Plastic waste – Recycled batteries 11-05-2023 - Arhive

Plastic waste – Recycled batteries

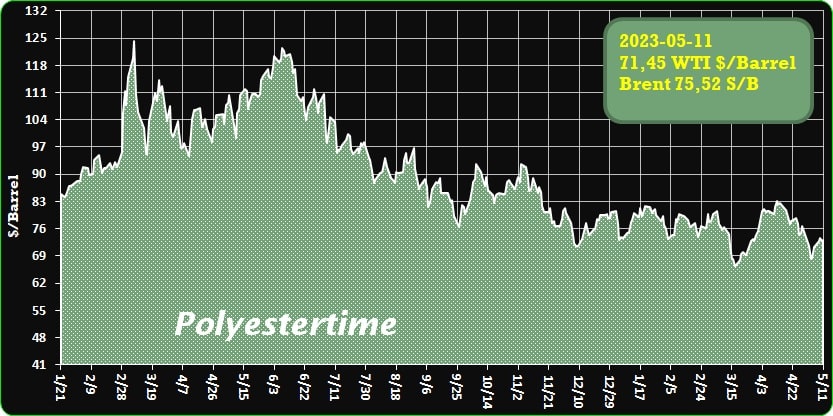

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

-Borealis showcases a new PP monomaterial pouch that is fully compatible for mechanical recycling of polypropylene at PRSE 2023

-Newly-developed high barrier flexible pouch for dry food is designed for recycling

-Monomaterial pouch containing over 95% polypropylene (PP) helps producers and brand owners fulfil stringent Packaging and Packaging Waste Regulation (PPWR) guidelines

-Value chain collaboration in the spirit of EverMinds™ continues to advance plastics circularity

Borealis announces that it is using the occasion of the Plastics Recycling Show Europe (PRSE) in May to highlight a new monomaterial pouch containing over 95% PP and designed for recycling.

Developed in collaboration with value chain partners, this more sustainable high barrier packaging format offers a range of benefits for the blown and cast film extrusion processes as well as for brand owners and end consumers. Plastic waste – Recycled batteries

As a monomaterial PP packaging format, it can help meet ambitious recycling and waste reduction targets set forth in the EU’s Packaging and Packaging Waste Regulation (PPWR) as well as eco-modulation criteria for Extended Producer Responsibility (EPR) programmes.

Accelerating plastics circularity through value chain co-operation

High barrier packaging is used to preserve and protect foodstuffs that are sensitive to moisture, oxygen, aromas, and light, like dry ingredients and powders, coffee, and snack foods.

Producers and consumers benefit from the longer shelf life and reduced food waste made possible by these convenient high barrier pouches.

In the extrusion lamination process, laminating PP cast and BOPP (biaxially oriented polypropylene) films yields mono PP laminates with uniquely advantageous properties. These include high barrier and stiffness, and excellent sealing performance.

Using conventional adhesion lamination structures, producers have previously been able to obtain pouch laminate materials containing approximately 90% PP.

However, by pooling their respective areas of expertise, Borealis and value chain partners have now been able to boost the share of PP to over 95%. Plastic waste – Recycled batteries

When processed within dedicated mechanical recycling streams for PP, this monomaterial pouch yields greater volumes of high-quality recyclate fit for use in non-food, flexible PP packaging applications.

It is thus the ideal format with which to fulfil the principle aims of the PPWR: improve recyclability, grow the market for recycled content, and reduce packaging waste.

While eco-modulated EPR fees based on packaging recyclability credentials and recycled content may differ among EU Member States, the new monomaterial pouch made of over 95% PP meets the (Circular Economy for Flexible Packaging) definition of “fully compatible to mechanical recycling PP.”

It is thus a cost-saving alternative to conventional pouch formats composed of a greater number of different materials.

“In re-inventing essentials for sustainable living, our aim is to uphold the integrity and quality of packaging materials while ensuring that these convenient formats are more and more circular,” says Peter Voortmans, Borealis Global Commercial Director Consumer Products. “We are very proud of this value chain collaboration.

It equips our partners and customers with yet another viable and more sustainable solution to help manage the updated requirements of the PPWR.”

The high barrier pouch made of over 95% PP demonstrates excellent seal strength and hermetic sealing properties thanks to the material solutions and production expertise contributed by each of the value chain partners involved in this project.

