Sustainable-nylon-tire – H2 – rPC 17-01-2023 - Arhive

Sustainable-nylon-tire – H2 – rPC

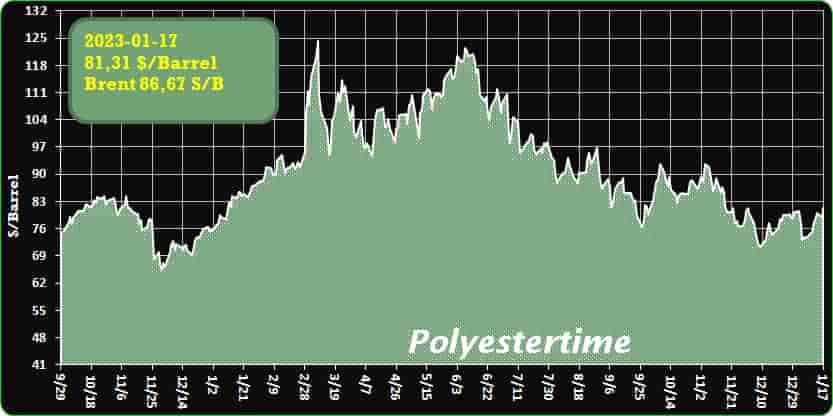

Crude Oil Prices Trend

Crude Oil Prices Trend Polyestertime

-Century Enka begins commercial production of sustainable nylon tire cord fabric

A new sustainable material developed by Century Enka will be utilized by Apollo Tyres for selected ranges in various segments. In what it states is a first, Century Enka has launched commercial production of NTCF (nylon tire cord fabric) made from 100% recycled nylon waste.

NTCF was unveiled in November 2022 at the Century Enka Bharuch plant in Gujarat, India, when the first consignment of commercial supplies was dispatched to Apollo. The two companies worked jointly on this project for over a year.

Century Enka is the largest consumer of caprolactam in India, and generates in-process waste during manufacturing of polyamide yarn. This waste is then recycled back to caprolactam, which, after extensive distillation, is made suitable for production of NTCF.

“We decided to use our in-house waste for caprolactam and, with our technology from Akzo, some could be converted back to Caprolactam,” said Suresh Sodani, managing director of Century Enka. “The idea was to conserve crude oil, a finite natural resource, for making virgin caprolactam and avoid misuse of polyamide waste – which is highly detrimental to the environment. I am proud of our teams for this remarkable achievement.” Sustainable-nylon-tire – H2 – rPC

Sustainable fabric from Century Enka is subject to rigorous quality assessments and is GRS certified.

-We hope that the DAVOS economists get this forecast wrong too – two thirds of the chief economists of banks and companies, present at the “WORLD ECONOMIC FORUM”, believe a global recession is “extremely probable” – they all expect weak, or very weak growth, in EUROPE, and 91% feel the same opinion for the USA

2023 will bring a global recession, with the economy continuing to be marked by geopolitical tensions and the Fed and the ECB continuing with monetary tightening.

This is the summary of the Chief Economists Outlook, a survey of the chief economists of the major financial institutions and companies.

Of which two-thirds – double that of last September – consider a global recession “extremely probable”. Sustainable-nylon-tire – H2 – rPC

All the economists interviewed in the survey expect weak or very weak growth in Europe, 91% have the same opinion for the USA. Judgment divided for China, where the choice to abandon the zero Covid policy would give a boost to growth, but with repercussions from the health impact that all need to be evaluated.

-DSM Expands Fuel Lock for Hydrogen Storage

Augmented portfolio offers more robust performance in Type IV pressure vessels.

DSM Engineering Materials has launched two new grades — FLX40-HP and FLX-LP — for use as liner materials in Type IV pressure vessels for hydrogen storage. By adding these new materials to its Akulon Fuel Lock portfolio, more robust performance in processing and greater resiliency in sustainable large-sized designs will be possible for tank and pressure vessel manufacturers. The polyamide used to make the Akulon Fuel Lock compounds has a minimal CO2 footprint and contributes to an overall more favorable life-cycle analysis in line with the intended green application of hydrogen use and storage as an alternative carbon-free fuel in mobile transport. Sustainable-nylon-tire – H2 – rPC

With these two new products, DSM Engineering Materials is staying abreast of the trend of designing sustainable and large-sized pressure vessels for trucks, buses, and mobile hydrogen transport. The advanced PA 6 is suited for producing Type IV pressure vessels that are 70% lighter than steel alternatives and offer mechanical strength, dimensional stability, and impact resistance throughout part lifetimes.

