Polyester-flakes – HDPE-Resin – MEG 23-11-2022 - Arhive

Polyester-flakes – HDPE-Resin – MEG

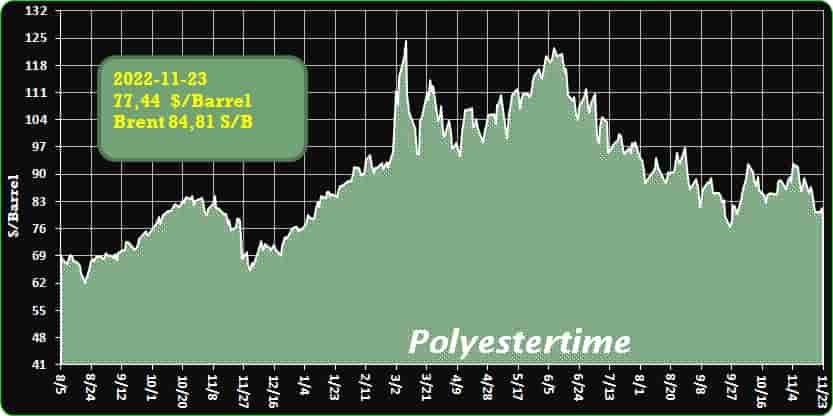

Crude Oil Prices Trend

Crude Oil Prices Trend Polyestertime

-A contractor for the construction of a polyolefin complex in Uzbekistan has been identified

Gas Chemical Complex MTO Central Asia (GCC), the construction operator of the MTO Gas Chemical Complex in Uzbekistan, has identified Enter Engineering Pte Ltd as an EPC contractor (Engineering, procurement and construction) for a project to convert methanol to olefin (MTO). A contract worth about $3 billion. includes the design, procurement of equipment and construction of facilities, as well as the necessary infrastructure. Completion of work is expected in 2025, according to a press release from Enter Engineering.

The innovative complex for the production of polymers will become an anchor resident in the newly created Karakul Free Economic Zone in the Bukhara region. The MTO Gas Chemical Complex (MTO GCC) is wholly owned by Sanoat Energetika Guruhi (SANEG), one of the largest oil and gas companies in Uzbekistan.

The innovative technology of the MTO (Methanol To Olefin) will allow processing 1.3 billion m3 of Uzbekistan-specific natural gas with a low content of valuable components, which will be supplied from fields managed by SANEG. Polyester-flakes – HDPE-Resin – MEG

The enterprise will be able to produce polypropylene (250 thousand tons / g), low-density polyethylene (LDPE, 80 thousand tons / g), ethylene vinyl acetate (EVA, 100 thousand tons / g) and polyethylene terephthalate (PET, 300 thousand tons / year). At the same time, LDPE, EVA and PET will be produced in Uzbekistan for the first time.

“Building a modern gas chemical complex is a complex engineering task – a challenge that Enter Engineering is honored to cope with. For its timely solution, we have mobilized the necessary resources – we allocate our own construction equipment and transport, form teams of specialists, determine logistics routes for the delivery of special equipment. At the time of the peak of construction, more than 10,000 builders will work at the site,” saidUlugbek Usmanov, CEO of Enter Engineering.

Enter Engineering Pte is a leading EPC contractor in Uzbekistan with experience in implementing major industrial and infrastructure projects in Central Asia. Among the implemented are such landmark projects of the company as: Uzbekistan GTL, Kandym Gas Processing Complex, Humo Arena, Samarkand Tourist Center, Ammonia and Urea Production Complex at Navoiazot and others.

The MTO MCC project is an example of global cooperation between local and foreign specialists based on advanced achievements in the oil and gas industry, which is being worked on by John Wood Group (UK), Topsoe (Denmark), Koch Industries Inc. (USA), Chemtex Global Corp. (USA), Scientific Design (USA), Versalis (Italy), Sinopec (China) and Grace Catalysts Technologies (USA). Polyester-flakes – HDPE-Resin – MEG

It is noted that the MTO gas chemical complex will become the largest plant of this type in Central Asia for the production of polymer products, which will meet local demand for raw materials for the production of goods with high added value.

