Shrink-film – FDCA – PEF – Tires 25-11-2022 - Arhive

Shrink-film – FDCA – PEF – Tires

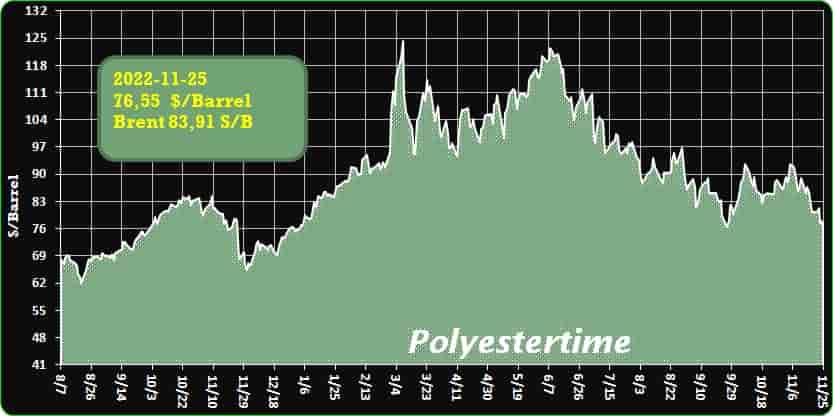

Crude Oil Prices Trend

Crude Oil Prices Trend Polyestertime

-European recyclers urge tougher scrutiny of EPR Schemes

Recycling companies in Europe are urging national and European policymakers to examine proposals more carefully before creating new Extended Producer Responsibility (EPR) Schemes.

Often portrayed as a silver bullet to improve waste management, EPR Schemes have significantly multiplied in recent years as the burden of the polluter-pays principle has shifted to producers. In its latest position paper, European recyclers warn that sufficient assessment of whether a waste stream has a positive or negative value is needed prior to establishing new schemes.

“EPR Schemes can be effective when they involve recyclers or their representatives in their governance bodies, thereby providing an expertise that manufacturers typically lack. They also have an instrumental role in bringing together manufacturers and recyclers through effective eco-modulation of fees that promote recyclability and recycled content,” says Emmanuel Katrakis, Secretary General of EuRIC, the European Recycling Industries’ Confederation. “Good examples exist with respect to end-of-life vehicles (ELVs) and industrial packaging, yet other notable Schemes pose a fundamental risk to recycling investments,” he added. Shrink-film – FDCA – PEF – Tires

European recyclers argue that EPR Schemes should only be established where collection and treatment costs are adequately assessed and exceed the economic value of the waste stream. This includes deciding on appropriate governance, an organisational or operational role, and whether alternative policy instruments could be implemented. Recyclers, rather than EPR schemes, should retain ownership of the waste stream to maintain their ability to invest and scale up recycling, otherwise this will further erode the competitiveness of recycled over extracted raw materials.

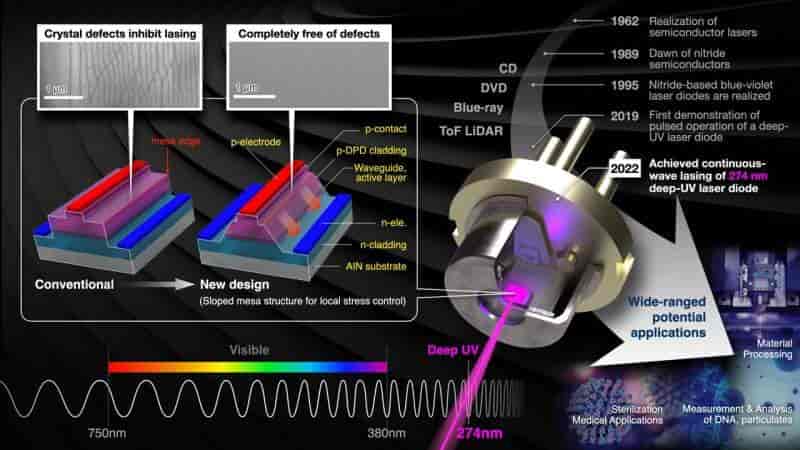

-Scientists demonstrate world’s first continuous-wave lasing of deep-ultraviolet laser diode at room temperature

A research group led by 2014 Nobel laureate Hiroshi Amano at Nagoya University’s Institute of Materials and Systems for Sustainability (IMaSS) in central Japan, in collaboration with Asahi Kasei Corporation, has successfully conducted the world’s first room-temperature continuous-wave lasing of a deep-ultraviolet laser diode (wavelengths down to UV-C region).

