bacteria can even digest. But, an enzyme from PET-consuming bacteria recognizes TPA like a hand in a glove. The study then demonstrated that this enzyme, called TPADO, breaks down TPA with amazing efficiency,” said Professor Jen DuBois, the study editor. Enzymes-breaks-down-PET – Plastic-recycling

-Surge into plastic recycling by chemicals and oil groups meets pushback

Industry tests the definition of sustainability as it uses energy-intensive processes to break down waste Enzymes-breaks-down-PET – Plastic-recycling

Please use the sharing tools found via the share button at the top or side of articles. Copying articles to share with others is a breach of FT.com T&Cs and Copyright Policy. Email licensing@ft.com to buy additional rights. Subscribers may share up to 10 or 20 articles per month using the gift article service.

The surge by the world’s largest petrochemical and oil companies into plastic recycling as an industry “plan B” is in question, after a historic UN agreement to negotiate a legally binding treaty to tackle plastic pollution.

Despite extensive lobbying efforts to narrow the proposal to deal with plastic waste management, the treaty signed by 175 countries could place equal onus on plastic makers to limit their production

By 2050, petrochemical production will account for nearly half of growth in global oil demand, according to estimates by the International Energy Agency.

The industry needs solutions to plastic pollution that do not require it to scale back this production, as the world grapples with it’s reliance on oil and gas.

A growth area it had alighted on was chemical or “advanced” recycling, technology that turns plastic waste back into raw materials, or oils and gases, that are then fed back into petrochemical production. Enzymes-breaks-down-PET – Plastic-recycling

Less than 10 per cent of the near 370mn tonnes of plastic produced annually is recyclable. Yet the demand for recycled plastic is surging as consumer goods companies come under pressure to reduce their environmental impact.

The world’s largest petrochemical companies, including Dow, Sabic and Chevron Phillips Chemical, have all formed partnerships with recycling start-ups.

In China, Zhejiang Petrochemical is putting almost $29bn into an integrated facility to produce both fuels and plastics from the same complex, with backing from oil major Saudi Aramco. Shell and ExxonMobil are also building their own units to upgrade plastic waste.

-Teknor Apex Launches TPE Series with Up to 35% PCR

Monprene RX CP-15100 is available in standard grades from 55 to 80 Shore A, and also can be tailored to specific customer requirements.

Teknor Apex has introduced a line of thermoplastic elastomers containing 25 to 35% recycled content to help brands achieve their sustainability goals.

The Monprene RX CP-15100 series, formulated with post-consumer recycled (PCR) content, is manufactured around the world with locally sourced raw materials procured to exacting specifications, turning local waste into a resource. Unlike competitive TPEs with recycled content, available in black only, these materials are delivered in a consistent light, natural color, similar to their prime offsets, said Teknor Apex. Enzymes-breaks-down-PET – Plastic-recycling

Monprene RX CP-15100 is available in standard grades from 55 to 80 Shore A, and also can be tailored to specific customer requirements. The grades are designed for injection molding applications, including overmolding onto polypropylene. The materials perform and process like prime TPEs and are suited for personal care products, lawn and garden tools, writing instruments, appliances, sporting goods, and dunnage.

Teknor Apex has introduced a line of thermoplastic elastomers containing 25 to 35% recycled content to help brands achieve their sustainability goals.

The Monprene RX CP-15100 series, formulated with post-consumer recycled (PCR) content, is manufactured around the world with locally sourced raw materials procured to exacting specifications, turning local waste into a resource. Unlike competitive TPEs with recycled content, available in black only, these materials are delivered in a consistent light, natural color, similar to their prime offsets, said Teknor Apex.

Monprene RX CP-15100 is available in standard grades from 55 to 80 Shore A, and also can be tailored to specific customer requirements. The grades are designed for injection molding applications, including overmolding onto polypropylene. The materials perform and process like prime TPEs and are suited for personal care products, lawn and garden tools, writing instruments, appliances, sporting goods, and dunnage. Enzymes-breaks-down-PET – Plastic-recycling

-Polymer prices in China face pressure from high input costs and Covid-induced lockdowns

A sustained rise in new coronavirus (Covid) cases and resultant lockdowns in industrial towns have started posing a threat thereby giving rise to possible production disruptions at major petrochemical plants in China.

As evident from the price movement of major polymers currently being traded at the benchmark Dalian Commodity Exchange (DCE), consumers in the downstream industry in China have started booking for delivery in the future to ensure raw material supply for operating their factories smoothly. Since the number of new Covid-19 cases accelerated so far this month and worsened in the last one week, the prices of most polymers have risen by over 3 percent.

On the DCE, linear low-density polyethylene (LLDPE) opening price contract for near month delivery jumped by 1.71 percent or Yuan 150 from March 17, 2022, to Yuan 8,916 a tonne on Wednesday. Enzymes-breaks-down-PET – Plastic-recycling

Similarly, the price quote of polypropylene (PP) jumped by 2.36 percent or Yuan 203 since March 17 to trade on Wednesday at Yuan 8,820 a tonne. The opening quote of polyvinyl chloride (PVC) rose by 3.66 percent or Yuan 320 to trade on Wednesday at Yuan 9050 a tonne. Along with polymers, prices of raw materials like mono-ethylene glycol (MEG) have also risen by 1.95 percent or Yuan 99 for the near month delivery to trade on Wednesday at Yuan 5,168 a tonne.

In addition to futures, prices of key polymers have begun to firm up in spot markets as well. Between March 17 and 22, prices of all major polymers have jumped by 2-3 percent due primarily to disruption in supply from the production units to consumption centers on account of lockdowns.

