PET-flakes -Car battery solutions 12-05-2023 - Arhive

PET-flakes -Car battery solutions

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

–Emerging car battery technologies

Emerging battery technologies are currently the subject of great interest and research around the world, as the increased demand for clean and sustainable energy has made batteries a crucial component for a wide range of applications including solar energy, the electrification of transport and the balancing of the electricity grid.

Here are some of the emerging battery technologies:

- Lithium-sulfur batteries: use sulfur as the anode and lithium as the cathode, offering a higher energy density than current lithium-ion batteries.

- Magnesium batteries: use magnesium instead of lithium as an anode, offering greater storage capacity and lower cost.

- Flow batteries: use liquid rather than solid electrolytes to store energy, which allows you to flexibly increase storage capacity.

- Solid-state batteries: Use solid materials rather than liquids as electrolytes, which increases the safety and stability of batteries and allows for increased energy density. PET-flakes -Car battery solutions

- Hydrogen batteries: use hydrogen as fuel and produce electricity through a chemical reaction, offering a clean and sustainable energy source.

However, many of these technologies are still in development and are not yet ready for large-scale commercial use. Some of the major hurdles that need to be overcome include reducing costs, increasing efficiency, and fixing security issues.

Lithium-sulfur batteries are a promising technology for energy storage due to their high theoretical energy density, low cost, and the abundance of sulfur. However, there are several challenges that must be addressed before they can be widely used.

- Short cycle life: Lithium-sulfur batteries can suffer from rapid capacity loss after just a few cycles, which is attributed to the dissolution of lithium polysulfides and the formation of a solid electrolyte interphase (SEI) layer on the surface of the lithium anode. PET-flakes -Car battery solutions

- Low energy efficiency: During discharge, lithium-sulfur batteries can suffer from a loss of energy due to the formation of insulating sulfur species, which can block the flow of lithium ions and reduce the overall efficiency of the battery.

- Safety concerns: Lithium-sulfur batteries can be prone to dendrite formation, which can cause short circuits and potentially lead to fires or explosions. Additionally, the high reactivity of lithium with sulfur can lead to thermal runaway and thermal decomposition.

- Performance degradation at high temperatures: Lithium-sulfur batteries can suffer from rapid performance degradation at high temperatures due to the increased mobility of lithium ions, which can lead to capacity fade and reduced cycle life.

- Manufacturing challenges: The manufacturing of lithium-sulfur batteries is still in the research and development phase, and there are several technical challenges that must be addressed before they can be produced at scale. These include the development of stable cathode materials, the optimization of the electrolyte composition, and the implementation of new manufacturing techniques.

Magnesium batteries are a promising alternative to lithium-ion batteries due to their higher energy density and lower cost. However, there are several challenges that need to be addressed before they can become a viable option for commercial use. Here are some of the main problems associated with magnesium batteries: PET-flakes -Car battery solutions

- Limited availability of electrolytes: Magnesium ions are larger than lithium ions, which makes it difficult to find suitable electrolytes that can effectively transport them. As a result, the development of efficient and stable electrolytes for magnesium batteries is still a significant challenge.

- Poor conductivity: Magnesium metal has poor electrical conductivity, which can result in low battery efficiency and slow charge/discharge rates. To overcome this problem, researchers are exploring different strategies such as using magnesium alloys or coating the magnesium electrodes with conductive materials.

- Dendrite formation: Like lithium-ion batteries, magnesium batteries are also susceptible to dendrite formation, which can cause short circuits and reduce battery performance. Dendrites are tiny, needle-like structures that grow on the surface of the electrode and can pierce through the electrolyte, causing a short circuit. Researchers are investigating ways to prevent dendrite formation, such as using additives in the electrolyte or modifying the electrode surface.

- Safety concerns: Magnesium is a highly reactive metal that can catch fire if exposed to air or water. This poses a safety risk for magnesium batteries, especially during manufacturing and recycling. To ensure the safe handling of magnesium batteries, researchers are developing new production techniques and recycling processes that minimize the risk of fire.

Overall, magnesium batteries have the potential to offer significant advantages over lithium-ion batteries, but more research and development are needed to overcome the current challenges and make them a viable alternative. PET-flakes -Car battery solutions

Flow batteries are a type of rechargeable battery in which the energy is stored in chemical form in two liquid electrolytes, which are kept separate by a membrane. When the battery is charged or discharged, the electrolytes are pumped through a reactor, where the chemical reaction takes place.