These results, published in Applied Physics Letters, represent a step toward the widespread use of a technology with the potential for a wide range of applications, including sterilization and medicine. Shrink-film – FDCA – PEF – Tires

Since they were introduced in the 1960s, and after decades of research and development, successful commercialization of laser diodes (LDs) was finally achieved for a number of applications with wavelengths ranging from infrared to blue-violet. Examples of this technology include optical communications devices with infrared LDs and Blu-ray discs using blue-violet LDs.

However, despite the efforts of research groups around the world, no one could develop deep ultraviolet LDs. A key breakthrough only occurred after 2007 with the emergence of technology to fabricate aluminum nitride (AlN) substrates, an ideal material for growing aluminum gallium nitride (AlGaN) film for UV light-emitting devices.

Starting in 2017, Professor Amano’s research group, in cooperation with Asahi Kasei, the company that provided 2-inch AlN substrates, began developing a deep-ultraviolet LD. At first, sufficient injection of current into the device was too difficult, preventing further development of UV-C laser diodes.

But in 2019, the research group successfully solved this problem using a polarization-induced doping technique. For the first time, they produced a short-wavelength ultraviolet-visible (UV-C) LD that operates with short pulses of current. However, the input power required for these current pulses was 5.2 W. This was too high for continuous-wave lasing because the power would cause the diode to quickly heat up and stop lasing.

But now, researchers from Nagoya University and Asahi Kasei have reshaped the structure of the device itself, reducing the drive power needed for the laser to operate at only 1.1W at room temperature. Earlier devices were found to require high levels of operating power because of the inability of effective current paths due to crystal defects that occur at the laser stripe. But in this study, the researchers found that the strong crystal strain creates these defects.

By clever tailoring of the side walls of the laser stripe, they suppressed the defects, achieving efficient current flow to the active region of the laser diode and reducing the operating power.

Nagoya University’s industry-academic cooperation platform, called the Center for Integrated Research of Future Electronics, Transformative Electronics Facilities (C-TEFs), made possible the development of the new UV laser technology. Under C-TEFs, researchers from partners such as Asahi Kasei share access to state-of-the-art facilities on the Nagoya University campus, providing them with the people and tools needed to build reproducible high-quality devices.

Zhang Ziyi, a representative of the research team, was in his second year at Asahi Kasei when he became involved in the project’s founding. “I wanted to do something new,” he said in an interview. “Back then everyone assumed that the deep ultraviolet laser diode was an impossibility, but Professor Amano told me, ‘We have made it to the blue laser, now is the time for ultraviolet’.”

This research is a milestone in the practical application and development of semiconductor lasers in all wavelength ranges. In the future, UV-C LDs could be applied to healthcare, virus detection, particulate measurement, gas analysis, and high-definition laser processing. Shrink-film – FDCA – PEF – Tires

“Its application to sterilization technology could be groundbreaking,” Zhang said. “Unlike the current LED sterilization methods, which are time-inefficient, lasers can disinfect large areas in a short time and over long distances”. This technology could especially benefit surgeons and nurses who need sterilized operating rooms and tap water.

-CCL presents first-ever approved shrink film material for the South African beverage market

After having been successfully introduced into the markets in Europe and the USA, CCL announced that their EcoFloat shrink sleeves have successfully been trialed in South Africa by PET recycling specialist Extrupet and have been approved for the local recycling system. This marks the arrival of the first approved shrink sleeve decoration solution for the PET beverage market in South Africa and is intended help boost recycling rates in the future. Shrink-film – FDCA – PEF – Tires

“In the past shrink sleeves have been made from PVC or PET and have always been viewed as a great way to decorate PET bottles because they stand out on shelves and can easily contain all needed information on the container like nutrition information or recycling codes, but they have been viewed as problematic in recycling – and had to be removed by hand to not contaminate the PET resin”, says Shivern Reddy, Business Development Director of CCL in South Africa.

