Recycling Processes Petrochemicals – Petrochemicals rPET PA6 – Will petrochemicals rise with oil? 24-07-2023 - Arhive

Recycling Processes Petrochemicals

Petrochemicals rPET PA6 – Will petrochemicals rise with oil?

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

Balancing High Oil Prices and Production Strategies: A Closer Look

Introduction

Since the invasion of Ukraine in 2022, the global oil industry has been grappling with soaring prices, reaching levels not seen in decades. This surge in oil prices prompted the Biden administration to urge US producers and OPEC to increase production to stabilize prices. However, differing approaches by major players like Saudi Arabia and the US shale sector have led to complex dynamics in the oil market. This article delves into the factors influencing oil production, the role of US shale oil, and the potential impact on global supply and prices.

US Shale Oil Sector’s Response

In response to President Biden’s call, the US shale oil sector has been proactive. The US Energy Information Administration predicts that total US production is expected to reach 12.61 million barrels per day by 2023, surpassing the previous record of 12.3 million barrels per day in 2019.

This surge in production is driven by increased investment and advancements in technology, making extraction more cost-effective. Recycling Processes Petrochemicals

Challenges in US Shale Oil Growth

Despite the optimistic outlook, US shale oil growth is not without hurdles. Fluctuating crude oil inventories and rising production rates, which have increased by 9% annually, have put pressure on OPEC’s efforts to limit supplies and control prices. Saudi Arabia’s decision to cut production by an additional one million barrels per day in July further complicates the situation.

However, the pace of growth in the US shale oil sector may be slower than anticipated. Several factors contribute to this trend, including the focus of shale oil companies on capital discipline and increasing returns to shareholders instead of aggressive expansion. Although the break-even costs for most domestic producers hover around $90 per barrel, the challenges of rising costs, labor shortages, and equipment constraints have hindered rapid production ramp-up. Recycling Processes Petrochemicals

Hydraulic Fracturing: A Potential Game-Changer

To combat these challenges, some oil giants, like ExxonMobil, are pinning their hopes on hydraulic fracturing (fracking) as a game-changing technology. ExxonMobil’s CEO, Darren Woods, believes that hydraulic fracturing can potentially double production from existing wells and extend their lifespan. This innovative technology is not only up to 40% cheaper than drilling new wells but also has the potential to deliver two to three times more oil than older wells, according to COO Garrett Fowler. Recycling Processes Petrochemicals

The Complex Role of OPEC+

As the US shale oil sector aims to boost production, OPEC and its allies are faced with crucial decisions to maintain supply restrictions to stabilize oil prices. Saudi Arabia, being a prominent OPEC member, has stated that the price of oil must be at least $81 per barrel to meet this year’s budget targets. Balancing the interests of OPEC+ members and global market demands is a challenging task that will have far-reaching implications for the oil industry.

The Impact on Global Oil Supply and Prices

The interplay between US shale oil growth and OPEC+ production cuts can significantly influence global oil supply and prices. Moderate increases in US oil production, coupled with production cuts by OPEC+, might lead to limited crude supplies in the coming months and potentially drive prices higher.

It is essential for policymakers and industry leaders to closely monitor these developments to avoid undue volatility in the energy markets. Recycling Processes Petrochemicals

Conclusion

As the world grapples with high oil prices and attempts to boost production, the global oil industry stands at a critical juncture. The US shale oil sector has shown promise in responding to the call for increased production, driven by technological advancements and investments. However, challenges such as capital discipline, labor shortages, and equipment constraints have slowed down the pace of growth.

In parallel, OPEC+ faces the delicate task of balancing production cuts to stabilize prices while meeting budget targets. The ongoing geopolitical dynamics and technological innovations, such as hydraulic fracturing, further add complexity to the oil market’s trajectory.

