Recycled car interiors – New technique can capture or reuse CO2 as a chemical source for the production of sustainable plastic 16-11-2023

Recycled car interiors

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

Recycled car interiors are the new chic luxury

Carmakers are lining their electric vehicles with trash — literally — and hoping sparse, eco-friendly cabins will redefine luxury for a new generation of buyers.

Why it matters: Turning recycled denim, fishing nets and plastic bottles — or even mushroom roots — into automotive cockpits may help the industry reduce its carbon footprint.

- Plus, it’s what today’s premium customers prefer in place of plush leather or polished wood, carmakers say.

- “Sustainability is luxury,” says Anders Karrberg, head of global sustainability at Volvo Cars. “It speaks to a younger generation.”

Driving the news: Volvo’s newest electric vehicle (EV), the compact EX30 SUV, will test that theory. Recycled car interiors

- The Swedish luxury brand is known for its clean and simple Scandinavian design, with light oak interiors that are functional yet beautiful.

- The EX30, starting at $34,950, puts a whole different spin on that theme, blending an array of recycled and renewable materials into an austere cabin.

- The bare-bones interior features seat fabric sewn from denim scraps, a dashboard woven with thread from flax and linseed plants, and speckled door accents made from ground-up vinyl window frames.

- The EX30 has the smallest carbon footprint of any Volvo, the company says.

The big picture: Some automakers have used products like soy or sugar cane fibers in inconspicuous areas for years, like in wiring harnesses under the hood or in the headliner fabric on the inside roof of the car. Recycled car interiors

- But there’s a new urgency to use more recyclable and renewable materials as automakers face looming targets to be “carbon neutral” by 2050 or sooner.

- They won’t hit those goals simply by adding more EVs to their lineups, since evidence shows EVs aren’t driven as much as gasoline-powered cars.

- To dramatically reduce their carbon footprint, automakers need to decrease greenhouse gas emissions across their operations, including in manufacturing and logistics.

Meanwhile: Like Volvo, Kia is integrating a lot more recycled or plant-based components into its lineup — starting with the EV9, a family-friendly SUV hitting dealerships by the end of the year. Recycled car interiors

- The EV9 uses 10 “must-have sustainable materials,” including bio-paint made from rapeseed oil on the door switches, recycled polyethylene terephthalate plastic (PET) in the seats and other surfaces, and recycled fishing nets in the carpet.

- The South Korean carmaker is taking the trend even further with newly revealed concept cars like the EV3, EV4 and EV5.

- For example, it’s replacing plastic molding with soft-but-strong plant-based parts “grown” from mycelium, the white hairlike fiber from mushroom roots.

What’s next: Kia eventually wants to develop grown materials using a process called bio-fabrication.

- “Using mycelium enables us to mimic the processes we see in nature and leverage it to design more sustainable solutions — the material can be grown in any shape you want using a mold,” Marília Biill, who heads up color, materials and fabric design at Kia, notes in a press release. Recycled car interiors

What to watch: Will these recycled components and biomaterials hold up during the wear and tear of daily driving?

- Complaints have been rolling in about the durability of a new recycled fabric Apple is using in place of leather for its iPhones and watches.

What they’re saying: “The industry’s been making interiors out of plastic for 70 years, so the supply chain is pretty good at it,” says Stephen Kosowski, manager of long-range strategy and planning for Kia America.

- “To engineer new parts that are as durable, and have the same look and feel and that will last as long as plastic, is not easy.”

- “I think we’ve cracked the code on durability,” he said, but the cost of developing sustainable materials remains a challenge. Recycled car interiors

Technip Energies Creates Reju – An Innovative Polyester Textile Regeneration Company

Building on its technology partnership with IBM and Under Armour, Technip Energies announces the launch of Reju, an innovative company focused on creating new solutions at scale for the vast amount of plastic fiber in textiles that goes unrecycled and ends up as waste. Former Under Armour CEO and apparel industry veteran Patrik Frisk is heading the new company along with Alain Poincheval, COO, a senior executive with Technip Energies.

Technip Energies (PARIS: TE) (ISIN:NL0014559478) announces the creation of Reju, a new company focused on PET (Polyethylene terephthalate) recycling (rPET) of textiles that will leverage the innovative technology co-developed in joint-venture with IBM and Under Armour as well as Technip Energies’ global engineering and technology integration expertise. Recycled car interiors

Reju will address the fast-growing market of global rPET whose demand from the textile market is expected to grow up to 20 Mtpa by 2033, driven by industry pledges and targets on recycling, regulation and consumer awareness of the need to reduce plastic waste.

