r-Polyester – Flexible packaging 17-05-2023 - Arhive

r-Polyester – Flexible packaging

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

-The Chinese economy is flying, but not enough

Industrial production in the Asian country rises by 5.6% per year, about half of analysts’ estimates, which gave it to 10.9 –

The reason, officially, would lie in weak external demand . But even the domestic one is not enjoying excellent health: retail sales, thanks to the “Golden Week” holiday, jump by 18.4%, but less than the 21% expected – record youth unemployment: 20.4%

Industrial production in China rose 5.6% on an annual basis, up from 3.9% in March, but about half of analysts’ estimates at +10.9%, due to weak external demand.

The economic recovery is still unstable: retail sales, thanks to the Golden Week holiday, jumped by 18.4% (+10.6% in March), but less than the 21% expected. Urban unemployment drops to 5.2% (from 5.3% in March), with the youth component (16-24 years) soaring to a record 20.4% (from 19.6% in the previous month).

Investments in fixed assets are holding back: +4.7% in January-April, against +5.1% in the first quarter and +5.5% expected. r-Polyester – Flexible packaging

China – President Xi Jinping

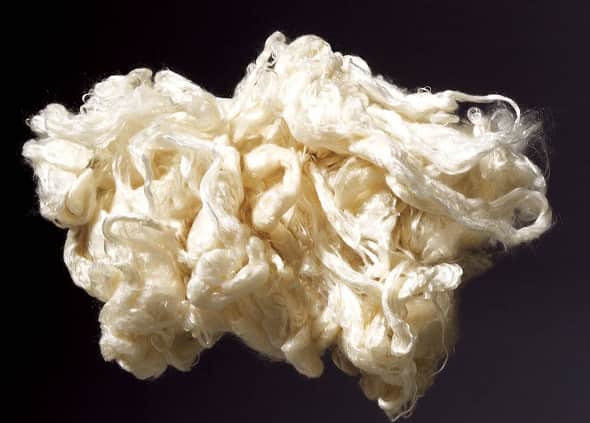

-Renewcell has entered into an accord with TextileGenesis, a company specializing in blockchain, with the aim of ensuring complete traceability of its Circulose pulp

The Circulose pulp is produced through Renewcell’s patented method of breaking down and recycling cotton and other forms of cellulosic textile waste, such as production scraps and worn-out jeans. The resulting biodegradable raw material can be used to produce a range of man-made cellulosic fibers including acetate, lyocell, modal, and viscose. These regenerated fibers can be used to make high-quality textiles and nonwovens.

Renewcell intends to provide its customers and supply chain partners with real-time digital traceability through the partnership with TextileGenesis. The platform employs digital tokens to ensure a secure chain of custody for all supply chain processes, from the source of raw materials to the retail point. Renewcell’s traceability program for fibers captures real-time shipments, while its Fibercoins digital tokens confirm the origin of the materials and eliminate duplication of sustainable materials.

The company’s augmented intelligence engine confirms transactions between supply chain partners. r-Polyester – Flexible packaging

TextileGenesis has already partnered with fiber manufacturers like Lenzing AG, Eastman, and Birla Cellulose. According to Renewcell CEO, Patrik Lundstrom, the partnership with TextileGenesis would guarantee a reliable and transparent supply chain, from their facilities to the retail consumer, to ensure the genuineness of Circulose products. Lundstrom said Renewcell had been on a mission since 2012 to establish circularity in the fashion industry. Renewcell’s Sundsvall facility in Sweden is designed to recycle more than 1.4 billion T-shirts annually.

-According to Makoto Uchida, CEO of Nissan, solid-state batteries have the potential to revolutionize electric vehicles

Nissan, widely recognized as a leader in EVs since the release of the all-electric Nissan Leaf in 2010, has announced a new strategy called X-in-1. This plan will enable the automaker to produce new engines for electric and hybrid vehicles at a significantly lower cost and bring solid-state batteries to the market within five years.

At the Financial Times Future of the Car summit in London, Uchida stated that the X-in-1 strategy would reduce electric motor component production and component costs by 30% compared to 2019 by 2026. This will play an essential role as Nissan aims to launch 27 new electrified vehicles, 19 of which will be 100% electric, by 2030.

Nissan’s latest plan is for the internal combustion engine of a hybrid powertrain to operate with an electric motor and a modular generator and related gear set integrated into its structure, operating synergistically. r-Polyester – Flexible packaging

This reduces weight and size while also lowering costs. By 2026, Uchida claims that the new hybrid powertrain will be no more expensive than a conventional internal combustion engine and will provide a smoother ride, better torque control, and improved fuel efficiency.

According to Uchida, solid-state batteries have a high energy density, which will allow electric vehicles to travel farther distances, reduce charging times by a third, and be significantly less expensive to produce. Additionally, solid-state batteries will enable a larger electric vehicle with more interior space. Nissan engineers believe that by utilizing the economies of scale provided by the X-in-1 strategy and solid-state batteries, they will be able to make EVs no more expensive than traditional cars.

Uchida says that Nissan has already developed the first solid-state battery, and a pilot plant for such batteries will be launched next year. Full-scale production is expected to begin in 2028, with a four-year lead time due to the complexity of solid-state battery production. r-Polyester – Flexible packaging

Mr. Makoto Uchida