Pyrolysis -UV Absorber – Sustainability 24-11-2022 - Arhive

Pyrolysis -UV Absorber – Sustainability

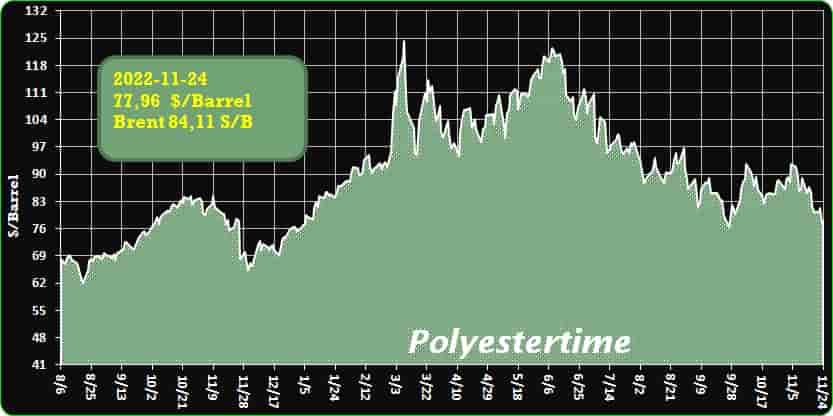

Crude Oil Prices Trend

-Michelin and Pyrowave join forces to industrialize an innovative plastic waste recycling technology

Pyrowave, a pioneer in the electrification of chemical processes and plastics recycling, and Michelin agree to industrialize an innovative plastic waste recycling technology

- Michelin Group and the Canadian firm Pyrowave join forces to accelerate time-to-market for an innovative plastic waste recycling technology.

- They agree to fast‑track the process industrialization.

- The purpose of the technology is to increase the rate of sustainable materials not only in Michelin tires, but also in other industries.

The Canadian firm Pyrowave proudly announces a joint development agreement with the Michelin Group. Through the Pyrowave‑developed technology, it is possible to generate recycled styrene from plastics found in packaging, insulation panels and/or household appliances. This recycled styrene is an important monomer*: it is used in the production of polystyrene and synthetic rubber for tires and a large number of consumer products.

The scientific breakthrough behind Pyrowave technology helps recycle plastics using microwaves. Unlike current thermal processes, this unique technology enables the recycling of plastic waste into high-quality raw materials using electricity – the energy form currently providing the highest decarbonation potential. It also provides higher yields, while being more accurate than conventional technologies, to replace virgin raw materials from oil and gas. Pyrolysis -UV Absorber – Sustainability

The joint development agreement between Pyrowave and Michelin will result in the implementation of new value chains in the circular plastics economy. Redesigning new packaging or manufacturing new products from recycled plastics in the automotive, electronics or tire sectors will become possible.

AN INDUSTRIAL DEMONSTRATOR BY 2023

The two companies will work together in the coming months to fast‑track the industrialization of Pyrowave technology with a view to a certification and commercial roll-out in international markets. The joint development agreement, which will ultimately account for an investment of more than €20 million, will combine Pyrowave’s expertise with Michelin’s industrial know-how.

In order to fast‑track the validation of the technology and the certification of its products, Michelin’s technical teams will work with their Pyrowave’s counterparts to develop an industrial demonstrator, funded and operated by Michelin, by 2023. The technology will meet the highest standards in place within the Group in terms of safety, operation and performance.

TOWARDS AN INCREASE IN THE RATE OF SUSTAINABLE MATERIALS IN MICHELIN TIRES, BUT ALSO IN OTHER INDUSTRIES

After a year of evaluation, Michelin was able to see the process in operation and test samples of recycled styrene in the composition of its tires. This polymer regeneration process is fully in line with Michelin Group’s strategic vision and its product sustainability objectives. Pyrolysis -UV Absorber – Sustainability

This partnership is an ultimate illustration of the Group’s sustainable strategy. The purpose is to manufacture tires made of increasingly sustainable materials and to make these technologies available to innovative recycling channels. We believe in the potential of Pyrowave technology and share their vision for a more sustainable future through innovation

Our partnership marks the beginning of the industrialization phase, drawing on the expertise and technical soundness of the Michelin Group. This strategic partnership reflects the attractiveness and potential of chemical process electrification, both environmentally and commercially, for world-scale players in the chain value. Through this partnership with Michelin, we will be in a position to develop a breakthrough technology with a view to transforming future materials in a sustainable way.

