EV-battery revolution – Recycling 22-05-2023 - Arhive

EV-battery revolution – Recycling Petrochemicals – PET Resin

Petrochemicals – r-POY – PSF

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

-LanzaTech and Plastipak Collaborate to Manufacture World’s First PET Resin Crafted from Recycled Carbon

LanzaTech Global, Inc. (Nasdaq: LNZA), an inventive carbon capture and conversion (“CCT”) firm that transforms waste carbon into materials like eco-friendly fuels, textiles, packaging, and other items utilized in everyday life, and Plastipak Packaging, Inc. (“Plastipak”), a leading global company involved in the design, production, and recycling of plastic containers, announce their successful creation of PPK Natura, the inaugural polyethylene terephthalate (PET) resin derived from captured carbon emissions.

This resin is suitable for food, personal care, pharmaceutical packaging, and various other non-packaging applications. Petrochemicals

Introducing PPK Natura

PET is a polymer molded into plastic bottles and containers for packaging food, beverages, personal care products, and numerous consumer goods. PET Resin

PET resin typically contains 30% monoethylene glycol (MEG) derived from conventional petroleum sources. EV-battery revolution – Recycling

PPK Natura utilizes CarbonSmart™ MEG from LanzaTech’s CCT process, retaining the technical properties of virgin fossil-based PET while presenting a reduced carbon footprint.

PPK Natura resin diminishes greenhouse gas emissions, and its manufacturing process does not necessitate land or food resources.

Additionally, packaging produced from this material can be fully recycled at the end of its life, ensuring the carbon remains in a circular material cycle.

Leading Swiss retailer Migros and its subsidiary Mibelle Group were the first to adopt this PET resin for their in-house brand packaging, including PET bottles for smoothies and containers for household cleaners that also contain LanzaTech ethanol as a crucial component.

“LanzaTech’s commercial technology is designed to empower our partners across various industries to minimize their carbon footprint and overall environmental impact,” stated Jennifer Holmgren, Chief Executive Officer of LanzaTech. “Our collaboration with Plastipak is vital in showcasing the possibilities available today. Presently, we are producing food- and pharmaceutical-grade packaging and making substantial progress toward forging a more sustainable future for all.” PET Resin

Producing PET with Reduced Environmental Impacts

LanzaTech’s CCT technology functions similarly to a brewery, wherein exclusive bacteria consume pollution and convert it into CarbonSmart chemicals.

These chemicals are then transformed into a range of products, from clothing and laundry detergent to sustainable aviation fuel. EV-battery revolution – Recycling

By utilizing diverse waste feedstocks, LanzaTech’s technological platform is shaping a future in which consumers are not reliant on virgin fossil resources for all their daily needs.

“We are thrilled to collaborate with LanzaTech to make early strides toward our objective of manufacturing PET with diminished environmental impacts.

The utilization of CarbonSmart MEG marks a significant initial milestone in our journey towards this objective. PET Resin

Combined with the use of renewable electricity during the production process, it has contributed to noteworthy advancements in areas such as carbon reduction and the utilization of fossil resources. Petrochemicals

PPK Natura resin represents one aspect of Plastipak’s ESG program, which, among other initiatives, aims to enhance the circularity of our products to support customers in reducing their Scope 3 emissions.

We eagerly anticipate a long and mutually beneficial partnership with LanzaTech as we work together to achieve our long-term goals,” commented Pedro Martins, Executive Managing Director Europe of Plastipak.

“The utilization of fossil fuels must be avoided. EV-battery revolution – Recycling

When this is not feasible, it is logical to incorporate greenhouse gases into products to prevent these gases from contributing to global warming and climate change,” explained Christoph Meili, an expert in life cycle assessments at WWF Switzerland.

Credit : Plastipak

-Charging times set to be slashed in electric car battery revolution

Charging durations poised to be reduced in electric vehicle battery revolution Nyobolt, the battery technology firm, intends to significantly reduce the time required to charge electric cars as it announces its collaboration with design and engineering enterprise, CALLUM. Nyobolt is introducing its patented rapid-charging battery technology to the realm of electric vehicles. PET Resin

Through the CALLUM partnership, it will redefine the notion of swift charging by cutting charging durations from up to one hour to mere minutes.