Technip Energies, IBM and Under Armour have been working together since 2021 in a joint venture to bring VolCat, an IBM technology for rejuvenating waste PET packaging and polyester, to an industrial scale. VolCat allows the selective breakdown of polymers which IBM first applied to technologies like semiconductor lithography and microelectronics packaging. Reju intends to use this technology to address hard-to-recycle polyester garments and PET packaging lost to the waste stream today. With this technology, acting as a molecular sorter, PET could be regenerated infinitely.

The groundbreaking ceremony for Reju’s demonstration plant took place in September in Technip Energies Frankfurt Research Center with the facility expected to come on stream in 2024. Recycled car interiors

Arnaud Pieton, CEO of Technip Energies , commented: “Globally, l ess than 1% of PET textiles waste is recycled today . This means that most textiles end up as waste in landfills when they could be repeatedly reused in new clothes. What has been holding the world back in textile circularity is not a lack of demand for textile recycling but the lack of a solution that makes recycling of textiles economical on an industrial scale. For the first time in this domain, a unique scalable technology is directly associated with a scalability expert like Technip Energies. Reju will deliver the promise of economical textile recycling, and we are proud to extend our role as an active agent of circularity.”

Arvind Krishna, CEO of IBM , said: “The health of our planet has never been more pressing, and the amount of fashion apparel and textiles that end up in landfills today is enormous. Recycled car interiors

The good news is that technology can help solve this challenge. IBM is proud to provide its VolCat technology to support Reju in advancing sustainable textile recycling.

We look forward to collaborating with Technip Energies and Reju to champion initiatives like these that place sustainability at the heart of the global textile industry.”

The LYCRA Company launches new LYCRA® FiT400™ fiber

The LYCRA Company, a global leader in developing innovative and sustainable fiber and technology solutions for the apparel and personal care industries, announced today the launch of new LYCRA® FiT400™ fiber for knits.

The company’s latest EcoMade offering is a unique bicomponent fiber engineered to optimize the performance and comfort of knits. It delivers a durable soft hand-feel, low shrinkage and high uniformity to fabrics. LYCRA® FiT400™ fiber is made from 60% recycled PET and 14.4% from bio-derived resources and is GRS certified.

The fiber includes two different polyester polymers, which together create a helical crimp, providing permanent stretch and recovery properties, as well as breathability, cooling comfort and chlorine resistance to fabrics. Recycled car interiors

LYCRA® FiT400™ fiber helps set the stage for circularity, a key priority for The LYCRA Company. In controlled tests under specific conditions, this fiber was recycled back into new polyester fibers, thereby demonstrating the technical feasibility of this process.*

“We developed LYCRA® FiT400™ fiber to deliver in-demand performance benefits and an enhanced soft hand to the knit fabric category,” said Steve Stewart, chief brand and innovation officer at The LYCRA Company. “This innovation also meets customer and consumer expectations for more sustainable solutions since it is made with recycled and bio-derived materials.”

LYCRA® FiT400™ fiber will be advertised to the trade. The “It’s Time for Better” campaign aims to disrupt the activewear, athleisure and swimwear categories with the message that consumers and the planet deserve better—better-functioning garments offering reduced environmental impact. Recycled car interiors

Fabrics and garments powered by LYCRA® FiT400™ fiber are eligible for LYCRA® XTRA LIFE™ or COOLMAX® EcoMade brand hangtags if they meet specific brand quality standards. Both brands enjoy high levels of consumer brand awareness worldwide.

To learn more about LYCRA® FiT400™ fiber for knits, visit lycra.com.

*LYCRA® FiT400™ fiber is compatible with established polyester chemical recycling processes.

In multiple tests, LYCRA® FiT400™ fiber components were blended with standard polyester components and recycled back into new polyester fibers with comparable performance as standard recycled polyester fibers. Recycled car interiors

TOMRA has entered into a long-term agreement to provide ‘reverse vending machines’ for a new deposit return scheme in Quebec starting in 2024.