Commercially available polyolefins in the Borealis PP extrusion coating and lamination grade portfolio offer stable processability and good laminate bond strength.

These were used in tandem with tie layers contributed by the Mitsui Chemical Group, a leading international manufacturer of specialty chemicals, including polyolefin-based tie resins. Plastic waste – Recycled batteries

As a global leader in the development and manufacture of specialty BOPP films, Jindal Films contributed to this innovative solution for recyclable packaging.

With locations in Europe, America, and China, Profol, known for its innovative cast PP films and lightweight composites, produced the cast films.

Based in Finland and operating in 38 countries, Huhtamaki Flexible Packaging provides solutions that enhance wellbeing and convenience for consumers around the world, and contributed innovative laminates to the new monomaterial pouch.

-An investment syndicate comprising of Invest-NL, Infinity Recycling, and LyondellBasell has injected nearly €13 million into Pryme, an advanced plastic waste recycler located in Rotterdam, the Netherlands

Pryme has developed an economical pyrolysis technique for recycling plastic waste on an industrial scale, with a high conversion rate and a low carbon footprint.

According to the Dutch research organization TNO, chemically recycling plastic waste can help avoid 92,000 tonnes of CO2 emissions per year for each Pryme reactor line of 40,000 tonnes compared to incineration.

The new funds raised will be used by Pryme to enhance the commercialization of its recycling process. The CEO of Pryme, Chris Herve, expressed his excitement about the new investors, adding that they are expected to bring valuable experience and insight to advance the technology further.

The recycling plant in Rotterdam, with a yearly input capacity of 40,000 tonnes, is being constructed by Pryme and will commence operations in 2023.

Infinity Recycling, a member of the consortium, is a portfolio company of Pryme, with a focus on investing in valorisation technologies for recycling plastic.

Invest-NL is the Netherlands’ national financing and development institution.

Elisabeth Storm de Grave, its principal, described the investment round as a significant step towards expanding Pryme’s advanced recycling capabilities.

For LyondellBasell, the investment provides a potential source of feedstock for the integrated hub it is developing in Cologne, Germany. Plastic waste – Recycled batteries

The company aims to process up to 2 million tonnes of renewable or plastic waste-based feedstock annually, and it is engineering an advanced recycling plant with its proprietary MoReTec technology.

Martino Gabellich, Vice President of Advanced Recycling and Low Carbon Solutions at LyondellBasell, emphasized the importance of investing in rapidly growing firms like Pryme to support the scaling-up of new advanced recycling commercial operations and decrease the amount of plastic waste sent for incineration as the demand for more circular products increases.

-In a statement, Glencore and Li-Cycle, who are leaders in the lithium-ion battery resource recovery industry and have been partners with the Swiss multinational since May 2022, have announced a joint study to develop a Recycling Hub in Europe by converting an existing metallurgical plant owned by Glencore in Portovesme

This will become the largest source of high-quality recycled lithium for batteries, as well as recycled nickel and cobalt in Europe.

The official announcement of the plant’s conversion study comes just a few days before the working group scheduled for May 17th at Mimit, which will discuss the future development of the industrial site after the lead line closure.

The creation of the first fully closed-loop European solution for raw materials from lithium batteries to high-quality battery products is expected. The new Hub’s processing capacity is estimated to be between 50,000-70,000 tonnes of black mass per year, according to the Swiss multinational’s statement. The definitive feasibility study will begin in mid-2023 and will benefit from Li-Cycle’s cutting-edge technology and the advantage of being the first in Europe. The timeline has been accelerated thanks to the reuse of some of Glencore’s existing facilities in Portovesme, Italy. Plastic waste – Recycled batteries

A letter of intent has also been signed “to jointly evaluate the feasibility and subsequent development of a Hub plant in Portovesme,” which will produce critical battery raw materials, including nickel, cobalt, and lithium, from the content of depleted batteries. “The Portovesme Hub will benefit from Li-Cycle’s cutting-edge hydrometallurgical technology and will be the largest sustainable battery product manufacturing plant in Europe.”

