PET-preforms – Chemical-recycling 16-11-2022 - Arhive

PET-preforms – Chemical-recycling

-Russia-Ukraine War – The yellow of the missile that fell in Poland

– In the first moments after the impact, Warsaw immediately confirmed that the missile was “Russian-made” – then there was a phone call between Biden and Polish President Duda who turned around: “there is no unequivocal proof of the identity of the missiles” – Biden played the fireman: “it is unlikely that the missile departed from Russia, given the analysis of the trajectory” – shortly after Washington leaked the new version: it was probably an anti-aircraft missile from Ukraine – the Kremlin’s reaction: “there was an attempt by Kiev to provoke a NATO-Russia confrontation”

Poland confirms ‘Russian-made missile’ dropped

WARSAW, 16 NOV – Poland has confirmed that a “Russian-made missile” landed on its territory, killing two people. This was announced by the Warsaw Foreign Ministry. Spokesman Lukasz Jasina said in a statement that “a Russian-made missile fell, killing two Polish citizens” and that the Russian ambassador in Warsaw was summoned to provide “immediate and detailed explanations” of the incident. PET-preforms – Chemical-recycling

White House, Biden and Duda in contact on next steps

NEW YORK, NOVEMBER 15 – Joe Biden and the President of Poland Andrzej Duda will remain in close contact to “determine the appropriate next steps as the investigation proceeds”. This was stated by the White House referring to the telephone conversation between the two leaders.

Polish Prime Minister Mateusz Morawiecki has appealed to the Polish population to remain calm after the fall of Russian missiles on the territory of Poland which caused the death of two people.

Poland, there is no unequivocal evidence of missile identities

WARSAW, NOVEMBER 16 – Polish President Andrzej Duda says there is no “unequivocal evidence” about who fired the missile that killed 2 people on Polish territory. “At the moment we do not have unequivocal proof of who launched this missile. An investigation is underway,” the head of state told reporters in Warsaw.

Poland: Duda, ‘difficult situation, we work with NATO’

WARSAW, NOVEMBER 16 – “In this difficult situation we are operating with prudence together with our NATO allies”: Polish President Andrzej Duda said in a brief statement released to the Polish media tonight. Duda revealed that American experts will assist Polish experts in analyzing the details of the explosion that took place in Przewodow, which claimed the lives of two Polish citizens aged between 50 and 60. The president confirmed that he had held talks with several heads of state including the American Joe Biden, the British premier Rishi Sunak and the German chancellor Olaf Scholz.

Blinken spoke to Poland’s foreign minister

NEW YORK, NOVEMBER 15 – US Secretary of State Antony Blinken spoke with his Polish counterpart Lukasz Jasina after the incident on the border with Ukraine.

Biden called for G7 emergency and NATO leaders meeting

NEW YORK, NOVEMBER 15 – US President Joe Biden has called for an emergency meeting of G7 and NATO leaders on the sidelines of the G20 after a Russian-made missile fell in Poland. The American media report it. PET-preforms – Chemical-recycling

The talks – according to reports – are attended by Japanese Prime Minister Fumio Kishida, British Prime Minister Rishi Sunak, Canadian Prime Minister Justin Trudeau, French President Emmanuel Macron, European Council President Charles Michel, European Commission President Ursula von der Leyen, Spanish Prime Minister Pedro Sanchez, Netherlands Prime Minister Mark Rutte, German Chancellor Olaf Scholz and Italian Prime Minister Giorgia Meloni.

Biden, the missile is unlikely to have started from Russia

BALI, 16 NOV – It is “improbable” that the missile that fell in Poland came from Russia. President Joe Biden said this after the emergency meeting in Bali with allies. “This is due to the trajectory analysis but I don’t mean that a real investigation into the incident has already been completed.”

‘Missile dropped in Poland could be Ukrainian’

According to some indications, the rocket that hit a village in eastern Poland was an anti-aircraft missile from Ukraine. US President Joe Biden said so to the G7 leaders, according to Dpa. He would also have specified that it was a missile of the S-300 system.

