Plastics recycling

PET Bottles – Group Partners with HYDS to Boost Green Hydrogen Use in Europe

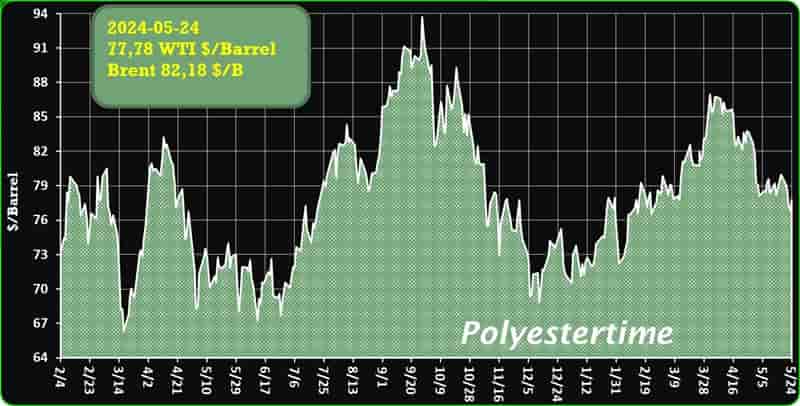

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

German R-PET Prices Continue Upward Trend Amid Supply Constraints

Germany’s Recycled Polyethylene terephthalate (R-PET) market has been experiencing a wave of rising prices in recent months. A perfect cluster of supply constraints, higher production costs, and robust demand across multiple sectors has been putting upward pressure on R-PET prices.

From April through early May 2024, R-PET prices climbed steadily higher, mirroring the broader market trends. By May 24th, the price of R-PET flakes on an FD Hamburg basis had reached approximately $1,275 per metric ton – a notable increase from just weeks prior. Plastics recycling

The key factor behind the price surge was the shortage of post-consumer bales – the crucial raw material needed to produce R-PET. With supplies running tight, scarcity set in, leaving suppliers with little choice but to raise their rates to make up for the shortfall.

In addition, there were the fluctuating costs of upstream materials like crude oil and Ethylene. As the prices of these key feedstocks ebbed and flowed, R-PET manufacturers were forced to adjust their pricing accordingly to maintain profitability margins.

The situation was further exacerbated by new EU regulations on packaging and packaging waste. Plastics recycling

These stringent rules, which set rigorous recycled content requirements for imports into the EU, have significantly impacted R-PET exports from Asia to Europe.

Asian exporters now face the challenge of meeting these strict standards to retain access to the European market, where customers must adhere to minimum recycled content criteria.

More…

Chemical and physical recycling play essential roles in realising the objectives of the Green Deal and advancing the circular economy. These technologies are indispensable for the green transition. A wider range of different chemical and physical recycling processes are needed to keep as much of the carbon embedded in plastics as possible in the cycle. Through this, the required volumes and scalability of the circular economy can be achieved. Chemical and physical recycling enable the utilisation of waste streams that cannot be mechanically recycled and are currently sent to incineration or landfill. They are the only ways to ensure these materials remain in a cycle, reducing reliance on disposal methods like incineration and landfill. Plastics recycling

Mechanical, physical, and chemical recycling complement each other due to differences in available waste stream composition, sorting needs, target products and economics. Each technology has distinct strengths and weaknesses in terms of input, output quality and quantity. Chemical and physical recycling are fundamental for a comprehensive carbon management that creates sustainable carbon cycles and enables the defossilisation of the chemical industry. While they hold considerable high-volume potential, significant investment is needed to fully leverage these technologies.

More…

The APR Design® Guide for Plastics Recyclability

The APR Design® Guide for Plastics Recyclability is the most comprehensive resource outlining the plastics recycling industry’s recommendations in the marketplace today. The content is regularly updated to ensure APR’s Recyclability Categories represent today’s North American plastics recycling infrastructure. Although it is designed as an online resource, with links to all relevant information, a PDF of the complete document can be downloaded as well. Plastics recycling

The APR Design® Guide specifically addresses plastic packaging, but the principles can be applied to all potentially recycled plastic items. APR encourages package designers to utilize The APR Critical Guidance and Responsible Innovation programs, as well as the APR Design® Guide to create the most recyclable packaging. Assistance is available through APR or one of the APR member, independent laboratories found in the member directory. The intended audience for the APR Design® Guide for Plastics Recyclability is the package design engineer for use in designing packaging that complies with the capabilities of the recycling infrastructure. Plastics recycling

Before accessing the APR Design® Guide for Plastics Recyclability the user should thoroughly understand the fundamentals of its concept as described in the scope, definition of recyclability and recyclability categories outlined below.

