Spandex capacity growth – Recupero Etico Sostenibile (RES) has partnered with Dutch company BlueAlp to establish a chemical recycling plant in Pettoranello del Molise, Italy, targeting operations by 2026 11-05-2024

Spandex capacity growth

Spandex capacity growth peaks in 2024, competition continues

Spandex prices have been undergoing downward adjustments for nearly three years since the previous cycle of high prosperity. From the beginning of 2022 to April 2024, only a few companies in the industry have been profitable, with the majority facing losses. However, the overall industry losses have marginally improved over the past two years. How will the expansion speed of spandex production capacity be in 2024, and when will the growth rate of production capacity slow down in the future? Spandex capacity growth

Cash flow: Marginal improvement in losses

In the past five years, the spandex industry experienced a significant increase in profits in 2020-2021 due to the mask outbreak during the pandemic. However, in 2022, the industry suffered deep losses as inventories depreciated significantly. Although there was a reduction in losses in 2023, widespread losses persisted. From the beginning of 2024 to date, the average cash flow of 40D spandex has somewhat recovered compared to the second half of 2023, but it is still lower than the first quarter of the previous year. Due to the evident oversupply in the industry in 2024, it may be challenging for industry profits to see significant improvement.

Most companies are expected to face significant operational pressures, and internal competition within the industry is likely to continue. Spandex capacity growth

Resourcify’s “State of circularity for enterprises in Germany” report assesses the recycling and circularity efforts of 313 prominent German companies

The findings expose a notable trend: many companies count waste-to-energy processes, primarily incineration, as recycling. This classification inflates their recycling rates, even though 68% of them fall below a 50% recycling rate when these methods are excluded. This misclassification highlights an urgent need to redefine recycling to exclude waste-to-energy to encourage genuine circularity.

Nearly half of the companies (47%) invest in the circular economy by adopting waste-to-energy processes, yet this approach prevents recyclable materials from being reused, pushing companies towards using new, virgin resources. Despite its controversial nature, waste-to-energy remains a popular method, rivaled only by chemical recycling, which 41% of companies utilize. Spandex capacity growth

When excluding landfill and incineration data, the average recycling rate plummets to 44%, well below the 2025 target of 55%. Furthermore, without these practices, only 32% of companies meet a 50% recycling rate, and a mere 12% reach the 70% national average for production and commercial waste recycling.

The importance of circular economy practices varies across industries, with over 50% of companies in automotive, manufacturing, and retail/fashion rating it highly, compared to just 32.5% in the travel and tourism sector. Spandex capacity growth

More insights can be found in RECYCLING magazine’s next international issue in May.

Mitsui Chemicals Asahi Life Materials Develops Spunbond Nonwoven Suitable for Home Composting

Mitsui Chemicals Asahi Life Materials Co., Mitsui Chemicals Asahi Life Materials Co., Ltd. (Tokyo; President: YANASE Koichi) has developed a spunbond nonwoven using a biodegradable plastic suitable for composting in domestic settings. The move comes in response to increasing global demand for home composting.

Mitsui Chemicals Asahi Life Materials intends to establish the production setup for regular and thermoformable grades of this nonwoven before the end of 2024.

Applications being eyed cover a wide variety of industrial fields, including beverage filters and packaging materials that come into contact with food, along with agricultural materials. Spandex capacity growth

The newly developed biodegradable plastic’s key feature is its capacity to decompose in a home composting environment at a temperature of around 28 degrees Celsius.

■ Biodegradable plastic

Biodegradable plastic has all the durability of ordinary plastic, but is broken down after use into water and carbon dioxide via the action of microorganisms found in nature. The material is attracting increasing attention due to the potential for its widespread use to reduce the environmental impact of plastic.

Different biodegradable plastics are able to break down in compost, soil, water and other such environments, so each biodegradable plastic is categorized according to the specific environment in which it decomposes. Spandex capacity growth

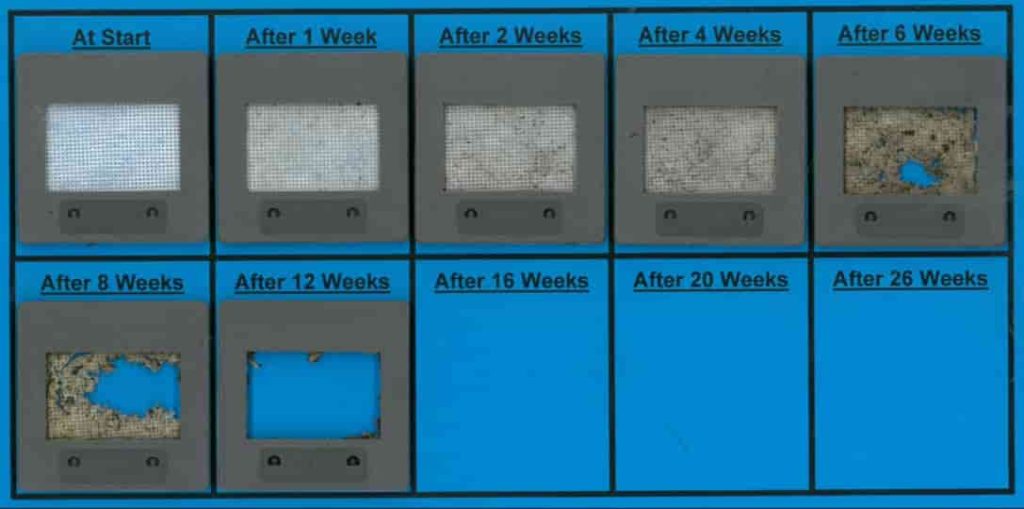

Results of a preliminary disintegration test in a home composting environment (28 degrees Celsius)