While flow batteries offer several advantages over other types of batteries, such as longer cycle life and the ability to store large amounts of energy, they also have some limitations and problems, including:

- Cost: Flow batteries can be more expensive than other types of batteries, due in part to the need for a large reactor and a membrane to separate the electrolytes. PET-flakes -Car battery solutions

- Efficiency: The efficiency of flow batteries is lower than that of other types of batteries, such as lithium-ion batteries. This is due to the energy loss that occurs as the electrolytes flow through the reactor and the membrane.

- Complexity: Flow batteries are more complex than other types of batteries, which can make them more difficult to design, manufacture, and operate.

- Limited energy density: Flow batteries have a lower energy density than some other types of batteries, which means they require more space to store the same amount of energy.

- Membrane degradation: The membrane that separates the two electrolytes can degrade over time, which can lead to reduced performance and shorter battery life.

- Chemical compatibility: The electrolytes used in flow batteries must be carefully selected to ensure that they are chemically compatible with the reactor and membrane. This can limit the choice of materials that can be used in the battery.

Overall, while flow batteries have some limitations and problems, they are still a promising technology for energy storage and have the potential to play a significant role in the transition to a more sustainable energy system. PET-flakes -Car battery solutions

Solid-state batteries are a promising technology for energy storage due to their potential to offer higher energy density, faster charging times, and improved safety compared to traditional lithium-ion batteries. However, there are still several challenges that need to be addressed before solid-state batteries can become a viable alternative to current battery technologies. Some of the major problems with solid-state batteries include:

- Cost: Solid-state batteries are currently more expensive to produce than traditional lithium-ion batteries. This is partly due to the use of exotic materials and complex manufacturing processes. As a result, the cost of solid-state batteries is a major barrier to their widespread adoption.

- Manufacturing complexity: Solid-state batteries are more difficult to manufacture than traditional lithium-ion batteries. The complex manufacturing processes require specialized equipment and expertise, which adds to the cost and time required to produce the batteries. PET-flakes -Car battery solutions

- Limited capacity: Solid-state batteries have a lower energy density than traditional lithium-ion batteries, which means they can store less energy per unit of volume or weight. This limits the range and performance of devices that use solid-state batteries, such as electric vehicles.

- Temperature sensitivity: Solid-state batteries are sensitive to temperature changes, which can affect their performance and lifespan. High temperatures can cause the electrolyte to break down, while low temperatures can reduce the battery’s output power.

- Safety concerns: While solid-state batteries are generally considered safer than traditional lithium-ion batteries, there are still some safety concerns related to their use. For example, the use of lithium metal electrodes in solid-state batteries can lead to the formation of dendrites, which can cause short circuits and lead to battery failure. PET-flakes -Car battery solutions

Researchers are actively working to address these challenges and improve the performance and reliability of solid-state batteries. It is expected that with further development, solid-state batteries will become a more viable alternative to traditional lithium-ion batteries.

While hydrogen fuel cells have the potential to be a clean and efficient source of energy, there are several challenges and problems associated with hydrogen batteries. Some of these include:

- Storage: Hydrogen is a highly flammable gas that requires special handling and storage. It is difficult to store hydrogen safely and efficiently, and it often requires expensive infrastructure to transport and store.

- Cost: Hydrogen fuel cell technology is still relatively new, and the cost of producing, transporting, and storing hydrogen is still high. This makes it more expensive than other forms of energy, such as fossil fuels and even other types of renewable energy sources like solar and wind power.

- Efficiency: While hydrogen fuel cells have the potential to be highly efficient, converting hydrogen to electricity can be less efficient than other forms of energy conversion. Some of the energy is lost in the conversion process, which can make hydrogen fuel cells less efficient than other types of batteries.

- Availability: While hydrogen is the most abundant element in the universe, it is not readily available on Earth in its pure form. It must be extracted from other compounds, such as water or natural gas, which can be costly and energy-intensive. PET-flakes -Car battery solutions

- Infrastructure: To make hydrogen fuel cells a viable alternative to other forms of energy, a robust infrastructure is required. This includes hydrogen storage, transportation, and distribution systems, which can be costly to build and maintain.