Moscow, there was an attempt to provoke a NATO-Russia confrontation

– MOSCOW, NOVEMBER 16 – The news circulated last night on the alleged fall of Russian missiles in Poland was an attempt to “provoke a direct military confrontation between NATO and Russia, with consequences for the entire planet”. This was stated by Russia’s Deputy Permanent Representative to the United Nations, Dmtry Polyansky, quoted by Tass.

Moscow, a ‘classic provocation’ from Ukraine

– MOSCOW, NOVEMBER 16 – “A classic provocation” of the “Kiev regime which dreams of provoking a direct military confrontation between NATO and Russia to save Ukraine from inevitable defeat”. Thus, in a tweet, the Russian Deputy Permanent Representative to the United Nations, Dmitry Polyansky, defined the accusations made against Moscow by Ukrainian President Volodymyr Zelensky for the missiles that fell in Poland.

Medvedev, the West is approaching a world war

MOSCOW, 16 NOV – The accusations against Russia for the missiles that fell on Poland prove that “by fighting a hybrid war against Russia, the West is approaching a world war”. Former Russian President Dmitry Medvedev wrote on Twitter. The Tax reports it.

Sources, Poland has not invoked Article 4 of NATO

BALI, NOVEMBER 16 – Poland – according to what we learn – has not yet invoked article 4 of NATO. Article 4 of the Washington Treaty provides that “the Parties shall consult each other whenever, in the opinion of either of them, the territorial integrity, political independence or security of any of the Parties is threatened”. It is not known at the moment if he intends to do it later. PET-preforms – Chemical-recycling

Scholz, wait for the investigation into Poland, remain objective

BERLIN, 16 NOV – On the missiles exploded in Poland “the result of the investigation must be awaited”. This was stated by German Chancellor Olaf Scholz, speaking at the end of the G20 summit in Bali. According to the Bundeskanzler, it was “right and important that today there was a quick meeting of the NATO countries here”. “It is important that we have made it clear that all this would not have happened if Russia had not carried on the war against Ukraine and without the strong offensive against infrastructure. But we must remain objective”, concluded the chancellor.

– The probability of a technical recession in the Euro area has increased

– ECB Vice-President Luis de Guindos communicates it: “the vulnerability of more indebted households, businesses and governments is increasing in the Eurozone and, if the outlook worsens further, an increase in corporate defaults can no longer be ruled out, especially for energy-intensive companies” – the invitation to governments to “ensure that aid to vulnerable sectors is targeted, and does not interfere with the normalization of monetary policy”

ECB: towards recession, more financial stability risks

Risks to financial stability in the euro area “have increased” amid energy shocks, high inflation and low growth and with financial conditions tightening. The ECB writes it in the November Financial Stability Report. “The likelihood of a technical recession in the euro area has increased,” said ECB Vice President Luis de Guindos in a statement.

ECB: more risk of company default, aid must be selective

– The vulnerability of the most indebted households, businesses and governments is increasing in the euro area and “if the prospects worsen further, an increase in the frequency of corporate defaults can no longer be ruled out, especially for energy-intensive companies”. The ECB writes it in its Financial Stability Report, inviting Governments to “ensure that aid to vulnerable sectors is targeted, and does not interfere with the normalization of monetary policy”. PET-preforms – Chemical-recycling

ECB, urgent regulation of non-bank finance

In the non-bank financial sector, “persistent vulnerabilities” are emerging that require “strong attention” from the supervisory authorities: “regulation progress is urgently needed” to increase the solidity of the sector, and “manage liquidity and financial leverage mismatches”.

