PET bottle packaging – DOMO Chemicals responds to surging demand in China with new TECHNYL® polyamide production plant 09-05-2024

PET bottle packaging

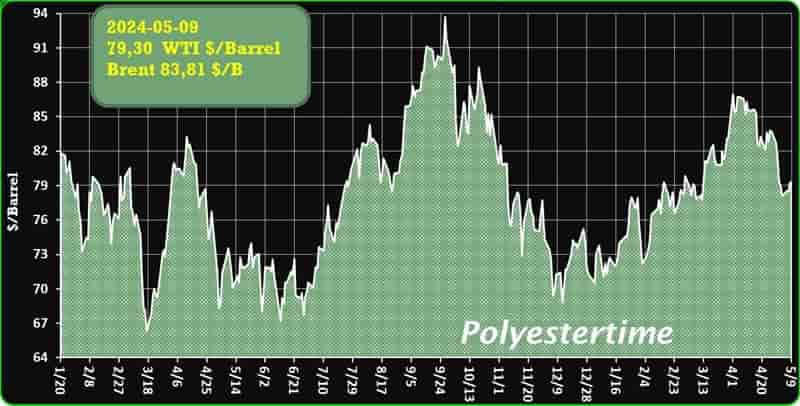

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

U.S. R-PET Shows Mixed Price Trends for Different Grades Amid Changing Market Situation

Recycled Polyethylene Terephthalate (R-PET) market in the U.S. has recently shown a mixture of constant and varying prices across different product segments, according to market analyses by ChemAnalyst.

As of the first week of May 2024, prices for R-PET food grade pellets have remained stable, regularly priced at USD 1,600 per metric ton on FOB basis in Los Angeles. This steadiness indicates a balanced market, where the supply and demand for these pellets are well-matched, ensuring no significant disruptions in the pricing structure. PET bottle packaging

However, the broader R-PET market has experienced notable price shifts over the past month, highlighting the dynamic nature of supply and demand for different R-PET products. R-PET clear flakes, vital for certain recycling processes, have seen a 4% increase in price from the beginning of April to May, now exceeding $1,200 per ton. This rise signals a surge in demand coupled with a potential shortage, inducing buyers to obtain additional supplies and explore alternative sources.

Further, the prices for R-PET clear flakes for delivery in Los Angeles have seen a considerable increase, climbing by approximately 17% during the same period, with prices varying from about $1,200 to $1,400 per ton. This deviation between FOB and delivery prices, averaging around $200 per ton, underscores the additional costs associated with distribution within the market. PET bottle packaging

Sacmi Group has announced the sale of its Beverage Business Unit to Omnia Technologies, a global automation technology provider with Italian roots specializing in the food, beverage, and pharmaceutical industries

This strategic transaction is expected to conclude by the end of summer and is part of Omnia’s broader goal to become one of the world’s foremost operators in beverage packaging systems.

This sale marks a pivotal shift for Sacmi, allowing it to leverage over two decades of industry experience to explore new growth avenues under Omnia’s expansive strategy. The acquisition will incorporate Sacmi Beverage’s extensive expertise in key beverage processes such as stretch-blowing, filling, and labeling, which are essential for handling products like mineral water, soft drinks, and alcoholic beverages. Sacmi Beverage’s proven track record of steady revenue growth and solid market reputation makes it a valuable addition to Omnia Technologies. PET bottle packaging

Sacmi has been a significant presence in the beverage industry since 2000, pioneering innovations and expanding its product range through strategic acquisitions and technological advancements. This divestiture is seen as a strategic move to simplify Sacmi’s business structure, enabling it to concentrate on expanding its other business sectors.

The Future Of Stretch: Introducing Under Armour’s First Product Made With High-Performing Elastane Alternative NEOLAST™

In 1996, Under Armour proved a single shirt can change the game forever. The brand’s original performance stretch, compression technology wicked away sweat faster than anything else out there and kept athletes cool, dry and light.

