Recycled Packaging Sustainability – Can Brics create a new currency to replace the hegemony of the dollar? 12-09-2023

Recycled Packaging Sustainability

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

Coca-Cola Phl Expands Recycled Packaging Program, Sustainability Initiatives

More Coca-Cola products in the Philippines will use 100 percent recycled PET bottles, the company announced during the launch of its “May Ikabobote Pa” initiative.

Coca-Cola Philippines has expanded its sustainable packaging program by strengthening its campaign to educate consumers and use more recycled material in the packaging of their products.

The company on Thursday, Sept. 7, launched a consumer engagement initiative called “May Ikabobote Pa,” which aims to educate consumers about waste reduction and recycling.

“Coca-Cola recognizes that the plastic waste problem in the Philippines is both urgent and complex. Therefore, it will take a collaborative effort to solve this issue,” Coca-Cola Philippines president Tony del Rosario said. Recycled Packaging Sustainability

“In line with our commitment to helping build a circular economy in the country, we are working to offer innovative packaging design, expand collection and recycling programs, and forge strategic alliances with stakeholders—including government agencies, industry partners and local organizations,” he added.

Del Rosario committed to use their “brand power” to engage consumers in collection and recycling initiatives, as well as build awareness about ways to recycle and reuse plastic bottles.

Part of the campaign is a new webpage, which can be accessed through a QR code that will be printed in every product of Coca-Cola Philippines.

Users can view the company’s current sustainability efforts, along with an interactive graphic for their recycling process. A database of over 2,800 bottle collection sites nationwide is also available. Recycled Packaging Sustainability

“We believe it’s very important to approach this topic holistically, and sustain our actions and commitment for the long term,” del Rosario said during the launch event held at The Fifth at Rockwell in Makati.

Aside from the webpage, del Rosario said Coca-Cola Philippines would also use social media and out-of-home advertisements to further educate consumers.

“May Ikabobote Pa” is the latest addition to Coca-Cola’s “World Without Waste” program. Launched in 2018, it seeks to collect and recycle the equivalent of every bottle or can that the company sells by 2030.

Under the program, Coca-Cola aims to make 100 percent of its packaging recyclable by 2025 and use at least 50 percent recycled material in its packaging by 2030.

Recycled PET bottles

During the launch, del Rosario also revealed the expansion of their use of recycled packaging. Recycled Packaging Sustainability

Now, Coca-Cola Original in 190ml and 390ml and Wilkins Pure in 500ml will also use recycled PET (Polyethylene terephthalate) or rPET plastic bottles, excluding caps and labels.

“We will also continue to use recycled plastic packaging for our Sprite 500 ml bottles as we’ve been doing since 2019,” Del Rosario added.

The said products now include a “I’m a 100% recycled plastic bottle” text at the bottom of the label, as well as a call to action meesage “Recycle Me Again.”

According to Coca-Cola, it has launched at least one brand in bottles made from 100 percent rPET in more than 40 countries around the world.

It said the rPET bottles maintain high-quality standards that consumers expect from the company and comply with local regulations as well as The Coca-Cola Company’s strict global standards for food-grade rPET packaging.

Challenging Times Ahead for European Chemistry

The European chemical industry faces a daunting economic landscape, with a substantial decline in production and sales during the first half of the year. According to Cefic’s latest analysis, production plummeted by 12.3% compared to the same period in 2022, although it did stabilize in the second quarter. This situation is reminiscent of the challenges faced in 2020 during the COVID-19 pandemic. Recycled Packaging Sustainability

The aftermath of the 2022 energy crisis continues to cast a shadow, particularly in Germany and the Netherlands. Notably, these two countries experienced a more severe production decline, exceeding 15%, compared to a 10.8% drop in Italy.

Across various sectors, basic chemicals saw a double-digit production decline, while petrochemicals and polymers also suffered significant losses. Specialties were the only segment that managed to maintain production at a moderate level.

Despite these difficulties, chemical product prices remained stable throughout the first half of the year, although they did exhibit a 10% decline in June compared to the same month in 2022. Sales followed a similar trend, falling by 12.7% in the first half of the year, while production capacity utilization in the second quarter of 2023 remained at 74%, mirroring levels observed during the COVID-19 pandemic.