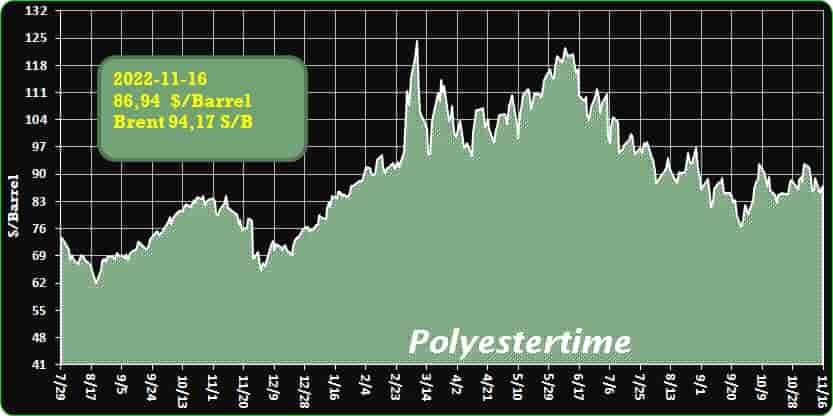

Crude Oil Prices Trend

Crude Oil Prices Trend Polyestertime

-Coca Cola – From drinks to preforms

The Coca-Cola plant in Gaglianico, in the province of Biella, reopens, redeveloped to print nine different types of preforms for rPET bottles.

The new Coca-Cola HBC Italia center for the treatment of rPET flakes and the molding of preforms destined to become bottles for the group’s drinks was inaugurated in recent days in Gaglianco, in the province of Biella, with an annual treatment capacity around 30 thousand tons per year. The redevelopment of the site – which in the past produced drinks, but had now been closed for eight years – involved an investment of more than 30 million euros, part of the 100 million invested by Coca-Cola HBC in Italy in recent years.

The Piedmontese plant covers a total area of 18,000 m2 – of which 6,000 for production and 12,000 m2 for storage -, is entirely powered by electricity from renewable sources and will employ around forty people when fully operational. PET-preforms – Chemical-recycling

Since July 2022, production has been in a continuous cycle seven days a week with shifts covering 24 hours. The production department is divided into three areas: in the first, in one ton big bags, the flakes of post-consumer recycled PET are received, already washed but not yet usable in contact with food. Here they undergo an initial selection treatment which eliminates any impurities, and are then stored in five silos, each with a capacity of 80 cubic metres.

In the second area we proceed with the crystallization and drying of the material. Then, two decontamination reactors eliminate the potentially present polluting substances: the material is brought to approximately 290°C, passing from the solid state to the liquid state and then subjected to a filtration and vacuum process. The food grade flakes are extruded and transformed into granules which, once cooled, are sent to three silos with a capacity of 80 cubic metres. PET-preforms – Chemical-recycling

In the third area of the factory, the preforms are molded using three injection presses: two with a 400-ton clamping force and a 96-cavity mold and one of 500 tons with a 128-cavity mold. To guarantee the consumer, over 4,700 quality checks are carried out in the laboratories every day.

Of the 31 million euros invested in the plant, 27 were used for the purchase and installation of material treatment equipment, extruders, presses, molds, and IT systems, while the remaining 4 million were used for the restructuring of the plant, mainly construction works, electrical part and fire system.

The new Biella factory can produce 9 different types of preforms (in the photo below), both for carbonated and still drinks, with a weight ranging from 17 to 44.7 grams for bottles with capacities from 0.4 to two litres, thus covering the entire requirement of Coca-Cola HBC Italia.

The preforms are packaged in octabins and stored in the warehouse of the Gaglianico plant. From here they take the road to the Coca-Cola HBC Italia production sites in Nogara (VR), Oricola (AQ) and Marcianise (CE), where they are blown to be transformed into bottles.

“We want to continue to invest and do our part both to move towards a real circular economy in the country and to contribute to the development of innovative projects in a territory to which we are particularly linked, despite the difficulties in our sector linked to the increase in the cost of raw materials and energy – said Frank O’Donnell, General Manager of Coca-Cola HBC Italia at the ribbon-cutting ceremony – . This renovated plant demonstrates that giving companies the opportunity to do business and invest allows them to innovate and be more sustainable, unlike taxation which instead blocks any possibility of development”.

-Eastman to provide PepsiCo with recycled PET

Chemical recycler Eastman will be supplying PepsiCo with processed PET under a new offtake agreement.