The gas chemical complex of the MTO will provide more than 2,000 direct jobs and more than 10,000 related jobs due to the multiplicative effect. The project will contribute to the development of regional production, social, business, logistics, transport and other infrastructure in Bukhara region and will become a new industrial gas chemical center not only in Uzbekistan, but throughout Central Asia.

-Indorama Ventures’ Deja brand awarded as ‘Best Sustainable Product’

Indorama Ventures Public Company Limited (IVL), a global chemical company, has been named winner of the Best Sustainable Product Award at the Chemical Week Sustainability Awards 2022. The award was for IVL’s Deja Carbon Neutral pellets, the world’s first carbon-neutral virgin PET resins, helping to reduce environmental impact.

The Deja brand covers carbon neutral virgin and recycled PET resins and a range of recycled PET (rPET) products, including flakes, resins, fibres, and yarns. It provides IVL’s global customers with a range of high-performance applications, including packaging, lifestyle, automotive, apparel, and medical equipment. The solutions help environmentally conscious companies meet their sustainability goals. Polyester-flakes – HDPE-Resin – MEG

IVL has set ambitious 2025 and 2030 targets, which shall be met through its six-pronged decarbonisation strategy, including energy transition, improving operational efficiency, circular feedstock, and future technologies. The company also has a goal to recycle 100 billion PET bottles annually by 2030.

Chemical Week Sustainability Awards recognise the industry’s best efforts in addressing financial, operational, and strategic challenges by focusing on ESG and sustainable product development. The awards were assessed by S&P Global, the world’s leading credit rating agency, and a panel of experts from various companies across the chemical industry’s value chain.

-Improved moisture wicking for sportswear fabrics

Dyeing and finishing specialist CHT has used recycled polyester flakes as the base chemistry for a new hydrophilic finish that improves the moisture wicking of sportswear fabrics and is said to give garments fast-drying properties and improved protection against dirt and oil.

The company says the new formulation is optimal for moisture management and thermoregulation in sports and active wear, socks and technical textiles.

Of the approximately 353 million tons of plastic waste worldwide, around 22 per cent of this waste ends up in the environment, according to figures from the OECD, which just 9 per cent of this plastic being recycled.

As both regulators and companies start to look at discarded plastic more as a starting raw material – rather than just waste – a range of potential end-uses in the chemical sector for post-consumer plastic are being evaluated.

This has led German firm CHT to launch its first textile finish based on post-consumer recycled polyester flakes to make the base chemistry for this new hydrophilic finish.

After the recycled PET flakes arrive at the CHT facility, they go through in-house processing where different hydrophilic additives are added to the recycled polyester base.

These polymers are then subjected to a high temperature reaction in an aqueous solution, before being emulsified into the final, hydrophilic formulation, which has been dubbed ‘Arristan rAir’. Polyester-flakes – HDPE-Resin – MEG

When applied to fabrics via padding, exhaust, spraying the formulation covers the surface of the textile fibre with a microscopic thin film to give it excellent absorbency. This gives fabrics good moisture wicking and fast-drying properties, makes soils easier to remove during laundering and claims to prevent oily stains penetrating deep into the fibres.

The new finish is said to be optimal for both 100 per cent synthetic fabrics and blends with natural fibres.

“Since Arristan rAir is made out of recycled PET flakes, it is suitable for finishing recycled yarns and fabrics enabling varietal purity.” said Robert Zyschka, head of application field finishing from CHT.

-PPRC Europe 2022: Friendly competition, for now

Mechanical recyclers of plastic are keeping an eye on a chemical recycling sector that says it wants to target hard-to-recycle plastic scrap.

If household consumers and waste management companies can be convinced to increase the collection of plastic scrap, existing and new technologies can be deployed to recycle it. That was the message from panelists during a session on recycled-content polymers at the 2022 Paper & Plastic Recycling Conference Europe, held in mid-November in Rotterdam.