By expanding its patented battery technology to the automotive industry, Nyobolt is preparing to revolutionize the sector, eliminating batteries as the constraining factor in the development of electric cars. Petrochemicals

By harnessing the potential of battery performance, Nyobolt has developed a currently achievable and scalable technology that will make recharging as convenient as refueling a gasoline or diesel vehicle. EV-battery revolution – Recycling

To accomplish this technological breakthrough, Nyobolt’s leading team has adopted a comprehensive approach to the development of high-power, fast-charging battery solutions. PET Resin

They have pioneered novel materials, cell designs, efficient software control, and power electronics. With CALLUM’s established capabilities in automotive design and engineering, along with its in-house engineering facilities in Warwickshire, the companies will collaborate on projects incorporating this patented battery technology.

The first automotive concept, which showcases the application of the technology in passenger vehicles, will be unveiled in June this year.

It has been conceived by esteemed car designer Julian Thomson, currently the design director at General Motors Advanced Design Europe, with the concept developed and executed by CALLUM. Dr. Sai Shivareddy, CEO of Nyobolt, stated: “At Nyobolt, we are unlocking the potential of battery technology to drive immediate innovations.

The rapid transition to battery electric vehicles worldwide is a prime example of an industry that urgently requires our patented battery to drastically reduce charging times from hours to minutes. PET Resin

“Partnering with an established entity like CALLUM and leveraging its experience and expertise in automotive design and engineering will aid us in achieving our strategic goal of widespread adoption in this sector.” EV-battery revolution – Recycling

David Fairbairn, managing director at CALLUM, commented: “We continue to observe charging, access to battery materials, and battery degradation as major challenges in the shift to electric vehicles. Petrochemicals

Nyobolt’s groundbreaking battery technology offers the automotive industry a solution to these significant obstacles.

In the upcoming months, we will demonstrate the compelling advantages this new technology offers to the sector and motorists.” PET Resin

CALLUM and Nyobolt will unveil their initial collaborative concept in June 2023.

For more information, please visit www.nyobolt.com.

Credit : Nyobolt

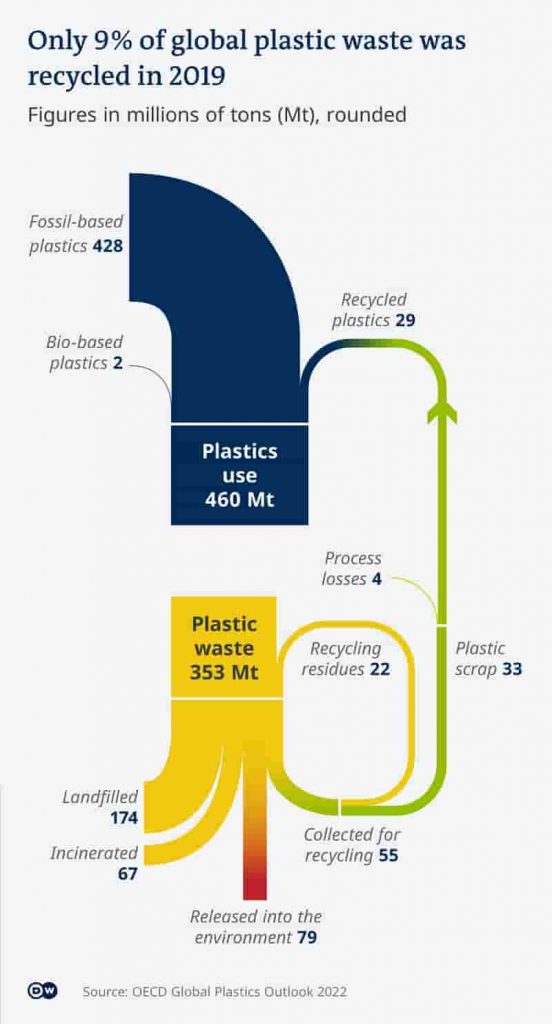

-Global agreement could reduce plastic pollution by 80%

As plastic production continues without restraint, recent findings suggest that with adequate ambition, the world has the potential to decrease plastic pollution by over three-quarters. Petrochemicals

One year after international representatives committed to reaching an agreement on plastic pollution and finalizing it by 2024, the United Nations Environment Programme (UNEP) has released a report outlining a pathway to significantly diminish the amount of plastic waste that ends up in the environment. PET Resin

Based on a framework of established methods to address plastic pollution, the report published on Tuesday establishes the foundation and demonstrates what is achievable.