Overall, hydrogen fuel cells have the potential to be a clean and efficient source of energy, but there are several challenges and problems that must be addressed before they can become a widely used energy source.

-China is currently experiencing deflation with prices approaching zero and production values in significant decline

The country’s macro data is causing investors to question its real growth after ending its Covid-zero policy.

The Nikkei is below parity, Hong Kong is down by 0.45%, and Shanghai has decreased by 0.2%.

Despite this, US WTI oil prices have risen by 1% to $73.23 a barrel due to a report on US inventories from the EIA, while futures on Wall Street are showing an average of 0.2% positivity.

China’s annual inflation rate has dropped to 0.1% in April 2023, its lowest since February 2021, and is causing deflation due to an uneven economic recovery after the end of the Covid-zero policy.

This has led to a further decrease in both food and non-food costs. Additionally, producer prices have dropped sharply, with a 3-year high and remaining in deflation for seven months. PET-flakes -Car battery solutions

In April 2023, Chinese producer prices fell 3.6% YoY, which is worse than the expected 3.2% decline and faster than March’s 2.5% drop.

This is due to weakening commodity prices, with manufacturing materials decreasing faster than processing prices, raw materials, and extractions.

Meanwhile, consumer goods inflation has fallen, and the cost of durable goods has also decreased.

Despite this, WTI crude futures have climbed to $73 a barrel on Thursday after US gasoline inventories fell, indicating that oil demand remains strong.

However, trade data from China showed crude oil imports falling by 16% YoY in April, heightening fears of an economic slowdown in the country.

In a surprising move, China has appointed a local government official, Li Yunze, as the nation’s top financial regulator, overseeing the $61 trillion industry.

This has caused some market observers to question the choice, as they were expecting someone with more seniority and experience. PET-flakes -Car battery solutions

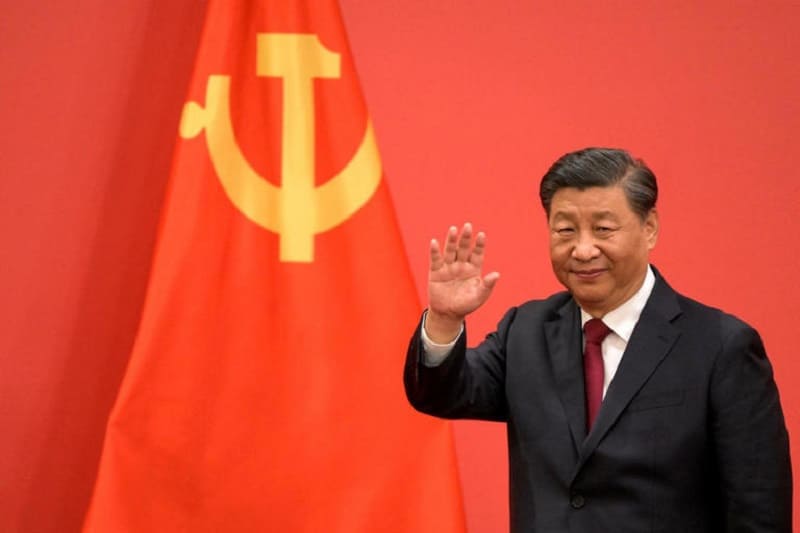

Additionally, President Xi Jinping’s anti-spy campaign is shaking up the advisory and research industry that helps global investors do business in China.

-Ambienta enters Previero

The private equity fund focused on sustainability has taken over the majority of the Como-based manufacturer of equipment for the recycling of plastics and rubber.

Previero headquartersThe Italian financial company Ambienta Sgr, specialized in green investments, has acquired the majority of Previero, an Italian manufacturer of equipment and lines for the recycling of plastic materials, based in Anzano del Parco (CO), which has belonged to the founder’s family for three generations , Previero Christmas.

Active since 1922 – initially in the manufacture of woodworking plants -, Previero designs and builds machinery for grinding plastics, natural and synthetic rubber, as well as recycling plants for copper cables, tires and post-consumer packaging. Production is divided between the Alzate Brianza and Anzano del Parco sites, where around 110 people work.

The Previero family will maintain a minority stake and the operational management of the company.PET-flakes -Car battery solutions

Ambienta will support the company by providing financial and managerial resources, promoting further investments in fixed and human capital and, more generally, collaborating with the three Previero brothers to consolidate their presence on the global market.