-Enviro receives pyrolysis oil order from Swedish fuel company

Enviro sees “favourable conditions” for large-scale tire recovery plant in UK

End-of-life tire recycler to deliver oil for production trials in first quarter 2023

Stockholm – Scandinavian Enviro Systems has received a SEK2 million (€180,000) order to supply pyrolysis oil from end-of-life tires to Swedish fuel company Preem.

The oil will be delivered in the first quarter 2023 and used by Preem for production tests, said Enviro in a statement 17 Nov.

Preem will use the delivered oil as a raw material to run production tests for different biofuels, according to Enviro.

“A large player in the oil industry in our own home market… provides important support for our expansion in both Sweden and internationally,” said CEO Thomas Soerensson.

This oil will be produced at Enviro’s plant in Åsensbruk where the company recovers oil, carbon black and steel from waste tires.

According to Enviro, Preem is Sweden’s “largest fuel company” and has high environmental ambitions, including the production of 5 million cubic metres of renewable fuel by 2035.

Pyrolysis oil, Enviro went on to say, contains a high percentage of renewable material due to the high amounts of natural rubber found in the vehicle tires.

The new order follows a recent successful trial of the recycler’s pyrolysis oil by a “leading US oil company”.

-Songwon Debuts New UV Absorber, Antioxidant

Higher processing temperatures, better color protection, and a longer service life are among the core attributes of the materials.

Global polymer additives supplier Songwon has expanded its portfolio with two new products, which it featured at K 2022: Songnox 9228 antioxidant and Songsorb 1164 UV absorber. These polymer additives are suitable for packaging, agriculture, and building and construction as well as home and personal care applications.

Because of its hydrolytic stability, Songnox 9228 antioxidant overcomes the challenges faced by traditional high-performance phosphites/phosphonites by allowing more severe polyolefin processing, especially at high temperatures. In addition, it provides color protection for chromium-catalyzed high-density polyethylene (HDPE), polypropylene (PP), and engineering resins. Pyrolysis -UV Absorber – Sustainability

The latest addition to Songwon’s range of UV absorbers is a triazine — Songsorb 1164 — that protects plastics against UV light degradation. Compared to conventional benzotriazole UV absorbers that are falling out of favor in some markets, Songsorb 1164 makes it possible to achieve a longer service life for polyolefins and engineering plastics exposed to outdoor weathering. The product was originally developed for food-contact polyolefins but it has also found use in automotive bumpers.

“Songwon continues to support the industry with innovation by delivering in-house produced antioxidants and UV absorbers to the market. Songnox 9228T (new to Songwon) phosphite secondary antioxidant brings valuable features to our solid phosphite product range, and Songsorb 1164 UV absorber complements our Songsorb 1577 triazine range of UV absorbers,” said Franky Cuypers, Leader Global Sales at Songwon.

“Now we have the broadest range of phosphite AOs in the market,” added Thomas Schmutz. “Previously there was only one supplier, Dover Chemical, so the industry will embrace a second supplier for stability.”

Songwon manufactures a comprehensive range of antioxidants and UV stabilizers in physical product forms.

-SK Innovations opts for Plastic Energy chemical recycling technology at Ulsan site

Plastic Energy, a London headquartered chemical recycling company and SK Innovation’s subsidiary for its green chemicals business, SK Geo Centric (SKGC), are joining forces to build a new chemical recycling plant based on technology developed by Plastic Energy. The new plant will be located at SKGC’s recycling cluster in Ulsan, South Korea and will have a projected annual processing capacity of 66,000 tonnes of plastic waste.

A Heads of Agreement was signed by Na Kyung-soo, CEO of SKGC, and Carlos Monreal, CEO of Plastic Energy, 16 Nov. on behalf of their respective companies, according to a statement released earlier today.