The discoveries indicate systemic changes that could reduce plastic pollution by more than 75% by 2040, while generating hundreds of thousands of employment opportunities and saving trillions of dollars. EV-battery revolution – Recycling

“The report reveals that only an integrated, systemic transition from a linear to a circular economy can prevent plastics from entering our ecosystems and bodies, and instead keep them within the economy,” stated Inger Andersen, Director of UNEP.

The release of the report precedes a gathering of international representatives scheduled later this month in the French capital.

This meeting will mark the second round of discussions on the agreement, which the UN Environment Assembly has hailed as “the most significant environmental accord since the Paris (climate) agreement.” PET Resin

At present, the world produces approximately 350 million tons of plastic pollution each year, resulting in biodiversity depletion and global concerns regarding health and food supply. Petrochemicals

What actions need to be taken? The report calls for prohibitions and agreements to eliminate unnecessary and problematic plastics, including those that are non-recyclable, non-reusable, non-compostable, as well as excessive packaging or plastics containing hazardous chemicals detrimental to human health.

Furthermore, it outlines a three-pronged approach of reusing, recycling, and transitioning to alternative materials.

Measures to promote reuse, such as refillable bottles, reusable bags, bulk dispensers in grocery stores, deposit-return programs, and packaging take-back initiatives, present the most readily achievable solutions, reducing plastic pollution by 30% by 2040.

Certain countries, like France, have already taken initial steps to enhance reuse rates by mandating large grocery stores to provide reusable containers to customers and banning disposable plates through their anti-waste law implemented in 2021.

Enhancing recycling rates could be accomplished by implementing stricter design standards, prohibiting problematic additives and polymers that hinder recycling processes, and discontinuing subsidies for fossil fuels, thereby making recycling economically favorable compared to producing new plastic. EV-battery revolution – Recycling

The report suggests that improved recycling rates could lead to a 20% reduction in plastic pollution. Petrochemicals

Spain and the UK have already imposed taxes and levies on the production of virgin plastic to create a level playing field, while Mexico incentivized recycling and increased its recycling rates from 8.8% in 2002 to 56% in 2018. PET Resin

An additional 17% reduction in plastic pollution could be achieved by transitioning to alternative materials for products like wrappers, sachets, and takeaway items. Nevertheless, humanity would still generate approximately 100 million metric tons of plastic waste from short-lived products, necessitating responsible disposal methods to prevent the accumulation of plastic in oceans.

To address microplastic pollution, the report proposes modifications in textile production practices and reducing vehicle mileage to minimize tire abrasion.

The economic advantages According to the UNEP report, implementing the recommended systemic changes would result in savings of $4.5 trillion (€4.1 trillion) by 2040.

While producing less single-use plastic would contribute to cost savings, most of the benefits would be derived from reducing the expenses currently borne by plastic manufacturers, such as healthcare and cleanup initiatives. EV-battery re volution – Recycling

-Will Artificial Intelligence Revolutionize Recycling?

Automation and artificial intelligence are driving efficiencies in the recycling operations of a materials recovery facility in Boulder, CO. PET Resin

Automation and artificial intelligence are revolutionizing industries globally and that includes the recycling sector. Petrochemicals

One remarkable example can be found at a materials recovery facility (MRF) in Boulder, CO, where cutting-edge AI technology has been deployed to enhance recycling operations.

This intelligent system has acquired the ability to distinguish between different materials, accurately identifying pieces of plastic among sheets of paper and then efficiently separating them. EV-battery revolution – Recycling

This also increases accuracy and speeds while reducing manual labor requirements. By seamlessly integrating AI into recycling processes, this facility is paving the way for more efficient and effective recycling practices. PET Resin

The automated sorting systems are from AMP Robotics.

-‘Infinite recycling’ startup Samsara Eco partners with Lululemon

Samsara Eco, an Australian startup that uses enzyme-based tech to recycle plastics, textiles and other materials countless number of times, has struck a major partnership with Lululemon. Petrochemicals

The deal means Samsara Eco and Lululemon will create what they describe as the world’s first infinitely recycled nylon 6,6 and polyester from apparel waste.