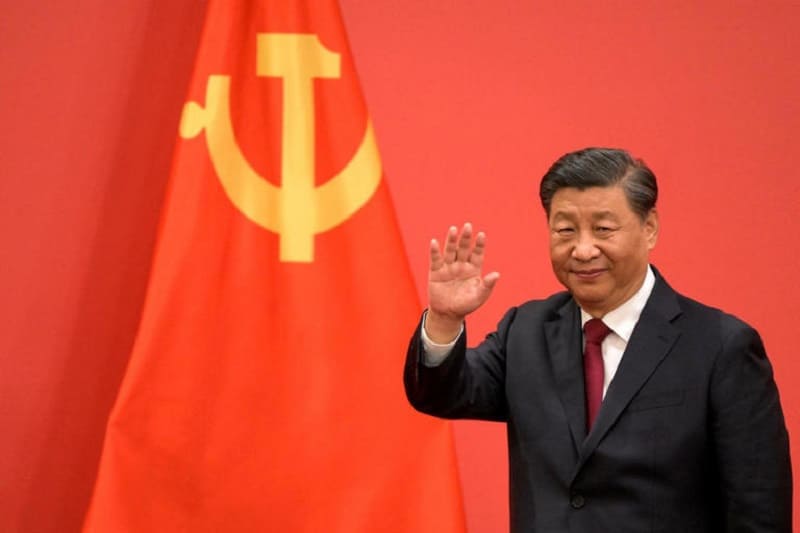

-China’s foreign policy has become more lenient, as evidenced by recent efforts to establish itself as a mediator between Russia and Ukraine

President Xi Jinping’s country now expresses support for normalizing relations with the United States. The Chinese Foreign Minister, Qin Gang, urged better management of the Taiwan issue to preserve the “one China” principle. He also requested that the US respect China’s sovereignty, security, and development interests. Qin met with US Ambassador Nicholas Burns to discuss the importance of stabilizing relations following a series of misleading actions and statements by the US.

The US-China relationship experienced heightened tension after Speaker of the US House Nancy Pelosi visited Taiwan in August 2022. Although the tension eased after Joe Biden and Xi Jinping’s meeting at the G20 summit in Indonesia, relations have cooled again due to subsequent actions and statements by the US. Plastic waste – Recycled batteries

Qin also hopes to cultivate relations with Europe, and he will visit Germany, France, and Norway, where he plans to mediate the EU’s decision to impose sanctions on seven Chinese companies for aiding the Russian war machine.

-Taiwan, China asks the US to stabilize relations. Military aid to Moscow: EU sanctions on seven Chinese companies

China softens its foreign policy. After the initiatives to establish itself as a qualified mediator between Russia and Ukraine, President Xi Jinping’s country says it is in favor of a normalization of relations with the United States.

The message comes from Chinese Foreign Minister Qin Gang, who in a meeting in Beijing with US Ambassador Nicholas Burns spoke of the “need to stabilize relations after the series of erroneous statements and actions that have cooled ties”.

Qin, according to a note from the Chinese Foreign Ministry, has asked the United States for better management of the Taiwan affair, so as to put an end to the erosion of the “one China” principle, according to which Hong Kong, Macao and Taiwan are part of a single national entity. Plastic waste – Recycled batteries

“The United States should adequately address the issue of Taiwan and stop supporting and legitimizing the separatist forces of independence”, added the Chinese foreign minister, who also asked Washington to respect the “red lines” imposed by China and to stop violating its interests of sovereignty, security and development.

The spiral of tensions between the US and China

Relations between the two largest economies in the world cracked in August 2022 after the trip to Taiwan of the then speaker of the US House, Nancy Pelosi.

Tensions only eased in November, when Joe Biden and Xi Jinping met at the G20 summit in Indonesia, where they pledged to talk more frequently.

“However, since then, a series of misleading actions and statements by the US have disrupted the hard-won positive momentum in bilateral relations, and relations between countries have cooled down again,” Qin said.

In fact, even China has its faults. The climate of tension reached its peak again in February after the discovery of the Chinese spy balloon flying in US airspace.

After his downing, US Secretary of State Antony Blinken canceled a planned visit to Beijing. Blinken recently corrected the shot and stressed the importance of re-establishing regular lines of communication with Beijing. Plastic waste – Recycled batteries

Idea reproposed by the Chinese Foreign Minister: “The top priority is to stabilize relations and avoid a negative spiral in order to prevent any incidents between China and the United States.”

The EU will sanction Chinese companies accused of aiding the Russian war machine

In addition to the US, the Chinese foreign minister is also trying to cultivate relations with Europe. From May 8 to 12, Qin Gang will be visiting Germany, France and Norway.