Looking ahead, the situation remains precarious. Cefic states that demand for chemicals continues to decrease, and any recovery is expected to be slow and sluggish.

The second half of the year may pose additional challenges for the chemical industry, as new orders are likely to be hampered by weak demand in the industrial sector, driven by high interest rates, stricter lending conditions, and persistent inflationary pressures.

In conclusion, considering the overall weak economic conditions, it is anticipated that chemical production will significantly decrease in 2023. Recycled Packaging Sustainability

The plastic pollution crisis

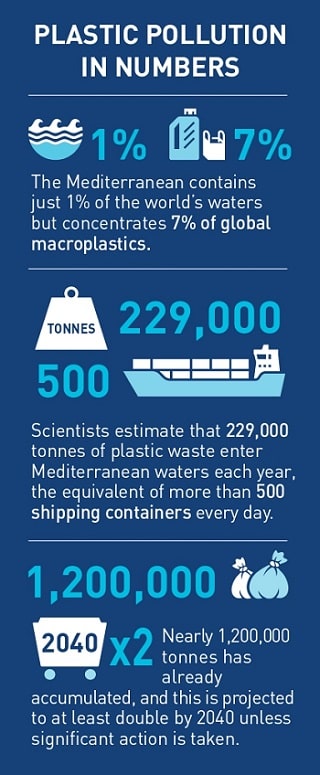

Plastics only began to be produced in large quantities following the second world war – but plastic pollution has since become one of the most serious threats humanity faces. By 2015, 60% of all plastic ever produced had become plastic waste, and in today’s world, plastic waste is ubiquitous – it’s in the air, in the soil, in freshwater, and in the sea.

Overall, 80% of marine plastic debris comes from land, and 20% is produced by ocean-based sources such as fishing, shipping and aquaculture. 3 Much of it is comprised of industrial and domestic waste from metropolitan and urban areas with poorly managed collection and disposal systems. Rubbish finds its way into rivers and other waterways, sometimes through storm drains and sewage outfalls, and these take it all the way to the sea. It’s estimated that 94% of the plastic pollution that enters the Mediterranean comes in the form of macroplastics, but microplastic pollution is significant too. Land-based sources of microplastics include agricultural polyethylene sheets that fragment from weathering, biosolids and sewage sludge from wastewater treatment plants, and grey water from washing clothes made with synthetic fibres. 4 Sewage entering municipal treatment systems is high in microfibres from textiles, microplastics from personal care products, and degraded consumer products. Recycled Packaging Sustainability

Between 80 and 90 percent of microplastics entering treatment systems remain in residual sewage sludge. This sludge is often used as fertilizer in agriculture, resulting in plastic being deposited on agricultural fields where it can remain for long periods of time – or be washed into the rivers and out to sea. Based on a recent study, microplastics can persist in soils for more than 100 years, due to low light and oxygen conditions5.

The plastics life cycle

Plastic pollution is a design, production, consumption and disposal challenge that must be tackled across plastic’s entire life cycle. Many factors contribute to the issue, most obviously unsustainable consumption patterns, non-existent or ineffective legislation, inefficient waste management systems, and a lack of coordination between different sectors.

The impacts of plastic pollution on biodiversity and human health

Plastic pollution has adverse impacts on ocean ecosystems, the integrity of food supplies, and people’s livelihoods.

Entanglement and ingestion are the most common hazards for marine species, almost all of which – from microscopic zooplankton to the largest marine mammals – will come into contact with plastic waste during their lives.

Entanglement in plastic ropes, lines and discarded fishing gear injures and kills all kinds of marine animals; while ingestion at every stage of the food chain can cause fatalities or have major impacts on physiological functions including nutrition, growth, behaviour and reproduction. Recycled Packaging Sustainability

Needlepunch focus for Autefa at Techtextil India

Autefa Solutions will present its latest customizable needlepunch production lines at next week’s Techtextil India, which takes place from 12-14 September at the Jio World Convention Centre in Mumbai.

Autefa says that its comprehensive range of nonwoven needlepunch lines, which are tailored to meet specific customer requirements, are designed to offer the highest possible levels of performance, reliability and quality.