At NPE2024: The Plastics Show in Orlando, Florida, SABIC unveiled its advancements in thermoplastics designed to enhance fire safety in electric vehicle (EV) batteries

The company displayed a thermoplastic battery module box, part of its BlueHero initiative, which supports the automotive industry’s shift towards electric power. This demonstration includes a variety of EV battery components, such as module enclosures and busbars, all made using SABIC materials.

SABIC’s tests at the sub-system level have shown that using a battery module box crafted from Stamax 30YH570—a long glass fiber polypropylene resin with an intercellular thickness of just 1mm—acts as an effective thermal barrier. Spandex capacity growth

This material provides essential thermal insulation and flame resistance, thereby reducing the risk of fire spreading from cell to cell during thermal runaway incidents.

These findings add to previous assessments, including a 2023 evaluation where Stamax 30YH570 received the UL Verified Mark for its flame-delaying capabilities. The recent tests at NPE involved lithium-ion battery cells in a steel chamber, showing that the Stamax resin blocks effectively prevented heat and flame propagation, securing the integrity of adjacent cells.

Additionally, SABIC showcased other uses of its thermoplastics in EV batteries, such as in the 2023 Hyundai Ioniq 6, which incorporates the H1030 polypropylene compound for battery module enclosures. Spandex capacity growth

Recupero Etico Sostenibile (RES) has partnered with Dutch company BlueAlp to establish a chemical recycling plant in Pettoranello del Molise, Italy, targeting operations by 2026

The facility, costing approximately €20 million, will handle up to 20,000 tons of plastic waste annually, producing about 15,000 tons of pyrolysis oil. This initiative marks RES’s entry into the chemical recycling sector, enhancing its portfolio that includes waste collection, disposal, and mechanical recycling. The construction is aligned with the objectives of Italy’s National Recovery and Resilience Plan (PNRR) and is set to begin shortly, employing around twenty people. Spandex capacity growth

Antonio Lucio Valerio, CEO of RES, highlighted the project’s significance in integrating various recycling processes and reducing reliance on fossil-based resources. The plant will be the first of its kind in Italy, converting non-mechanically recyclable polyolefin waste into high-quality raw materials for new plastics. BlueAlp brings to this partnership their experience from a similar large-scale facility in Ostend, Belgium, utilizing their low-temperature pyrolysis technology known for its economic and environmental benefits.

Valentijn de Neve, CEO of BlueAlp, expressed pride in collaborating with RES, emphasizing the importance of advancing recycling technologies to transform plastic waste management globally. This project reflects both companies’ commitment to sustainability and innovation in the recycling industry. Spandex capacity growth

Farrel Pomini goes all in on continuous mixer technology for recycling

At NPE 2024, Ansonia, Conn.-based Farrel Pomini is betting on mechanical and chemical recycling applications for its continuous mixer technology

The Farrel continuous mixer is a compounder that feeds to an extruder, based on the principle of two counter-rotating, non-intermeshing rotors, and a large free volume mixing chamber. First introduced in 1963, the machine is now adapting to market dynamics of increased demand for recycled plastics and biopolymers. Spandex capacity growth

“We have high expectations for this fair,” Farrel Corp. President Paul Lloyd told Sustainable Plastics. “It’s the first NPE in six years, the North American market is very busy, so we expect our business and the show to be very active.”

Analyst lays out cyclic pattern of recycled resin markets

HDPE example shows recycled premium ceiling

Friedman gave a rundown of how recycled resin pricing has evolved over time, noting that recycled material historically was used as a cheaper alternative to virgin or wide-spec resin. “Wide-spec” refers to virgin material that does not meet specifications for prime plastic and is sold as a cheaper feedstock. Spandex capacity growth

Friedman said post-industrial or mixed-color recycled resin pricing still battles with wide-spec and virgin, but that the pricing dynamic for other grades is changing, in part because of brand owner demand. These materials, which Friedman called “sustainability-driven recycled resins,” are the post-consumer, typically clear, resins.

PET imports add new pressure

Friedman also touched on a major trend in the PET space: Plastics recycling companies are facing rising competition from imports of recycled plastic, which play into the prices domestic reclaimers can charge. Spandex capacity growth

“We are really feeling that here in the U.S. market, particularly in the PET space,” Friedman said. Recovered PET imports into the U.S. shot up 33% last year, highlighting how plastics recycling has become a global industry, Friedman added.

Spandex capacity growth