“But this material is new – as EcoFloat sleeves are made from low density polyolefin material they make the difference in the crucial sink/float recycling step at the PET recyclers. The sleeve material automatically detaches from the bottle and floats; this allows for a clean separation from the heavier PET flakes that sink to the bottom of the washing basin. This easy separation forms the basis of the yield of high-quality PET flakes that can be used in bottle-to-bottle recycling, closing the loop”, explains Marika Knorr, Head of Sustainability and Communication at CCL Label.

South Africa has undergone different legislation changes in the past years. This new legislation makes an “Extended Producer Responsibility” (EPR scheme) mandatory for all producers and importers of packaging. It changes how producers, brand owners, retailers and importers design, make, sell and keep their products in the recycling loop as far as is practicably possible.

“In the recent years we have seen big changes in the market. Brands are increasingly following Design for Recycling guidelines and are re-creating their packaging to meet the latest requirements. Labels can make a huge difference here, they are functional and support recyclability and re-usability”, says Reddy.

CCL and Coca-Cola South Africa entered partnership for proof of concept

Leading up to the trials of the new shrink sleeve material CCL Label and Coca-Cola had entered a partnership to prove the feasibility of substituting the materials used for sleeves in the past with EcoFloat.

CCL Label has been partnering with multinational brands to develop recyclable plastic packaging that allows for PET bottle-to-bottle recycling in a closed loop. They have been endorsed by the European PET Bottle Platform (EPBP) as well as American Plastic Recyclers (APR) in the United States. Shrink-film – FDCA – PEF – Tires

-Polyvinyl chloride (PVC) prices journey southward in Asia

PVC prices dropped in the Asian region this week.

An industry source in Asia wishing to remain unidentified informed a Polymerupdate team member, “The price fall was driven by reduced offer levels from overseas suppliers. A fall in VCM feedstock prices also pressured prices lower. A weak buying undertone was observed in the Asian markets with buyers adopting a wait and watch approach to assess the near to medium term market fundamentals.”

The source added, “A drop in PVC futures on the Dalian Commodities Exchange (DCE) in China also proved to be a key contributory factor in exerting a bearish pressure on prices.”

In China, PVC prices were assessed at the USD 715-735/mt CFR levels, a fall of USD (-25/mt) from the previous week. Shrink-film – FDCA – PEF – Tires

In China, a Taiwanese producer has offered its PVC resin suspension grade at the USD 735/mt levels for shipment in December 2022.

In South East Asia, PVC prices were assessed at the USD 730-780/mt CFR levels, a week on week decline of USD (-20/mt).

In Vietnam, overseas suppliers have offered their PVC resin suspension grades in the range of USD 730-780/mt levels for shipment in December 2022.

In India, PVC prices were assessed at the USD 740-770/mt CFR levels, a tumble of USD (-40/mt) from last week.

A domestic industry source informed a Polymerupdate team member, “In India, A Taiwanese producer has offered its PVC resin suspension grades at the USD 740/mt levels on CIF Nhava Sheva/Chennai/Mundra ports basis for shipment in December 2022 (LC at Sight). This offer is sharply lower by USD 90/mt from its previous offer.” Meanwhile, A producer from South Korea offered its PVC resin suspension grade at the USD 740-750/mt levels for shipment in December 2022 (LC at Sight).

In Bangladesh, PVC prices were assessed at the USD 710-740/mt CFR levels, down USD (NC/-30/mt) from the previous week.

In Bangladesh, overseas suppliers have offered their PVC resin suspension grades in the range of USD 710-740/mt levels for shipment in December 2022.

In Sri Lanka, PVC prices were assessed at the USD 800-860/mt CFR levels, a week on week fall of USD (-20/mt). Overseas suppliers have offered their PVC resin suspension grades in the range of USD 800-860/mt levels for shipment in December 2022.

In Pakistan, PVC prices were assessed at the USD 750-800/mt CFR levels, a drop of USD (NC/-20/mt) from the previous week.

In Pakistan, overseas suppliers have offered their PVC resin suspension grades in the range of USD 750-800/mt levels for shipment in December 2022.