The four panelists included one firm with an advanced or chemical recycling investment underway: United Kingdom-based Greenback Recycling Technologies; another U.K,-based firm called Fiberight Ltd. using a newly developed Hydracycle process; and two mechanical reprocessing firms: Latvia-based PET Baltija and U.K.-based Berry Circular Polymers.

Jeremy (Jez) Blake of Berry Circular joked that his business unit of the wider United States-based Berry Global packaging firm, is the “tree-hugging hippy part of the company, trying to save the planet” from the plastic products made by the wider company. To that effect, Berry Circular will soon be recycling about 50,000 tons per year of discarded plastic films and rigid containers. Polyester-flakes – HDPE-Resin – MEG

Also on the mechanical recycling and reprocessing side is PET Baltija. As the company’s name implies, it seeks out discarded polyethylene terephthalate, handing some 70,000 tons per year “and still growing,” according to the firm’s Philippe De Munter.

De Munter came to PET Baltija recently via its acquisition of the Czech Republic-based Tesil Fibres. While PET Baltija had been focusing on converting collected PET scrap into food-grade rPET, Tesil spins its materials into spooled fibers that can be used to make carpet backing, auto components or absorbent diaper material.

On the chemical recycling side, Samuel Martinez of Greenback said that firm is taking a “distributed” or small-scale approach to sighting chemical recycling capacity. The end products it intends to produce can serve as a feedstock within the “poly chain,” including for food-contact applications, said Martinez.

James Marshall of Fiberight said that firm is installing a larger-scale “Hydracycle” sorting and reprocessing plant in South Wales in the U.K. He said the Fiberight facility will have access to sometimes difficult-to-recycle materials from 85 waste collection jurisdictions in the U.K., with a 10-year contract in place.

He said the firm’s greater challenge may not be supply, but rather securing the best off-take agreements for the recycled-content flakes and pellets it intends to produce. “De-risking the off-take is incredibly difficult” currently said Marshall, in part because of European “waste” export directives that are in the process of changing.

De Munter said price swings are a current challenge, but he does not see Tesil customers in the automotive sector backing away from recycled-content goals. That sector, he said, is “not swinging back to virgin” plastics. In addition to price volatility, he cited narrow auto industry specifications as a Tesil Fibres challenge, commenting the firm does not simply produce black recycled plastic for that market, but “18 different shades of black” for different automakers. Polyester-flakes – HDPE-Resin – MEG

Martinez does not see mechanical and chemical recycling firms as bidding against each other for material. “We are not competing with mechanical recyclers,” he remarked. “I call it a cascade,” said Martinez, with discarded plastic heading to reprocessors of different types depending on where it sits on the quality and purity chain.

Simply recycling more plastic is a primary objective, said panelists, in light of the negative reputation plastic holds in the minds of some Europeans. “We have to be broad-shouldered and just take it; to steel ourselves and be more positive,” Blake said of the criticism. He said producing and collecting “perfectly recyclable plastic” is the best antidote to the criticism.

-MEGlobal reduced December MEG prices by USD10 per ton

MEGlobal, the world leader in monoethylene glycol (MEG) and diethylene glycol (DG), has nominated December’s MEG contract price for Asia at USD800 per tonne, usd10 per tonne below November levels, the company’s press service said.

The price was named on the terms of delivery of CFR Asia.

The Asian MEG market froze due to price pressures and slowing demand, with buying interest in the market being very low amid a seasonal lull at the end of the year.

Earlierit was reported that MEGlobal, the world leader in the production of monoethylene glycol (MEG) and diethylene glycol (DH), nominated the November contract price of MEG for Asia at USD810 per ton, which is USD10 per ton below the level of October.

According to theSknaPlast review, the estimated consumption of PET in September of this year increased by 32% compared to a year earlier and amounted to 78.81 thousand tons. According to the results of the first nine months of this year, 621.61 thousand tons of PET were processed in Russia, which is 1% more than the same indicator in 2021.

