Circular economy – In beverage bottling plants, the closure process is crucial for product quality 23-05-2024

Circular economy

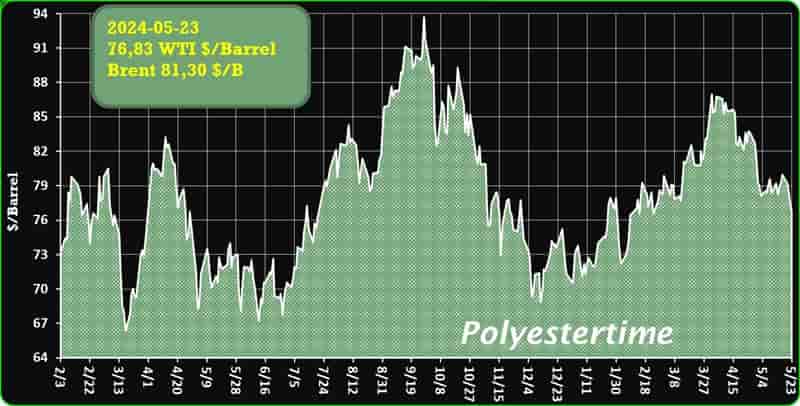

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

Lummus and Sumitomo Chemical Announce Collaboration for Circular and Polyolefins Technologies

Agreements bolster circular economy efforts and enhance polyolefins offerings

Lummus Technology, a global leader in process technologies and energy solutions, and Sumitomo Chemical have signed two collaboration agreements to license and commercialize proprietary technologies:

- Sumitomo Chemical’s low-density polyethylene/ethylene vinyl acetate (LDPE/EVA) production technology

- Sumitomo Chemical’s efficient poly methyl methacrylate recycling (rPMMA) technology Circular economy

Lummus will serve as the exclusive worldwide licensor of these technologies, utilizing its global marketing reach and engineering expertise to deliver Sumitomo Chemical’s innovations to a global audience. The companies will further develop the rPMMA technology, building on progress from Sumitomo Chemical’s pilot plant in Japan, to achieve early commercialization and support a more carbon-neutral society.

“Lummus is honored to partner with Sumitomo Chemical, combining their polyolefin technology leadership with our global marketing and design expertise,” said Leon de Bruyn, President and CEO of Lummus Technology. Circular economy

Polypropylene Gains Bearish Momentum in the USA, Stability Persist in Asia and Europe

In the third week of May 2024, concluding on May 17, the price of polypropylene (PP) in the U.S. market decreased by approximately 1%, driven by low demand from overseas markets and ample global supply. On the resin front, few fresh polyethylene and PP railcar offers were available in the spot market. However, there was a notable number of urgent truckloads needs that a short-staffed trading desk managed to fulfil, primarily from market-making inventory.

The average price for PP copolymer grade delivered to Houston was USD 1,011/MT over the week. This trend reflects the dynamic interplay of supply and demand, impacting the market prices and availability of PP in the U.S. market. Circular economy

Following two weeks of stability, the price of PP in the European market remained stable this week due to a balanced gap between demand and supply. The price of feedstock propylene also remained unchanged, contributing to the PP price stability. The market demonstrated resilience in demand, while industry load remained average during this period. Additionally, new overseas queries related to PP were muted, further contributing to the stable trend in the region. Circular economy

In beverage bottling plants, the closure process is crucial for product quality

Krones has developed a 360° closure inspection unit to meet high standards and accommodate innovations like tethered caps and lightweighting

This unit combines precise lighting with high-resolution cameras to measure the bottle’s closure and neck finish in 3D space, achieving ultra-precise measurements down to 20 micrometres. Its high accuracy ensures leakproof integrity, reducing the need for manual lab testing. Circular economy

The unit performs a comprehensive inspection of closures, checking for presence, color, correct placement, damage, and defects. Unlike previous models, it handles water beads effectively, allowing the use of a modular, hygienic, and economical blower. Stefan Piana, Head of Inspection and Monitoring Technology at Krones, highlights its high selectivity, ensuring minimal false positives. Despite reduced dimensions, the inspector includes the TopCheck feature for inspecting closure logos.

The technology also inspects tethered caps, mandatory in the EU from July 2024, for correct placement and integrity of the twist-and-clip mechanism. It ensures the perforation at the breakaway band is intact, regardless of cap orientation. Circular economy

The unit is suitable for inspecting plastic closures and crowns, detecting skewed crowns, drawn-in skirts, and measuring each crown’s diameter precisely. This eliminates the need for manual lab tests every shift.