“In Ambienta we have found a partner capable of understanding the company’s history and potential – comments Flavio Previero, President of the Como-based company -. We believe he can provide complementary industrial and international experience, which will allow us to grasp more quickly and effectively the many opportunities we see before us.”

Previero is the first investment of Ambienta’s most recent fund, Ambienta IV. With assets of €1.55 billion, it is the largest European private equity fund focused exclusively on companies that facilitate positive environmental change in their respective sectors.

-A significant recycling plant that processes PET flakes into food-grade PET granules has opened in Târgu Mureș, Romania

The new factory, called PET Recycling Team Târgu Mureș, was built following a €7.5 million investment by a group composed of Alpla Group (Austria), Ecohelp SRL (Romania), and United Polymer Trading (Switzerland).PET-flakes -Car battery solutions

The plant is one of the most advanced facilities of its kind in the European Union and will produce 18,000 tons of recycled plastic annually, supplying carbonated soft drinks, dairy products, mineral water, beer, and oil bottlers in Romania and the surrounding area.

The first extrusion line is already in operation, and the granules produced serve as raw materials for new preforms and bottles.

According to Mihai Moloiu, CEO of PET Recycling Team, the plant’s location in the center of Romania was intentional, as it is natural to process at home what is collected and recycled at home.

The new facility was inaugurated in the presence of state counselor and coordinator of the department of sustainable development within the General Secretariat of the Romanian Government Lazlo Borbely and the vice-president of the National Environmental Protection Agency, Adrian Bidu, both of whom praised the investment as a significant step forward in Romania’s recycling efforts.PET-flakes -Car battery solutions

-Kelheim and Santoni join forces on sustainable menstrual underwear

Kelheim Fibres has teamed up with Italian seamless knitting machine builder Santoni on the manufacture of energy-efficient and zero waste production menstrual underwear.

Under the terms of the project, the speciality viscose fibre manufacturer and Santoni Spa have jointly developed an innovative and sustainable menstrual underwear garment based on advanced machine technology and high-quality performance viscose fibres. The product consists of a soft outer layer and an inlay made from special wood-based fibres from Kelheim. The result is a sustainable and high-performance product that combines comfort and functionality.

The soft outer layer is produced either on the Santoni SM8-TOP2V circular knitting machine or on the SM4-TL2 machine. One of the major advantages of these circular knitting machines is that they significantly reduce the amount of cutting waste or even allow production with zero-waste PET-flakes -Car battery solutions

The Santoni XT-Machine, originally developed for the footwear market, is used for the functional inlay of the period panty. The unique XT-Machine allows for different layers to be produced with different yarns and knitting structures. This enables all three functions of the inlay – the absorption and distribution layer ADL, the absorbent core, and the back layer – to be knitted in a single tube.

This reduces production time and costs and enables zero-waste production.

In the inlay, wood based Kelheim specialty fibres such as trilobal Galaxy or the hollow Bramante fibre replace synthetic materials.

Santoni and Kelheim Fibres both stand for tradition as well as sustainability and innovation and Patrick Silva Szatkowski, Marketing Manager at Santoni, is extremely pleased with the collaboration: “Our machines have changed the manufacturing process, making garments almost seam free and offering solutions for 3D knitting. PET-flakes -Car battery solutions

-ITMA 2023 Exhibitor Preview: Starlinger & Co. G.m.b.H

The Austrian machinery provider is showing its latest developments for sustainable woven sack production at ITMA in Milan. The highlight: the new circular loom FXa 6.0.

For over 50 years, Starlinger has been a leader in the technological development of circular looms for the production of woven sacks from plastic tapes. With the new six-shuttle circular loom FXa 6.0, the company is introducing an even more efficient and user-friendly machine that produces polypropylene tape fabric of highest quality.

“With the new FXa 6.0, we offer a circular loom with significantly reduced energy requirements and a low noise level,” said Harald Neumüller, CSO of Starlinger. “At the same time, longer spare parts lifetime ensures significant cost savings.

By investing in new processes and innovative manufacturing methods for our in-house production we have been able to significantly minimise quality fluctuations in shuttle roller production and increase their service life.”PET-flakes -Car battery solutions

Regarding machine control, a 7-inch touchscreen display and a high-performance CPU ensure convenient operation.