Following on from the November 1st expansion of Quebec’s deposit return system (DRS), the agreement with the local producer responsibility organization, the Quebec Beverage Container Recycling Association (QBCRA), will see the installation of approximately 1350 TOMRA machines.

The roll-out of automated collection equipment in Quebec will begin in the first quarter of 2024 and continue over three years, during which time TOMRA will make an investment of approximately €36 million in the new infrastructure. Recycled car interiors

“Today, eleven out of 13 Canadian provinces and territories offer deposit return systems, to combat litter, increase recycling, and drive a circular economy,” explained Alain Nault, SVP, General Manager of TOMRA Canada.

“It is inspiring that Quebec is making huge new strides with the modernization of their drink container recycling program, promising to become one of the most efficient systems in the world. TOMRA is excited to be on board as the major provider of automated collection technology for that expansion.”

The Quebec redemption centers will be equipped with TOMRA T9 and T70 reverse vending machines, as well as installations of TOMRA’s Expert Line bulk collection technology for industrial facilities, configured for consumer interaction. Recycled car interiors

The return centers automated by TOMRA include smaller centers that will purchase the reverse vending infrastructure and subscribe to a service agreement, and larger centers that will operate on a throughput model.

The building of new containers’ return centers follows on from the expansion and modernization of Quebec’s deposit return system on November 1st.

Prior to November 1st, the DRS included only beer/soft drink cans, PET and a small portion of one-way glass. Now it will expand to all drinkable beverages between 100ml and 2L, including all cans, plastic and glass bottles, and cartons. The deposit/refund value has also increased from 5 cents to 10 cents, except for glass, which has increased to 25 cents.

The DRS expansion also includes a change to the types of locations where consumers can return their drink containers for recycling. Quebec was until now a return-to-retail model (meaning that supermarkets where drinks are purchased also served as return points), but the province will now move to a “hybrid” return model, with the introduction of return centers, starting from 2024. Recycled car interiors

New technique can capture or reuse CO2 as a chemical source for the production of sustainable plastic

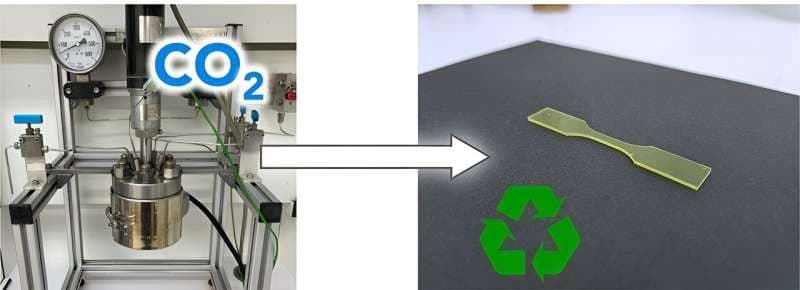

To obtain their new compound, the researchers put a raw material into a pressurized reactor filled with CO2. The transformed CO2-based compound is then purified and used to produce monomers to make polymers. When the material is obtained, it is hot-pressed in molds and can be cut into various shapes. Credit: University of Liège / Th.Habets

A team led by chemists at the University of Liège has developed a new polyurethane production technique using CO2 to create new types of easily recyclable plastics. The study, published in the Journal of the American Chemistry Society, could provide a solution for the development of truly sustainable plastics. Recycled car interiors

Commodity plastics have transformed global industry. Whether in construction, clothing, vehicles or food packaging, these plastics are everywhere in our daily lives, so much so that their global use has been estimated at around 460 million tons in 2019.

“This number is staggering, but not surprising, because plastics, also known as synthetic polymers, have met a large success thanks to their irreplaceable characteristics: they are light, cheap and incredibly versatile,” explains Christophe Detrembleur, chemist at the Center for Education and Research on Macromolecules (CERM) of the University of Liège. “However, the fact that they are difficult to recycle, or even impossible to recycle in the case of thermosets, has serious consequences.” Recycled car interiors

This impossibility of recycling not only leads to the depletion of the fossil resources used to manufacture them, but also to their very long-term accumulation in nature and the oceans. It is therefore imperative for our society to quickly design and manufacture plastics that can be easily recycled at the end of their life.

In this context, a study led by researchers at the University of Liège and carried out in collaboration with the University of Mons and the University of the Basque Country, reports on a new technique for producing easily recyclable polyurethane plastics.