Material will come from Eastman’s third planned PET chemical recycling facility in the U.S., the location of which has not yet been announced, according to a report from energy market analysis firm ICIS, which cited Eastman’s third quarter earnings information.

Eastman did not provide exact volumes but noted the facility will come on-line by the end of 2026.

“Eastman did confirm that the third methanolysis facility will have a planned input capacity of 160,000 tonnes/year of hard to recycle PET waste and a planned output capacity of over 150,000 tonnes/year,” the ICIS report stated.

Eastman unveiled its methanolysis process in 2019, which targets hard-to-recycle plastics by reducing them to their component monomers using methanol at fairly high temperatures.

Eastman’s Q3 prepared remarks called the agreement “an important milestone for Eastman’s circular economy platform.”

“We are looking forward to making progress on this and our other two molecular recycling projects in the coming quarters as we continue to prove to the world what is possible,” the statement said. PET-preforms – Chemical-recycling

The company’s Kingsport, Tenn. facility will be finished at the end of the first quarter of 2023, the statement said, and its Port-Jerome-sur-Seine, France facility will be operational by 2025. Eastman has a feedstock supply agreement with InterZero for the French facility. Several other companies, including P&G, have said they will use Eastman’s material.

-INVISTA site in South Carolina breaks ground on new polymer facility

Today the INVISTA nylon site in South Carolina hosted a groundbreaking ceremony for its new nylon polymer facility, a milestone that represents the site’s transformation to a global nylon 6,6 production facility. The highly anticipated 90,000-square-foot facility is part of a $64 million investment over two years to enhance the site’s polymer and CORDURA® fiber spinning production. It will include nine loading docks, twenty-two storage/packaging silos and bulk loading capabilities.

“Kershaw County would like to congratulate INVISTA on their decision to retool their facility which provides well-paying jobs for our citizens. INVISTA is famous in Kershaw County for decades of community partnership and this is yet another example that Kershaw County is a great place to live, work and raise families,” said Julian Burns, Chairman of Kershaw County Council.

With a strong demand for nylon polymer products, the new facility will allow the site to increase production volume of polymer to new markets, deliver newly developed polymers to the market, implement future volume expansion opportunities, and have the flexibility to meet customers’ individual packaging needs. PET-preforms – Chemical-recycling

“We are excited to be one step closer to the transformation of the Camden site into one of INVISTA’s global nylon 6,6 production facilities. Our vision is built on decades of knowledge around polymer development, the flexibility to meet our customers’ needs and the strength of our teams to be world class in our operations. This transformation allows us to grow and meet the future needs of our global customers along with continued support of our local community,” said Jay Johnson, site manager.

The project is in partnership with KATOEN NATIE Specialty Chemicals USA Inc with completion expected in 2024.

-NERC reports recycled commodities prices plunge in New England

As prices for commodities have fallen in the third quarter, processing costs have risen.

Recycled commodities prices have fallen in New England, according to a report published by the Northeast Recycling Council (NERC).

While the prices for recycled commodities plummeted from the second quarter to the third quarter, processing costs have risen, reports the Brattleboro, Vermont, organization.

Prices for recycled materials with no residuals have fallen 61 percent to $109.94 per ton since NERC’s second quarter report when the price was $180.73 per ton.

NERC also reports a 41 percent decline in prices for materials including residuals. The average price during the third quarter was $100.07 per ton, down from $169.75 per ton during the second quarter.

Meanwhile, processing costs—the cost to sort and prepare commodities for sale—have increased 9 percent from the second quarter, says NERC. The cost rose to an average of $93 per ton from $85 per during the second quarter.

The processing costs seem to shift significantly from quarter to quarter, NERC adds.

NERC’s report includes survey results from 12 material recovery facilities (MRFs) across eight New England states. PET-preforms – Chemical-recycling

Among the respondents to NERC’s survey that serves as a basis for the report are single-stream, dual stream and source-separated MRFs. These survey results reflect differing laws and collection options in the participating states. Five of the states have beverage container deposit laws. As a result, fewer glass bottles, polyethylene terephthalate (PET) bottles and aluminum cans are processed in MRFs in those states. Those MRFs are also likely to have less revenue from those recyclables.