“China has adopted a ‘zero-tolerance policy’ which means the local administration cordons off and declares the area under lockdown, even with one Covid case. With the increase in new Covid cases which fears the fourth wave, the Chinese authorities have declared lockdowns in a number of industrial hubs which has started affecting production on petrochemical refineries, albeit on a low scale. The impact on petrochemical refineries on the production of polymers and feedstock will be assessed depending upon the intensity of increase in Covid cases. The impact on industrial production, however, will be visible in near future,” said a senior official of a large polymer producing company in India. Enzymes-breaks-down-PET – Plastic-recycling

After nearly two years of stability, the number of new Covid cases started rising early this month but surpassed the magical four-digit mark of 1000 on March 14, for the first time since March 13, 2020. On March 22, the total number of new Covid cases stood at 4,770, as China’s ‘zero-tolerance Covid policy’ was confronted by an Omicron wave. A sharp increase in Covid cases has been reported in the northeast province of Jilin, and the city of Shenyang in neighbouring Liaoning province. Lockdown in this city with a population of around 9 million was announced late Monday.

According to reports, the Chinese government has imposed travel restrictions and lockdown across 20 major cities in the country including Hubei, Guangdong province, Shanghai, Shaanxi, and Henan, which have reported a sudden increase in the new Covid cases. In Shanghai alone, the new Covid cases are rapidly approaching 1000. Last week, Chinese President Xi Jinping stressed the need to minimize the impact of the Covid pandemic on China’s economy but stressed the need to follow a ‘zero-tolerance’ strategy.

-Calculating The Intrinsic Value Of Aquafil S.p.A.

How far off is Aquafil S.p.A. from its intrinsic value? Using the most recent financial data, we’ll take a look at whether the stock is fairly priced by projecting its future cash flows and then discounting them to today’s value. We will use the Discounted Cash Flow (DCF) model on this occasion. Believe it or not, it’s not too difficult to follow, as you’ll see from our example! Enzymes-breaks-down-PET – Plastic-recycling

We generally believe that a company’s value is the present value of all of the cash it will generate in the future. However, a DCF is just one valuation metric among many, and it is not without flaws. Anyone interested in learning a bit more about intrinsic value should have a read of the Simply Wall St analysis model.

Check out our latest analysis for Aquafil

The model

We are going to use a two-stage DCF model, which, as the name states, takes into account two stages of growth. The first stage is generally a higher growth period which levels off heading towards the terminal value, captured in the second ‘steady growth’ period. In the first stage we need to estimate the cash flows to the business over the next ten years. Where possible we use analyst estimates, but when these aren’t available we extrapolate the previous free cash flow (FCF) from the last estimate or reported value. Enzymes-breaks-down-PET – Plastic-recycling

We assume companies with shrinking free cash flow will slow their rate of shrinkage, and that companies with growing free cash flow will see their growth rate slow, over this period. We do this to reflect that growth tends to slow more in the early years than it does in later years.

-New investment by Dow aimed at developing more energy efficient advanced recycling

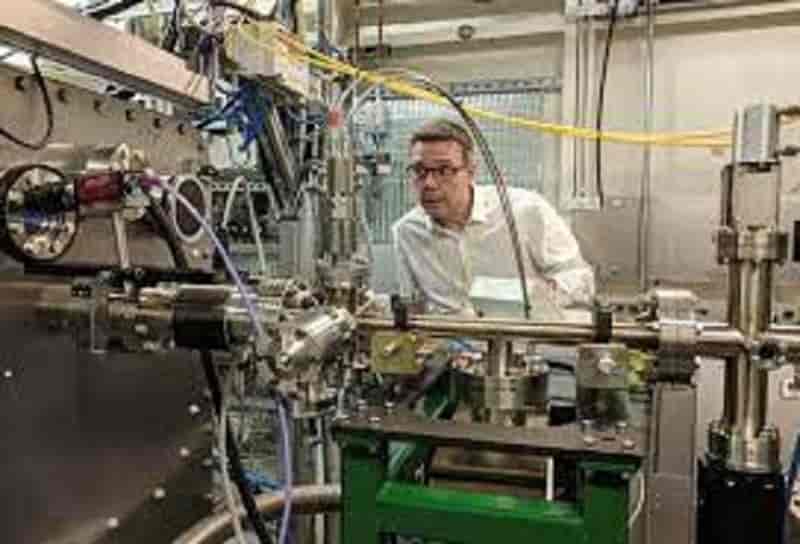

Dow and Plastogaz SA, a technology start-up, have announced a strategic investment to develop the latter’s catalytic hydrocracking technology for advanced recycling, which the companies claim is less energy-intensive than other forms of advanced recycling.

According to the companies, Plastogaz’s proprietary catalytic hydrocracking technology solution can simplify the process of converting plastic waste into high-quality hydrocarbons. The aim of the technology is to increase the efficiency of advanced recycling and minimise the energy required during the process, offering a lower CO2 footprint overall. Enzymes-breaks-down-PET – Plastic-recycling

The collaboration between Plastogaz and Dow will seek to accelerate the commercialisation of the technology.

Dow says it is bringing its global reach and material science expertise to further develop technologies with smaller innovative companies like Plastogaz, as part of its commitment to providing circular feedstock for plastics. The investment was therefore structured and led by Dow Venture Capital, which is focused on pursuing strategic investments in start-up companies that accelerate Dow’s business growth and value.

Keith Cleason, business vice president of olefins, aromatics and alternatives at Dow, comments: “This is an important strategic step for Dow and advances our commitment to create circular plastics with General Business the lowest possible CO2 footprint. Enzymes-breaks-down-PET – Plastic-recycling

Enzymes-breaks-down-PET – Plastic-recycling

CPL-fixes-its-bottom – Russia-crude-oil 25-03-2022