The partnership is also Lululemon’s first minority investment in a recycling company, though the amount was undisclosed, and Samsara Eco’s first partnership in the apparel industry. PET Resin

The startup has raised a total of $56 million from investors like Breakthrough Victoria and Temasek and its commercial partners include Woolworths Group.

Nylon and polyester currently make up about 60% of clothing produced today, but at the end of their lifecycle, 87% end up in a landfill or incinerated. EV-battery revolution – Recycling

Samsara Eco’s enzyme-based technology breaks down mixed apparel derived from plastics into their molecular building blocks to produce new apparel, which in turn can be broken down again, creating what the company refers to as infinite recycling.

Paul Riley, the CEO and founder of Samsara Eco, explained that nylon 6,6 is one of the textile and fashion industries’ most commonly used materials, because its complex chemical structure makes it very versatile and resilient. But it’s also difficult to break down and recycle. Petrochemicals

Both nylon and polyester are derived from fossil fuels and usually end up in landfills. By working with Lululemon, however, Samsara Eco has expanded its library of plastic-eating enzymes to include ones for polyester and nylon 6,6. PET Resin

“What this means is that we can now break down apparel made from blended materials back down to its core molecules, which can then be used to recreate brand-new apparel again and again.” EV-battery revolution – Recycling

-Enabling manufacturers to enhance production yields by allowing automation to take on additional unsupervised night shifts, Sumitomo (SHI) Demag will also unveil how existing and potential customers can decrease expenses and unlock untapped profit opportunities

Debuting in the UK & Ireland market and tailored for trade molders and small to medium-sized enterprises (SMEs), the linear 4-axis robot with cartesian kinematics for standard applications provides a compact production unit with efficient handling functions and fully integrated robotic controls. Petrochemicals

All sourced from a single origin. PET Resin

The comprehensive turnkey cell, with dimensions as small as 3.95m x 2.4m, incorporates the all-electric IntElect75 accompanied by the company’s new SAM-C5.

The cell also includes a storage and conveyor system with a buffer and integrated boxing unit. Every component was developed in-house by Sumitomo (SHI) Demag’s automation experts. EV-battery revolution – Recycling

This equips molding companies with the necessary technology and tools to confidently operate “ghost” workflow shifts and save costs with minimal human intervention.

Instead of implementing split shifts or keeping workers in the factory until late at night, the 75-ton IntElect turnkey cell, showcased at Interplas, demonstrates to trade molders and SMEs the untapped production opportunities during after-hours.

Additionally, day-shift teams benefit from the augmented workflow process by automating monotonous and repetitive tasks. Petrochemicals

This allows individuals to allocate their time to more creative and business-enhancing responsibilities, resulting in a more motivated and engaged workforce. PET Resin

Optimizing business efficiency, the Interplas 2023 exhibit in Hall 4, Stand C40 emphasizes the reduction in operational errors and efficiency improvements, thereby transforming the night shift into an additional source of valuable production.

Equipped with a tool from Germany, visitors at Interplas 2023 can witness the molding of a precision slide gauge.

The tool-dependent buffer system can be acquired with or without an optional robot removal feature. The conveyor belt technology is designed to transport standard-sized industrial containers.

This handle&box solution is ideal for injection molding machines within the 75 to 280-ton clamp force range. For ease of operation, the SAM-C robotic system is fully integrated into the IntElect machine control system. EV-battery revolution – Recycling

Underscoring the significance of alleviating workforce pressures, Nigel Flowers, the incumbent UK managing director, adds, “Our new SAM-C robots fulfill a crucial need in the processing market and assist molders in increasing the production capacity of standard components while simultaneously addressing skill and labor challenges.

Customers benefit from process and system technology provided by a sole supplier, complete with hardware and software control integration, as well as robotic mechanics that are fully customized to Sumitomo (SHI) Demag machines.” PET Resin

Sumitomo (SHI) Demag will also present its new productivity whitepaper to visitors at Interplas. Petrochemicals

The whitepaper reveals how a combination of automation, digital tools, remote diagnostics, expert field tests, processing adjustments, and workforce training can result in an additional 168 days of production, equivalent to approximately a 50% boost in productivity. EV-battery revolution – Recycling

Credit : Sumitomo