-“Artificial Leaf” To Produce Green Hydrogen

The green hydrogen market has been taking off like a rocket, thanks mainly to the availability of low-cost wind and solar power for water electrolysis. Researchers are not resting on their laurels, though. The race is on to mimic nature’s own high-efficiency hydrogen production system, aka photosynthesis. It has been a long road, but the dream of an “artificial leaf” is finally beginning to take shape.

Many Roads To Green Hydrogen

To be clear, fossil energy resources still dominate the global hydrogen market. Not for long. Alternative sources are surging into the market, with plain old water is in the lead.

So far, most of the sustainable H2 activity has focused on electrolysis, in which renewable energy generates an electrical current that jolts hydrogen gas from water.

That’s a giant step up the sustainability ladder. However, electrolysis does require the conversion of renewable resources to electricity. With plenty of other users are crowding the field, hydrogen stakeholders will have to elbow their way into the competition for wind and solar power. PET-preforms – Chemical-recycling

One way to make more elbow room is to improve the efficiency of electrolysis systems. However, the pressure to deploy wind and solar resources for other uses will continue to persist as the climate crisis grows worse.

Another way to relieve the pressure is to develop alternative pathways for sustainable hydrogen, such as gas from organic matter or industrial wastes.

A human-made photosynthesis system would add a powerful new tool to the alternative green hydrogen toolkit, partly because it could provide a workaround to the site selection issues that can obstruct solar development.

Across the pond, for example, a research team at the University of Cambridge is preparing to market a low cost, durable artificial leaf. Their device can be floated on canals and other bodies of water, as a land-conserving alternative to solar arrays.

What Is The Artificial Leaf?

The idea of an artificial leaf first hit the CleanTechnica radar in 2011, when we noted Harvard professor Daniel Nocera’s work on a low cost, solar powered, sustainable H2 system that could be down-scaled for home use in off-grid communities.

Water electrolysis has grabbed practically all of the media spotlight since then, but artificial leaf research has continued apace.

The basic idea behind the artificial leaf sounds simple enough. You simply fabricate a specialized solar cell called a photoelectrochemical cell, dip it in a water-based solution, and expose it to light, thereby recreating the chemical reactions in natural photosynthesis.

Depending on who’s talking, the class of photoelectrochemical cells includes two subsets, only one of which is used in direct solar-to-hydrogen production. However, we’ll follow the lead of the US Department of Energy, keep things simple, and stick with the general term photoelectrochemical. If you have an issue with that, take it up in the comment thread.

Why Is The Artificial Leaf?

Either way, it’s fair to ask why bother to produce green hydrogen with photoelectrochemical systems, if we already have water electrolysis.

Artificial leaf researchers point out that the efficiency of an electrolysis system is just one piece of the green hydrogen puzzle. The other is the efficiency of the energy inputs. When compared to electricity sourced from solar cells, the artificial leaf approach is far more efficient.

Purdue University researcher Yulia Pushkar summed it up in press release last year, when she said that “there are not fundamental physical limitations” with artificial photosynthesis. PET-preforms – Chemical-recycling

“You can very easily imagine a system that is 60% efficient because we already have a precedent in natural photosynthesis. And if we get very ambitious, we could even envision a system of up to 80% efficiency,” Pushkar added.

In contrast, the average solar conversion efficiency of solar cells is still within the area of 20%. Specialized versions can go much higher, but they are also much more expensive than those in general use.

NREL Eyeballs Artificial Leaf For Green Hydrogen

Photoelectrochemical hydrogen production still isn’t ready for the market. Researchers know how to duplicate the reactions in photosynthesis, but durability has been an obstacle. They haven’t yet figured out how Mother Nature keeps all her balls up in the air for an extended period of time.

The main problem is that the semiconductors used in photoelectrochemical cells are corroded by the water-based solution. The Energy Department, for one, is anticipating that the durability issue is solvable.