Akulon Fuel Lock tank liners also enhance vehicle safety and fuel efficiency through a barrier that reduces permeation leakage of hydrogen from the pressure vessel. The Akulon Fuel Lock portfolio of PA 6 materials all have a higher barrier than standard PA 6, allowing for thinner walls in monolayer tanks.

Akulon FLX-LP is an injection molding grade with excellent processing behavior and extremely high toughness and ductility at low temperatures (-40°C and below). These properties enable designs for increased life-time performance through extended pressure cycle testing.

Akulon FLX40-HP is a high-viscosity material, which makes it suitable for extrusion and blow molding. Material advantages include:

- Improved heat stabilization package, which creates a more robust processing window during extrusion and blow molding and reduces oxidation at the surface;

- better impact modifier system, which creates more toughness and ductility at low temperatures (-40°C and below);

- improved pinch line performance in the blow molding process.

Both material grades are launching in addition to the existing FLE-LP and FLE40-HP grades in the Akulon Fuel Lock portfolio. All these materials meet the requirements of EC79 and R134 standards.

DSM’s patented Fuel Lock technology in both new grades ensures excellent barrier performance against hydrogen permeation and enables reduced thickness of the liner compared to polyamide and polyolefin products. Sustainable-nylon-tire – H2 – rPC

-Eco-friendly Polycarbonate Boasts 90% Recycled Content

Korea’s Samyang targets automobiles, appliances, laptops, medical devices, and building & construction with its latest UL-certified flame-retardant offering.

Samyang Corp. has developed Korea’s first eco-friendly polycarbonate (PC) resin containing more than 90% post-consumer recycled (PCR) material. Transparent and resistant to impact and heat, PC is mainly used in interior and exterior components for automobiles, home appliances, soundproof walls, and medical device parts. The new grade is UL-rated at V-0.

Compounding recycled PC with virgin PC requires a high level of technology and expertise, according to Samyang. When manufacturing PC, flame retardants, reinforcing materials, and colorants are added to enhance the performance of the polymer and improve aesthetics. However, such additives cause adverse effects during the melting process at high temperature, weakening the physical properties of PC. For this reason, PCR PCs developed by other Korean companies contain a maximum of 85% of recycled PC material, according to Samyang, while the majority of PCR PCs on the market contain 30 to 50% of recycled PC material. Sustainable-nylon-tire – H2 – rPC

Within two years, Samyang succeeded in developing a PCR PC that contains more than 90% recycled PC content while retaining the inherent physical properties of PC, such as heat resistance, transparency, and impact resistance. This is enabled by optimizing the ratio of recycled material and additives during the compounding process. Securing suppliers of quality recycled PC material who closely monitor the degree of contamination and foreign substances was also paramount.

Samyang says that the newly developed PCR PC has the effect of reducing carbon dioxide emissions by about 6,200 tonnes based on production of 1,000 tonnes compared with fossil fuel-based PC. This is an equivalent amount of carbon dioxide emitted by 3,200 cars per year.

Samyang plans to first apply PCR PC to small electrical home appliances such as laptops, then expand its application extensively in various areas in the future, namely electronics and decorative applications. Meanwhile, the company plans to continue expanding the scope of applications by applying PCR PC to various plastic resins such as ABS and PBT.

“There are only a few places in the world that produce PCR PC products that contain more than 90% of recycled plastic materials while retaining the physical properties of conventional PC. We will continue to expand our high-quality, eco-friendly product portfolio to meet the global market’s demand and contribute toward the group’s ESG competitiveness,” said Samyang CEO Hosung Kang.