M&S takes the lead in Polytag’s UV tag plastic recycling initiative

Polytag has named M&S as a founding member of its Polytag Ecotrace Programme, which seeks to trace and recycle single-use plastic packaging using Invisible UV Tag detection – and encourages other businesses to get involved.

In an effort to meet demand for recycled PET from FMCG brand owners, Polytag applies Invisible UV Tags to labels during the production process. These can be identified by Polytag UV Tag Readers once the packaging enters the recycling stream at a recycling centre. Circular economy

In turn, this process is expected to unlock accurate sorting and cleaner feedstock for recycled PET packaging materials, improve recycling rates, and give companies clearer insights into recycling rates for their plastic packaging.

Polytag’s Invisible UV Tag detection equipment will be installed in ‘strategically chosen’ recycling centres that process high volumes of waste. FMCG brands, retailers, and waste management businesses are encouraged to participate in the programme and, in doing so, receive granular data on over 50% of the UK’s household waste recycling stream.

Taiwan Polyamide 66 Prices Steady Despite Bearish Trends in Key Industries

The Polyamide 66 market is currently experiencing stability, with prices remaining steady due to sufficient supply and low demand. The downstream textile, automotive, and electrical sectors have remained bearish since April 2024, contributing to the overall subdued demand for Polyamide 66. Circular economy

Despite the challenging market conditions, there have been no supply disruptions in the domestic market. Manufacturers have been able to meet demand without any significant issues, ensuring a consistent supply of Polyamide 66 to customers. However, export orders have declined in April compared to March 2024, indicating a slowdown in international demand for this versatile material. In April 2024, Taiwan’s exports fell to $37,480.04 million from $41,815.44 million in March 2024.

According to the Research Centre for Taiwan Economic Development (RCTED), Taiwan’s consumer confidence index fell sharply to 63.37 in April 2024 from a 14-month high of 73.51 in the previous period. Circular economy

The textile industry, which is one of the key consumers of Polyamide 66, has been facing challenges due to changing consumer preferences and economic uncertainties.

thyssenkrupp Uhde and Johnson Matthey sign MOU to offer blue ammonia solution

thyssenkrupp Uhde and Johnson Matthey have announced that they have signed a Memorandum of Understanding to jointly offer a fully integrated low carbon (blue) ammonia solution, building on a nearly 25-year ammonia relationship between the companies. Circular economy

In the drive to reduce CO2 emissions, the role of ammonia has expanded from a vital ingredient used to produce fertilizer for the agricultural sector, to a decarbonised carrier and supplier of hydrogen energy that’s easier to store and transport than pure hydrogen. The movement of low carbon ammonia can utilise existing infrastructure making it a leading energy transition solution that is ready to capture, store, and ship vast quantities of hydrogen for use in the power and shipping sector, and industrial value chains globally.

By joining forces, thyssenkrupp Uhde and JM can access the blue ammonia market together offering technologies combining the uhde® ammonia process and JM’s hydrogen expertise through its LCHTM technology, which will enable the production of blue ammonia with up to 99% CO2 capture. Circular economy

BASF, a global leader in chemicals, is committed to a sustainable future

The company aims to reduce its Scope 3.1 emissions by 15% by 2030 and achieve net zero by 2050. A key strategy is sourcing raw materials with a lower Product Carbon Footprint (PCF).

In its Ultramid® A & B portfolio, BASF is now using glass fibers from 3B Fibreglass, produced with green electricity. 3B, a leading glass fiber supplier, has implemented renewable energy solutions, including solar panels and green energy agreements at its Battice site in Belgium, significantly cutting its carbon emissions. Circular economy

Ludovic Piraux, CEO of 3B, highlights their commitment to carbon neutrality through technical innovations and increased renewable energy use. From January 1, 2024, 3B will produce glass fibers exclusively with green electricity, aligning with the glass fiber industry’s goal of climate neutrality by 2050. This sustainable production approach allows BASF to attribute the green electricity used to its glass fiber products, reducing the PCF of its reinforced products by about 10%, equating to savings of approximately 5000 metric tons of carbon annually. This reduction is comparable to the yearly emissions of 200 average German households. Circular economy

Circular economy