“The FXa 6.0 also features a so-called IQ of 350. This means that on average there is only one warp tape break every 350 metres – an immense advantage in terms of machine downtime and work for the machine operators,” Neumüller added.

The FXa 6.0 circular loom achieves a production speed of up to 1200 picks per minute and is designed for the gentle and energy-efficient production of light tape fabrics from 45 g/m² to 140 g/m². The circular loom will be shown in operation at the stand of Starlinger textile packaging in Hall 3. PET-flakes -German industrial output

Closed packaging loops for woven bags made of PP and PET

The use of recycled materials has become one of the leading topics in the packaging industry. In this respect, Starlinger is a pioneer when it comes to woven plastic packaging. With its “Circular Packaging” concept, the company has developed a closed packaging cycle for big bags, in which used big bags are turned into new big bags again. “As part of our “Circular Packaging” concept, big bags made of polypropylene fabric are equipped with a material passport that allows to trace their life cycle from production to use to return and recycling,” explains Neumüller.

“This means that used big bags can be recycled without significant loss of quality and the regranulate used for producing new big bags – the packaging cycle is closed.” Fabric for big bags produced on Starlinger equipment with high shares of recycled polypropylene has the same specifications as fabric produced from virgin material and has been tested with standardised test procedures.PET-flakes -Car battery solutions

With the technology for the production of tape fabric from PET and rPET, Starlinger has harnessed the great advantage of this material for woven packaging. Correctly processed, PET recyclate has properties like virgin material and can be recycled repeatedly. PET tape fabric is strong, food-safe, has excellent creep resistance and can be made from 100% recycled material. As with bottle-to-bottle recycling, “bag-to-bag” recycling is possible in this case to close the packaging loop. This not only reduces raw material requirements, but also CO2 emissions and energy consumption. Both PET and rPET tape fabric are already being used successfully in the production of big bags.

Post-consumer rPET for textile applications

Starlinger recycling technology will be present at ITMA with its own stand in Hall 9, providing information on recycling solutions for fibre and filament production. In addition to recycling production waste, Starlinger also offers solutions for the use of recycled post-consumer plastics such as rPET in textile production. PET-flakes -Car battery solutions

In order to be able to use recycled PET for the production of polyester filaments and fibres, it must meet the highest quality standards – any foreign particles and polymers must be removed before extrusion. In order to optimally clean the melt in the recycling process, Starlinger has developed a special cartridge filter for fibre applications, the so-called Rapid Sleeve Changer (RSC). It guarantees finest filtration of the melt down to 15 μm and achieves a throughput of up to 2000 kg per hour. The filter elements can be changed without interrupting production, which significantly reduces melt loss and machine downtime.

For PET bottle-to-bottle recycling applications, Starlinger offers the new recoSTAR PET art, an energy-efficient and user-friendly recycling system. It achieves 15% more output with less maintenance and space requirements than the previous model and saves around 21% in production costs. PET-flakes -Car battery solutions

-German industrial output plummets 3.4% in March 2023

- German industrial production fell 3.4 per cent MoM in March 2023, following a 2.1 per cent rise in February.

- Despite this, Q1 2023 production was 2.5 per cent higher than Q4 2022.

- Significant decreases were seen in machinery manufacturing at -3.4 per cent and in industry excluding energy and construction at -3.3 per cent; energy production rose 0.8 per cent.

German production in industry in real terms was down by 3.4 per cent month-on-month (MoM) on a price, seasonally, and calendar adjusted basis, in March 2023. This decrease follows an increase of production in industry by 2.1 per cent in February 2023, provisional figure—2.0 per cent. PET-flakes -Car battery solutions

Considering the first quarter (Q1) of 2023, production was 2.5 per cent higher compared with Q4 2022, according to provisional data provided by the Federal Statistical Office (Destatis).

Decreases in the manufacture of machinery and equipment at -3.4 per cent accounted for a large share of the significant decrease in total production.

In March 2023, production in industry excluding energy and construction was down by 3.3 per cent compared with February 2023 in seasonally and calendar adjusted terms. The production of intermediate goods decreased by 3.5 per cent and the production of consumer goods by 0.1 per cent in March 2023 compared with the previous month. Whereas energy production rose by 0.8 per cent compared with the previous month.