Feedstock ethylene prices on Tuesday were assessed at the USD 875-885/mt CFR South East Asia levels while CFR North East Asia ethylene prices were assessed at the USD 875-885/mt levels, both stable from the previous week.

Feedstock EDC prices were assessed at the USD 230-240/mt CFR China levels while CFR South East Asia EDC prices were assessed flat at the USD 255-265/mt levels, both unchanged week on week. CFR China VCM prices were assessed at the USD 555-565/mt levels, a plunge of USD (-70/mt) from last week. CFR South East Asia VCM prices were assessed at the USD 585-595/mt levels, sharply lower from the previous week by USD (-40/mt).

In plant news, Formosa Plastics Corp (FPC) is presently running its Polyvinyl chloride (PVC) plants at curtailed capacity levels. Located at Mai Liao and Jen-wu, Taiwan, the plants have a total production capacity of 1.075 million mt/year. Shrink-film – FDCA – PEF – Tires

-Apollo Tyres and Tyromer Inc announce Sustainable Material Partnership

Taking forward its commitment to Sustainability, Apollo Tyres has partnered with Tyromer Inc, a leader in non-chemical devulcanisation of end-of-life tyres.

Tyromer Inc, through their Indian associate, Tyromer India LLP, is committed to supplying recycled rubber material, produced using its environmentally sustainable processes, to

Apollo Tyres.

Announcing the partnership with Tyromer, P K Mohamed, Chief Advisor, R&D, Apollo Tyres Ltd, said “This partnership with Tyromer is a step towards achieving our sustainability goals, and it also enables us to honour our Extended Producer Responsibility (EPR). Producing new tyres Shrink-film – FDCA – PEF – Tires

using the sustainable raw materials, is currently, the most efficient path to meet our circular economy goals.”

Apollo Tyres and Tyromer share a deep commitment to sustainability and social responsibility.

This partnership has validated tyre-derived polymer (TDP), produced by Tyromer’s proprietary and patented technology, as the raw material for tyres.

Commenting on the partnership, Dr Sam Visaisouk, CEO, Tyromer Inc, said “We are thankful to the Apollo Tyres’ team for its support of our vision of direct tyre-to-tyre recycling for

achieving a tyre circular economy. In the face of climate crisis, not using rubber derived from end-of-life tyres is no longer an option.”

Tyre-derived polymer (TDP) trivia:

- Using a tonne of TDP saves GHG emissions equivalent to 4 passenger vehicles driven for a year

- Producing a tonne of TDP requires less than 2 MWh of energy, compared to over 20 MWh required for new material

-Commissioning underway at Stora Enso’s Flanders FDCA pilot plant

Convinced that bio-based materials will be standard constituents of future packaging solutions, Stora Enso decided to act. The company announced in December 2019 that it was investing €9m in the construction of a pilot plant for the production of furandicarboxylic acid – FDCA – a building block to produce the biopolyester polyethylene furanoate, commonly known as PEF. Shrink-film – FDCA – PEF – Tires

The company selected the Flanders region in Belgium as the site for the plant, which it sees as a ‘hub’ for bio-based technologies. The location at the Langerbrugge recycled paper mill near Ghent ensures access to skilled workers and critical service providers in the region.

Stora Enso had previously developed a proprietary technology called FuraCore, and was able to move swiftly on the development of the pilot facility to test the technology.

Construction of the plant has since been completed and commissioning is well underway, with initial production of FDCA and PEF scheduled to start soon.

Together with a number of partners, Stora Enso will then work to validate the FuraCore products in a range of applications.

According to VP Emerging Business Dirk den Ouden, the pilot will soon be ‘up and running’,

producing material for testing. “The proof point of years of breakthrough R&D is now around the corner.”

The bigger picture of the piloting effort is to validate the chemical process and provide sample material to gain further insight into market needs and product demands. The pilot facility will initially use industrially available sugar (fructose) to produce high-value chemicals and materials for application testing. In the future, the intention is to run the process on sugars extracted from wood and other non-food-based biomass.

“Nature happens to provide our raw material in a very efficient way via crops. That’s where we’ll start. Implementing FuraCore chemistry at a large scale globally, however, requires us to rethink our raw material sourcing.