MEG, along with terephthalic acid (TPA), is one of the main raw materials for the production of polyethylene terephthalate (PET). Polyester-flakes – HDPE-Resin – MEG

-Avient’s NIR Dark Colorants Preferred by Recycling Association for HDPE Resin

The sortable dark colorants meet the Association of Plastics Recyclers’ preferred guidance program.

A line of near-infrared (NIR) sortable dark colorants from Avient Corp. was recently recognized by the Association of Plastics Recyclers (APR) under its Meets Preferred Guidance (MPG) program. Consequently, OnColor NIR Sortable Colorants are preferred for high-density polyethylene (HDPE) resin in black and dark colors, according to the APR Design Guide for Plastics Recyclability. In addition, testing is underway to support an application for MPG recognition for the same colorants for polypropylene resin (PP).

Dark packaging, traditionally using colorants containing carbon black, is a popular choice for brand owners, said Avient, noting that detecting and sorting dark packaging in material recovery facilities is challenging. OnColor NIR Sortable Colorants from Avient allow packaging to be visible to a NIR optical sorter, enabling it to sort into the correct plastic stream. Polyester-flakes – HDPE-Resin – MEG

“As a leader in sustainable colorant and additive solutions for polymers, we are proud to have received this recognition from the Association of Plastics Recyclers and look forward to further supporting our customers to reach their recycling goals,” said Avient’s Mayendran Pillay, Director of Marketing for Color & Additives, US and Canada. “Avient is committed to enabling 100% of our products manufactured for packaging applications to be recyclable, reusable, or compostable by 2030. This solution aligns with that commitment.”

APR’s MPG program helps brand owners be more confident that the materials they incorporate into their products support recyclability.

-Saurer’s premier solutions for spinning and twisting machines

Saurer, the premier solution provider for spinning and twisting machines, will be present at the INDIA ITME 2022 from 8 – 13 December in New Delhi in booth 10C7E12. The highlight will be our air-jet spinning machine Autoairo, to be exhibited for the first time in India. Saurer’s spinning and twisting machines are renowned for their energy saving features, automation, and digitalisation solutions. Saurer machines enable the circular economy in textiles and are the leaders in processing recycled textile materials.

With the Autoairo, Saurer is the only supplier offering five different spinning systems from one company: ring, compact, worsted, rotor, and air spinning systems. Exhibits to be presented at the booth are: the new Autoairo air-spinning machine, the Autospeed roving frame, the Autocoro and BD rotor spinning units, the FusionTwister for two-for-one twisting, as well as exhibits of Texparts and Fibrevision quality monitoring.

Excellent sliver quality with Saurer’s blow room and carding machines

The right combination of Saurer’s blow room and carding machinery ensures excellent fibre utilisation and sliver quality, thus increasing the efficiency of the spinning process and improving the quality of yarn. The new Autocard was developed to create further value in the fibre preparation chain. Polyester-flakes – HDPE-Resin – MEG

Autoairo – the new air spinning technology

The Autoairo sets new benchmarks for air spinning. Saurer has combined its most advanced automation solutions with proven technology to create an air-spinning machine with unique properties. The Autoairo features autonomous spinning positions with automation per spinning unit for more productivity and integrated intelligence. The exhibited Autoairo will remain in India to conduct customer trials. Belairo, the new air-spun yarn impresses with low hairiness and high pilling resistance.

Saurer – the market leader in rotor spinning

The Autocoro is the market and technology leader which revolutionised automatic rotor-spinning technology and opened the door to more productivity, flexibility, and sustainability for customers worldwide. In just 10 years, Saurer installed 1 million Autocoro spinning positions with individual drive technology and energy saving features. The BD 7 semi-automated rotor spinning machine is powered by the technologies of Autocoro. With the patented digital piecing technology, DigiPiecing, and take-up speeds of up to 230 m/min, the BD 7 remarkably improves yarn quality and productivity for spinning mills.

The benchmark for intelligent roving and ring spinning

The use of the Autospeed roving frame with automatic doffer ensures that spinning mills do not have to rely on skilled workers, and simultaneously increases the quality of the roving. The Autospeed roving frame with up to 240 spindles saves up to 20% of energy compared with the previous model, while doffing takes less than 2 minutes. Also in action at the ITME exhibition, customers can see the Autospeed in combination with the bobbin transport system and Roweclean, the automatic tube cleaner.