The new plant will be the largest in Asia. The companies say it is expected to open in 2025. Pyrolysis -UV Absorber – Sustainability

The project in Ulsan is not Plastic Energy’s only iron in the fire in Korea. Together with SKGC, it is also considering bringing chemical recycling operations to the Gyeonggi province in Korea, in the metropolitan area of Seoul.

“Korea is an important market for advanced recycling of end-of-life plastics,” said Monreal.

He has already met with Kim Dong-yeon, the governor of the province, to discuss his company’s technology for processing end-of-life plastics and to explore whether this could fit into the Gyeonggi province’s plans to reduce greenhouse gas emissions by 40% by 2030.

Together, the two plants would have the capacity to process over 100,000 tonnes of waste plastic per year into a feedstock – Tacoil – that would be used by SKGC, for example, to make new plastics.

Tacoil is obtained through Plastic Energy’s patented TAC process, which heats mixed post-consumer plastic waste in the absence of oxygen. Multilayer plastics can be processed together, with no separation by type or color needed. All are heated in an oxygen-free atmosphere to create hydrocarbon gases, which are then condensed into Tacoil, which can be used by petrochemical companies as a replacement for fossil oils in the production of virgin-quality plastics.

Plastic Energy already operates two advanced recycling plants in Spain; one in Almeria and the other in Seville. The company also has three plants currently under construction in the Netherlands and France, an MoU for a project in Malaysia, and several other projects in Europe and the US. This will be Plastic Energy’s first project in Korea.

SKGC is looking forward to working with Plastic Energy to establish the largest advanced recycling plant in Asia, said Na Kyung-soo. He added that SK Geo Centric will remain committed to ‘expanding our cooperation for achieving the circular economy’.

-Milliken offers added value for recycled polypropylene

Milliken & Company, a diversified global manufacturer with more than 70 locations worldwide, will use this fall’s K 2022 trade fair to introduce our latest DeltaFlow™ Viscosity Modifier for recycled polypropylene (rPP), based on latest viscosity-modification chemistry, said the company.

At the K Show in Dusseldorf from October 19-26, we’ll be showing our broad portfolio of plastic additives and colorants, but these new grades of DeltaFlow deserve special attention. All our viscosity modifiers are solid concentrates designed to specifically help polypropylene (PP) recyclers by increasing the melt flow rate of rPP for injection molding processes. This serves to reduce energy use, enhance circularity and advance our goal of creating a healthier future. Pyrolysis -UV Absorber – Sustainability

Our newly developed DeltaFlow grades use the latest viscosity-modification chemistry. The technology also has lower volatile organic compounds (VOCs) and improved organoleptics and could nicely complement the advances being made in recycling machinery, according to Allan Randall, Global Product Line Manager. As communicated earlier this year, as an additional sign of our commitment to the recycling industry, Milliken is further expanding production capacity in our German manufacturing plant by 60 percent.

Recycled polypropylene – encompassing recyclers, compounders, converters, and brand owners – is the key target market for this product. DeltaFlow-optimized resins allow for lower processing temperatures, which can enable converters to significantly reduce processing temperatures, reduce energy use, boost productivity and improve processability.

Brand owners stand to benefit, as well. DeltaFlow enables rPP to feasibly replace virgin resin in many end-use applications. This allows brands to use more rPP in their products, thereby helping them to meet their sustainability goals.

“Demand in the market for recycled content is only increasing,” noted Randall. “These products enhance the properties of rPP and make it more suitable for more applications, thereby helping to close the loop in more end uses. Our goal is to enable more and better utilization of rPP. This product line helps to deliver on that promise.”

Milliken is the only company offering this latest viscosity-modification chemistry in an easy-to-handle, non-dusting, solid concentrate form for the recycling market. “Our initial focus will be on Europe, but we intend to offer these DeltaFlow options globally,” Randall added.

We remind, Milliken, an American polymer additives and coloring company, has launched a new masterbatch plant to increase the clarity of polypropylene (PP) in Blacksburg, South Carolina, USA. The plant will increase the company’s masterbatch capacity by 50% to increase the clarity of Millad NX 8000 polypropylene (PP).