“At the invitation of German Foreign Minister Annalena Baerbock, French Foreign Minister Catherine Colonna and Norwegian Foreign Minister Anniken Huitfeldt, State Councilor and Foreign Minister Qin Gang will visit Germany, France and Norway,” he said. announced Chinese Foreign Ministry spokesman Wang Wenbin.

The purpose of the visit is also to mediate the EU’s decision to sanction Chinese companies accused of aiding the Russian war machine. Plastic waste – Recycled batteries

-Chemical recycling of plastic in action: How four companies teamed up to turn industrial production waste into valuable products

In the polymers industry, there are waste streams that the industry has, so far, not been able to recycle. Finnish company Uponor found itself in a similar situation and decided it’s time to make a change: they decided to find ways to recycle materials that were considered not recyclable in the past. And together with three other partners, they succeeded. Plastic waste – Recycled batteries

Imagine you’re a producer of pipes for housing and construction purposes. Although you have already optimized your processes to a very high degree, some inevitable material losses remain with the production of every pipe: a small portion of production scrap. The problem with this scrap is that there is not really any use for it.

The situation described above is one that Finnish sustainable water solutions company Uponor was facing. Among a wide range of other products, Uponor is producing pipes for heating and plumbing. These pipes are made of a specific type of polymer: cross-linked polyethylene, often referred to as “PEX”. The PEX pipes are an important contributor to energy efficiency and safety. They are robust, temperature-resistant and long-living. They basically bring all the properties you want to see in the pipes transporting water through a building. Plastic waste – Recycled batteries

These properties go back to the cross-linking characteristic of the polyethylene. Cross-linking refers to the forming of connections between molecules in the polyethylene. Creating these “bonds” makes the polymer more durable, damage-resistant and flexible. Sounds complicated? Let’s try to make it simple: Think of polymers as very long chains – think of cooked spaghetti. If you put a bunch of cooked spaghetti on your plate, you’ll see that they do not form something spectacular, but end up just being a pile of spaghetti. But if you were to use some glue, you could connect strands of spaghettis with each other and form a real noodle network. With every connection you build, you add sturdiness to this pasta pile to form a spectacular piece of delicious art.

With that in mind, let’s consider PEX a very well glued together variant of the spaghetti pile, making it a great choice when in need of a durable product. Unfortunately, it also came with a downside in the past: PEX is considered nearly impossible to recycle with conventional recycling technologies.

When producing the PEX pipes, Uponor was left with no alternative but collecting the PEX production scraps and disposing of them. They were either incinerated or landfilled. That’s why the team looked for a more resource-efficient alternative – and found one after bringing together the right partners. Plastic waste – Recycled batteries

-GC Ventures invests in UK-based start-up Interface Polymers, a developer of high-performance additives for performance plastics

GC Ventures (GCV), a subsidiary of PTT Global Chemical PLC (GC), is investing in the British company Interface Polymers Ltd. The company says that this investment opens new horizons for GC Group, enabling more efficient and sustainable plastic recycling.

Interface claims Polymer’s Polarfin additives enable compatibilization between polyethylene (PE) or polypropylene (PP) with different kinds of plastics such as PET, PA, EVOH and other plastics. This makes it possible to recycle the mixed plastics widely used in food packaging chains across the world. Plastic waste – Recycled batteries

The Polarfin additive technology developed by Interface Polymers, are added to PP and PE at very low rates, which makes them more recyclable, easier to work with and enables strong surface adhesion to plastics, paints and general adhesives.

“Today, sustainability is key to business operations. We are committed to using innovative solutions to make our products environmentally friendly. Plastic is a crucial component in various daily life equipment. Applying the circular economy principle to the closed-loop plastic waste management, recycling, and upcycling is necessary. This includes studying new innovations and accessing up-to-date technologies to help improve the use of plastic to better meet people’s needs.” says Kamel Ramdani, Senior Vice President, Product Innovation and Innovation Management of GC.

Ross Baglin, CEO of Interface Polymers, said: “We are delighted to have GCV/allnex as investors and development partners respectively, and we look forward to making polymers the best environmental solution for so many human needs. We all know that we cannot go on consuming earth’s resources and consigning the results to history.

We need a materials revolution as well as an energy revolution: making things reparable, recyclable, perhaps even everlasting. Plastic waste – Recycled batteries

Polymers are a unique material made from the earth’s bounty and extraordinary human ingenuity. They are too good to waste. Polarfin® can help make polymers work for us, generation after generation”.