SCOPE This guide covers plastic items entering the postconsumer collection and recycling systems most widely used in industry today. Collection methods include single stream and dual stream MRF’s, deposit container systems, mixed waste facilities, and grocery store rigid plastic and film collection systems. Plastics recycling

More…

New polystyrene recycling process could be world’s first to be both economical and energy-efficient

Chemical method identified to tackle hard-to-recycle packaging material, cutting landfill waste

Engineers have modelled a new way to recycle polystyrene that could become the first viable way of making the material reusable.

Explained in a new research paper published in the Chemical Engineering Journal, the technique uses a chemical process called pyrolysis to break down polystyrene into parts which can be reformed into new pieces of the material. Plastics recycling

Dr Bernardo Castro-Dominguez, a Senior Lecturer in Chemical Engineering at the University of Bath and a Co-Director of the Centre for Digital, Manufacturing & Design (dMaDe), says: “Chemical recycling techniques are a major focus within chemical engineering right now, and cost- and energy-efficient ways to breakdown plastics to their primary building blocks such as polystyrene are urgently needed.

“Less than 5% of polystyrene is recycled at present — our work shows that as much as 60% of all polystyrene used today could be replaced by chemically recycled styrene.”

Michael Timko, PhD, Professor of Chemical Engineering at Worcester Polytechnic Institute, adds: “Our analysis finds polystyrene to be an ideal candidate for a chemical recycling process. Surprisingly, the process is energetically efficient and potentially economically competitive. Plastics recycling

More…

Teijin Frontier Co., Ltd., the Teijin Group’s fibers and products converting company, has developed a new multifunctional polyester material with high breathability and UV protection

This innovative fabric replicates the structure of traditional Japanese “Sudare” blinds, which allow air to pass through while blocking sunlight.

In response to rising summer temperatures, Teijin Frontier designed this polyester to offer enhanced heat protection, combining breathability, UV resistance, and anti-stickiness. Traditionally, breathability and UV protection were seen as mutually exclusive due to the need for gaps between fibers. Plastics recycling

The fabric is also sustainable, incorporating recycled polyester. Its structure and elastic fibers offer stretch, while an uneven surface due to thread shrinkage prevents stickiness. Special high-shrinkage technology and dyeing techniques ensure the combination of these functions.

Teijin Frontier plans to promote this material for the 2025 spring and summer fashion collections in Japan. They aim to achieve sales of 250,000 meters in fiscal 2024 and 750,000 meters in fiscal 2027.

The material’s potential applications span both fashion and casual clothing, making it a versatile addition to their product lineup. Plastics recycling

Cooperation between Lindner Washtech and EREMA delivers consistent quality in post consumer recycling

How to achieve consistent recycled pellet quality in plastics recycling by exchanging data between the extruder and washing system, and how intelligent energy management reduces costs, was revealed at IFAT in Munich by the EREMA Group and Lindner. This presentation saw the two Austrian companies show the first results of their joint venture.

Breaking new ground in plastics recycling means assessing the value chain from end to end. The big opportunities for the future are in finetuning the individual process steps; from the collection of recyclable materials to the recycling process and the end product. This is exactly where the cooperation of Lindner and the EREMA Group comes in, officially launched following the 50/50 founding of the holding BLUEONE Solutions in August last year to which shares of Lindner Washtech were contributed. Plastics recycling

The expertise and experience of EREMA, a manufacturer of extruders and filtration solutions for plastics recycling and the largest company within the EREMA Group, has now been combined with the expert know-how from Lindner Washtech, a leading provider of all-in-one solutions for shredding, sorting and washing plastic feed materials.

More…

Fiber Recycling – Global Naphtha Prices Plunge Amid Weaker Oil Demand and Geopolitical Shifts25-05-2024

Plastics recycling