Moving forward, collaboration and effective communication between major oil-producing nations and industry stakeholders will be vital to ensure a stable and sustainable energy future for the world. Recycling Processes Petrochemicals

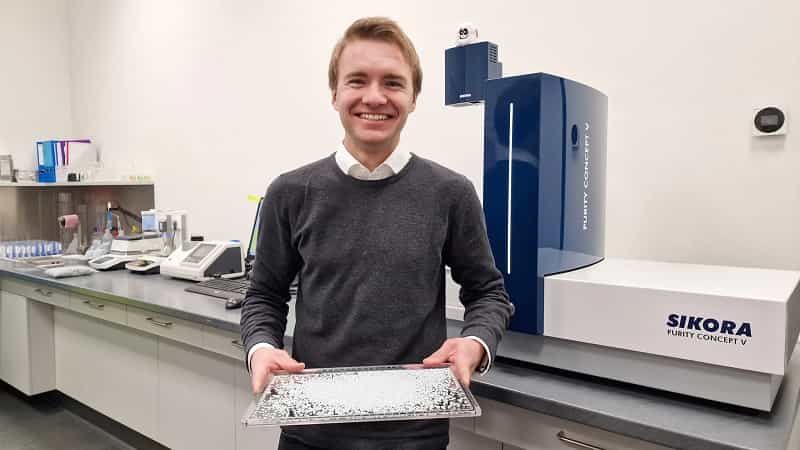

Sikora’s Purity Concept V: Enhancing Quality Control and Efficiency in Recycling Processes

Introduction

The RCS Group, a renowned medium-sized recycling and waste management company in Germany, has been leading the charge in sustainable practices since its establishment in 1985. With three core business segments, RCS Entsorgung GmbH, RCS Rohstoffverwertung GmbH, and RCS Plastics GmbH, the company is committed to ensuring high-quality recycling and waste processing. To maintain the food-grade quality of recycled materials, the RCS Group has partnered with Sikora, a cutting-edge technology provider, utilizing their Purity Concept V inspection and analysis system.

Importance of Quality Control in Recycling Processes

The significance of stringent quality control in recycling cannot be overstated. Impurities in recycled materials can have severe consequences, particularly in industries like non-food plastics processing and beverage bottle manufacturing. For instance, utilizing contaminated rPET pellets in bottle production can lead to defects and malfunctions, compromising both appearance and functionality, and potentially resulting in bottles that may even burst. Recycling Processes Petrochemicals

Enter Sikora’s Purity Concept V

Recognizing the challenges in maintaining uncompromised quality, the RCS Group turned to Sikora’s Purity Concept V to streamline their quality control process. The system offers rapid, reliable, and precise inspection, making it an invaluable asset for identifying impurities in rPET pellets. Instead of the time-consuming manual sorting that used to take up to 45 minutes, the Purity Concept V now achieves the same task in just 30 seconds, greatly saving time and resources.

Advantages of Purity Concept V

Cedric Steeg, an employee in Quality Assurance at RCS, praises the Purity Concept V, highlighting its efficiency in identifying contaminants within seconds. He further emphasizes that the system provides clear and reproducible results, a critical aspect in maintaining consistency and adhering to stringent quality standards. With the ability to detect black spots as small as 50µm, the system surpasses the limitations of human visual inspection, enhancing the overall quality control process. Recycling Processes Petrochemicals

Comprehensive Quality Control

The RCS Group has established its own defined limits for the quality of recycled materials. The Purity Concept V allows the company to verify whether each batch of rPET pellets meets these criteria immediately after analysis. The test results are thoroughly documented and stored for a period of five years, ensuring complete traceability and compliance with regulations. Additionally, beyond detecting black spots, RCS also utilizes the system to inspect for butterfly grains, which helps identify potential mechanical issues during granulation leading to undesired deformations.

Sikora’s Expertise and Partnership

Aside from the remarkable performance of the Purity Concept V, the RCS Group was equally impressed with Sikora’s pre-investment consultation and their outstanding service during the commissioning process. The collaborative relationship between the two organizations highlights the shared commitment to advancing recycling practices and the pursuit of sustainable solutions. Recycling Processes Petrochemicals

Conclusion

Sikora’s Purity Concept V has emerged as an indispensable tool in the RCS Group’s quality control process, elevating their recycling and waste management endeavors to new heights. By swiftly and accurately identifying impurities in rPET pellets, the system enables RCS to uphold the highest standards in recycled material production. Through their successful partnership, Sikora and RCS continue to make strides in advancing recycling technology and contributing to a more sustainable future.

Automotive industry PA-Recycling – Every day a new idea for EV-cars 22-07-2023

Recycling Processes Petrochemicals