“The special feature of this approach is the use of carbon dioxide (CO2 )—a major emblematic waste of our society—as a raw material for the production of the building blocks, or monomers, needed to manufacture these new products,” explains Thomas Habets, a doctoral student at CERM and first author of the article. “The structure of the monomers can be easily modified, making it possible to produce plastics with a wide range of properties, from highly malleable elastomers such as silicones to more rigid materials such as polystyrene.” Recycled car interiors

These plastics have a chemical structure that resembles a three-dimensional network rather than long linear chains. This structure, which is generally associated with thermosets that are very difficult to recycle, makes them more resistant than plastics made from long molecular chains. The polyurethanes created here have new “dynamic” chemical bonds, which means that despite their thermoset structure, they can be reshaped by exchanges of chemical bonds under relatively mild reaction conditions.

Duo and Plastix launch shrink film made from waste fishing gear

Duo will manufacture shrink film for food and beverage outer packaging using Plastix’s Oceanix recycled plastic, which is made from 98% maritime waste like fishing nets and ropes.

Fishing gear is one of the deadliest forms of marine waste, reportedly threatening 66% of marine animals and 50% of seabirds. Plastix says that its technology enables the maritime industry to minimise waste fishing gear pollution, which could otherwise end up in the oceans. Recycled car interiors

According to the companies, Oceanix has undergone a life-cycle assessment and is confirmed to provide up to 94% CO2e savings, when compared with virgin plastics.

Hans Axel Kristensen, CEO at Plastix, says: “Our independent LCA study on Oceanix not only shows world-class CO2 reductions, but at the same time highlights that it is 11 times more climate efficient on freshwater use, five times more on ocean acidification and 43 times more on fossil resource use, compared to virgin plastics.

“It is our mission here at Plastix to reduce maritime plastic pollution and offer the most sustainable recycled plastics as an immediate solution to the world’s climate emergency.

“Duo represents everything we look for in a partner; they demonstrate a shared motivation and drive to make the plastics economy circular to help solve the climate crisis. We’re delighted to partner with them as they step into new packaging territory with exciting products in shrink film.” Recycled car interiors

Zoe Brimelow, Brand Director at Duo, adds: “Duo remains unwavering in its mission to bring waste full-circle, so this partnership with Plastix was an easy choice; their recycled plastic ticks so many boxes for us as a business. Not only is it an innovative solution to a big environmental problem, but the quality of the green recycled pellet makes for a standout end product too.

NFW and Sage Automotive Interiors Partner to Revolutionise Cars with Biodegradable Plant-Based Leather

Plant-based material company Natural Fiber Welding (NFW) and automotive interior solutions supplier Sage Automotive Interiors (Sage) have partnered to develop animal and plastic-free materials for car interiors. Recycled car interiors

The strategic partnership aims to manufacture NFW’s plant-based leather MIRUM at scale, offering the automotive industry a recyclable and biodegradable alternative while supporting a circular economy.

“Asahi Kasei, Sage & NFW take a leading role in revolutionizing the market”

Sage, an affiliate of the Japanese company Asahi Kasei, is among the leading global suppliers of seat materials, door panel surfaces, and automobile headliners. With a strong presence in the US, China, and Europe, Sage has been expanding its lineup of growth-potential materials, including leather alternatives.

Dirk Pieper, chairman of the Sage Automotive Interiors board of directors, commented: “By jointly introducing MIRUM®, a plastic-free, plant-based, and fully circular leather alternative, Asahi Kasei, Sage & NFW take a leading role in revolutionizing the market for interior mobility materials.” Recycled car interiors

Asahi Kasei’s partnership with NFW is part of its “Care for Earth” investment framework, announced in April 2023. Over the next five years, the company will invest $100 million in startups addressing environmental issues. The car interior material industry is among Asahi Kasei’s future growth areas.

The most sustainable option

Based in Peoria, Illinois, NFW was founded in 2015 to develop and manufacture sustainable products using naturally circular, biobased ingredients to replace animal and petrochemical-based materials. Today, NFW has become a platform for plastic-free performance materials spanning sheet goods (plywood and other composite materials), textiles, molded composites, and foams.

The company’s patented leather alternative, MIRUM, is made from natural rubber, fibers, pigments, plant oils, and minerals. Recycled car interiors

Chemical recycling – Pyrowave introduces nanopurification technology for plastics 15-11-2023

Recycled car interiors