Ever since, Under Armour has continued to change the game with innovative performance gear. PET bottle packaging

Now, it honors its innovation heritage as it looks to the future of stretch.

On May 13, Under Armour will premiere the first product to feature its latest material innovation, a high-performing elastane alternative called NEOLAST™, on UA.com Part of its Vanish training franchise, Vanish Pro tees made with NEOLAST™ fiber are built to withstand the demands of all types of athletic training and feature a classic design to help athletes stay focused during workouts.

NEOLAST™ fibers at work in the fabric translate to a high-powered garment with exceptional durability and fit. PET bottle packaging

DOMO Chemicals responds to surging demand in China with new TECHNYL® polyamide production plant

- Opening of new Jiaxing plant bolsters commitment to stay close to customers

- Potential capacity up to 50,000 tons to serve growing demand for automotive, electronics, energy, and industrial and consumer goods sectors

- TECHNYL® polyamides provide intelligent solutions for China’s growth markets in the green energy and mobility sectors

DOMO Chemicals, a global leader in engineered technical materials, proudly inaugurates its newest plant in Haiyan, Jiaxing, Zhejiang, China. This significant milestone reinforces DOMO’s determination to meet rising demand in the Chinese market for its TECHNYL® polyamide-based intelligent solutions. PET bottle packaging

The €14 million (RMB 100 million) investment represents a potential doubling of DOMO’s commitment to the Chinese market, with the new plant capable of increasing the current capacity of 25,000 tons of TECHNYL® polyamides to 35,000 tons and eventually 50,000 tons in the long term. Covering an area of 40,000 square meters, the state-of-the-art facility underscores DOMO’s unwavering commitment to providing high quality products and services to its customers in key sectors such as automotive, electronics, energy, industrial and consumer goods. PET bottle packaging

Tronox’s Strong Performance in Q1 2024, Strengthen Market Fundamentals of Titanium Dioxide

Texas, USA: The prices of Titanium Dioxide have been demonstrating a contrasting trend across regional markets. With the rise in new sales volumes coupled with an increase in manufacturing costs, the Titanium Dioxide price trend has been progressing northwards in Asian markets. PET bottle packaging

On the other hand, downstream demand from the construction sector has taken a toll on the demand dynamics of Titanium Dioxide in European markets.

According to market sources, one of the leading manufacturers of Titanium Dioxide, Tronox Holding, has released its financial results for the first quarter of 2024.

Tronox’s first-quarter performance exceeded expectations, driven by lower production costs, the completion of destocking in the supply chain, and higher Titanium Dioxide demand levels, especially in comparison to typical seasonal patterns.

Revenue rose by 13% from the previous quarter, with a 20% increase in revenue from Titanium Dioxide and zircon alone, excluding other product sales which declined due to non-repeating sales. PET bottle packaging

Titanium Dioxide volumes surged by 18% from the fourth quarter, surpassing typical seasonal growth rates. Demand growth was strong across all regions, particularly in Europe, the Middle East, Africa, and Latin America, which had seen significant volume declines over the past six quarters.

5 questions for Thomas Gangl, CEO Borealis

In this new series, Sustainable Plastics asks 5 questions to notable figures in the plastics circularity industry. Thomas Gangl, CEO of Borealis, discusses the company’s transition to sustainable materials in its 30 year history

Borealis’ journey over the past 30 years has been remarkable. From its Nordic roots, the company has grown into a global force in polyolefins. Balancing growth with environmental sustainability is a priority. Borealis achieves this by investing in innovative technologies such as Borstar and Borcycle. These enable resource-efficient production, circularity, and value creation. The Borealis Strategy 2030 confirms that sustainability is at the core of all current and future Borealis operations. By 2030, Borealis aims to be a global leader in advanced and sustainable chemicals and materials solutions, balancing growth with environmental responsibility. PET bottle packaging

2. What is Borealis’ single greatest achievement in the past 30 years? And what will the company look like 30 years from now?

PET bottle packaging