Flexible Film

Dow and SCG Chemicals have signed a groundbreaking memorandum of understanding for a partnership aimed at transforming 200KTA of plastic waste into circular products by 2030, marking a first in the Asia Pacific market

This initiative will process plastic waste through both mechanical recycling (MR) and advanced recycling (AR).

Building on a successful 37-year joint venture in Thailand, the partnership seeks to develop comprehensive solutions for circular plastic, starting with post-consumer recycled materials (PCR) and advancing technology in waste sorting, MR, and AR.

Future phases will explore sourcing plastic waste feedstocks throughout Southeast Asia, including potential expansions into China, Korea, Japan, Taiwan, Australia, and New Zealand. Flexible Film

Chatchai Luanpolcharoenchai, Dow Thailand president, noted that this partnership marks a significant chapter in Dow’s 57-year journey in Thailand, enhancing customer value and contributing to regional sustainability. The partnership supports Dow’s goal of transforming plastic waste into 3 million metric tons of circular and renewable solutions annually by 2030 and aligns with SCGC’s sustainability targets, including achieving carbon neutrality by 2050.

The Global Market for Mono-material Packaging 2024-2035

In many food-packaging applications, including stand-up pouches and flow wrappers, films are typically made using mixed materials in the structure. When different types of plastics are combined in a single package, it can be challenging to separate and recycle them effectively, leading to contamination and reduced quality of recycled materials. The widely used multi-material packaging film cannot be practically delaminated and recycled at scale. Flexible Film

Mono-material packaging involves using a single type of recyclable plastic to avoid the issues associated with mixed recycling. By designing packaging using only one type of recyclable plastic, such as polyethylene terephthalate (PET) or high-density polyethylene (HDPE), the recycling process becomes more streamlined and efficient. Mono-material packaging eliminates the need for complex sorting and separation processes, increasing the likelihood of the material being recycled and reducing the chances of contamination. The use of mono-materials packaging films increases recycling rates and creates higher quality recyclate, reducing waste and strengthening the post-consumer recycled (PCR) supply chain. Flexible Film

A Detroit-based startup, Heartland, has received an investment from Chemovator, a German business incubator associated with BASF, to advance its development of hemp-based materials for use in plastics

Heartland specializes in natural fiber additives that can replace some chemical components in plastic compounds, emphasizing sustainability in the chemical industry.

Heartland’s innovative materials are designed to function seamlessly within traditional recycling systems, depending largely on the type of polymer they are mixed with. The company primarily blends these hemp fibers with olefins, ensuring that the specific gravity remains under 1.0. Flexible Film

This careful formulation allows the use of standard float tanks in the recycling process, maintaining the efficiency of conventional methods.

Moreover, the fibers are processed into a micronized form, small enough to be entirely encapsulated by the resin. This meticulous process ensures that the enhanced polymer maintains its original strength, impact resistance, and moisture absorption capabilities. Predominantly, these hemp fibers are utilized in the production of HDPE-based reusable items such as containers, pallets, and trays, showcasing their versatility and environmental benefits. Flexible Film

European BOPP Film Market Faces Challenges as Demand Remains Subdued

In recent weeks, the European market for Biaxially Oriented Polypropylene (BOPP) has encountered significant challenges, primarily driven by low demand from downstream packaging industries. The region has seen a surplus in BOPP Film supply, with market conditions characterized by sufficient stock levels. This surplus has been exacerbated by persistently weak demand, particularly from the packaging sector, a key consumer of BOPP Film. As a result, the cost of BOPP in Germany decreased by approximately 2% on a week-on-week basis, ending the last week. Flexible Film

The price of BOPP Film in Europe has been influenced by the pricing trends of its feedstock, Polypropylene (PP). PP prices have remained bleak, reflecting the overall subdued market conditions. This trend persisted as the European PP market faced a 4% price decline, reflecting the prevailing weak demand sentiment.

The demand for BOPP Film from the packaging sector has been notably low, with reports indicating a lack of new orders. Flexible Film

More…

INEOS Inovyn is enhancing Europe’s PVC recycling with two new pilot plants at its Jemeppe-sur-Sambre site in Belgium

This initiative is part of the strategic ‘Project Circle,’ aiming to commission an industrial unit with a 40KT recycling capacity by 2030. INEOS Inovyn has also joined two consortiums supported by Walloon and Flemish authorities to strengthen technical and commercial development.