Milliken & Company is a diversified company that has been in business since 1865. The corporate headquarters is located in Spartanburg, South Carolina. The company operates in a wide variety of areas: the chemical industry, flooring, performance and protective textiles, and healthcare. Pyrolysis -UV Absorber – Sustainability

-Polyplastics Signals Sustainability Goals

Cellulosic-fiber compounds high on the agenda for achieving a lightweighting, green footprint.

Global engineering thermoplastics vendor the Polyplastics Group is but one of numerous resin suppliers targeting carbon neutrality by 2050. What will interest converters immediately, however, is a stable of sustainable performance products for applications in a range of industries, from automotive and packaging to medical.

Among options on show at K 2022 in Düsseldorf, Germany, in October was a polyacetal resin polymerized from sustainable methanol. Under the ISCC PLUS mass-balance approach, the sustainable bG-POM option is applicable to a range of Duracon grades, including the Duracon PM line of medical resins.

Another sustainable option is Plastron LFT (long-fiber thermoplastic) resin, which is made of specially formulated regenerated cellulose fibers. The eco-friendly Plastron LFT provides weight reduction plus mechanical strength, enabling manufacturers to reduce their carbon footprint and meet today’s sustainability demands. “This material has a higher fiber content than its glass-fiber-reinforced equivalent, but because the density of cellulose is only 1.3 compared with 2.5 for glass, in the end you achieve close to the strength of glass but at a lighter weight,” said Dr. Gerhard Reuschel, Marketing & Sales Manager, Plastron LFT projects. “The composite density is 1.02 for cellulosics versus 1.12 at 30% filler for glass fiber.” Pyrolysis -UV Absorber – Sustainability

Cellulosic fibers also better maintain their length during processing, so it is easier to add regrind without compromising part quality, according to Polyplastics. “Fiber-length distribution can be critical in complex parts,” noted Reuschel. “Cellulosic fiber is more robust and maintains its length but you do need to ensure sound processing so as not to overheat the fibers, as they will burn.

“We already have multiple active projects underway [for Plastron LFT in general] in Europe,” added Reuschel. “Molding trials have proved very successful for a Plastron LFT long-carbon-fiber polyamide grade in a personal lifestyle application, while a second project involves a long-glass-fiber polyamide applied to agricultural machinery.” Moving forward, Polyplastics plans to aggressively push polyamide LFT grades in automotive applications.

Furthermore, Polyplastics’ Topas cyclic olefin copolymer (COC), a leading material in the packaging and healthcare industries, is also enabling sustainable packaging solutions. Here, Topas COC has raised the performance of commodity polyolefins (polyethylene for example), enabling the development of simpler, more recyclable and sustainable solutions. Mono-material film structures based on PE and enhanced with Topas COC are more easily recyclable than multi-material solutions using layers of PET or other PE-incompatible plastics.

Finally, Polyplastics has developed a grade of polybutylene terephthalate (PBT) that incorporates recycled content.

-Producer prices of industrial products in Germany up 34.5% YoY in Oct

Producer prices of industrial products in Germany increased by 34.5 per cent in October this year compared with the same month last year, according to the Federal Statistical Office (Destatis), which recently said the price increase at the producer level slowed down. In August and September, the rate of increase had been 45.8 per cent each.

Producer prices decreased by 4.2 per cent in October this year over September figures. This was the first month-on-month decrease since May 2020.

The main reason for the year-on-year (YoY) increase in producer prices of industrial products still was the development of energy prices. This was due to the large weight of energy prices in the overall index, combined with exceptionally high price changes.

Moreover, prices also rose significantly for non-durable consumer goods, intermediate goods, durable consumer goods and capital goods, one of the reasons being the increasing energy prices, Destatis said in a release. Pyrolysis -UV Absorber – Sustainability

Energy prices were up by an average of 85.6 per cent in October compared with the same month last year. The main factor influencing the year-on-year rate of change in energy prices was the strong price increases for natural gas (distribution), followed by electricity price rises.

Compared with September 2022, energy prices fell by an average 10.4 per cent, which was mainly caused by the decrease of electricity and natural gas prices (distribution).

Pyrolysis -UV Absorber – Sustainability