Needle punching is renowned for its ease of operation, low energy consumption, consistent product quality and reduced operating costs. Amongst Autefa’s latest technological innovations aimed at meeting the evolving needs of the industry, is the 3-level closed-loop control system, which provides customers with real-time web quality monitoring and improvement capabilities. Recycled Packaging Sustainability

At the heart of the system is a state-of-the-art scanner that meticulously evaluates the weight distribution of the finished product. This critical data is used as the basis for real-time adjustments in the crosslapper and card infeed section, ensuring highly consistent distribution of the carded web.

The WebMax web profile control system is seamlessly integrated into the 3-level closed loop control system. This integration ensures uniform web profiling in both machine direction and cross direction, a distinctive edge treatment that helps reduce edge-related problems and extend felt life.

At the show, Autefa will also present its latest solutions for sustainable textile production.

“As the fashion industry increasingly prioritises sustainability, the demand for circularity solutions in textile is also soaring,” says Autefa. “Both consumers and companies are actively seeking ways to recycle “fast fashion” and reduce the environmental impact of their choices. In response to this pivotal trend, Autefa Solutions is proud to introduce a range of groundbreaking solutions designed to process and reuse various types of fibres, including reclaimed, natural, and man-made materials.

For example, illustrating a significant step forward in sustainable textile production, the Airlay V 12/R Aerodynamic Web Forming machine can be combined with the Stylus Needle Loom or HiPerTherm Oven to fulfill customer requirements for maximum productivity and consistent high quality. Recycled Packaging Sustainability

Elsewhere. a collaboration between Autefa Solutions and PAMA Paper Machinery brings together the best of two worlds—fibre-based web forming, consolidation, and drying technology from the nonwovens industry with wetlaid technology commonly used in the paper industry.

Arburg to present its Allrounder 520 H at Fakuma 2023

Arburg will present the the Allrounder 520 H at Fakuma 2023. It is claimed that the new machine in the hybrid Hidrive series is particularly good at saving energy and conserving resources, as well as being production-efficient, user-friendly and reliable.

The machine technology of the Hidrive series has been significantly enhanced, with the new hybrid machines featuring an optimised energy footprint and reduced cycle times. Following the launch of the 470 H milestone machine in the spring to mark “100 years of the Hehl family company”, the next step has now been taken with the size 520 and 570 machines. Recycled Packaging Sustainability

New size 520 with 1,500 kN clamping force

The size 520 with a clamping force of 1,500 kN will be on show for the first time at Fakuma 2023. The exhibit, an Allrounder 520 H “Premium”, will use a 1+1+1-cavity mould to produce three different moulded parts from ABS in a cycle time of around 50 seconds: a machine base, a feed hopper, and a controller.

These three components are subsequently separated from each other in a cutting station and round off a set of 15 parts for a model Allrounder on a scale of 1:18.

In this application, the Moldlife Sense computer system enables sensor-controlled mould monitoring over the complete life cycle.

The recorded data is passed via an OPC-UA interface directly to the Gestica control system, which displays corresponding malfunctions as well as performance-dependent maintenance intervals, thereby enabling predictive maintenance.

The new Multilift Select 8 linear robotic system with an eight kilograms load removes the moulded parts and places them in a box. A box changer ensures an autonomy of about two hours. Recycled Packaging Sustainability

Cost- and resource-saving alternative

The Hidrive series combines an electric energy-efficient and precise clamping unit with a powerful and dynamic hydraulic injection unit. Compared to all-electric and Hydraulic machines are characterised by significantly reduced acquisition and operating costs as well as a better energy and carbon footprint.

A novelty in the new hybrid Allrounder “Premium” machines is flow splitting as standard, valve technology is used to split the main pump’s available flow volume when required.

Arburg claims that this enables simultaneous movements of hydraulic auxiliary axes with programmable control such as the ejector and core pull – without technology stages or multi-pump technology. Arburg says that this saves energy, costs and space on the machine and increases production efficiency.