-Stabilization Technology Delivers Sustainable HDPE for Blow Molding

Additive package from Baerlocher enhances the inconsistent quality of PCR content, opening up avenues in extrusion blow molding applications.

Plastics additives supplier Baerlocher has collaborated with processor Envision Plastics, machinery OEMs Bekum America and W. Müller, and polyethylene supplier ExxonMobil Chemical to develop new sustainable plastics for the packaging industry. Baerlocher’s innovative Baeropol T-Blends stabilization solutions significantly enhance the recyclability of virgin polyolefin resins and the quality of recycled high-density polyethylene (re-HDPE) resins used in extrusion blow molding (EBM) applications. The blends are equally applicable to post-industrial recycled (PIR) and post-consumer recycled (PCR) content used in polyethylene (PE) film. Baerlocher is involved in numerous commercial projects with leading members of the US Association of Plastic Recyclers (APR), such as Little Rock, AR–based recycler Revolution, as well as companies in the UK and Canada (Cascades Flexible Packaging). Shrink-film – FDCA – PEF – Tires

“Mechanical recycling utilizes only 20% of the energy of chemical recycling and much less water,” says Ed Hall, President and CEO, North America, at Baerlocher. “This means mechanical recycling is the most obvious choice right now, but high-quality PCR is rare.” This is where Baeropol T-Blends stabilization additives come in.

“Brand owners are increasing their use of PCR content in end products in response to growing consumer demand for greater sustainability and [the requirements of] new regulations,” said Andreas Holzner, Global Head of the Special Additives Business Unit at Baerlocher. “Historically, the inconsistent quality of PCR content has limited its use in extrusion blow molding applications. Working with industry leaders, Baerlocher continues to invest in cutting-edge application development that enhances the value of recycled HDPE and expands its use in extrusion blow molding.”

Customizable additives stabilize PCR content in packaging

Baeropol T-Blends are formulated with Baerlocher’s Resin Stabilization Technology (RST), customizable additive blends that act as an antacid and produce a synergistic effect with primary and secondary antioxidants to stabilize polyolefin resins. Baerlocher’s advanced RST packages create value far beyond the use of typical binary antioxidant blends. The technology enables companies to achieve superior stabilization in PCR content used in a variety of packaging applications and meets global calls for greater corporate responsibility and to better support the circular economy.

Baerlocher’s work with leading HDPE plastics recycler Envision Plastics enabled the development of a new grade of HDPE PCR content with improved consistency and processability, and ultimately resulted in high-quality packaging applications. The new re-HDPE grade was tested at Bekum America’s facility using an F-style 10-liter bottle with a handle. Results revealed the re-HDPE 100% PCR content displayed more robust processability and enhanced final bottle specifications versus the control.

New PCR grade available for trials

“We are delighted to work with Baerlocher on additives to enhance recycled content used in a broad base of commercial applications, including those for direct food contact,” said Jean Bina, Director of Sales and Market Development at Envision Plastics. “The new PCR grade is available for trials today and is being tested by world-class consumer packaged goods companies and their blow molders.”

Further experiments at Bekum demonstrated that Baeropol T-Blend has a significant positive impact on the processability and final properties of PCR materials that have varying concentrations of virgin material. Shrink-film – FDCA – PEF – Tires

Baerlocher also worked with W. Müller, a leading German EBM technology provider, to validate new PCR materials formulated with Baeropol T-blends. Results showed that these materials exhibit less variation in die pressure and parison length, while producing bottles with top load performance that matches those made with virgin resin.

Recycle-ready resins developed in collaboration with ExxonMobil

Additionally, Baerlocher’s upstream collaboration with polymer company ExxonMobil Chemical supports the company’s efforts to create virgin polyethylene (PE) resins that are easier to recycle. Baerlocher’s RST solution, along with ExxonMobil Chemical’s modification of the resin architecture, helped to successfully develop these novel recycle-ready resins.

“Baerlocher’s technical expertise supported our development of a new generation of high- performance and recycle-friendly resins,” said Mark Canright, HDPE Principal Engineer, ExxonMobil Chemical.

Shrink-film – FDCA – PEF – Tires