“PEC [photoelectrochemical] water splitting is a promising solar-to-hydrogen pathway, offering the potential for high conversion efficiency at low operating temperatures using cost-effective thin-film and/or particle semiconductor materials,” the agency explains on its website, while noting that “continued improvements in efficiency, durability, and cost are still needed for market viability.”

To help move things along, the Energy Department has come up with a set of best practices, developed by the National Renewable Energy Laboratory and the Lawrence Berkeley National Laboratory. The guidelines were recently published in the journal Frontiers in Energy Research under the title, “Best practices in PEC: How to reliably measure solar-to-hydrogen efficiency of photocathodes.”

“The article spells out the path so that all laboratories can follow a uniformity of experimental practices, beginning with the materials needed for the fabrication of photoelectrodes,” NREL explained in a press release last week.

Green Hydrogen Is Not Waiting Around For Your Artificial Leaf

If you’re wondering why water electrolysis took off so quickly while direct solar-to-hydrogen technology is still waiting for its closeup, that’s a good question.

Part of the answer probably lies in the historical record. Water electrolysis is a centuries-old technology that can trace its roots back to 1789. Water electrolysis has had plenty opportunities for fine-tuning in other applications, including the production of oxygen on the International Space Station. It just never made much sense as a hydrogen production pathway until solar cells and wind turbines began to power the global economy

In contrast, NREL points out that the artificial leaf is a relatively new development. According to the lab, a description of photoelectrochemical water-splitting did not show up in a scientific publication until 1972.

NREL cites itself as a good example of the need to establish standards and best practices in a new field of research. In 1998 NREL reported that it set a solar-to-hydrogen efficiency record of 12.4%, making it the first research institution to cross the 10% barrier. However, in 2016 the lab had to correct that figure downwards after determining that the experiment had been over-illuminated. PET-preforms – Chemical-recycling

With more sophisticated tools in hand, an NREL research team set a new record of 16.2% efficiency in solar-to-hydrogen conversion in 2017. That could come close to doing the trick. The Energy Department is aiming for 25%, efficiency, but an NREL analysis suggests that solar-to-hydrogen systems could be economically competitive without hitting that target.

-Solvay and Orbia join forces to create a Joint Venture in North America to supply critical materials to the battery market

Joint venture will create the largest PVDF production facility for battery materials in the region. The total investment is estimated around 850 million USD, partially funded by a grant to Solvay from the U.S. Department of Energy for a total of 178 million USD.

Solvay and Orbia today announced their entry into a joint venture framework agreement to create a partnership for the production of suspension-grade polyvinylidene fluoride (PVDF), creating the largest capacity in North America.

With more than half of U.S. car sales projected to be electric by 2030, demand for lithium-ion batteries and PVDF, a thermoplastic fluoropolymer used as a lithium-ion binder and separator coating, is revving up. PET-preforms – Chemical-recycling

The Solvay-Orbia joint venture would fill a significant supply gap and will build upon favorable regulatory conditions promoting regional production and material security. Solvay, a global leader in PVDF, brings process technology and unparalleled global market know-how to this venture. With a vertically-integrated value chain and material holdings, Orbia’s Fluorinated Solutions business Koura and Polymer Solutions business Vestolit will supply hydrofluoric acid, vinyl chloride monomer (VCM) and chlorine respectively. In combination, Solvay’s Solef® PVDF innovations and Orbia’s raw material assets and production expertise will enable delivery of PVDF that optimizes energy storage efficiency by increasing battery energy-density, safety and power.

The total investment is estimated to be around $850 million, and is expected to be funded in part by a grant awarded by the U.S. Department of Energy of $178 million to Solvay to build a facility in Augusta, Georgia. Solvay and Orbia intend to use two production sites, one for raw materials and the other for finished product, located in the southeastern United States. Both plants are expected to be fully operational by 2026. Commencement of the joint venture is subject to finalizing and entering into definitive agreements between the parties and satisfaction of customary conditions, including obtaining regulatory approvals.

PET-preforms – Chemical-recycling