Compared to corresponding hydraulic machines, it is claimed that the energy footprint of the new Allrounder H is up to 50 per cent better. In addition, the carbon footprint can be significantly reduced. Thanks to a new oil management concept, the new Allrounder machines require up to 35 per cent less oil.

The required cooling water capacity can be reduced by up to 70 per cent. The dry cycle time is also reduced by around 40 per cent. Recycled Packaging Sustainability

Can Brics create a new currency to replace the hegemony of the dollar?

Response to the suggestion has been muted.

The 15th Brics Summit, hosted by South Africa in Johannesburg from 22 to 24 August, culminated in the anticipated announcement of an expanded Brics bloc, with the admission of six new member countries in January 2024. There had also been speculation that the summit might discuss the issuance of a joint currency to compete with the hegemony of the US dollar as the world’s reserve currency.

Although the idea of a single Brics currency was not on the summit agenda, Brazil’s president mooted a proposal for the bloc to consider it. The response was muted, with South Africa’s representative stating that such an approach was never considered, and India’s foreign minister also dismissing the possibility. Comment from Russia and China was not forthcoming. Recycled Packaging Sustainability

What would be the implications if a single currency were to be introduced down the line? Data from the IMF’s 2023 World Economic Outlook shows that, together, the current five Brics economies – Brazil, Russia, India, China, and South Africa – account for roughly 40 per cent of the world’s population and 20 per cent of global trade flows. Despite the logic behind the idea to introduce a new currency in place of the dollar, the truth is that this would be rather complicated to implement – at least in the short to medium term.

If the idea were to come to fruition, there would be two main approaches:

- Create anew central bank that would issue a single currency to replace the national currencies of each of the five countries (Brazil’s real, Russia’s rouble, India’s rupee, China’s yuan and South Africa’s rand). However, this would require these countries to give up their monetary sovereignty, which would limit their ability to manage the value of their own currency according to their economic needs. To understand this better, if Brazil wanted to depreciate its currency to improve its exports, but the other countries did not agree, Brazil would not be able to make this decision unilaterally.

- Therefore, we are talking about an important risk in the management of each country and the different factors that affect its growth and economic and monetary management. Recycled Packaging Sustainability

BRICS Expansion and Challenges: Navigating the Path Forward

The 15th BRICS summit, held in Johannesburg, South Africa on August 24, 2023, marked a crucial moment in a world grappling with economic integration, global governance, and geopolitical complexities. Various factors, including the U.S.-China rivalry, outdated global institutions, the Russia-Ukraine conflict, supply chain disruptions, and Western sanctions, had prompted a growing inclination to challenge the prevailing U.S.-led international order.

BRICS, comprising Brazil, Russia, India, China, and South Africa, has steadily evolved and garnered global interest. It currently represents 27% of the world’s landmass, 42% of its population, and over one-fourth of the world’s GDP. With a combined GDP of $27.6 trillion, BRICS poses a substantial challenge to the G-7 and may become even more influential with future expansion (BRICS+). Recycled Packaging Sustainability

Initiated in 2001 as BRIC, this group expanded to include South Africa in 2010. Around 40 countries have expressed interest in joining, with six new members approved: Argentina, Egypt, Iran, Ethiopia, Saudi Arabia, and the UAE. Concerns about Chinese dominance and the appeal of a non-dollar economic order have motivated some developing nations to seek BRICS membership.

BRICS has achieved notable success, establishing the New Development Bank and creating alternative international transaction systems to reduce reliance on the U.S. dollar. The group is also working on trade corridors and technology projects.

The expansion of BRICS and the introduction of a common currency were discussed but require careful consideration to prevent inefficiency. India and Brazil advocated for a cautious approach, while Russia supported a common currency. India’s reluctance stemmed from its growing trade relationship with the U.S. and its post-COVID recovery.

Ethiopia’s inclusion, despite its smaller GDP, aimed to provide greater African representation. The summit addressed global issues, including climate change, WTO transparency, and international organization representation.

BRICS’ growing popularity signifies a shift towards multipolarity, with India playing a pivotal role. However, expansion should be guided by clear criteria, such as stable governance and economic growth. The criteria, yet to be disclosed, need refinement for effective expansion. Recycled Packaging Sustainability

Recycled Packaging Sustainability