Samyang Group established its mid- to long-term strategy last year, called Vision 2025, which pursues the growth of eco-friendly and specialty business. Since last July, Samyang has been producing and selling resins and compounded products of a newly developed eco-friendly transparent and flame-resistant PC that does not use flame retardants.

Last August, Samyang also signed a contract to supply plastic pellets made from recycled fishing nets, further expanding its eco-friendly business portfolio.

And, Samyang Innochem built a manufacturing facility last November at its Gunsan plant that is capable of producing 15,000 tons per year of isosorbide, an eco-friendly biomass material, thereby commencing its eco-friendly plastic business in earnest.

Isosorbide has potential for the synthesis of polyurethanes, polyamides, and hardeners for epoxy resins. Sustainable-nylon-tire – H2 – rPC

-Biorecycling of PET: Carbios and Novozymes strengthen collaboration with long-term exclusive strategic partnership

Carbios and Novozymes, leader in biological solutions, announce an exclusive long-term global strategic partnership. This major agreement ensures the long-term production and supply of Carbios’ proprietary PET-degrading enzymes at an industrial scale for the world’s first biological PET-recycling plant due to start production in 2025 in Longlaville, France, as well as Carbios’ future licensee customers. Sustainable-nylon-tire – H2 – rPC

Exclusive global partnership

Carbios and Novozymes have had a partnership since 2019 to develop enzyme-based solutions and address the sustainability challenge of plastic pollution, both within PET-recycling and PLA-biodegradation. Building on the current Joint Development Agreement (JDA), under the new agreement, Carbios and Novozymes will extend their collaboration to develop, optimise and produce enzymes that will subsequently be supplied by Novozymes to all licensees of Carbios’ technology. The new agreement grants both parties exclusivity in the field of the partnership.

Large-scale industrial deployment

The strategic partnership supports the large-scale industrial deployment of Carbios’ patented PET-recycling technology starting with Carbios’ future industrial reference unit in Longlaville, which will be be the world’s first biological PET-recycling plant. Construction will begin later this year, and both building and operating permits having been filed with local authorities. Production at the plant is set to start in 2025 and the processing capacity will be 50,000 t/a of waste.

-Stora Enso completes the acquisition of De Jong Packaging Group

Stora Enso has completed the acquisition of the Netherland-based company De Jong Packaging Group, one of the largest corrugated packaging producers in the Benelux countries. The acquisition announced in September 2022 with an enterprise value of approximately EUR 1,020 million was closed today following regulatory clearances and employee consultation. Sustainable-nylon-tire – H2 – rPC

The acquisition will significantly strengthen Stora Enso’s presence in European packaging markets and provide an entry into the corrugated packaging market in the Netherlands, Belgium, Germany, and the UK. With the acquisition, Stora Enso’s Packaging Solutions division will increase its corrugated packaging capacity by approximately 1,200 million m2 to more than 2,000 million m2, including De Jong Packaging Group’s ongoing expansion projects. De Jong Packaging Group’s full-year 2022 sales are estimated at approximately EUR 1 billion. Its product portfolio and geographic presence complement and enhance Stora Enso’s offering, especially in fresh produce, e-commerce, and industrial packaging.

“I am pleased to officially welcome De Jong Packaging Group as part of Stora Enso. This acquisition advances Stora Enso’s strategic direction by accelerating revenue growth and building market share in renewable packaging in Europe,” says Annica Bresky, President and CEO at Stora Enso.

For more information:

Anna-Lena Åström

Stora Enso

Tel. +46 70 210 7691

Email: info@dejongverpakking.com

www.storaenso.com

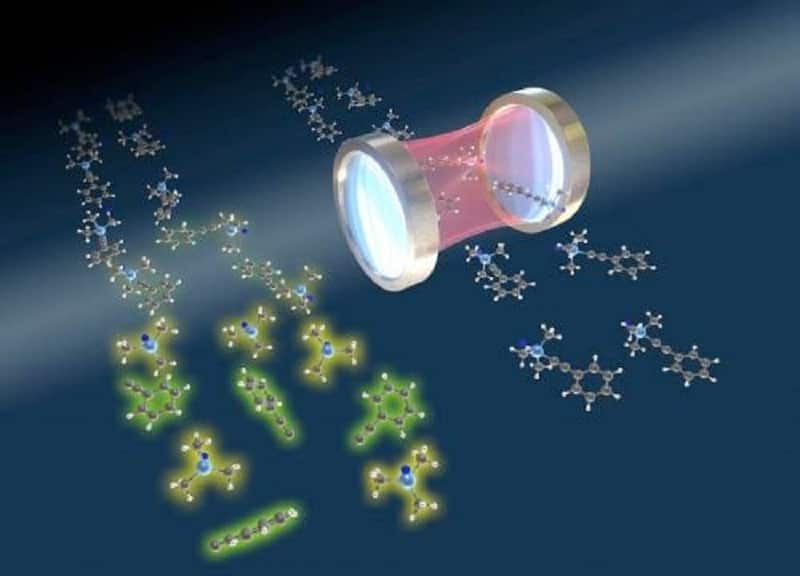

-Developments in polaritonic chemistry

A team of international researchers, which also includes Italians, is studying how to control chemical reactions through the use of electromagnetic fields.

An international research team, led by the Max Planck Institute for the Structure and Dynamics of Matter (MPSD) in Hamburg, which also includes Italian researchers from the Institute for Chemical-Physical Processes (IPCF) of the National Research Council (CNR) , is studying how to control chemical reactions through electromagnetic fields, a line of research that could also concern the sector of polymers and advanced materials.

Published in Nature Communications, the study is part of polaritonic chemistry, aimed at understanding how to manipulate materials through the use of optical cavities, i.e. confined spaces in which molecules interact strongly with light.

The methods commonly used to modify the course of a chemical reaction – the researchers explain – exploit parameters such as temperature and pressure, or use solid or solution catalysts: these approaches, however, act on a larger scale and often do not allow control specific and localized parts of the molecules involved. Sustainable-nylon-tire – H2 – rPC

The manipulation of materials through optical cavities instead aims at controlling the individual atoms during the reaction. When placed in these cavities, in close interaction with photons of light, the molecules undergo changes in some characteristics, including chemical reactivity.

The researchers have now succeeded in providing a theoretical explanation of the process observed so far only experimentally.

“The chemical reactions are directly related to the vibrations of the atoms involved, but it is very difficult to selectively control these movements – explains Enrico Ronca (Cnr-Ipcf), researcher who co-signed the study -.

If this were possible, however, it would be sufficient to supply only a small amount of energy to some atoms at the right time, just like a pool player wants to push only a ball on the table, for the reaction to take place”. “Our study – continues the researcher – has revealed that the conditions inside the optical cavity influence the vibration energy of the atoms around specific bonds of the molecule, thus modifying their chemical reactivity. Outside the cavity, that energy is usually deposited on a single bond during the reaction, which can eventually break — this difference is a key step in explaining why reactions are slowed down inside cavities.”

“Our theoretical work – adds Ronca – improves the understanding of the microscopic mechanisms involved in this process, in particular for the specific case of a reaction inhibited by the electromagnetic field, which we studied using the Quantum-Electrodynamical Density-Functional Theory (QEDFT) technique )”.

“We found that the cavity opens up a new reaction pathway, so energy is less likely to be channeled onto a single bond,” notes research team member Christian Schäfer of Chalmers University of Technology. Sustainable-nylon-tire – H2 – rPC

“This is the key process that it inhibits the chemical reaction, because it decreases the probability of breaking a specific bond”.

Before we can have practical applications, many important aspects still remain to be understood and further experimental validation is needed: “We expect the current results to be applicable to a broader set of relevant reactions (including click chemical reactions linked to the Prize Nobel Prize for chemistry this year) under conditions of strong coupling between light and matter”, concludes Angel Rubio, director of the theory department of the MPSD.

In addition to researchers from the Max Planck Institute for the Structure and Dynamics of Matter (MPSD) in Hamburg and the CNR, the team includes scholars from Chalmers University of Technology (Sweden), the Center for Computational Quantum Physics of the Flatiron Institute (USA) and the Harvard University (USA).

Sustainable-nylon-tire – H2 – rPC