Elix Polymers Unveils E-Loop Sustainable Materials at Fakuma 2023

Elix Polymers, a leading global supplier of specialty ABS materials headquartered in Spain, is set to unveil its latest eco-friendly E-Loop product line at the upcoming Fakuma 2023 exhibition in Friedrichshafen, Germany, scheduled for October 17 to 21. The company has consolidated its efforts in the circular economy realm under the E-Loop brand, encompassing two key initiatives from Elix Sustainable Portfolio Solutions: Circular Plastics and Responsible Innovation. Elix will use the Fakuma platform to present its most impactful circular solutions and innovations, carrying the banner of “Let’s close the loop” at booth 5003 in hall B5. Mixed-Plastics Recycling

Visitors to the Elix stand can expect to see an array of products featuring mechanically recycled content, including E-Loop H801 MR, E-Loop Ultra 4105 MR, and E-Loop PC/ABS 5120 MR. These offerings maintain properties akin to their conventional prime counterparts while achieving a remarkable 29% reduction in CO2 emissions. Notably, these materials have garnered approval from various premium automotive Original Equipment Manufacturers (OEMs) and have received validation from key tiers, with applications spanning the demanding landscape of both interior and exterior automotive components.

Among the highlights of the E-Loop range are the E-Loop CR products, crafted from sustainable certified raw materials that encompass circular and bio-based feedstocks. These products hold certification under ISCC+ (International Sustainability and Carbon Certification), with a meticulous mass balance model ensuring complete traceability and transparency across the supply chain. The flexibility of E-Loop CR products lies in the diverse sourcing options for the three primary monomers: fossil-fuel-based feedstocks, chemically recycled post-consumer waste, and bio-based feedstocks. Depending on the specific monomer blend employed, emissions reductions of up to 60% in comparison to prime-grade materials can be achieved. Mixed-Plastics Recycling

A testament to Elix Polymers’ commitment to sustainability, the company has received UL yellow cards for its E-Loop product lineup featuring certified raw materials, responding to the demands of customers within the electrical and electronics, as well as consumer goods sectors.

Salt Water-Degradable Plastics To Help Oceans

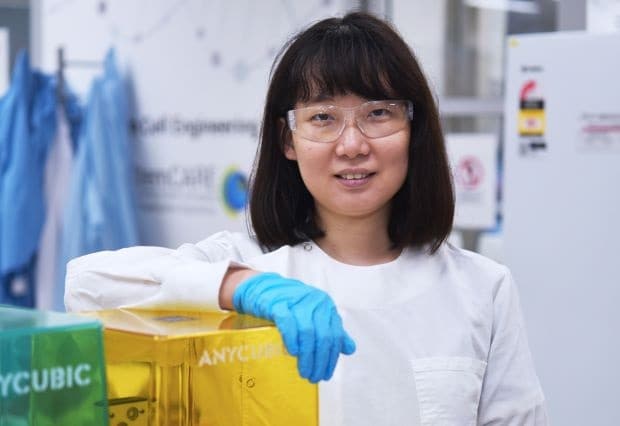

“Researchers at the University of Queensland are developing a groundbreaking solution to combat marine pollution: saltwater-degradable plastics. Dr. Ruirui Qiao, affiliated with UQ’s Australian Institute for Bioengineering and Nanotechnology, is spearheading the development of an affordable, biodegradable plastic that disintegrates in seawater, aiming to mitigate the proliferation of persistent plastic waste in our oceans.

According to Dr. Qiao, our oceans are increasingly contaminated by long-lasting plastic items such as containers, bags, and microplastics, posing a significant threat to marine ecosystems and the countless seabirds and mammals that rely on them. While awareness of this issue has grown in recent years, the scale of plastic waste entering the water necessitates innovative solutions. Dr. Qiao believes that plastic degradation technologies hold promise as part of the solution. Mixed-Plastics Recycling

Collaborating with fellow researchers, including Professor Tom Davis and Professors Xuan Pang and Xuesi Chen from the Changchun Institute of Applied Chemistry, Dr. Qiao’s team is utilizing cutting-edge 3D-printing techniques developed by her research group at AIBN and polymeric materials from the Chinese Academy of Sciences to create a range of customizable, high-value seawater-degradable plastics.

This collaborative effort has received $125,000 in funding from the Queensland-Chinese Academy of Sciences Collaborative Science Fund to expedite the project’s progress over the next two years. One of the techniques they are employing, known as ring-opening polymerization, enables precise control over the mechanical properties and form of the plastics while imbuing them with a low-toxic polyester “backbone.” As a result, these plastics can break down into a molecular state when exposed to marine environments.

The ultimate goal is to commercialize a new line of products in both Australia and China within five years, effectively replacing conventional plastics and capitalizing on a burgeoning biodegradable market projected to exceed $9.5 billion by that time. Dr. Qiao emphasizes that seawater-degradable polymer plastics will play a vital role in reducing plastic debris in the world’s oceans, enhancing the well-being of ecosystems and the quality of life for communities globally. Mixed-Plastics Recycling

In addition to their innovative work, the research team is fostering collaboration between research groups in Queensland and China to further advance their expertise in polymer science and additive manufacturing.”

UN Environment Chief Warns Recycling Alone Isn’t Sufficient

Over the past two decades, annual plastic production has surged, exceeding 460 million tons. With the global plastic production spiraling upward and causing escalating pollution, the UN’s environment chief has issued a stark warning that merely relying on recycling won’t extricate humanity from this crisis. Instead, she calls for a comprehensive reevaluation of our plastic consumption habits.

In an interview conducted on September 21st, during the General Assembly in New York, Inger Andersen, Director of the UN Environment Program, emphasized that the prevailing status quo is no longer a viable option. She pointed out that there are various approaches to find solutions to this predicament, but the urgency for change is evident to all.

Andersen’s remarks come on the heels of the publication of the initial draft of an impending international treaty on plastic pollution, set to be finalized by the conclusion of 2024. This treaty represents the diverse aspirations of 175 participating nations, notably highlighting the divergence between those advocating for reduced polymer production and those championing reuse and recycling. Mixed-Plastics Recycling

Initially, Andersen stressed the objective of eliminating as many single-use plastics as possible, targeting items that are evidently unnecessary, such as products wrapped in plastic that serve little purpose, or even those encased in natural packaging, like oranges or bananas. Subsequently, she highlighted the need to reconsider the very nature of products themselves. Questions about the necessity of products being in liquid form, and the potential for them to be reformulated as powders, compressed forms, or concentrates, must be seriously entertained. Andersen noted her personal habit of going straight to the soap aisle in supermarkets to check for solid alternatives.