The ZR 72XL and ZI 72XL are two highly productive ring and compact-spinning machines. They set the global benchmarks for intelligent spinning, low energy consumption, user friendliness, and flexible automation solutions. Polyester-flakes – HDPE-Resin – MEG

Texparts components for boosted ring spinning productivity

Saurer’s Texparts product line offers high quality components for the textile industry including drafting systems and spindles, spinning rings, and travellers. The new double elastic spindle, Eshape, has a reduced wharf diameter and is based on CS 1 S. Outstanding running properties up to 30 000 rpm and about 6% energy savings are the key performance factors. Eshape, combined with the best system for spinning without underwinding, Spinnfinity, is the perfect fit for automated and efficient ring spinning.

The FusionTwister – two-for-one twisting at highest speeds

At the ITME exhibition, Saurer will also show the two-for-one twisting machine FusionTwister, which offers high efficiency combined with the excellent quality of the cross-wound delivery packages produced. Up to 15% of energy can be saved with the FusionTwister while increasing the winding speed by 10%: This remarkable result was reported by an Indian customer. Consistent high yarn and package quality is a result of our robust machine construction and optimised yarn guiding elements, which consist of yarn-friendly ceramics or have plasma-coated surfaces for low friction and longevity.

Rolling the tire market up – CableCorder CC5 for direct cabling

Saurer’s twisting machines are as flexible as the market demands. The direct cabling machine, CableCorder CC5, for tire cord and industrial yarns, features a new spindle gauge 400 with up to 200 spindles, making it a true space saver. Its Cord Regulator technology ensures equal lengths of the individual yarns and thus high cord quality. Thanks to the balloon reduction technology developed by Saurer, the same, smallest possible balloon diameter can be set on every spindle – regardless of the titre. Energy consumption is thus kept to a minimum on the CC5. Polyester-flakes – HDPE-Resin – MEG

Saurer Fibrevision for quality monitoring of filament yarns

For all synthetic continuous filament yarns, Saurer Fibrevision’s online quality monitoring devices are well established in the market. Fibrevision products serve all areas of the industry: Fraytec FV2™ / Unitens ™ / FibreTQS™ are multi-parameter quality monitoring systems that can be used in filament spinning (POY, FDY, BCF, T+I), draw texturing (DTY) as well as in cabling, twisting, and elastomer production. Single and multi-threadline sensors assure customers of the quality of their production.

Saurer machines enable the circular economy in textiles

Saurer enables spinning mills to process a wide range of recycled and regenerated fibres in their production. The Saurer rotor spinning machines are leaders in the processing of recycled fibres.

The Saurer textile technology laboratory continuously assists customers in optimising their yarn production and yarn quality, especially for recycled fibres.

-Major PVC producer in Northeast Asia reduced December prices for supplies to China

A major Northeast Asian manufacturer has lowered its bid for Its December shipments of polyvinyl chloride (PVC) to China,ICIS reported.

Price offers for December PVC shipments are USD735 per tonne, CFR (cost and freight) China. Polyester-flakes – HDPE-Resin – MEG

On fob (free-board) terms for Northeast Asia, price offers are USD690 per tonne for Southeast Asia and remote regions.

The volume discount of USD10 per tonne applies to cargo volumes over 500 tonnes.

Earlierit was reported that LG Chem, a major South Korean manufacturer of petrochemical products, closed the production of PVC in Yeosu (Yeosu, South Korea) for scheduled repairs. This production with a capacity of 610 thousand tons of PVC per year was closed from November 8 and will stand until November 22 for maintenance.

According tothe ICIS-MRC Price Review, in October the final production of unmixed PVC in Russia decreased to 46 thousand tons against 75 thousand tons a month earlier. According to the results of ten months, the total volume of PVC production exceeded 759 thousand tons, which is 9% lower than a year earlier.

Polyester-flakes – HDPE-Resin – MEG