Currently, only 30% of PVC waste in Europe is mechanically recycled. Project Circle targets the remaining waste by developing new technologies such as dissolution, pyrolysis, and gasification. INEOS Inovyn aims to make all PVC waste recyclable and plans to have its first industrial unit ready by 2030. Flexible Film

The two pilot plants at Jemeppe-sur-Sambre will advance PVC dissolution technology to recycle complex PVC waste, including legacy additives, drawing on Vinyloop’s technology experience from 2002 to 2018.

Collaboration is key to Project Circle’s success. INEOS Inovyn has joined two Belgian consortiums. Flexible Film

The first, ‘CIRC-PVC,’ covers the entire chain from collecting PVC waste at construction-demolition sites to producing rejuvenated PVC without legacy additives.

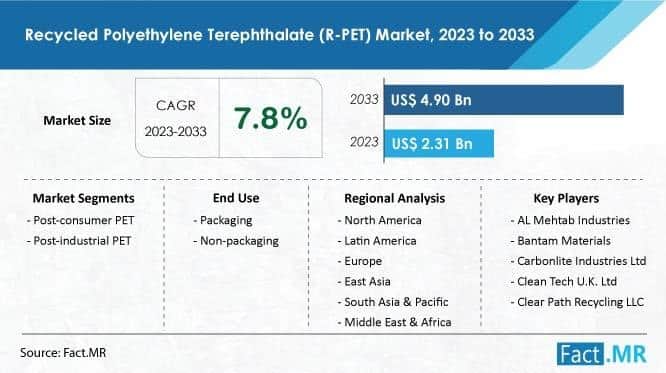

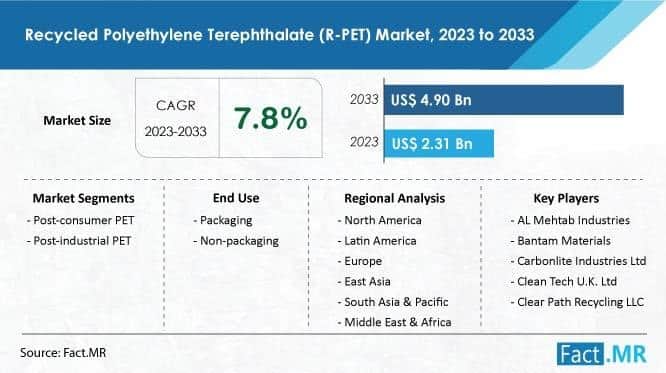

Recycled Polyethylene Terephthalate (R-PET) Market Riding the Wave to a Projected US$ 4.9 Billion by 2033

Recycled Polyethylene Terephthalate (R-PET) Market

The Recycled Polyethylene Terephthalate (R-PET) Market (再生ポリエチレンテレフタレート市場) is anticipated to grow at a compound annual growth rate (CAGR) of 7.8% during the forecast period, reaching a value of US $ 4.9 billion by 2033. R-PET is a transparent, robust, recyclable plastic that can be used to create new goods. In essence, this substance is a polymer made by mixing pure terephthalic acid with modified ethylene glycol.

Regularly melted and turned into fibres for carpets or fiberfill are PET bottles and container waste. Flexible Film

Polyethylene terephthalate can also be recycled back into its original use if it is recovered in a suitably pure state. Polyethylene terephthalate can now be reassembled using a variety of methods for dissolving polymers into their chemical components.

Key Driving Forces Accelerating the Market Growth:

Growing concerns about plastic pollution and environmental sustainability have heightened the demand for recycled materials. Consumers, governments, and industries are actively seeking more sustainable packaging solutions, leading to a surge in the adoption of R-PET. Moreover, demand for R-PET in the United States is expected to witness a CAGR of 7.7% during the forecast period. Flexible Film

More…

UPM Raflatac launches RecyClass-certified New Wave paper label material

Primarily designed for home and personal care products like soap bottles and washing detergent containers, New Wave provides functional utility throughout the product lifecycle

Labelling solutions provider UPM Raflatac has introduced New Wave, a new paper label material for plastic packaging that has received RecyClass certification.

New Wave is said to be the first of its kind to be officially recognised for compatibility with recycling processes for rigid high-density polyethylene (HDPE) and polypropylene (PP) containers. Flexible Film

The RecyClass certification includes a Letter of Compatibility, confirming that New Wave can be used on natural and white material streams without compromising the purity required by recyclers.

The New Wave label material is specifically designed to support the recycling of rigid plastic packaging.

More…

Flexible Film

Circular Recycling – Cepsa selects Siemens Energy’s PEM technology for 100 MW of electrolysis capacity for the Andalusian Green Hydrogen Valley 17-05-2024